Split welding fixed disposable blood taking needle

A one-time, split-type technology, applied in the field of medical devices, it can solve problems such as low strength, unstable firmness, and failure to meet shelf life requirements, achieve small welding deformation and residual stress, no cooling and solidification time, and is conducive to mechanization. Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

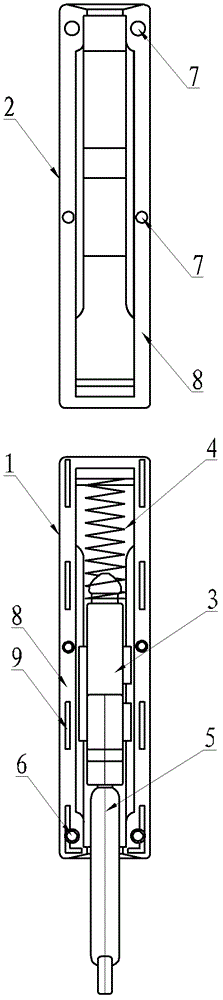

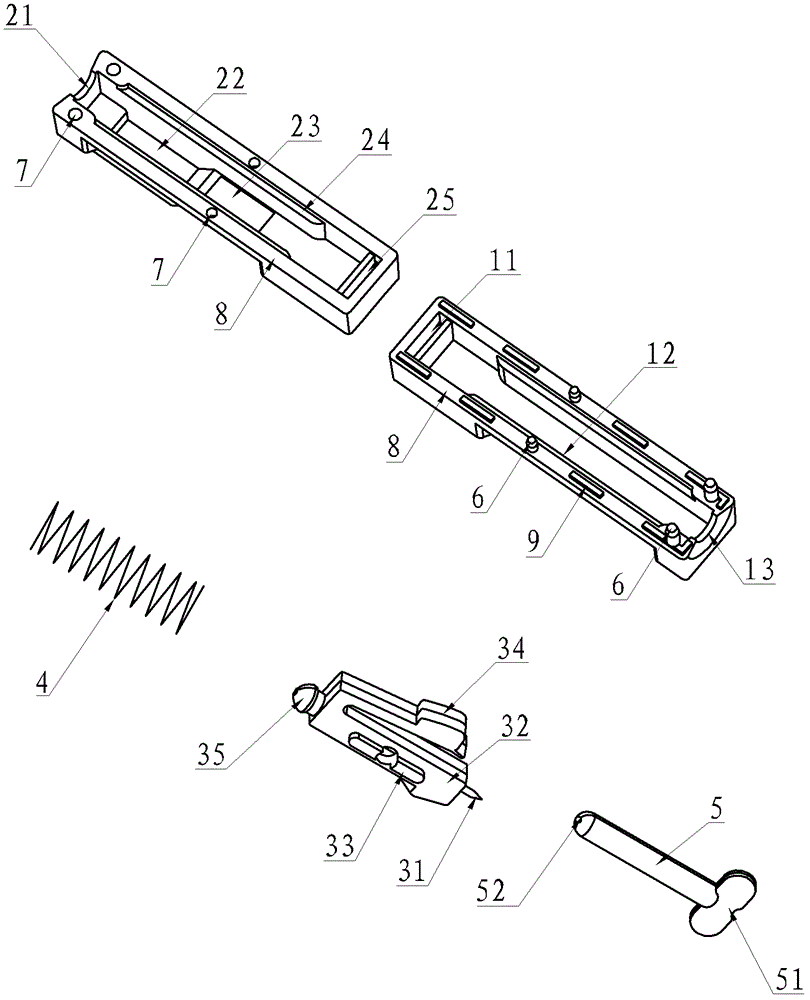

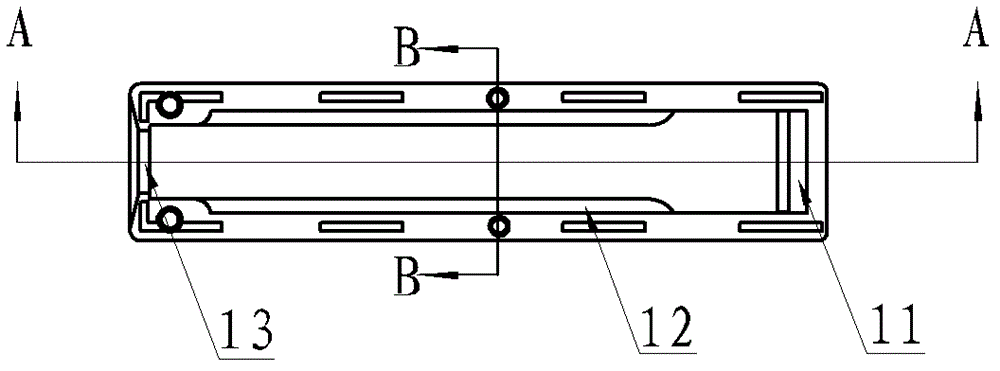

[0027] A split-type welded and fixed disposable blood collection needle, such as figure 1 , 2 As shown, it consists of a lower housing 1, an upper housing 2, a sliding needle block 3, a return spring 4 and a needle tip cap 5, wherein the lower housing 1 is as image 3 , 4 , 5, it includes the lower part 11 of the spring clamping slot, the lower rail 12 and the lower part 13 of the needle hole, the lower part 11 of the spring clamping slot is set at one end of the inner cavity of the lower casing 1, and the lower rails 12 are respectively set in the lower casing 1 On both sides of the cavity, the lower part 13 of the pin hole is arranged at the other end of the lower casing 1, and two positioning pins 6 and four welding and melting protrusions 9 are symmetrically distributed on the two long joint surfaces 8 of the lower casing 1; Upper shell 2 such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com