Preparation method of high-purity alkylammonium tetrafluoroborate for super capacitor

A technology of supercapacitor and tetrafluoroboric acid, which is applied in capacitors, electrolytic capacitors, chemical instruments and methods, etc., to achieve the effects of high conversion rate, small internal resistance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

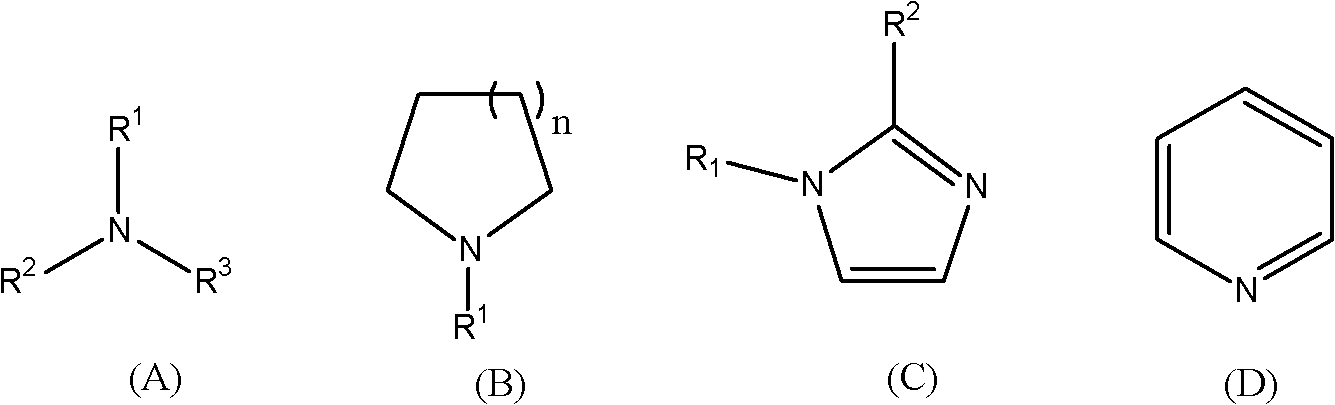

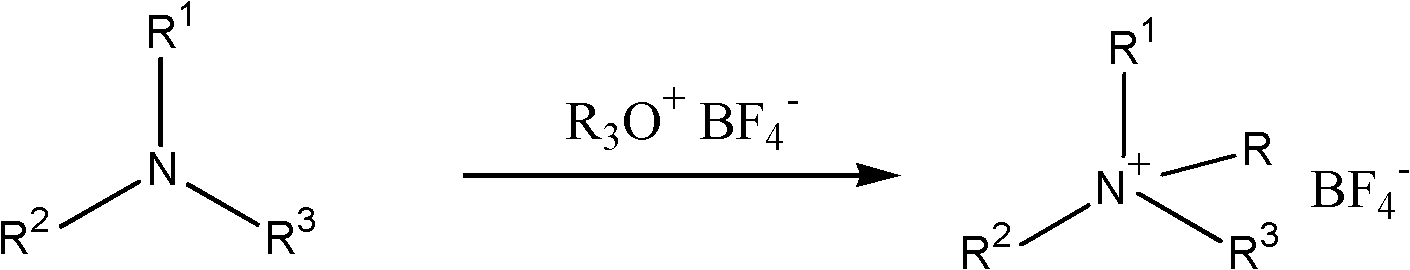

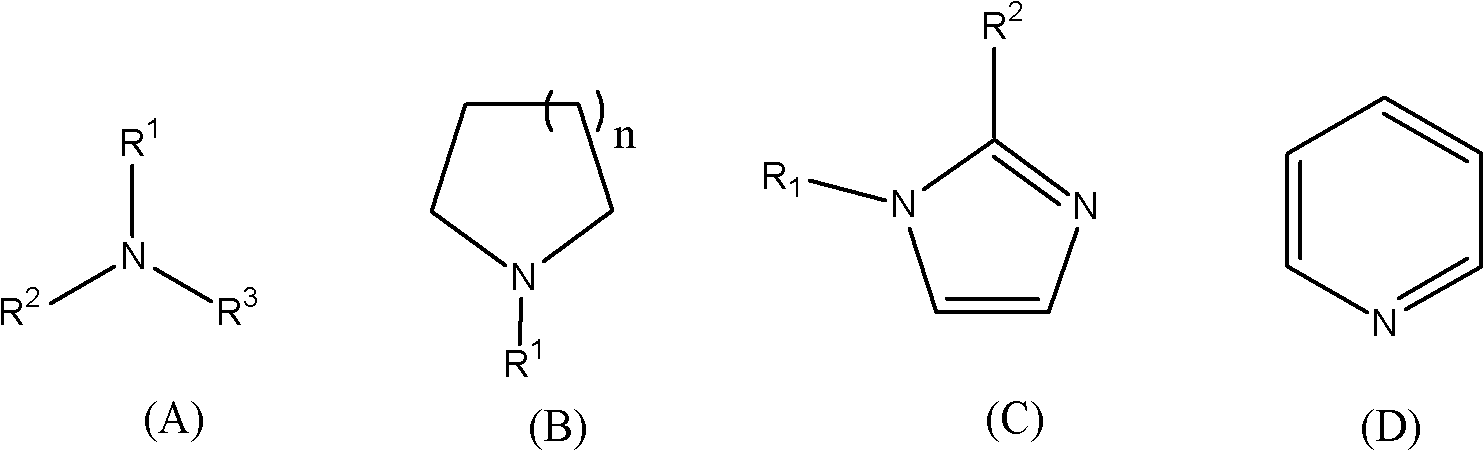

Method used

Image

Examples

Embodiment 1

[0036] Preparation of triethylmethylammonium tetrafluoroborate

[0037] Under a nitrogen atmosphere, triethoxonium tetrafluoroborate (47.5 g, 0.25 mol) was added to a solution containing N,N-diethyl-N-methylamine (26.1 g, 0.3 mol) and 150 ml of dichloro methane in a 500 ml reaction flask and stirred at room temperature for 15 hours. After filtration, the filtrate was concentrated to obtain the crude product of triethylmethylammonium tetrafluoroborate. Dissolve in ethanol, add activated carbon, heat to reflux for 30 minutes, filter, and cool the filtrate to obtain 46.6 g of white crystals of triethylmethylammonium tetrafluoroborate, with a yield of 92%.

[0038] Detected by ion chromatography: Na: 2.1ppm, K: 3.5ppm, Fe: 1.6ppm, Mg: 1.0ppm, Ca: 2.5ppm, no halogen ions.

Embodiment 2

[0040] Preparation of triethylmethylammonium tetrafluoroborate

[0041] Under a nitrogen atmosphere, trimethoxonium tetrafluoroborate (29.6 g, 0.2 mol) was added to a solution containing N,N-diethyl-N-methylamine (20.9 g, 0.24 mol) and 150 ml of dichloromethane In a 250 ml reaction flask, react at 40°C for 8 hours. After filtration, the filtrate was concentrated to obtain the crude product of triethylmethylammonium tetrafluoroborate. Dissolve in methanol, add activated carbon, heat to reflux for 30 minutes, filter, and cool the filtrate to obtain 38.2 g of white crystals of triethylmethylammonium tetrafluoroborate, with a yield of 94%.

[0042] Detected by ion chromatography: Na: 2.2ppm, K: 2.6ppm, Fe: 1.6ppm, Mg: 1.6ppm, Ca: 2.4ppm, no halide ions were seen.

Embodiment 3

[0044] Preparation of Tetraethylammonium Tetrafluoroborate

[0045] Under a nitrogen atmosphere, triethoxonium tetrafluoroborate (47.5 g, 0.25 mol) was added to a 500 mL reaction flask containing triethylamine (28.3 g, 0.28 mol) and 200 mL of chloroform, 60 °C for 10 hours. Filtration, the filtrate was concentrated to obtain the crude product of tetraethylammonium tetrafluoroborate, dissolved in methanol, added activated carbon, heated to reflux for 30 minutes, filtered, and the filtrate was cooled to obtain 47.7 grams of white crystals of tetraethylammonium tetrafluoroborate. The yield was 88%.

[0046] Detected by ion chromatography: Na: 1.8ppm, K: 2.8ppm, Fe: 1.5ppm, Mg: 2.4ppm, Ca: 3.2ppm, no halogen ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com