Device and method for continuously preparing azo compound

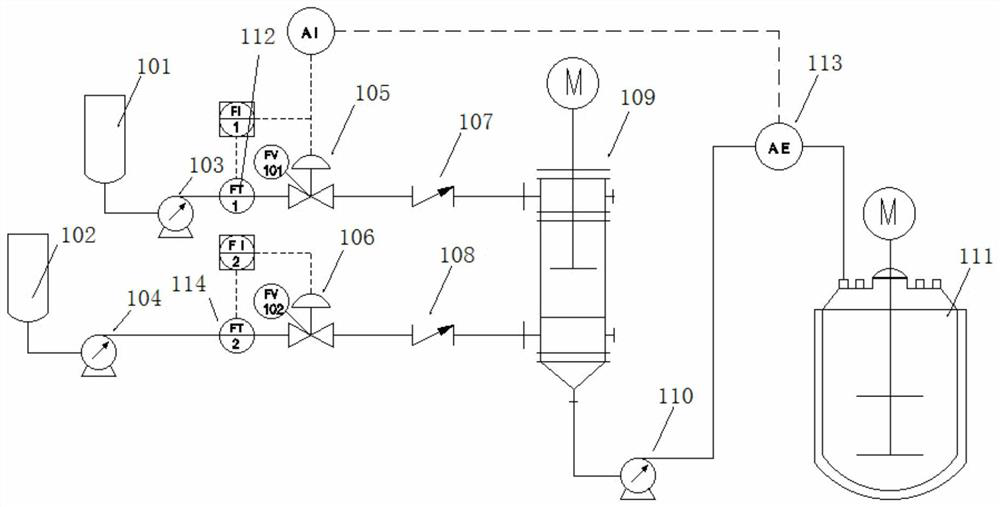

A technology of azo compounds and storage tanks, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., to achieve continuous synthesis, compact overall structure, and eliminate the impact of inaccurate material matching on product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

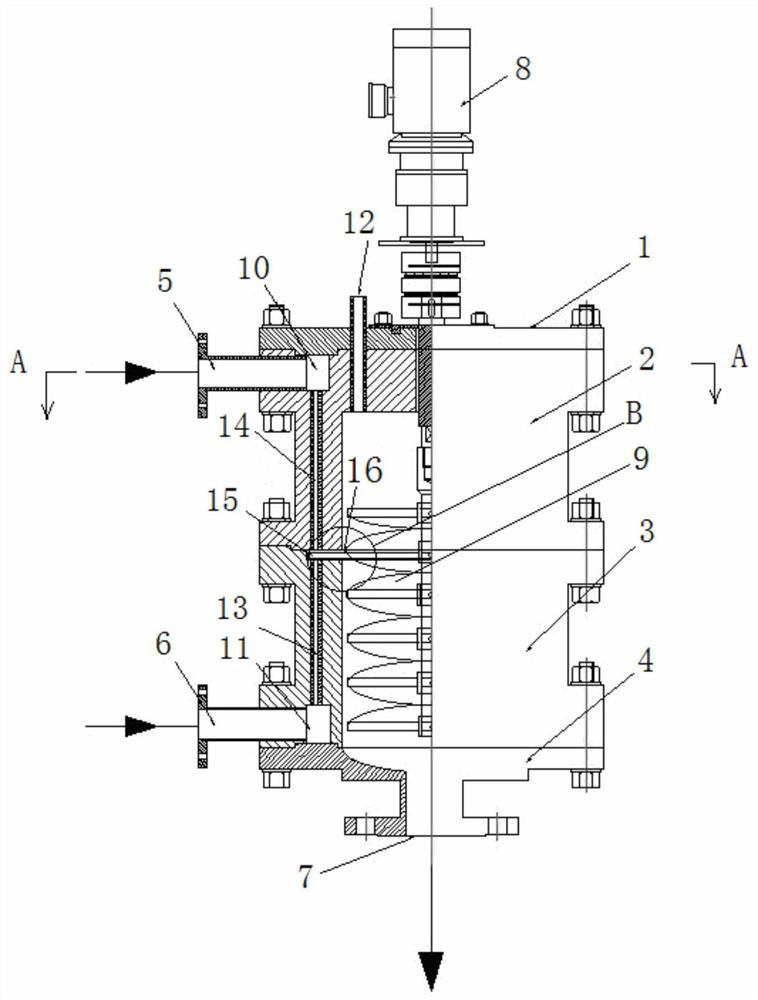

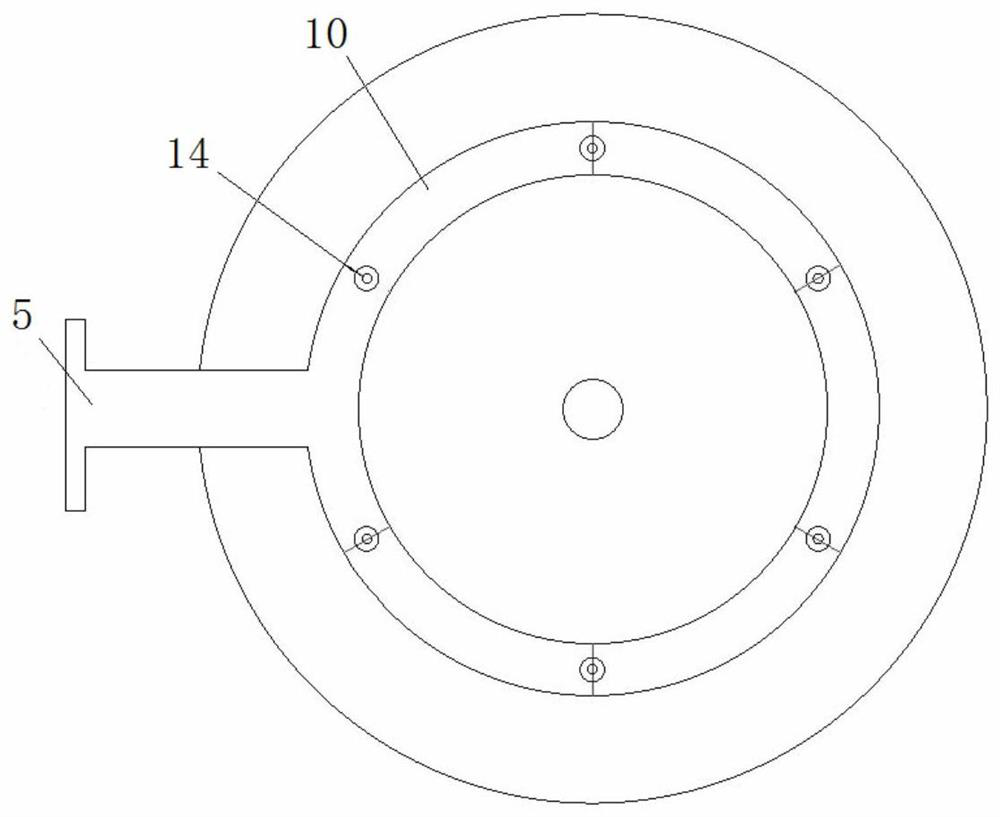

[0066] The above-mentioned continuous preparation of azo compounds is adopted, wherein the inner diameter of the nozzle used in the micro-collision flow stirring reactor 109 is 0.8mm, the nozzle is a single-hole structure, and the distance between the upper and lower nozzles is 15mm; the number of scrapers 16 is n=3, a =15mm, b=20mm, c=4mm; R=100mm, r=360 / min.

[0067] Continuous preparation of disperse red S-5BL compound:

[0068]

[0069] The temperature in the first storage tank 101 is 10°C, the concentration is 4.1% o-chloro-p-nitroaniline diazonium salt solution is sent into the collision flow stirring reaction through the first feed pump 103 through the first flow meter 112 and the first regulating valve 105 In the device 109, the N,N-diacetoxyethyl m-acetaniline solution with a temperature of 10°C and a concentration of 7.6% in the second storage tank 102 is passed through the second flowmeter 114 and the second The regulating valve 106 is sent into the collision flow...

Embodiment 1

[0070] Comparative Example One: Batch Synthesis of Disperse Red S-5BL Compound

[0071] Slowly add the solution of o-chloro-p-nitroaniline diazonium salt with a concentration of 4.1% at a temperature of 10°C to a stirred tank containing a solution of N,N-diacetoxyethyl m-acetamidoaniline with a concentration of 7.6%, and control the temperature to react at 10°C After the addition, the stirring was continued for 2 h, filtered and washed with water to obtain the dye red S-5BL compound, the chromatographic content of the main compound was 88.5%, and the yield was 93.7%.

Embodiment 2

[0072] Embodiment two prepares Disperse Yellow 211 compound

[0073]

[0074] Using the micro-collision flow stirring reactor of Example 1, the temperature in the first storage tank 101 is 12° C., and the concentration of 4.77% o-nitro-p-chloroaniline diazonium salt solution is passed through the first flowmeter 112 through the first feed pump 103. and the first regulator valve 105 into the collision flow stirring reactor 109, the temperature in the second storage tank 102 is 18 ℃, the N-ethyl-3-cyano group-4-methyl-6-hydroxyl group of concentration 4.92% - The 2-pyridone solution is sent into the collision flow stirring reactor 109 through the second flow meter 114 and the second regulating valve 106 through the second feeding pump 104, and the two-phase volume flow rate is 200 L / h, and the two materials After the collision and mixing reaction in the collision flow stirring reactor 109, the generated material is sent to the slurry tank 111 through the discharge pump 110, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com