Control method for stably adjusting purity of trichlorosilane

A technology of trichlorosilane and a control method, which is applied in chemical instruments and methods, silicon compounds, halogenated silanes, etc., can solve the problems of difficult and accurate control of extreme point components, delayed interference, and impact on recycling, etc. Achieve rapid and accurate control, ensure product quality, and reduce product loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

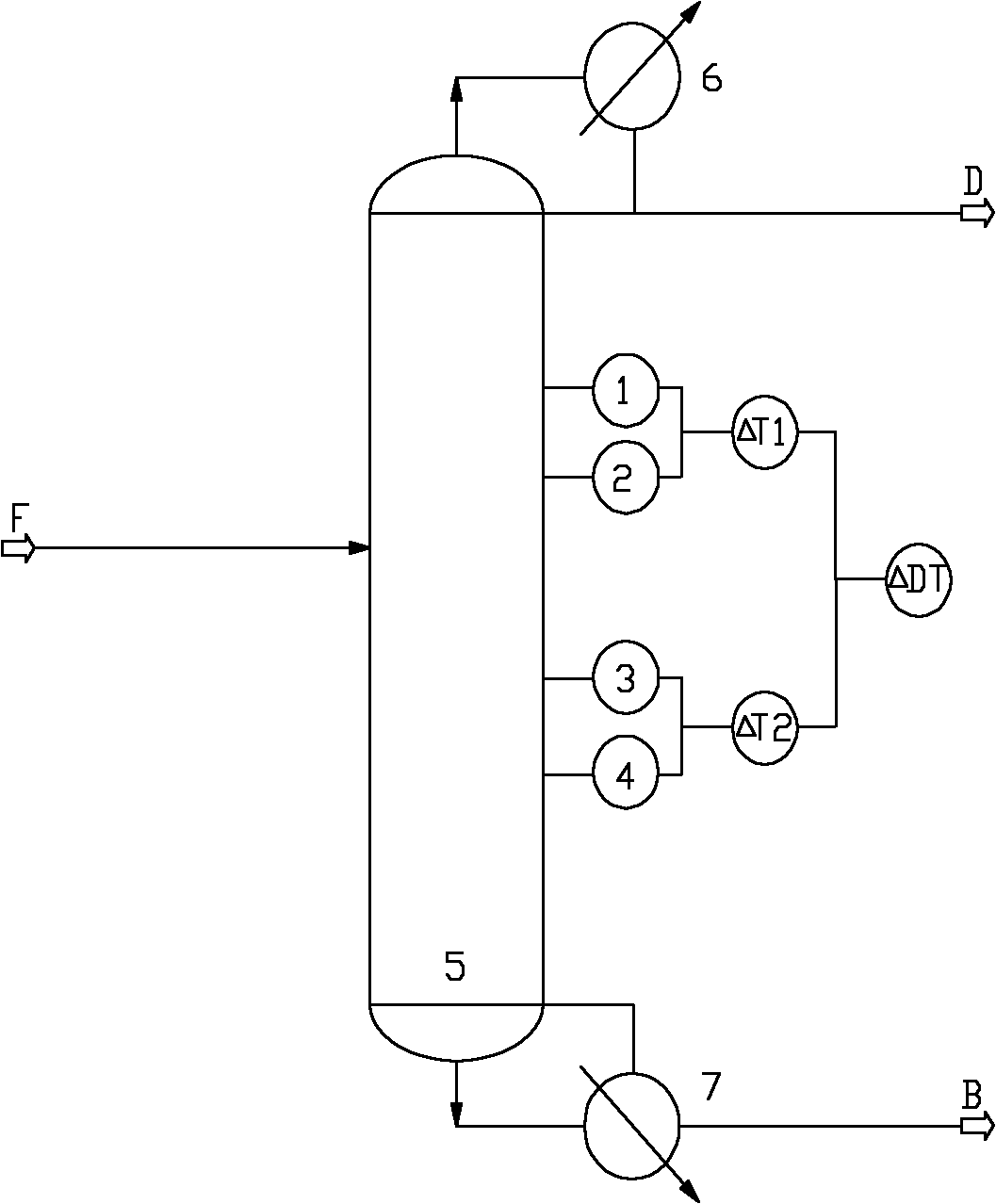

[0018] In this implementation, polysilicon is manufactured according to the vapor deposition method, and the trichlorosilane raw material used contains trichlorosilane and impurity boron. The purpose of this rectification tower 5 is to completely distill the light component boron from the top of the tower, and the product Trichlorosilane is extracted from the tower kettle. The material enters from the middle section of the tower, and the feed liquid in the tower is heated by the reboiler 7 at the bottom of the tower. The impurity boron rich in low boiling point becomes steam from the top of the tower after being condensed by the condenser 6, and another part of the liquid at the top of the tower flows back into the tower, and high-purity trichlorosilane is obtained at the bottom of the tower.

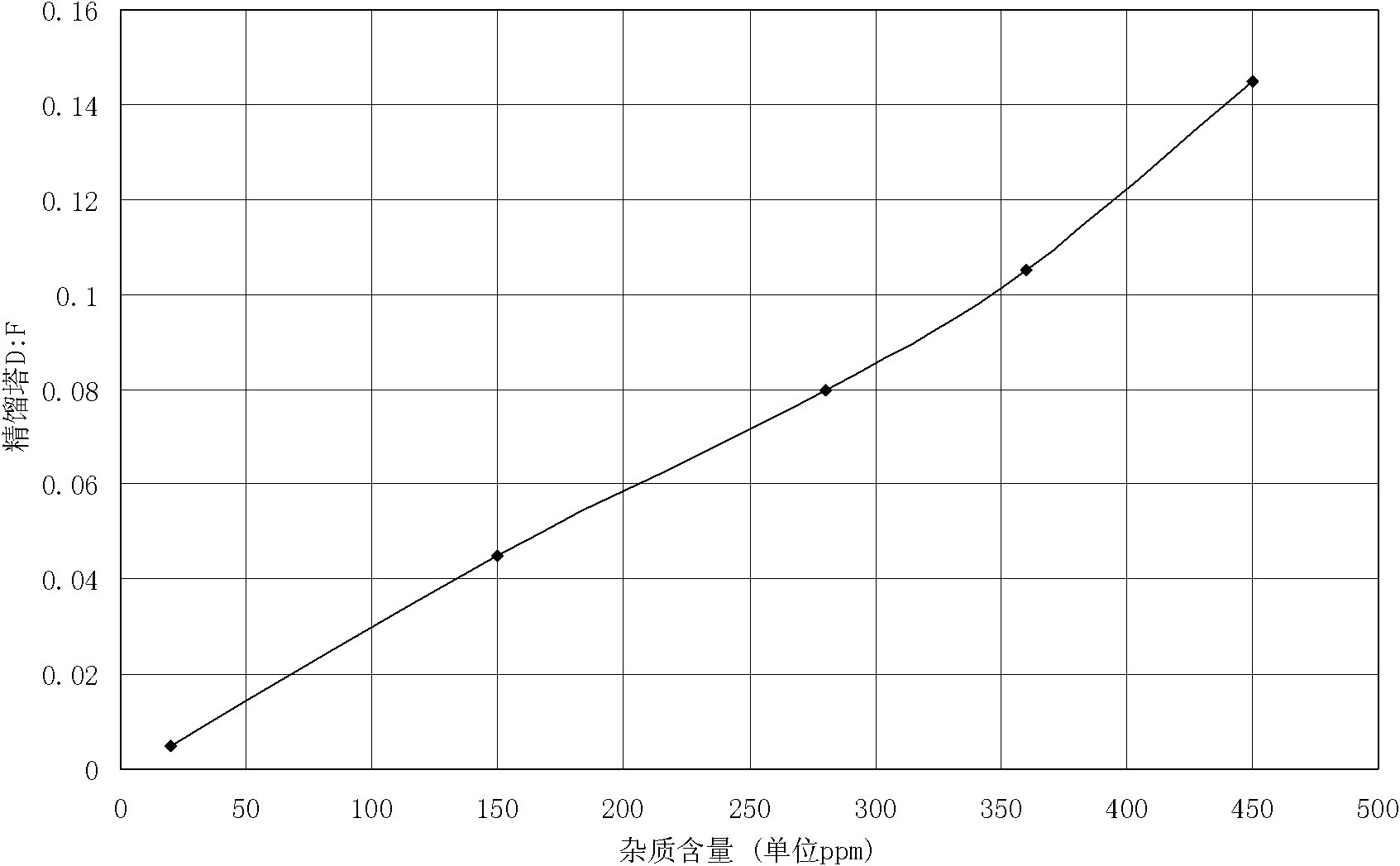

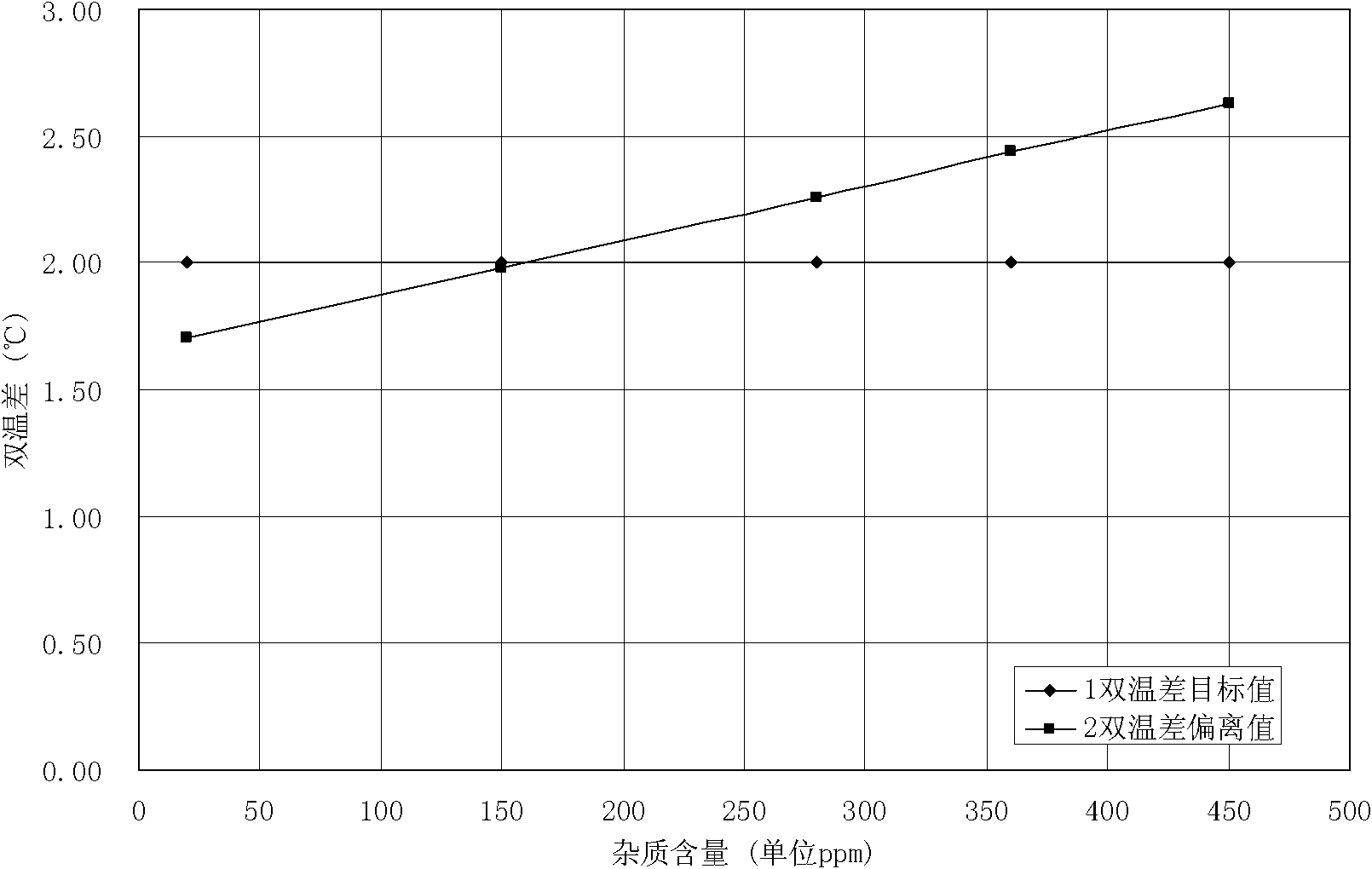

[0019] In this method of controlling the purity of trichlorosilane, the number of theoretical plates in the rectification tower is at least 30 to 100, the operating pressure at the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com