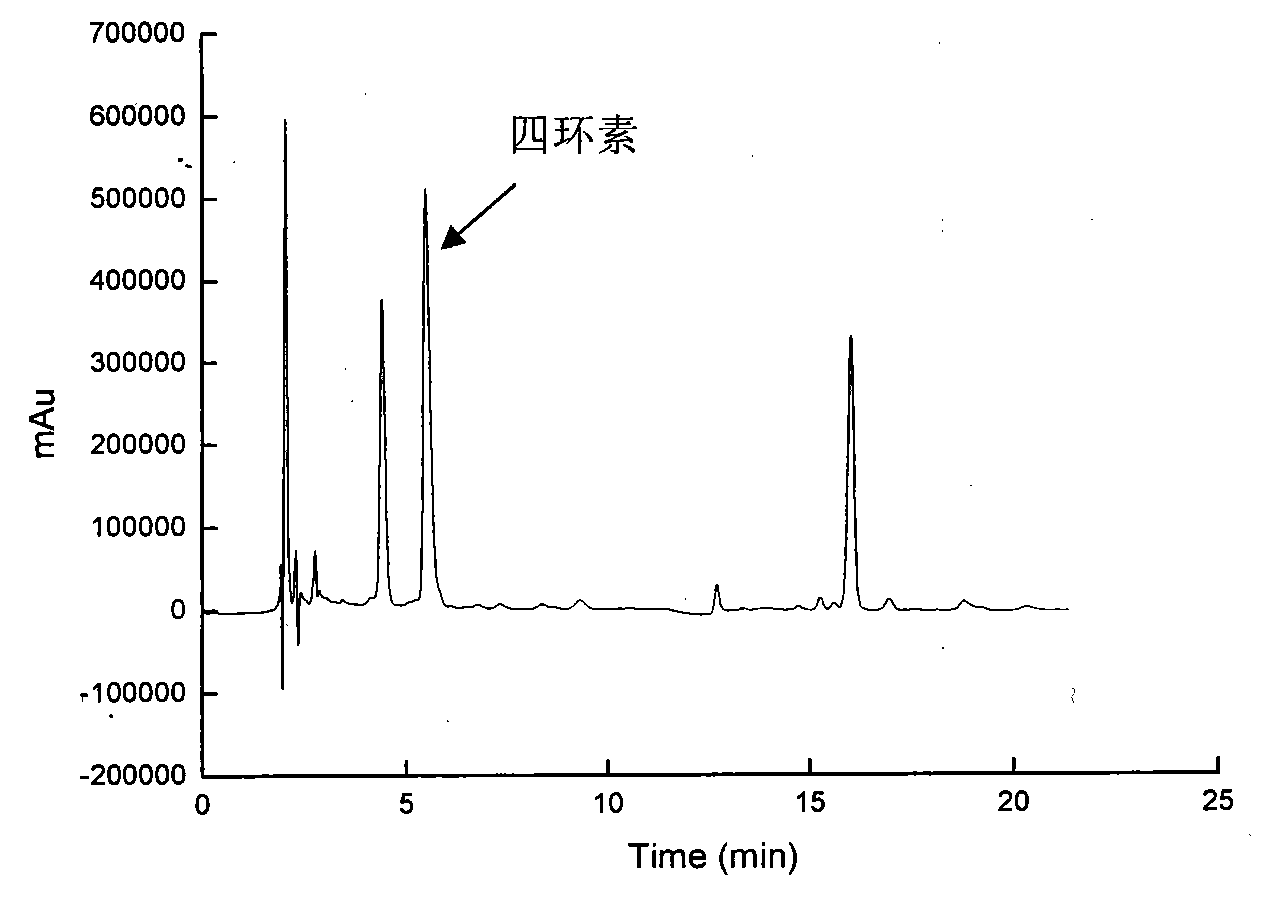

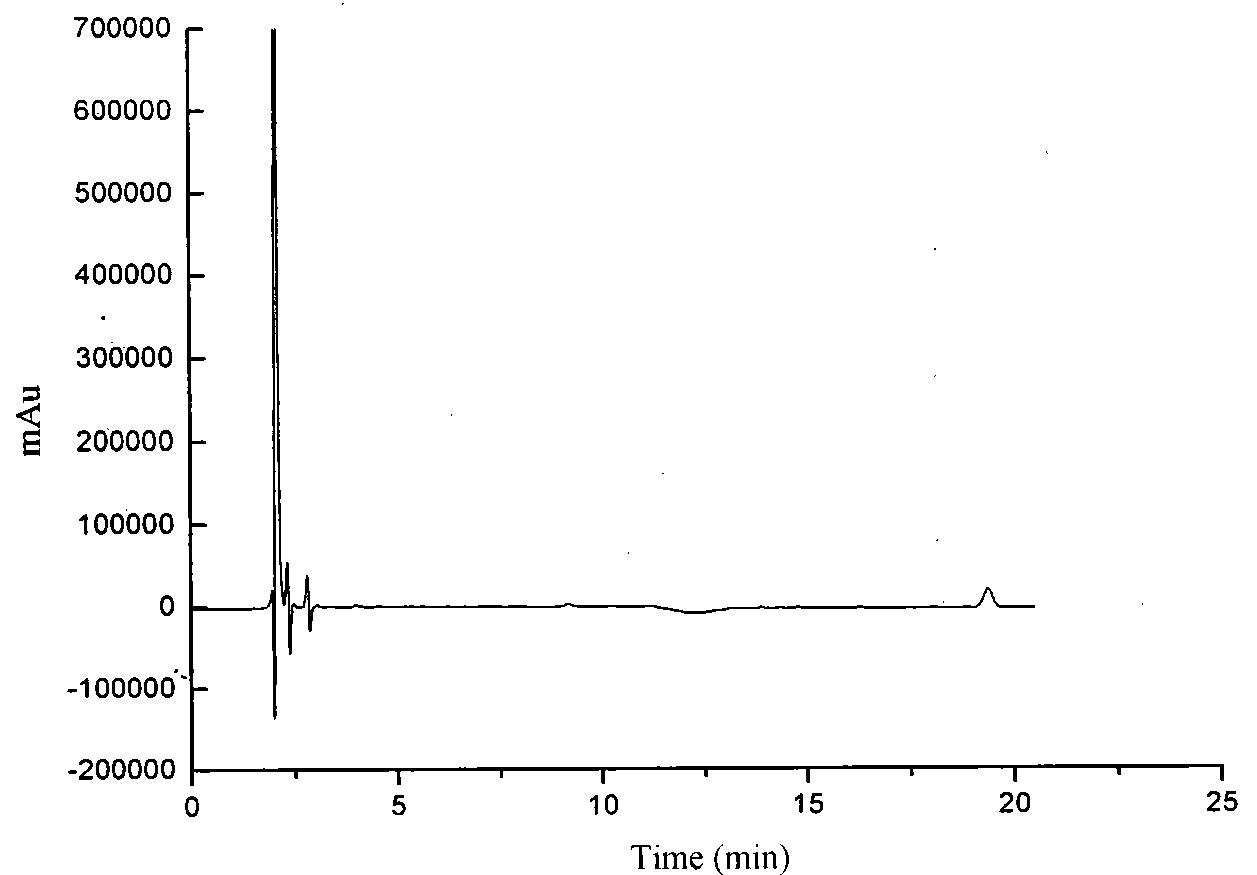

Method for producing yeast extract by use of bacterial residues after tetracycline degradation

A technology of yeast extract and tetracycline, applied in the field of microbial fermentation, to achieve high product quality, high value conversion, simple and unique preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for producing yeast extract by utilizing the bacterium residue after degradation treatment of tetracycline, comprising the steps of:

[0040] S1: Preparation of secondary seeds of Saccharomyces cerevisiae, Candida tropicalis and EM protosol:

[0041] a. Seed Activation Cultivation: Pick a ring from the storage tubes of Saccharomyces cerevisiae, Candida tropicalis, and EM original dew, respectively, and insert them into the seed activation expansion medium, and culture them aerobically at 30°C and 100r / min for 48h. Obtain activated Saccharomyces cerevisiae, Candida tropicalis and EM raw dew seeds respectively; Described seed concentration is 10 7 CFU / mL;

[0042] b. First-level seed preparation: Inoculate the Saccharomyces cerevisiae, Candida tropicalis and EM raw dew seeds prepared in the above step a with an inoculation amount of 1% by mass percentage, respectively, inoculate the seed activation expansion medium at 30°C, 100r / After 48 hours of aerobic cultu...

Embodiment 2

[0058] A method for producing yeast extract by utilizing the bacterium residue after degradation treatment of tetracycline, comprising the steps of:

[0059] S1: Preparation of secondary seeds of Saccharomyces cerevisiae, Candida tropicalis and EM protosol:

[0060] a. Seed activation culture: Pick a ring from the storage tubes of Saccharomyces cerevisiae, Candida tropicalis, and EM original dew, respectively, and insert them into the seed activation expansion medium, and culture aerobically at 33°C and 120r / min for 42h. Obtain activated Saccharomyces cerevisiae, Candida tropicalis and EM raw dew seeds respectively; Described seed concentration is 10 7 CFU / mL;

[0061] b. First-level seed preparation: inoculate the Saccharomyces cerevisiae, Candida tropicalis and EM raw dew seeds prepared in the above step a with an inoculation amount of 3% by mass percentage, respectively, inoculate the seed activation expansion medium at 33°C, 120r / m After 42 hours of aerobic culture under...

Embodiment 3

[0077] A method for producing yeast extract by utilizing the bacterium residue after degradation treatment of tetracycline, comprising the steps of:

[0078] S1: Preparation of secondary seeds of Saccharomyces cerevisiae, Candida tropicalis and EM protosol:

[0079] a. Seed activation culture: Pick a ring from the storage tubes of Saccharomyces cerevisiae, Candida tropicalis, and EM original dew, respectively, and insert them into the seed activation expansion medium, and cultivate them aerobically at 35°C and 140r / min for 36h. Obtain activated Saccharomyces cerevisiae, Candida tropicalis and EM raw dew seeds respectively; Described seed concentration is 10 7 CFU / mL;

[0080] b. Primary seed preparation: Inoculate the Saccharomyces cerevisiae, Candida tropicalis and EM protozoa seeds prepared in the above step a with an inoculation amount of 5% by mass percentage, respectively, inoculate the seed activation expansion medium at 35°C, 140r / m After aerobic cultivation for 36 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com