Automatic unloading device for UO2 grinding core blocks

A technology of automatic material cutting and pellets, applied in transportation and packaging, cleaning methods using tools, stacking of objects, etc., can solve problems such as weak, inconsistent operation methods, and difficulty in eliminating responsibility, and achieve reduction Effects of contact time, reduction of post labor workload, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of UO described in the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. 2 The automatic unloading device for grinding pellets will be described in further detail.

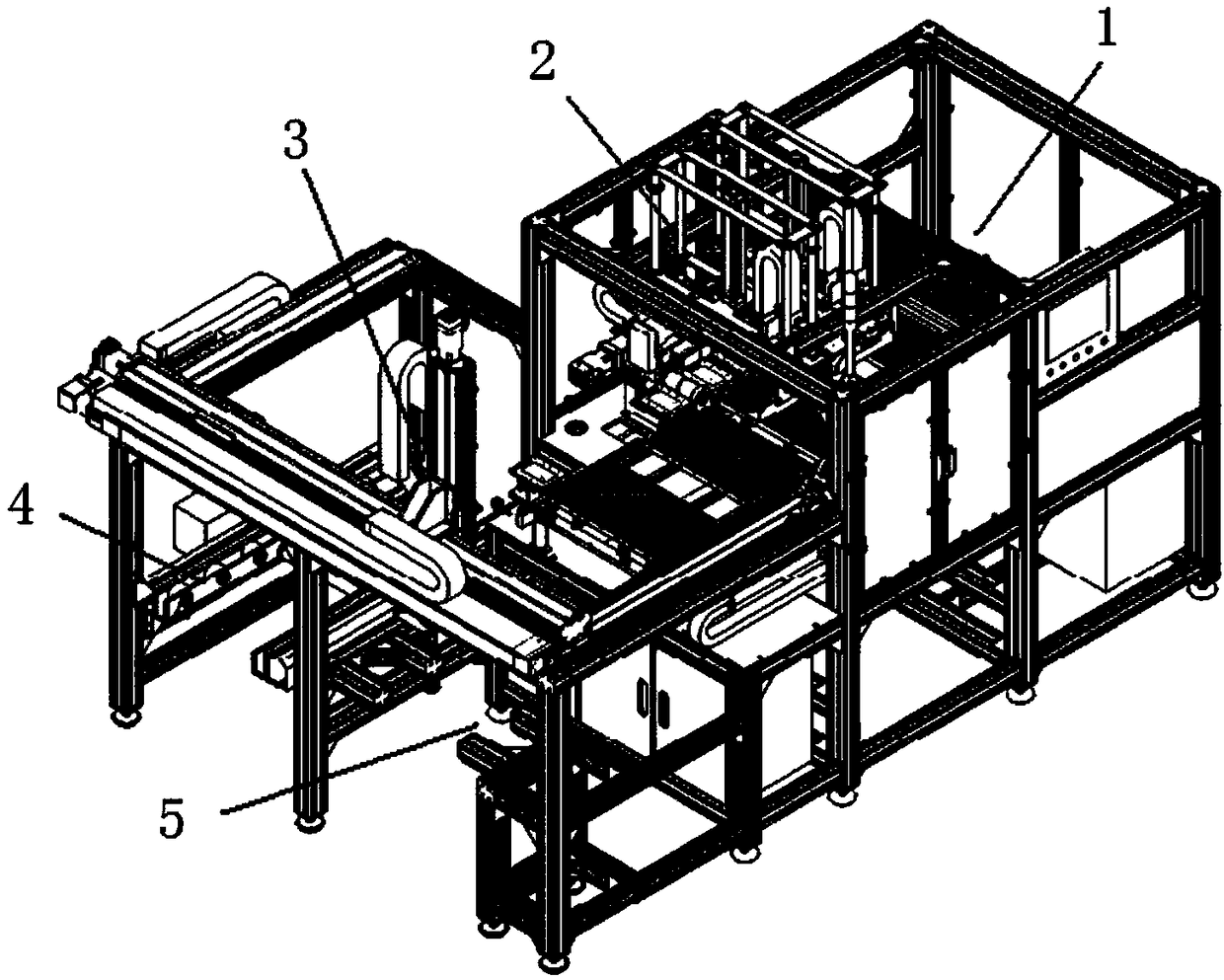

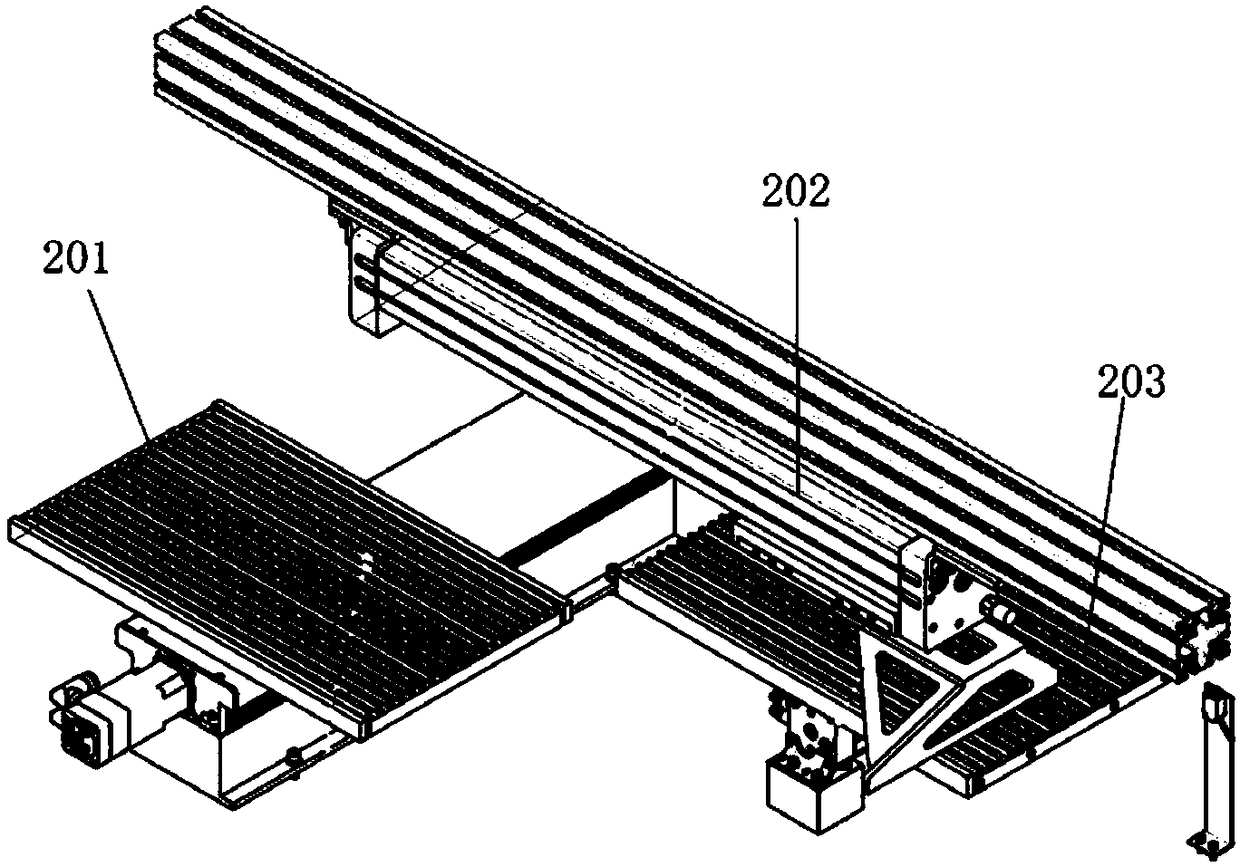

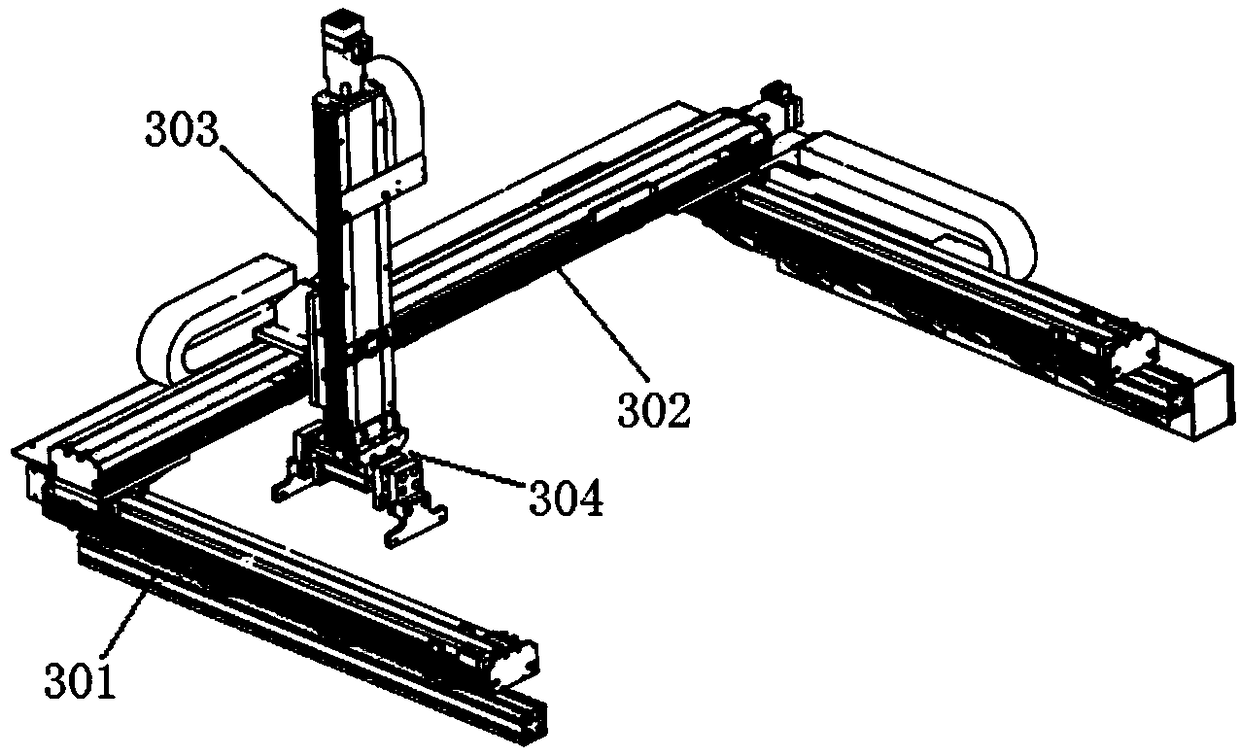

[0021] like Figure 1-4 As shown, a UO 2 Grinding pellet automatic unloading device, including pellet code disc mechanism 1, pellet off-line scrubbing mechanism 2, tray handling mechanism 3, empty tray loading mechanism 4 and full tray unloading mechanism 5;

[0022] When the pellets on the grinding line enter the device, the pellet code disc mechanism 1 firstly codes the pellets row by row; The offline scrubbing mechanism 2 performs offline scrubbing; after the offline scrubbing is completed, the trays filled with pellets are sent to the full tray unloading mechanism 5 by the tray handling mechanism 3 for stacking; The tray loading mechanism 4 moves the empty tray to the end of the pellet off-line scrubbing mechanism 2, waiting for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com