Heavy casting remote control polishing system and polishing method thereof

A technology for large castings and workshops, which is applied in the control of workpiece feed movement, grinding machines, grinding racks, etc. It can solve the problems of high operator skill requirements, few types of compatible products, and different grinding positions. Simple operation, low skill requirements, good practical value and promotional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

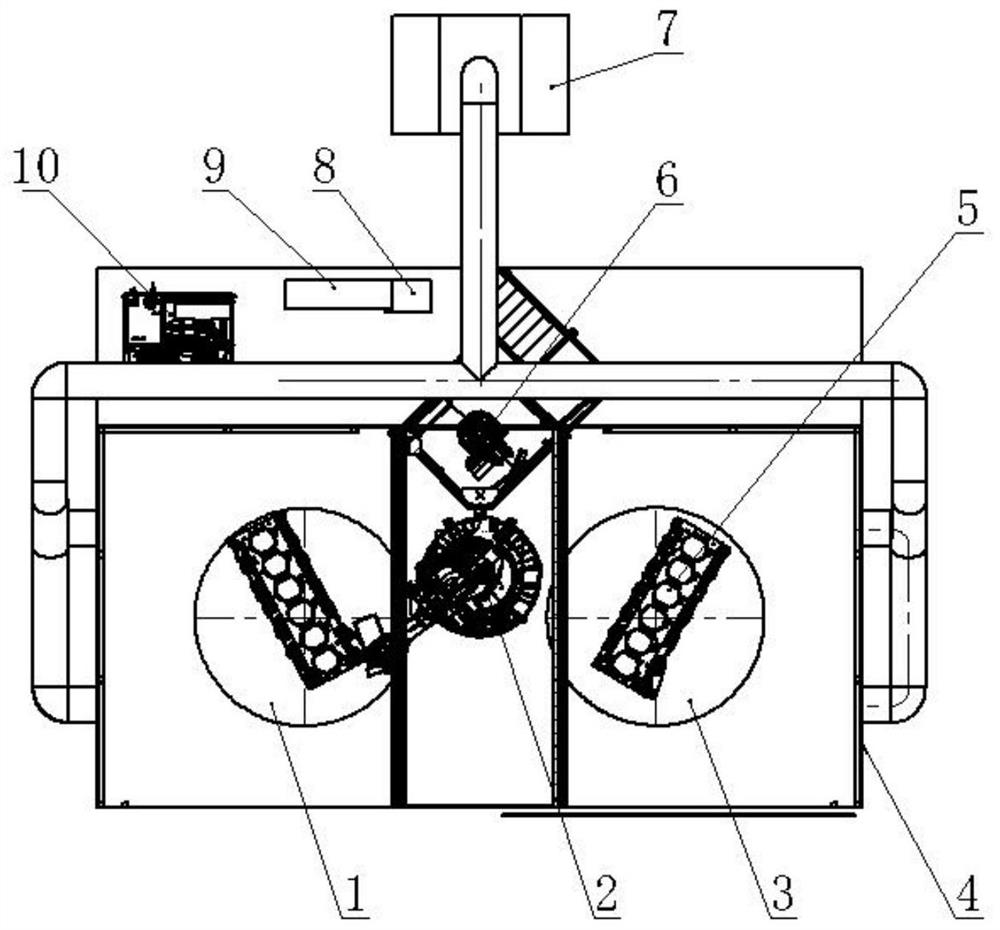

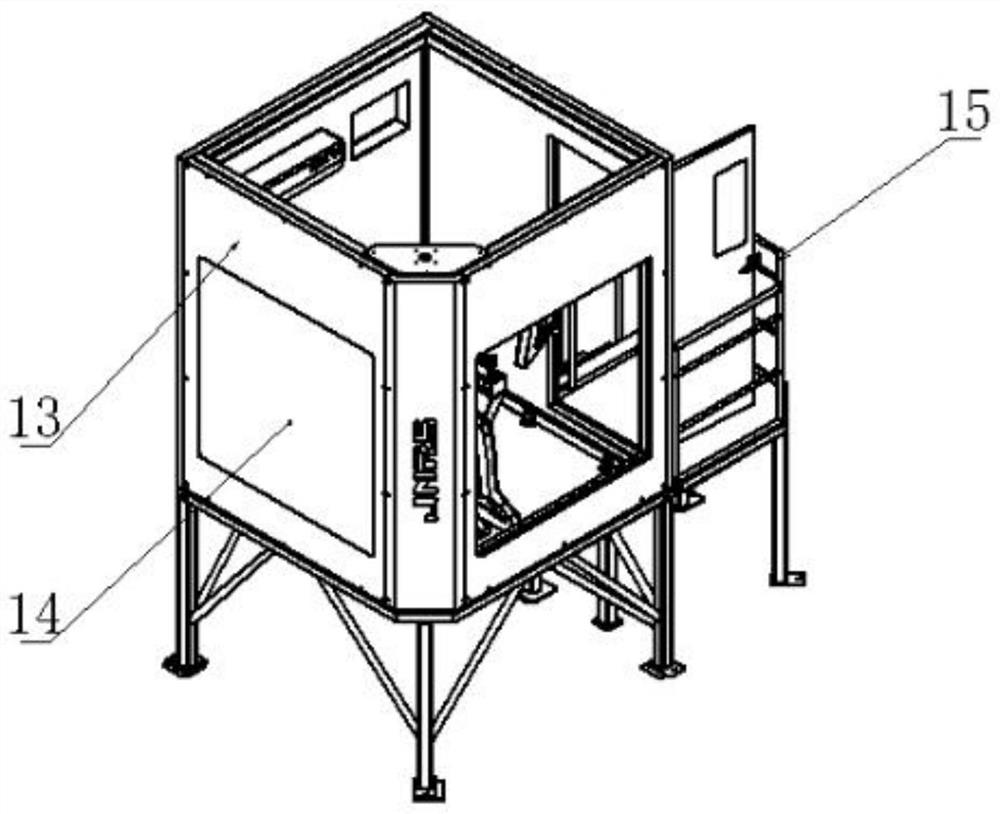

[0036]Example 1, such asFigure 1-6Down:

[0037]A large-scale casting remote control grinding system, including operational inter-operation 4, dust removal device, and several stationary retaining; the interior of the operation between the operation intervals into multiple operations 4; the interior of the left side operation 4 is installed Turndower 1, right operation interior 4 internal mounting station two-turn station 3, central operation between 4, mounted a grinding robot 2; and grinding robot 2 is provided with virtual cabin 6 for manipulating workshops 6; Virtual cabin 6 rear installation There is a dust collector device 7, and the operation between 4 rear is arranged in the rear of the robotic electric cabinet 8, the system total power cabinet 9, and the hydraulic system 10; the grinding spindle 11 is mounted on the front end of the arm of the grinding robot 2.

[0038]Preferably, the two sides of the operation between the operations 4 are respectively opened, respectively, and t...

Embodiment 2

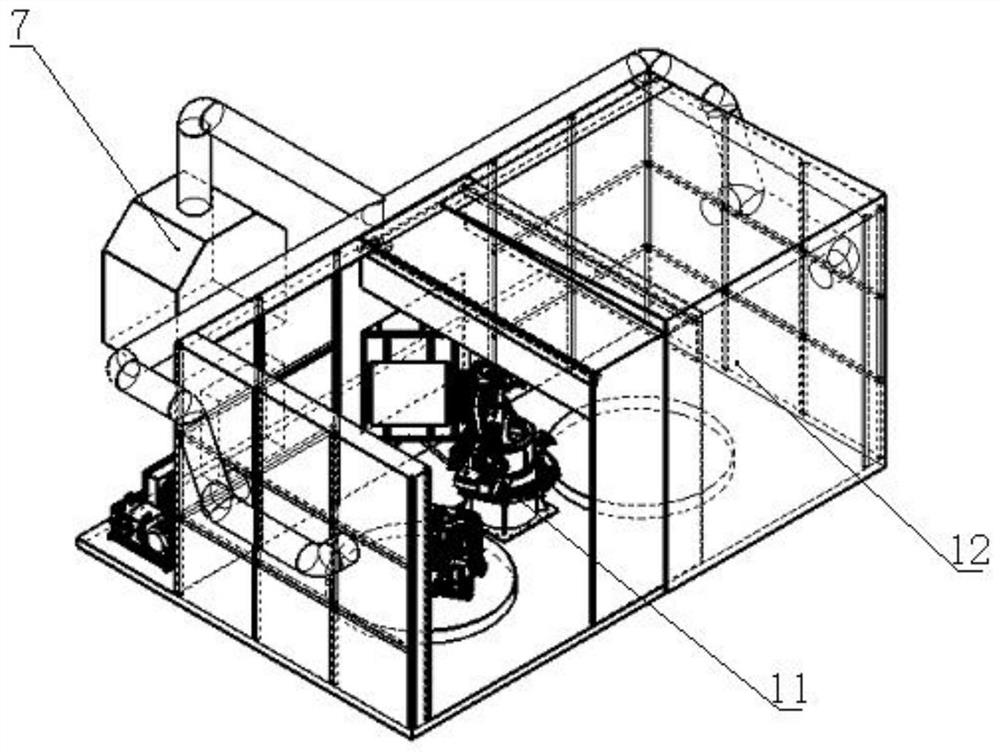

[0057]Example 2, such asFigure 1-6Down:

[0058]The overall grinding system layout of this program includes grinding robot 2, virtual cabin 6, operational inter-operative 4, ventilation equipment, grinding turntable system, polishing hydraulic station system, and system electric cabinet.

[0059]Among them, the grinding robot 2 is mounted, and the rear side of the robot is a virtual cabin 6, and the other side is the workpiece turntable. The operation between the operation is built from the steel structure, and the work area is effectively isolated from other environmental environment of the factory. Configure the air purification apparatus in operation between operation, 4 dust in the operation between 4 sides of the operation, effectively remove dust during the polishing process. It is guaranteed that there is a high visibility between the polishing operation 4, and the dust is concentrated, and the environment is protected.

[0060]Grinding robot 2 wrist with hydraulic spindle system, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com