Preparation method applicable to treating garbage derivate by being jointed with cement kiln

A technology of waste-derived fuel and cement kiln, which is applied in the field of preparation of waste-derived fuel combined with cement kiln disposal to achieve the effects of eliminating pollution, reducing quantity and increasing calorific value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

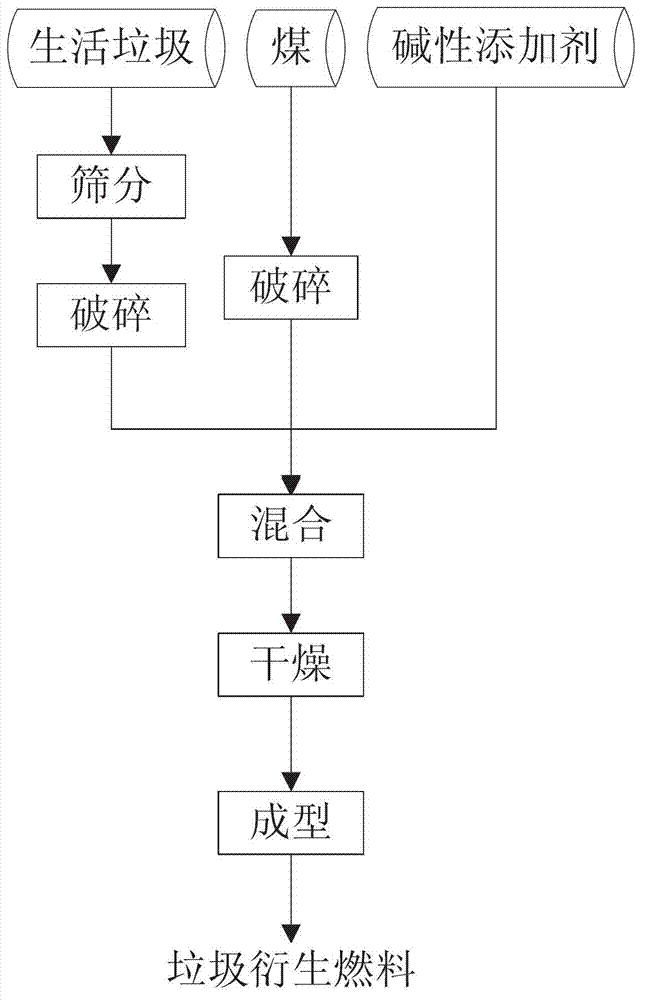

Image

Examples

Embodiment 1

[0021] The primary domestic garbage taken out of the landfill is screened by magnetic separation, air separation, and gravity separation to remove inorganic non-combustible materials such as metals, bricks, dust, and glass in the garbage;

[0022] The combustible household garbage left after screening is crushed by a shear crusher to a particle size of 50mm;

[0023] In the combustible domestic garbage after crushing, mix 20% of the coal and 8% of the total weight of garbage, coal and alkaline additive into the broken combustible domestic garbage, and then fully stir and mix uniformly; Described alkaline additive is made up of the papermaking black liquor of 70% weight part and the calcium oxide of 30% weight part;

[0024] Transport the mixture of the above-mentioned domestic garbage, coal and additives to the drying room, and dry it through forced ventilation to reduce the moisture content to below 20%;

[0025] The material output from the drying chamber is directly sent t...

Embodiment 2

[0027] The primary domestic garbage taken out of the landfill is screened by magnetic separation, air separation, and gravity separation to remove inorganic non-combustible materials such as metals, bricks, dust, and glass in the garbage;

[0028] The combustible domestic garbage remaining after screening is crushed by a shear crusher to a particle size of 40mm;

[0029] Add 10% of the total weight of coal and 10% of the total weight of garbage, coal and alkaline additives into the broken combustible domestic waste, and then fully stir and mix them uniformly; Described alkaline additive is made up of the calcium oxide of the papermaking black liquor of 50% weight part and 50% weight part;

[0030] Transport the mixture of the above-mentioned domestic garbage, coal and additives to the drying room, and dry it through forced ventilation to reduce the moisture content to below 20%;

[0031] The material output from the drying chamber is directly sent to the molding machine for e...

Embodiment 3

[0033] The primary domestic garbage taken out of the landfill is screened by magnetic separation, air separation, and gravity separation to remove inorganic non-combustible materials such as metals, bricks, dust, and glass in the garbage;

[0034] The combustible domestic garbage remaining after screening is crushed by a shear crusher to a particle size of 60mm;

[0035] Add 15% of the total weight of coal and 5% of the total weight of garbage, coal and alkaline additives into the broken combustible domestic waste, and then fully stir and mix them uniformly; Described alkaline additive is made up of the calcium oxide of the papermaking black liquor of 60% weight part and 40% weight part;

[0036] Transport the mixture of the above-mentioned domestic garbage, coal and additives to the drying room, and dry it through forced ventilation to reduce the moisture content to below 20%;

[0037] The material output from the drying chamber is directly sent to the molding machine for ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com