Patents

Literature

38results about How to "Reduce hydration temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

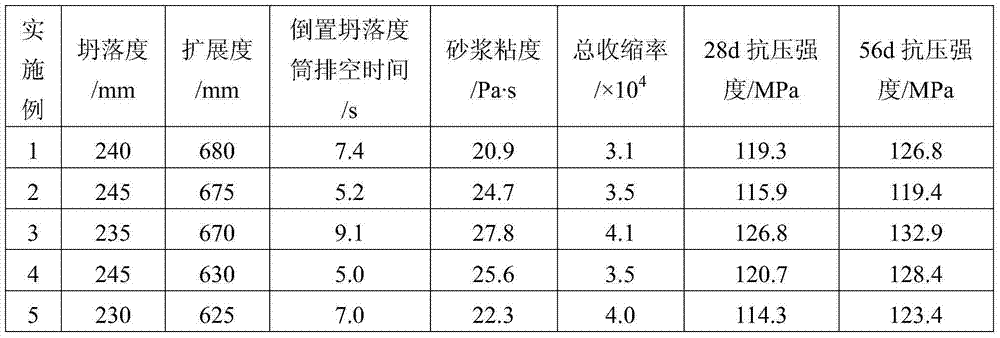

Low-shrinkage, low-viscosity and ultrahigh strength concrete

ActiveCN104844099AReduce hydration temperature riseReduce shrinkage cracksSolid waste managementWork performanceMicrosphere

The invention belongs to the technical field of building materials and particularly relates to low-shrinkage, low-viscosity and ultrahigh strength concrete. Based on a single formula proportional dosage, the low-shrinkage, low-viscosity and ultrahigh strength concrete comprises the following components by weight: 250-300kg of cement, 120-180kg of microspheres, 90-120kg of mineral powder, 820-860kg of machine-made sand, 950-1000kg of gravels, 7-11kg of a water reducer and 115-125kg of water. The components are mixed with stirring for 1.5-2 minutes to obtain a concrete mixture. The concrete provided by the invention is less in binding material use, the total shrinkage percentage is less than (0.03-0.04per mill), the emptying time of an inverted slump cone is 5-10 seconds, the viscosity of mortar in same proportion is 20-28 Mp.s, the 28d compressive strength is 110-130MPa, and the 56d compressive strength is 120-135MPa. The concrete has the characteristics of being low in bonding material use, short in stirring time, excellent in working performance and low in comprehensive cost, and can be produced on a large scale and has a broad application prospect.

Owner:中建商品混凝土(福建)有限公司 +1

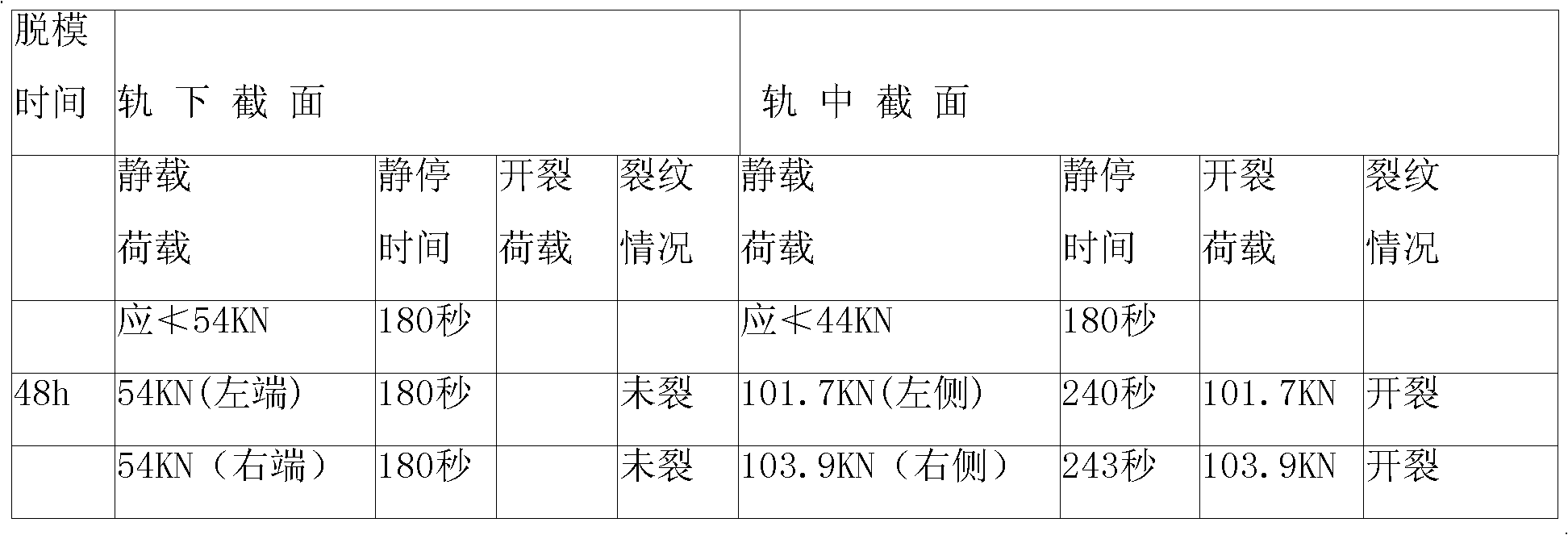

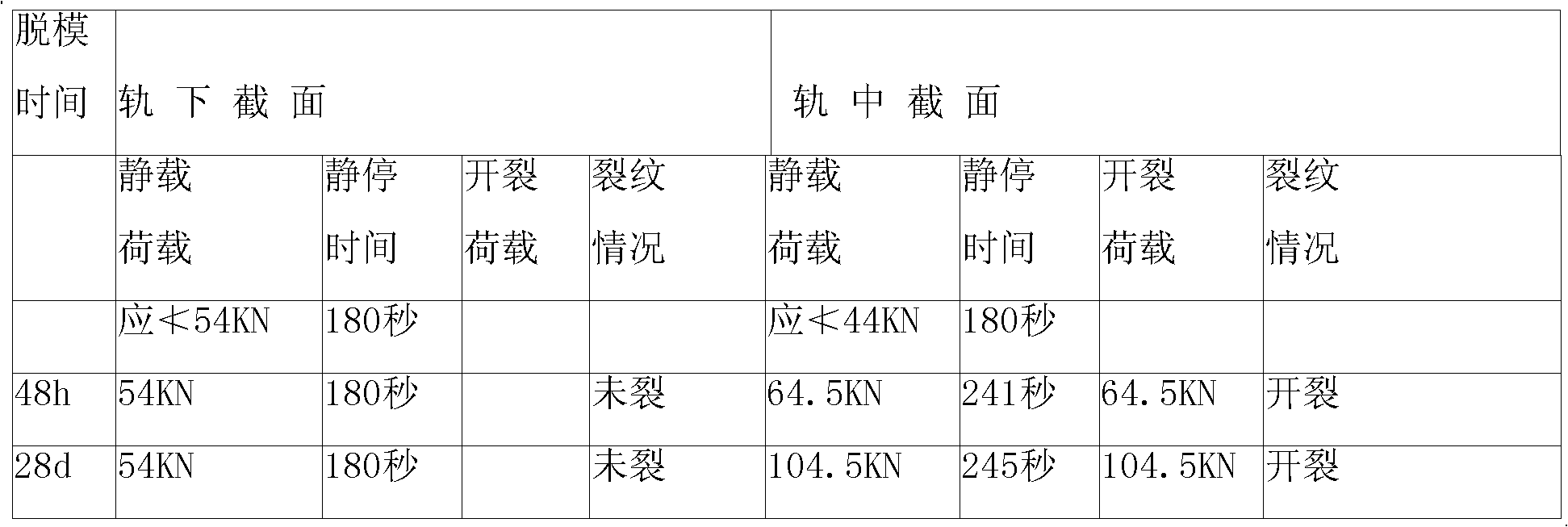

High-performance concrete material for prestressed component of ballastless track and method for preparing same

InactiveCN101289302ALow costSolve insufficient resourcesSolid waste managementSuperplasticizerWater reducer

The invention relates to a high performance concrete material used in prestressed components of non-ballasted tracks and a preparation method thereof. The gel material is cement, the aggregate is sand and stone, the admixture is complex mineral powder, and then high efficiency water reducing agent and water are added, stirred and vibrated, thus preparing the material. The components of the complex admixture are aluminosilicate, carbonate and sulfate, and the relative weight ratios are as follows: 15 to 80 percent of the aluminosilicate, 15 to 80 percent of the carbonate and 5 to 20 percent of the sulfate, and the total weight is 2 to 6 percent of the total weight of the concrete component. The material can ensure that the early strength of the concrete can achieve the required technical indexes of the prestressed concrete component used in non-ballasted tracks, thus obviously increasing the comprehensive properties, the workability and the durability of the concrete component. By using ordinary portland cement instead of superfine cement with deficient material source and exorbitant price, the product quality in mass production can be increased and the problem of high production cost of the prestressed concrete preformed component used in non-ballasted tracks can be solved.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +2

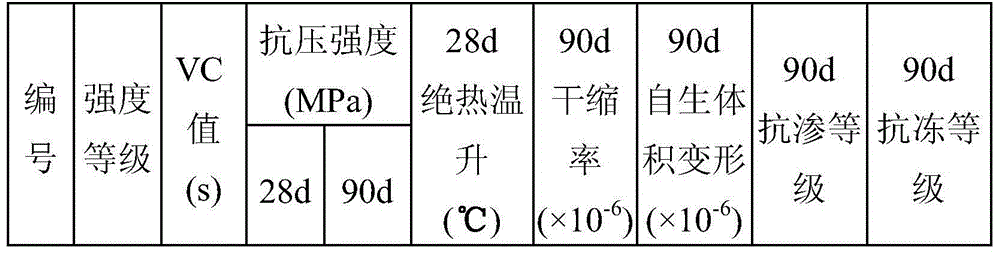

Four-graded roller compacted concrete suitable for water power hydraulic engineering and preparation method thereof

InactiveCN104402352AIncrease dosageReduce dosageSolid waste managementRoller-compacted concreteTemperature control

The invention provides four-graded roller compacted concrete suitable for water power hydraulic engineering, the four-graded roller compacted concrete per cubic meter comprises the following components: 49kg-64kg of cement, 78kg-92kg of fly ash, 70kg-71kg of water, 630kg-700kg of sand, 1520kg-1610kg of gravel, 0.98kg-1.42kg of a high efficiency water reducing agent and 0.07kg-0.14kg of an air entraining agent, the mass ratio of super large stone (80mm-120mm): large stone (40mm-80mm): middle stone (20mm-40m m): small stone (5mm-20mm) is 20:30:30:20. The four-graded roller compacted concrete is low in cementitious material use amount and low in adiabatic temperature rise, has good working performance, mechanical performance and durability, and can simplify the temperature control measures, improve the construction progress, and reduce cost.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

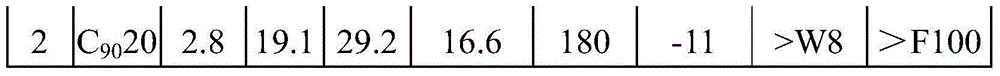

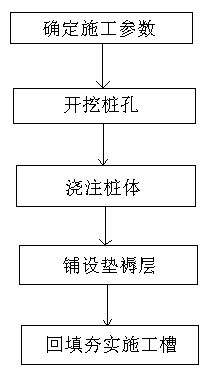

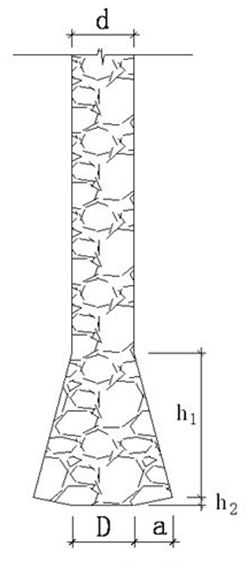

Method for consolidating existing building foundation

InactiveCN102071679AMeet mechanical needsReduce usageBulkheads/pilesSoil preservationStructural engineeringSoil horizon

The invention belongs to the field of consolidating existing building foundation, in particular relates to a method for consolidating the existing building foundation of which the upper structure cannot provide large counter-force. In the method, riprap concrete is adopted as a main material of a pile; holes are dug manually; and block stones or cobbles with the diameter of between 2 and 20cm are thrown into the dug holes in a mechanical or manual mode, and the poured concrete can be compactly filled in gaps generated in a block stone settling path at any time so as to form a compact riprap concrete pile with higher strength. Therefore, the pile end can be placed in a better bearing stratum on the deep part of the foundation, and complete or partial load of a building is transferred to the stratum to fulfill the aims of reducing additional stress of foundation soil under the substrate, reducing settlement and consolidating.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

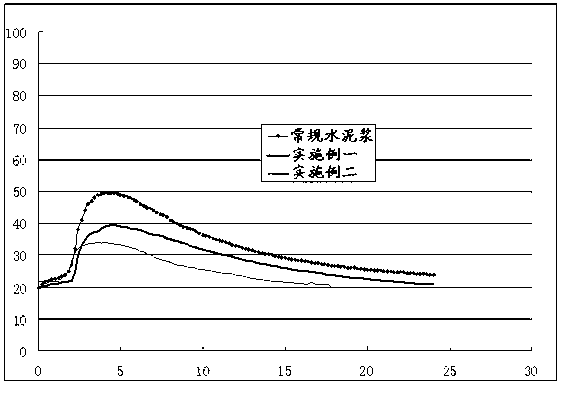

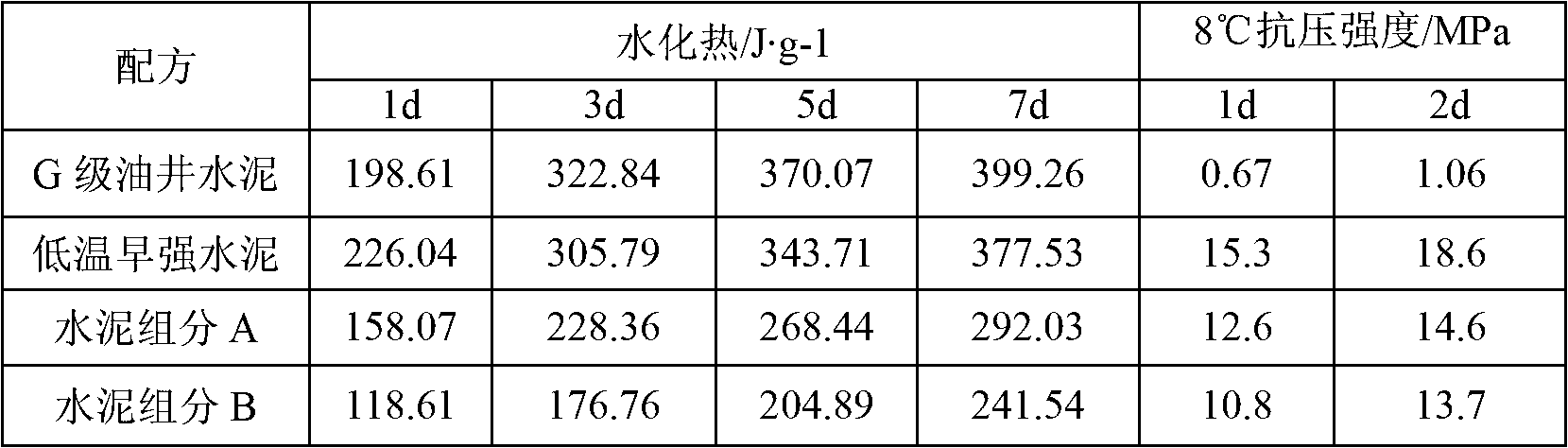

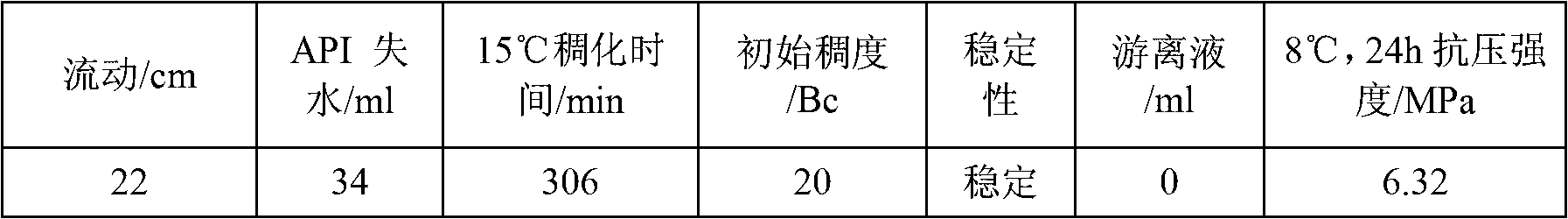

Low-hydration-heat early-strength cement for well cementation

InactiveCN102796500ARapid development of strengthImprove stacking effectDrilling compositionPermafrostHorizon

The invention relates to low-hydration-heat early-strength cement for well cementation, which is used in permafrost horizon or deepwater hydrate-bearing strata in oil drilling engineering. The cement disclosed herein comprises the following ingredients: 30-70wt% of low-temperature early-strength cement, 20-50wt% of pozzolanic material, and 10-40wt% of fine spherical particles. According to the invention, the hydration heat of the cement disclosed herein is 1 / 2 of that of ordinary cement, the low temperature strength develops fast; and the cement disclosed herein can be prepared into low-hydration-heat cement mortar, and has good effect and wide application.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Concrete temperature-control mold plate and use method thereof

ActiveCN105715040AAchieve warmingReduce the temperatureForming/stuttering elementsTemperature controlTemperature difference

The invention discloses a concrete temperature-control mold plate and a use method thereof. The concrete temperature-control mold plate comprises a steel plate structure body, a heat-preservation material plate and a reinforced plate, wherein the steel plate structure body and the heat-preservation material plate are matched together to form a hollow structure; the heat-preservation material plate is covered by the reinforced plate; a vent interface is formed in a double-layer structure of the reinforcing plate and the heat-preservation material plate; vent interfaces can be connected through an air connecting tube so as to communicate hollow structures of adjacent temperature-control mold plates and air flow of set temperature can be conveyed into the hollow structures through air conveying tubes; air flow is subjected to heat exchange with concrete through a steel plate surface, and thus temperature regulation and control of the temperature-control mold plate to concrete can be achieved. The concrete temperature-control mold plate mainly aims to solve the problem of temperature cracks of concrete of a wall structure, particularly a long (lateral) wall structure, and the problems that temperature cracks can be easily generated as the molding temperature and the hydration temperature of concrete are increased in a high temperature environment in summer, and a structure can be damaged as concrete at an early cast stage can be frozen and cracks can be generated as the surface and inner temperature difference is too large in a severe cold environment in winter.

Owner:JIANGSU SOBUTE NEW MATERIALS

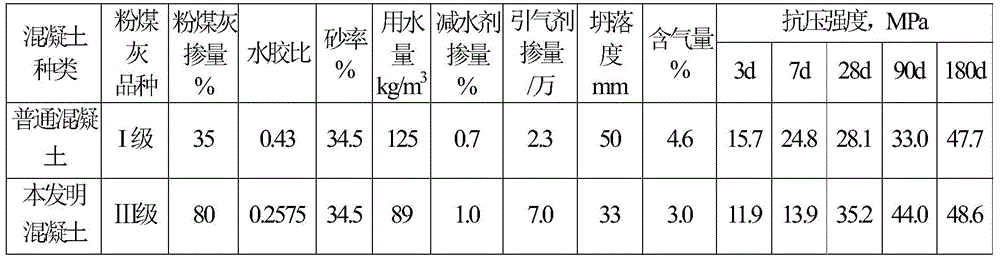

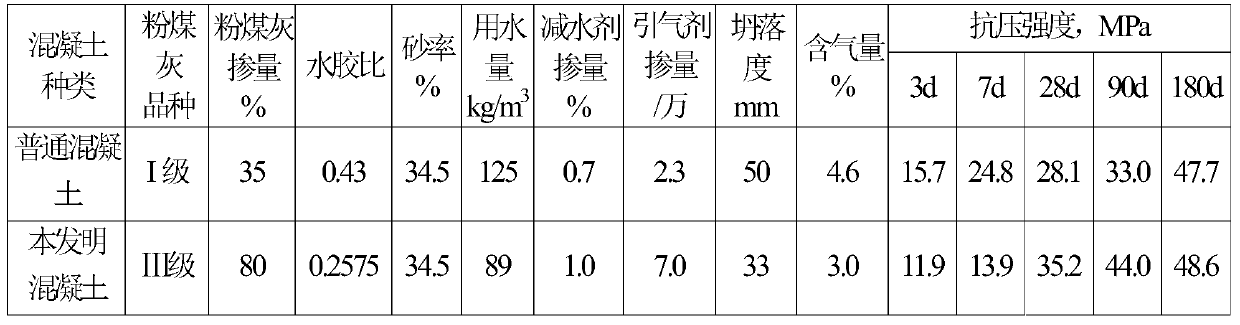

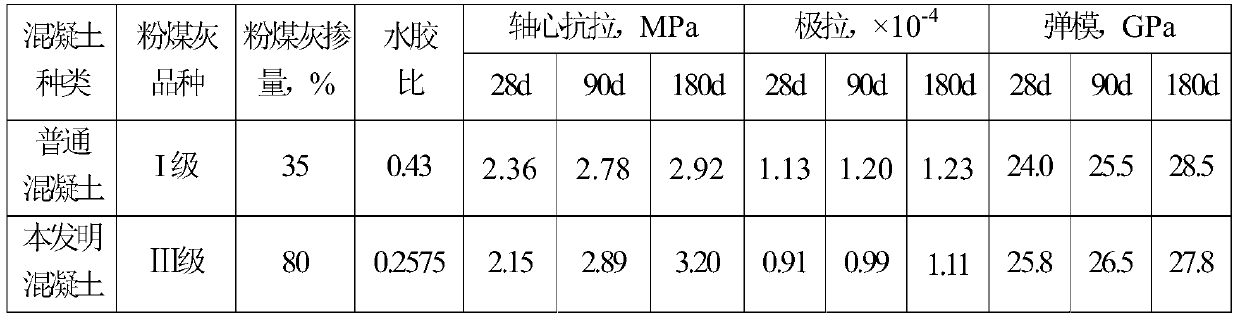

Concrete with ultrahigh content of mixed fly ash

ActiveCN105731919AReduce water consumptionGuaranteed StrengthSolid waste managementTemperature controlWater resources

The invention discloses a concrete with an ultrahigh content of mixed fly ash, and relates to the field of construction materials. The concrete comprises the following components in parts by weight: 48 to 60 parts of cement, 240 to 272 parts of fly ash, 656 to 696 parts of sand, 1293 to 1333 parts of broken stone, 3.0 to 4.8 parts of water reducer, 0.18 to 0.26 part of air-entrainer, and 80 to 90 parts of water. The mechanical performance and deformation performance of the concrete meet the requirements of water resources and hydropower engineering C18040 concrete and lower grades; moreover, the hydration temperature rise is lower, the anti-cracking performance is stronger, thus the happening rate of cracks in concrete is reduced, and the cost of temperature control is reduced.

Owner:HUBEI GEZHOUBA TESTING +1

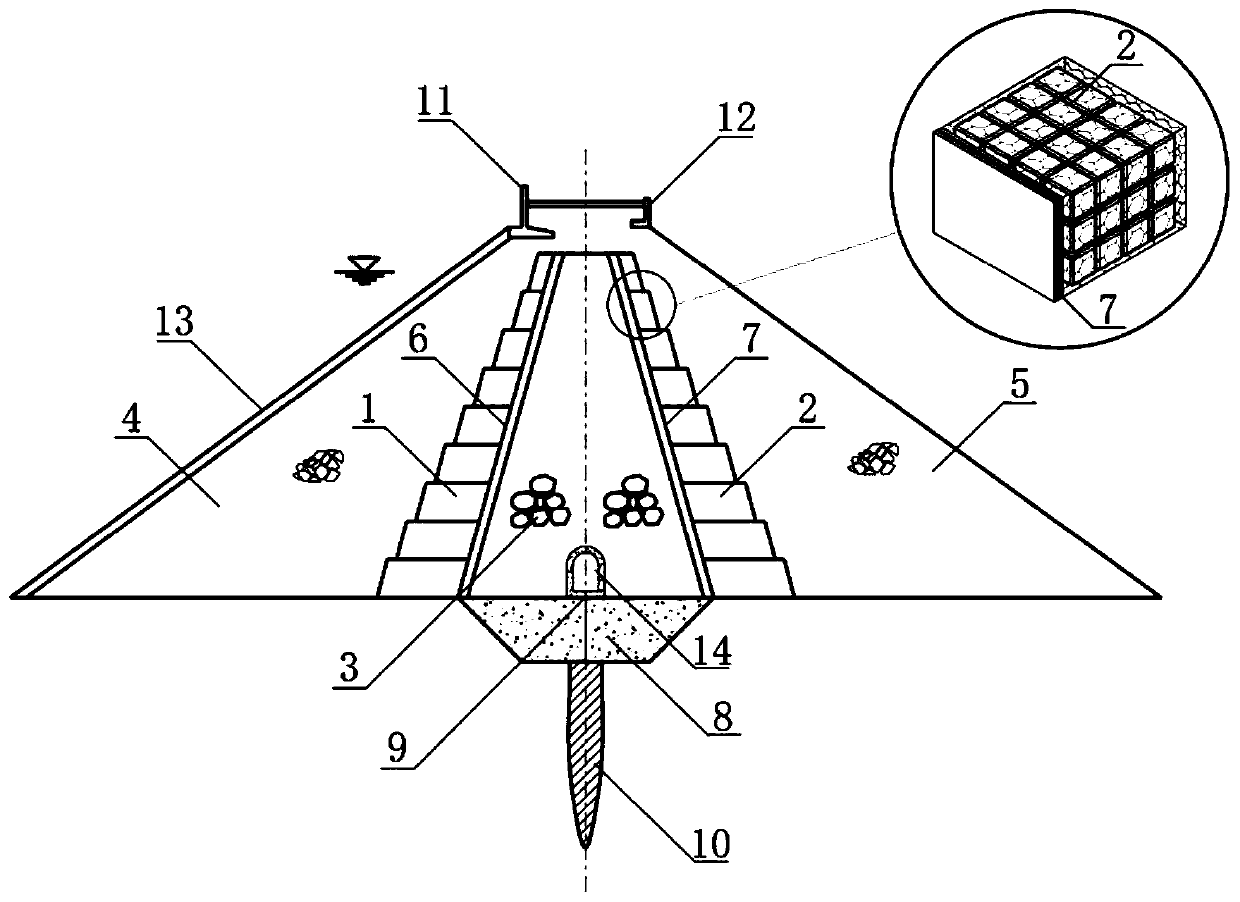

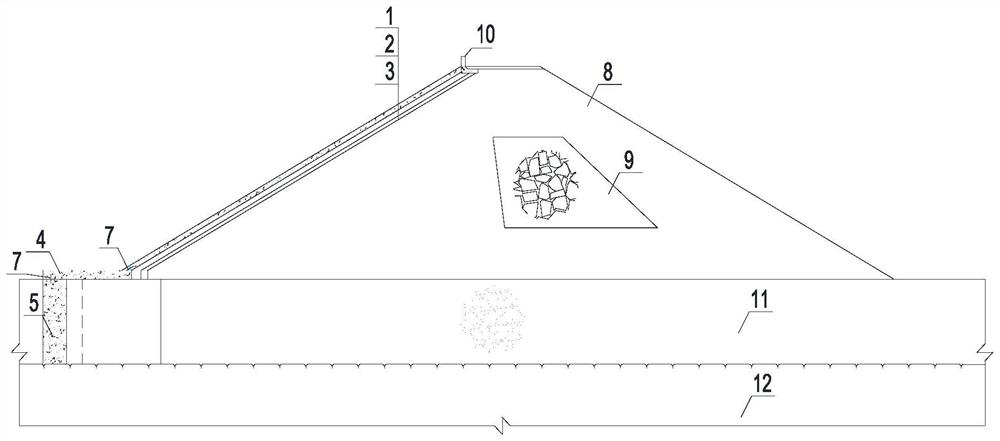

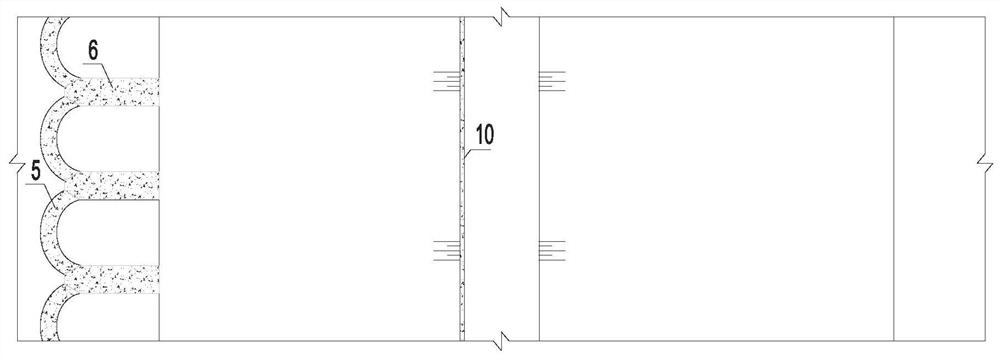

Core-wall rockfill dam

PendingCN111395267AImprove anti-seepage effectStrong ability to adapt to deformationProtective foundationEarth-fill damsSoil scienceGeomembrane

The invention discloses a core-wall rockfill dam comprising gabions, self-compacting concrete, upstream geotextile, downstream geotextile, an upstream rockfill area, a downstream rockfill area, a copper sheet water stop, a concrete base, a grouting gallery and the like. The self-compacting concrete replaces a traditional clay core wall or bituminous concrete core wall. The gabions and the geotextile are used for replacing a traditional transition area. The gabions are utilized to achieve the functions of stabilizing and protecting the core wall. By means of the watertightness of the geomembrane, the seepage-proof function is achieved. According to the core-wall rockfill dam, the type is simple, dam body section partitioning is optimized, the construction speed is rapid, construction interference is little, and construction and later-period overhauling are convenient.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

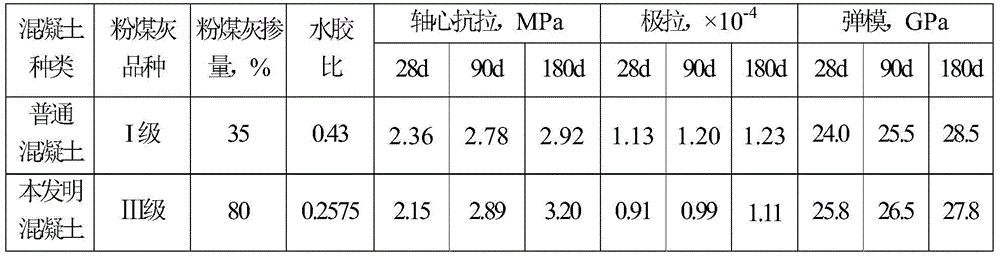

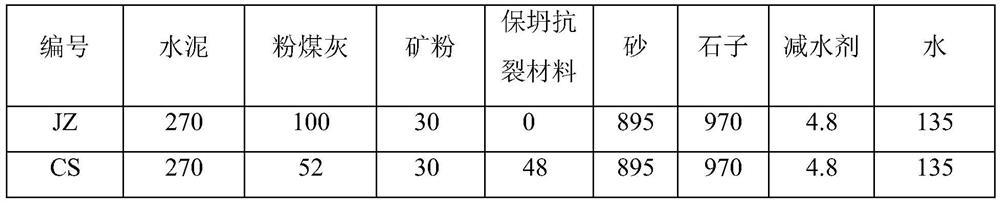

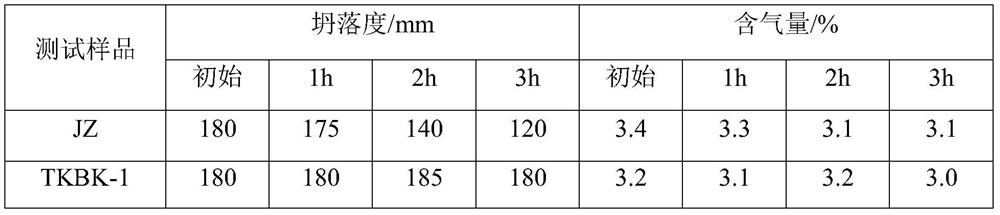

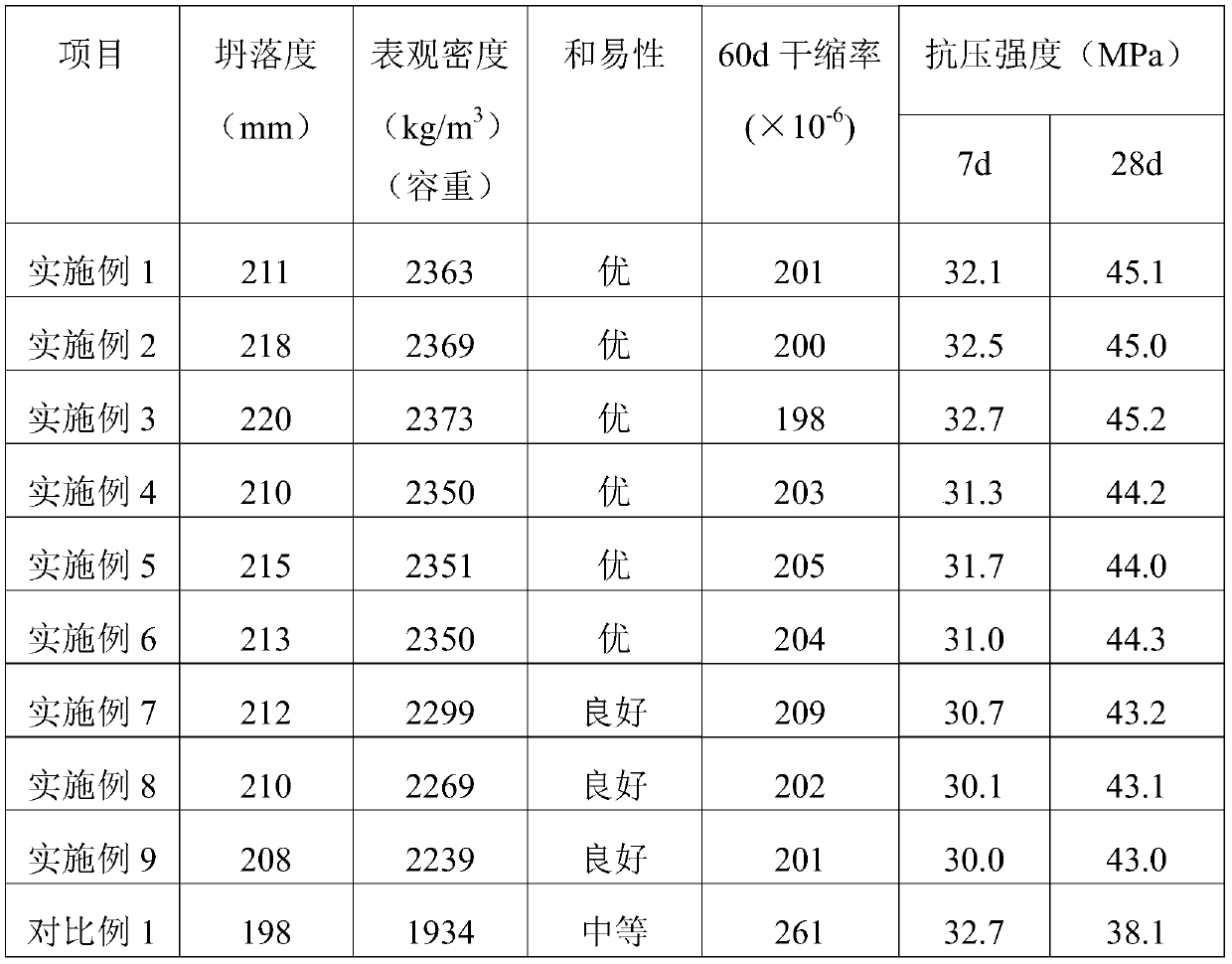

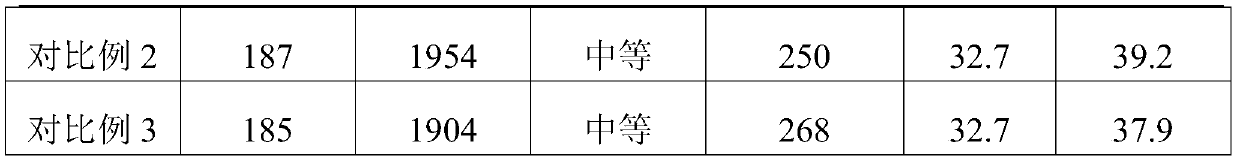

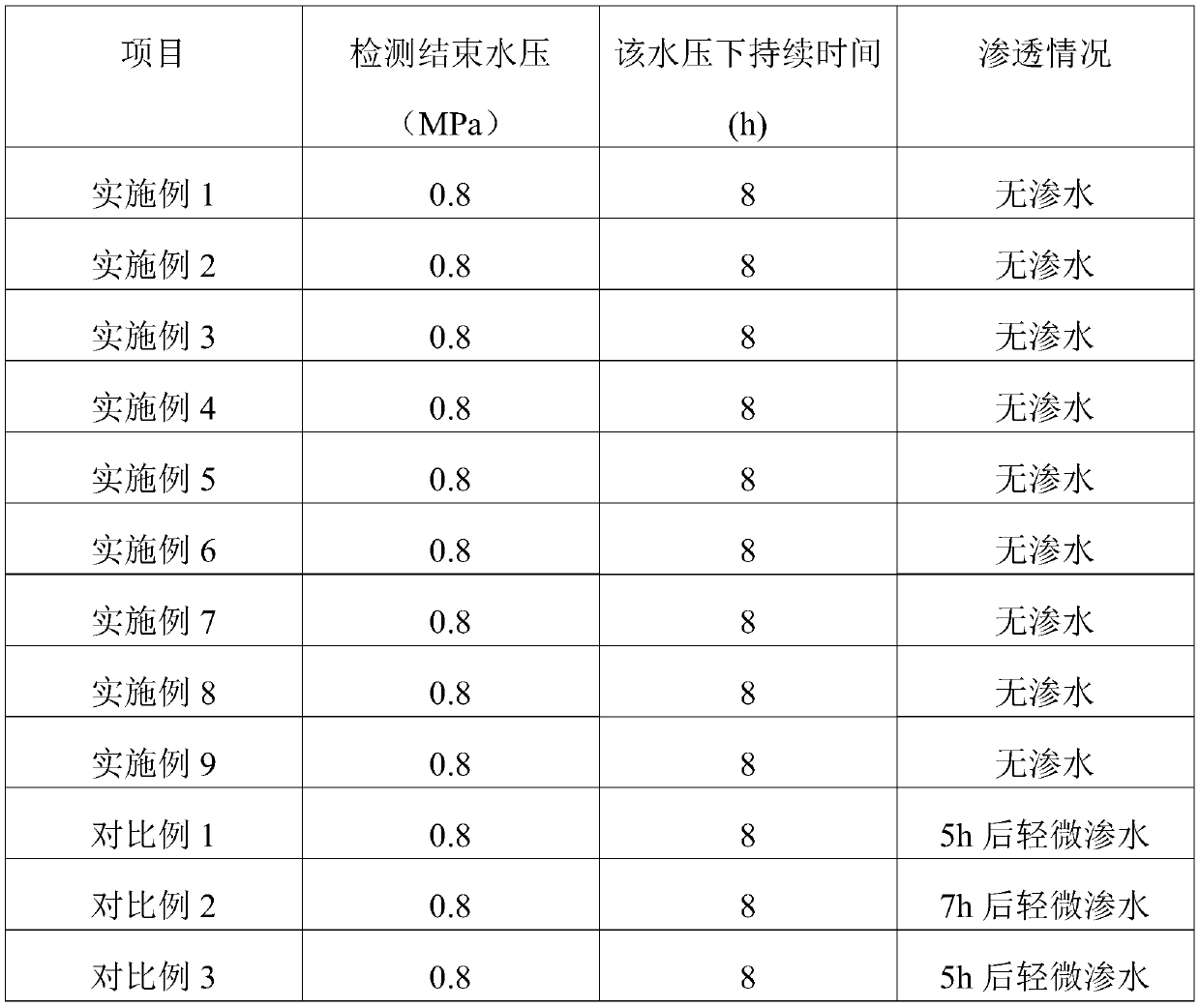

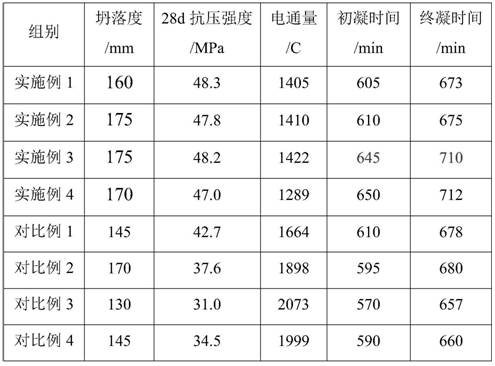

Ballastless track base concrete slump-retaining anti-cracking material and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a ballastless track base concrete slump-retaining anti-cracking material and a preparation method thereof. The slump-retaining anti-cracking material is prepared by mixing a shrinkage-reducing slump-retaining type polymer component, a retarding component, a hydration temperature rise inhibiting component, a composite anti-cracking component, a water storage component and a reinforcing and toughening component according to a certain proportion, wherein the mass ratio of each component is as follows:1.0-4.5 parts of the shrinkage-reducing slump-retaining type polymer component, 0.5-1.5 parts of the retarding component, 1-10 parts of the hydration temperature rise inhibiting component, 66-95 partsof the composite anti-cracking component, 0.5-10 parts of the water storage component and 2-8 parts of the reinforcing and toughening component. The ballastless track base concrete slump-retaining anti-cracking material provided by the invention is doped into concrete according to a proper mixing amount, the slump loss of the concrete can be avoided within 3 hours, the adiabatic temperature riseof the concrete is reduced by more than 20%, the shrinkage variation of the concrete in a plastic stage and a hardening stage is remarkably reduced, the maximum reduction coefficient of concrete cracks can reach 92%, and the anti-cracking efficiency grade reaches first grade.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Low-heat high-strength micro-expansion cement-based grouting material

InactiveCN109987896AGood liquidityReduce heat of hydration and hydration temperature riseSlagBuilding material

The invention belongs to the field of building materials, and discloses a low-heat high-strength micro-expansion cement-based grouting material, which is prepared from the following raw materials in parts by weight: 15-25 parts of Portland cement, 20-40 parts of fly ash, 20-40 parts of granulated blast furnace slag powder, 5-15 parts of limestone powder, 1-3 parts of zeolite powder, 8-12 parts ofexpanding agent, 1.2-1.8 parts of water reducing agent and 20-30 parts of water. High-reliability dense filling and plugging of a large-size building structure in underground engineering can be achieved.

Owner:63653 FORCES PLA

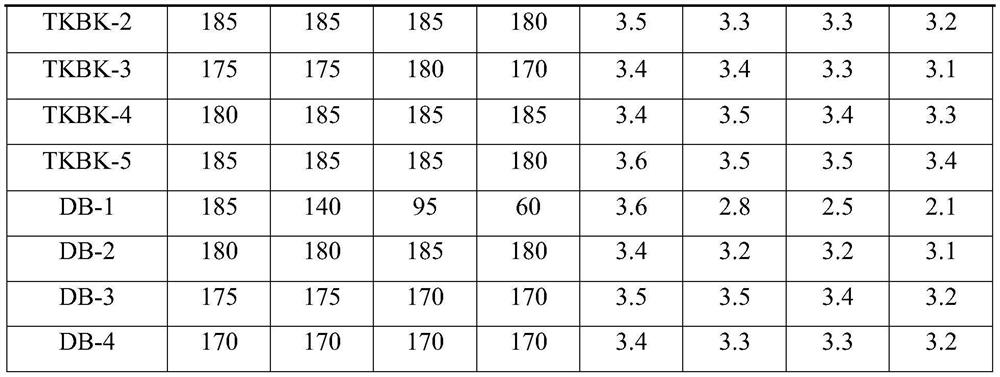

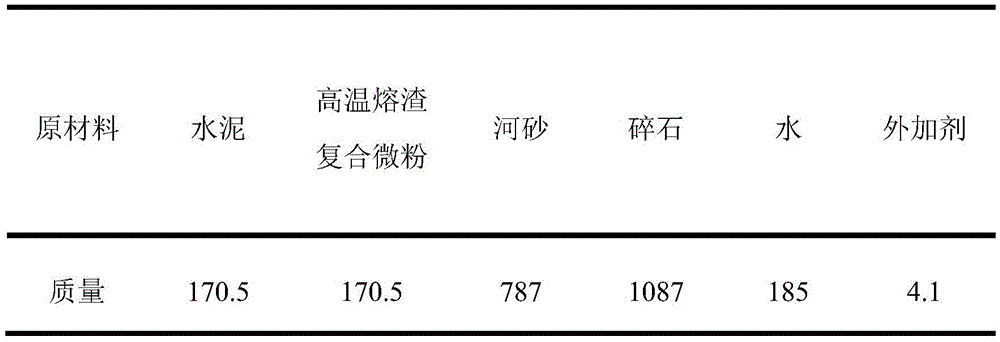

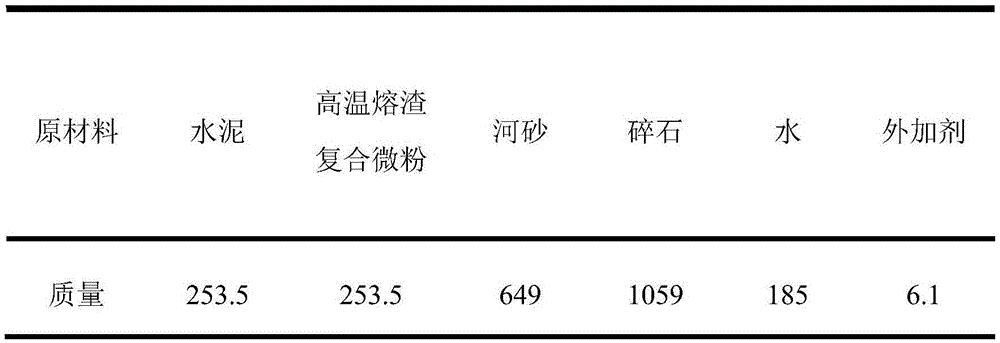

High-temperature molten slag composite micropowder concrete and preparation method thereof

InactiveCN105645874AReduce dosageReduce hydration temperature riseSolid waste managementWork performanceUltimate tensile strength

The invention relates to a high-temperature molten slag composite micropowder concrete and a preparation method thereof. The preparation method comprises the following steps: stirring and mixing cement, high-temperature molten slag composite micropowder, macadam, river sand, a water reducing agent and water, and carrying out hydration setting. Every cubic meter of the high-temperature molten slag composite micropowder concrete contains 170-360kg of cement, 100-270kg of high-temperature molten slag composite micropowder, 1000-1100kg of macadam, 650-800kg of river sand, 170-195kg of water and 4-6.5kg of water reducing agent. The high-temperature molten slag composite micropowder used as the auxiliary cementing material can effectively improve the bleeding isolation and workability of the concrete and enhance the working performance of the concrete; as compared with the cement concrete, the long-term folding strength, cleavage strength and chlorine ion penetrating resistance are greatly enhanced, thereby being beneficial to improving the toughness and durability of the concrete; and the high-temperature molten slag composite micropowder concrete lowers the cost, and has the advantages of energy saving and environment friendliness.

Owner:WUHAN UNIV OF TECH

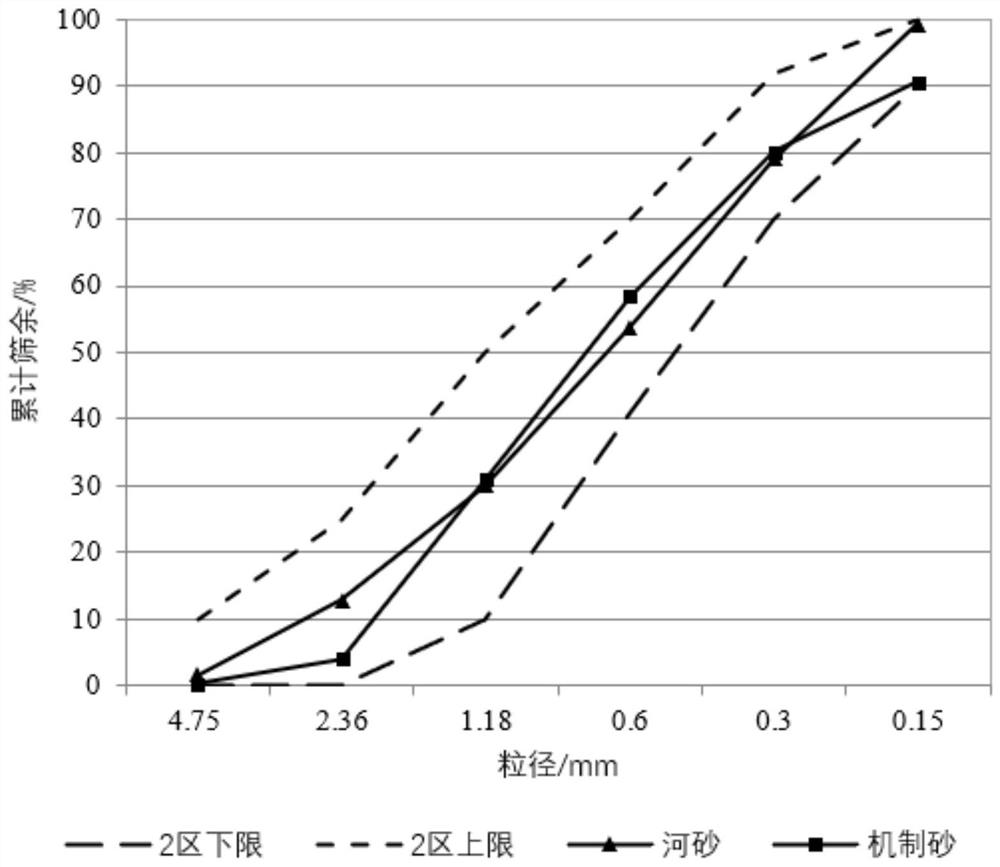

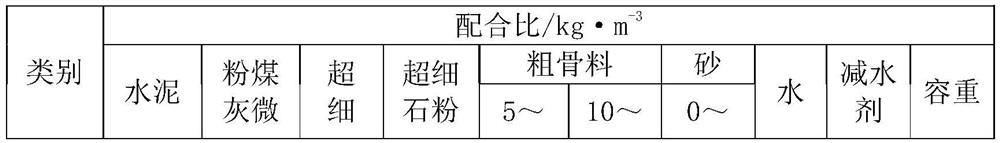

Low-carbon C130-C140 ultra-high performance self-compacting concrete containing coarse aggregate

InactiveCN114133177AHigh strengthStrength SustainabilitySolid waste managementSuperplasticizerCarboxylic acid

The invention discloses low-carbon C130-C140 ultra-high-performance self-compacting concrete containing coarse aggregates. Each cubic meter of the concrete is prepared from the following components by weight: 275 to 330 kg of cement, 178.5 to 220 kg of fly ash microbeads, 119 to 180 kg of superfine mineral powder, 52.5 to 110 kg of superfine limestone powder, 695 to 740 kg of 0 to 5 mm fine aggregates, 376 to 396 kg of 5 to 10 mm coarse aggregates, 564 to 594 kg of 10 to 16 mm coarse aggregates, 7 to 12 kg of polycarboxylate superplasticizer and 105 to 110 kg of water, and the total volume weight of the concrete is 2490 to 2520 kg / m < 3 >. Under standard curing, the highest strength is 154.7 MPa in 56 days and 161.6 MPa in 90 days, the rewinding emptying time is 4-8 s, the T500 flow rate is 4-10 s, the self-compacting filling property is higher than the grade II, the adiabatic temperature rise is not higher than 67 DEG C, the self-shrinkage rate in 7 days is not higher than 0.09%, the chloride ion electric flux in 56 days is not higher than 100 coulomb, the sulfate attack resistance reaches KS240 or higher, the construction viscosity can be comparable with that of common C50 concrete, and the concrete has good application prospects. The comprehensive performance and the cost of the concrete are obviously superior to those of the same-grade steel fiber-doped UHPC, and the concrete has wide application value in the fields of offshore wind power and land wind power.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Biological ash portland cement with low probability of cracking and production method of biological ash portland cement

The invention discloses biological ash portland cement with low probability of cracking and a production method of the biological ash portland cement. The biological ash portland cement is prepared from the following components by weight percent: 55-75% of ordinary Portland cement clinker, 4-8% of flue gas desulfurization gypsum, 4.5-10.0% of humus, 7-15% of biological ash, 1-3% of polyvinyl alcohol, 5-10% of gravel powder, 5-8% of zeolite powder and 0.2-1.0% of a biological bacterium additive. The biological ash portland cement can permeate into fine seams among cement seams, stratum and a sleeve joint, has favorable cement squeezing, leakage stopping and tiny gap filling functions for easy-to-leak layers, vertically fractured stratum or porous stratum, and meets the actual application demands; and the compactness and the strength of cement paste are enhanced, and the cement paste based on biological ash is a very good culture medium of biological bacteria.

Owner:葛洲坝石门特种水泥有限公司

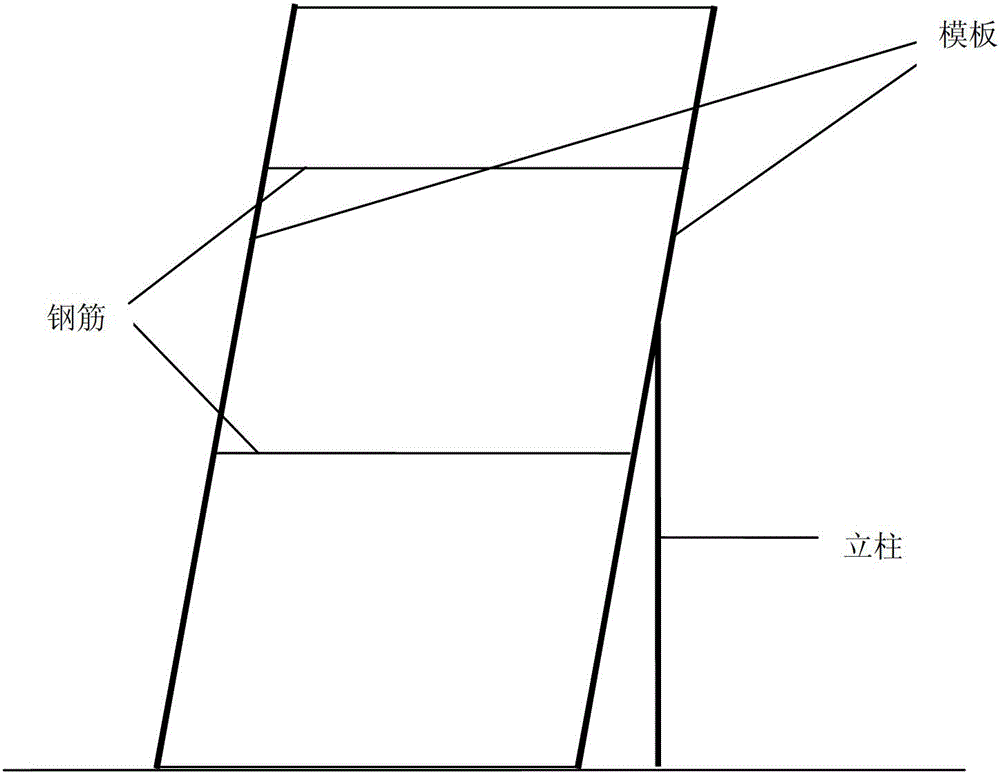

Anti-cracking construction method for side wall structure of underground rail transportation

ActiveCN109680717AReduce the temperatureLower mold temperatureArtificial islandsUnderwater structuresCold airRebar

The invention discloses an anti-cracking construction method for a side wall structure of underground rail transportation. The construction method comprises the following steps of preparation of construction: providing structures and equipment required in the construction process; bundling bottom plate reinforcing steel bars and guide wall reinforcing steel bars, installing a bottom plate formworkand a guide wall formwork, and pre-embedding bottom plate air ventilating pipes; bundling side wall reinforcing steel bars, installing a side wall formwork, and pre-embedding side wall air ventilating pipes; preparing concrete; casting bottom plate concrete; casting side wall concrete, introducing cold air into the side wall air ventilating pipes in the casting process, and introducing hot air into the bottom plate air ventilating pipes; constructing a top plate. The construction method has the beneficial effects that by reserving the air ventilating pipes in the bottom plate formwork and theside wall formwork, the cold air is introduced into the side wall air ventilating pipes while the side wall concrete is cast, so as to reduce the temperature of the side wall concrete after enteringthe formwork, which is equivalent to the reduction of formwork-entering temperature of the concrete; especially, before the concrete is finally set, the heat conduction coefficient is large, so that the temperature reduction effect on the concrete is obvious, and the forming of cracks can be effectively prevented.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Preparation method of concrete containing fly ash and silt

InactiveCN105171915AReduce heat of hydrationReduce hydration temperature riseSolid waste managementCement mixing apparatusEnvironmental engineeringWater reducer

The present invention relates to a preparation method of concrete containing fly ash and silt. The preparation method comprises: taking 30-35% by weight of gravel, 10-20% by weight of cement, 15-25% by weight of yellow sand, 8-10% by weight of a component A, 3-5% by weight of component B, 0.1-1% by weight of an efficient water reducer, 5-10% by weight of a component C, and 8-10% by weight of water, placing the component A, the component B, the component C, the gravel, the yellow sand and the cement in a concrete stirrer, stirring for 1 min, uniformly mixing the water and the efficient water reducer, pouring the mixture of the water and the efficient water reducer into the concrete stirrer, and carrying out mixing stirring for 3-5 min to obtain the concrete. According to the present invention, the cement consumption is reduced, the low-carbon concrete is prepared, and the hydration heat of the concrete can be significantly reduced so as to reduce the hydration temperature increase of the concrete and reduce the shrinkage caused by the cement hydration, such that the cement consumption is reduced, and the consumption of the slag and the fly ash is increased so as to utilize the more solid waste and provide the environmental protection advantage.

Owner:LUOYANG INST OF SCI & TECH

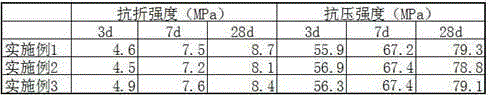

Low-shrinkage and low-viscosity high-strength concrete

InactiveCN109437705AReduce hydration temperature riseReduce shrinkage cracksCeramicwareFiberHigh strength concrete

The invention discloses low-shrinkage and low-viscosity high-strength concrete. The low-shrinkage and low-viscosity high-strength concrete is prepared from the following raw materials in parts by weight: 80 to 95 parts of microsphere, 75 to 90 parts of pottery sand, 50 to 65 parts of cement, 45 to 60 parts of mineral powder, 40 to 55 parts of ultrafine slag silicon ash, 25 to 40 parts of carbon fiber, 25 to 40 parts of fiber bar, 15 to 30 parts of a compound foaming agent, 5 to 20 parts of an efficient water reducing agent and the balance of water; a preparation method of the low-shrinkage andlow-viscosity high-strength concrete comprises the following steps: adding the microsphere, the pottery sand and the cement into a stirring machine in sequence according to the weight part; then adding the mineral powder, the ultrafine slag silicon ash and the carbon fiber in sequence and stirring for 20 to 35min to obtain a mixed solution A; adding the fiber bar into a crushing machine accordingto the weight part and crushing; then adding into the mixed solution A to obtain a mixed solution B; adding the compound foaming agent, the efficient water reducing agent and the water into the mixedsolution B in sequence; foaming and naturally airing at 135 to 140 DEG C to obtain the low-shrinkage and low-viscosity high-strength concrete. According to the low-shrinkage and low-viscosity high-strength concrete, concrete shrinkage cracks are reduced by adopting the fibers; the microspheres are used for improving the viscosity of the ultrahigh-strength concrete and the flowability is improved;the high-strength concrete can be widely applied to the field of construction engineering and has good performance.

Owner:王斐

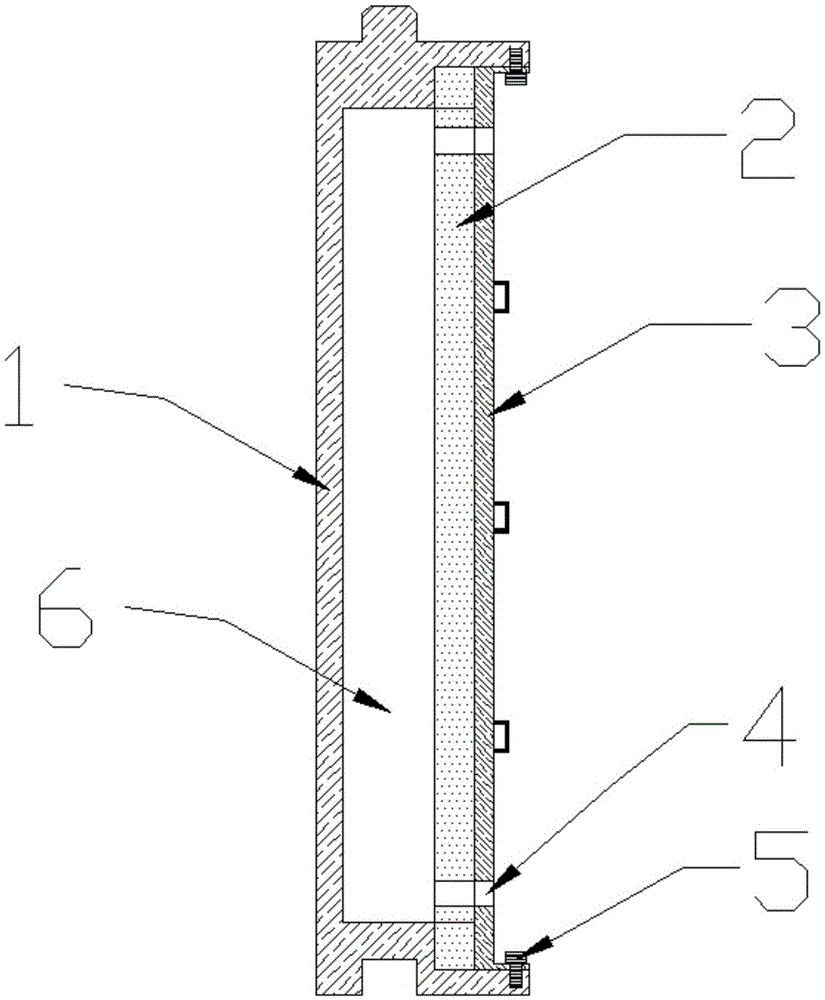

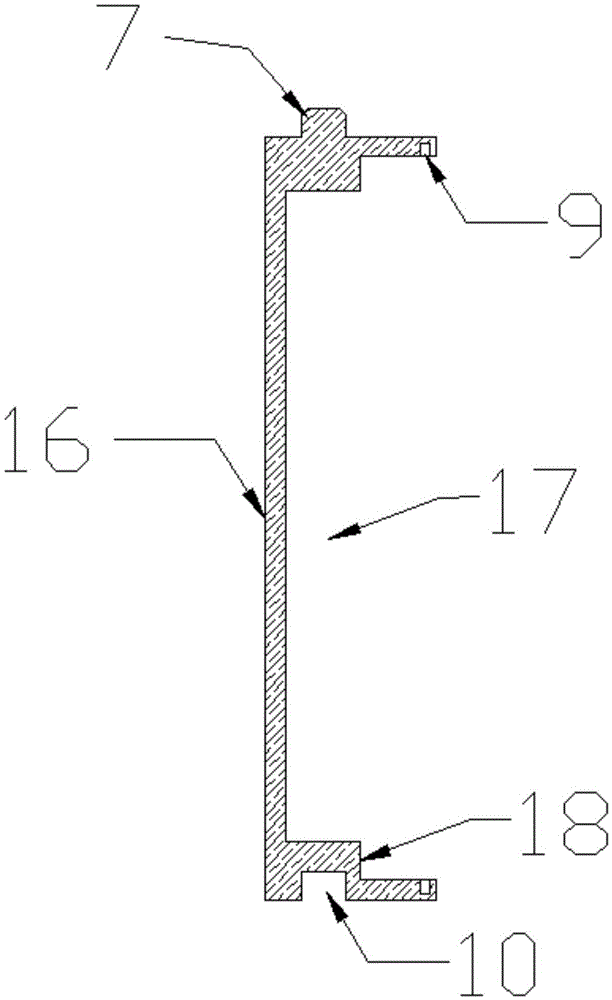

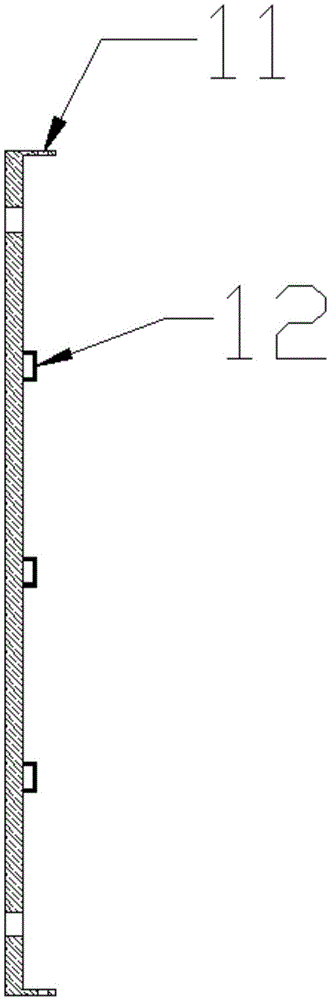

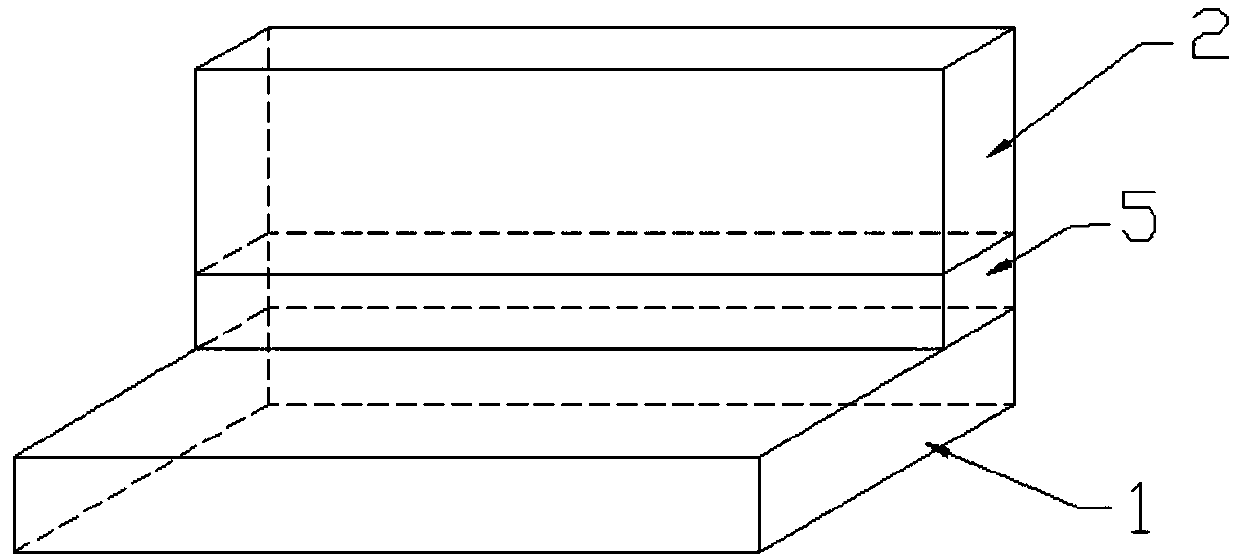

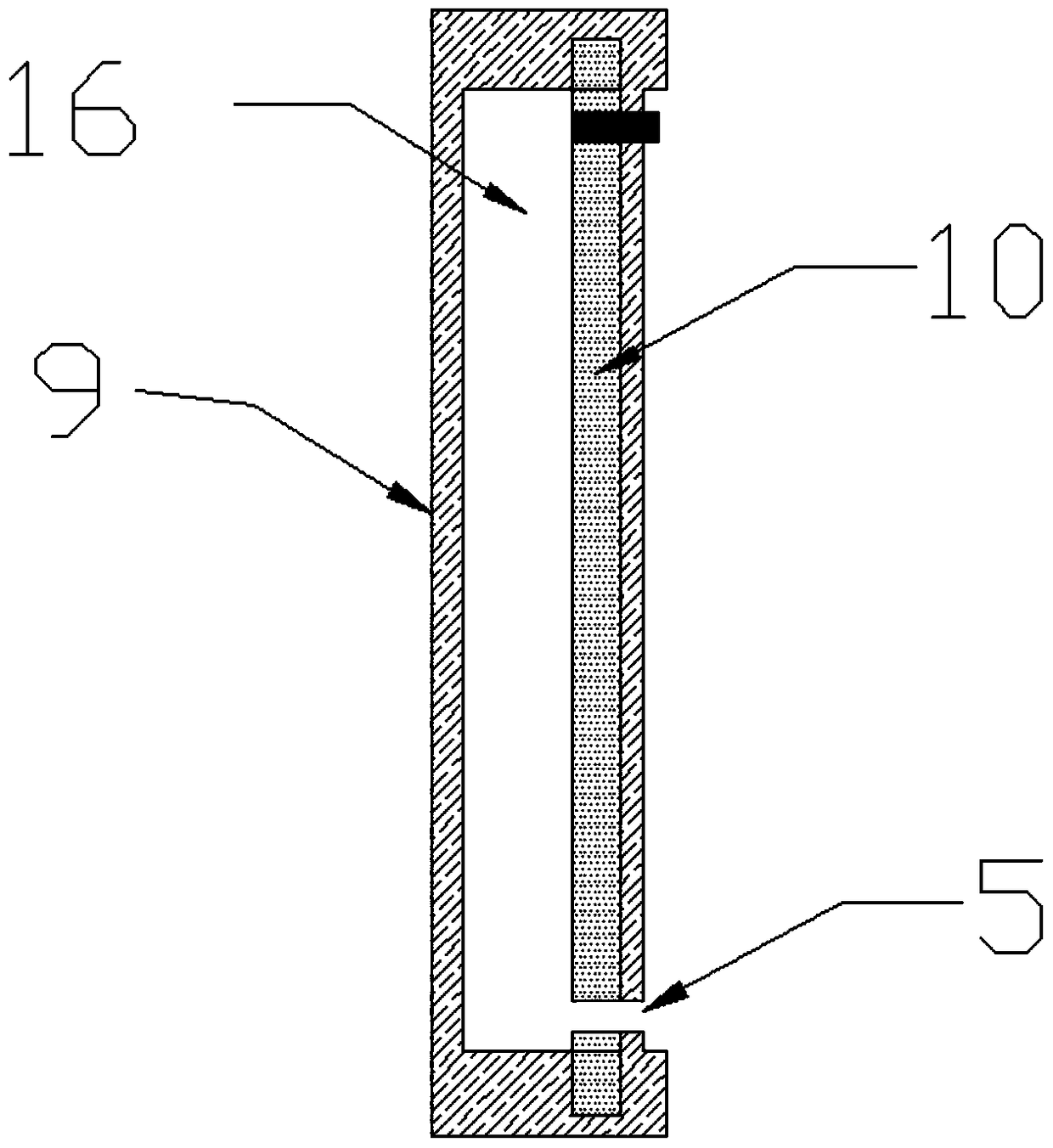

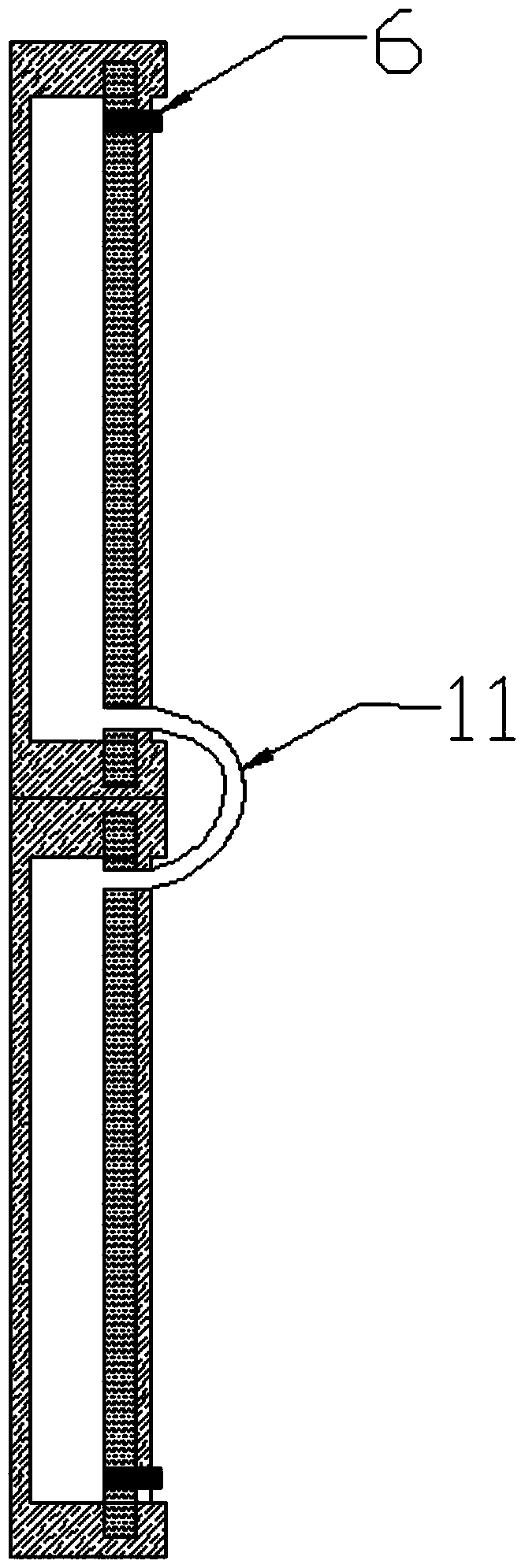

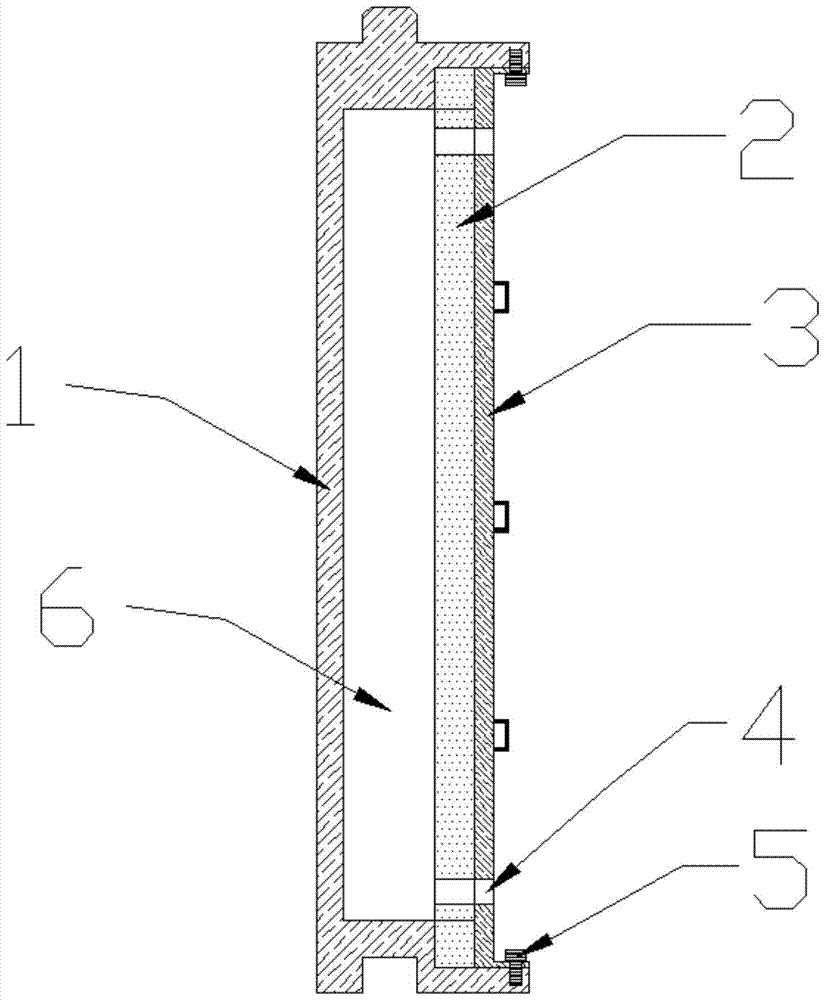

Mass concrete vacuum dehydration sliding template device, filtering layer and construction layer

ActiveCN102425297AReduce hydration temperature riseReduced risk of crackingForms/shuttering/falseworksBuilding material handlingSS - Stainless steelPore diameter

The invention discloses a mass concrete vacuum dehydration sliding template device, a filtering layer and a construction layer. The filtering layer is composed of a stainless steel plate and is provided with permeable micropores with pore diameter of 30-80 mu m and pore spacing of 1-3mm. The sliding template device with a dehydration function comprises an upper template and a lower template, wherein the upper template is a steel sliding template, the lower template is formed by airtightly connecting the filtering layer and a plastic sealing plate, the plastic sealing plate is provided with a plurality of drainage holes, and a drainage short pipe is fixed outside each drainage hole. The sliding template device with the dehydration function is arranged in a construction site, after concrete is demixed, poured and vibrated, the upper template is immediately slide for 30-50cm, and then put down to cover on the surface of exposed fresh concrete for carrying out vacuum dehydration for 10-20min; and the concrete in the next layer of sliding template is poured and vibrated continuously while the vacuum dehydration is carried out. According to the invention, construction progress is greatly increased, cost is remarkably reduced, and pouring quality is improved.

Owner:NANJING HYDRAULIC RES INST

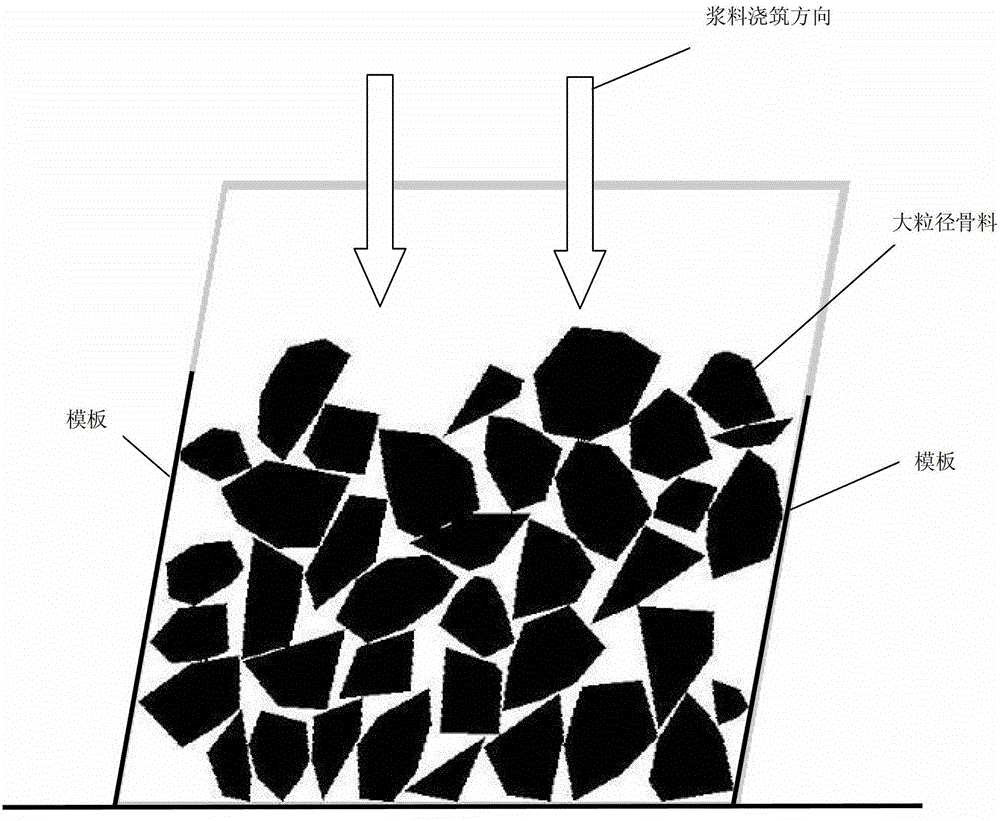

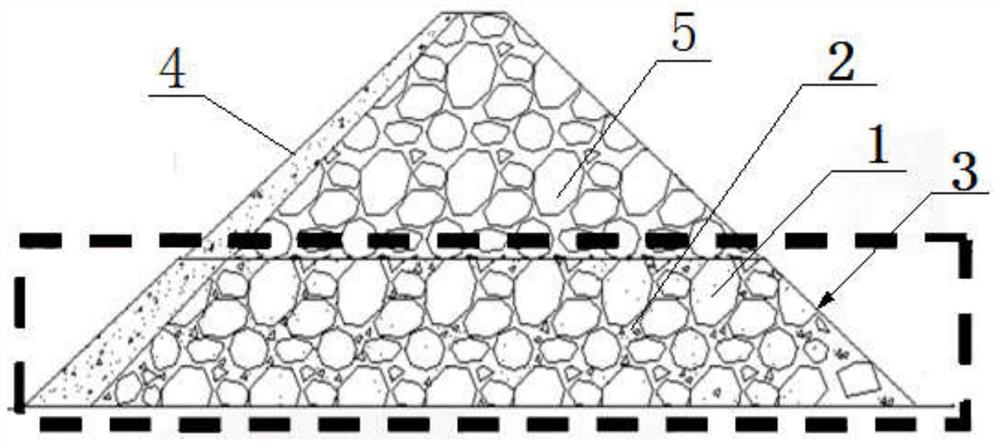

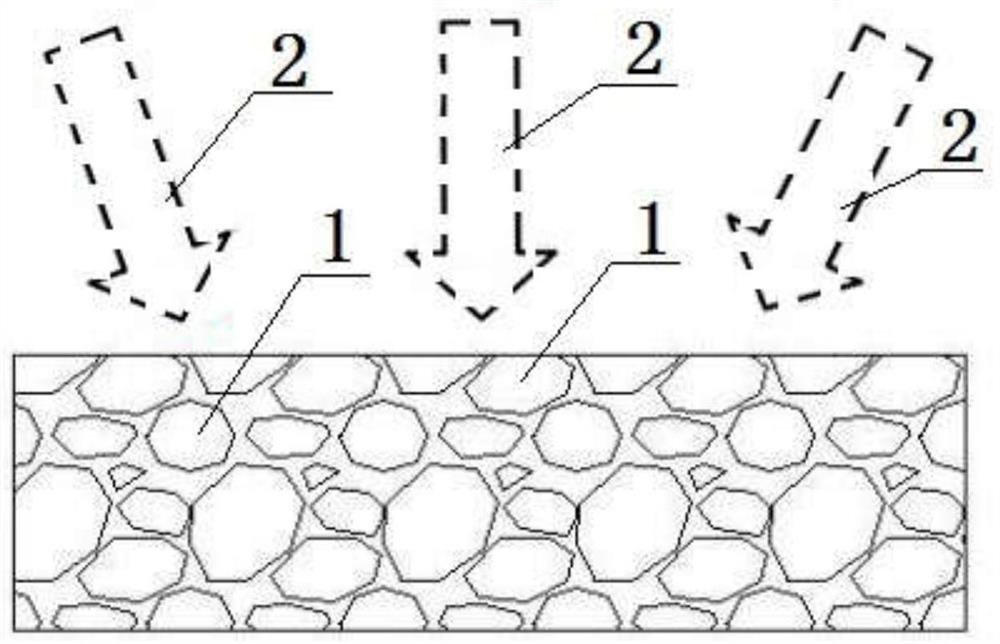

Roller-compacted concrete structure formed by pouring composite slurry into stone ballast and construction method of roller-compacted concrete structure

ActiveCN108643132ATake advantage ofEasy accessFoundation engineeringEarth-fill damsRoller-compacted concreteSlurry

The invention discloses a roller-compacted concrete structure formed by pouring composite slurry into stone ballast. The roller-compacted concrete structure consists of a plurality of composite-slurryroller-compacted concrete layers, wherein the composite-slurry roller-compacted concrete layers are formed by performing vibration rolling on the stone ballast and the composite slurry poured onto the surface of the stone ballast; the stone ballast is an excavated material with a particle diameter being greater than or equal to 5 mm; and the stone ballast is laid on a dam foundation in layers, the composite slurry is poured into the stone ballast laid in layers to fill gaps in the stone ballast randomly, and when the liquid level of the composite slurry gets close to the top surface of the stone ballast, rolling is performed on a storehouse surface through a vibrating roller to form a uniform, stable slurry-poured roller-compacted concrete structure. The roller-compacted concrete structure has the advantages of use of local materials, uniform and stable structure, excellent performance, fast construction and project cost saving. The invention also discloses a construction method of the roller-compacted concrete structure formed by pouring the composite slurry into the stone ballast.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

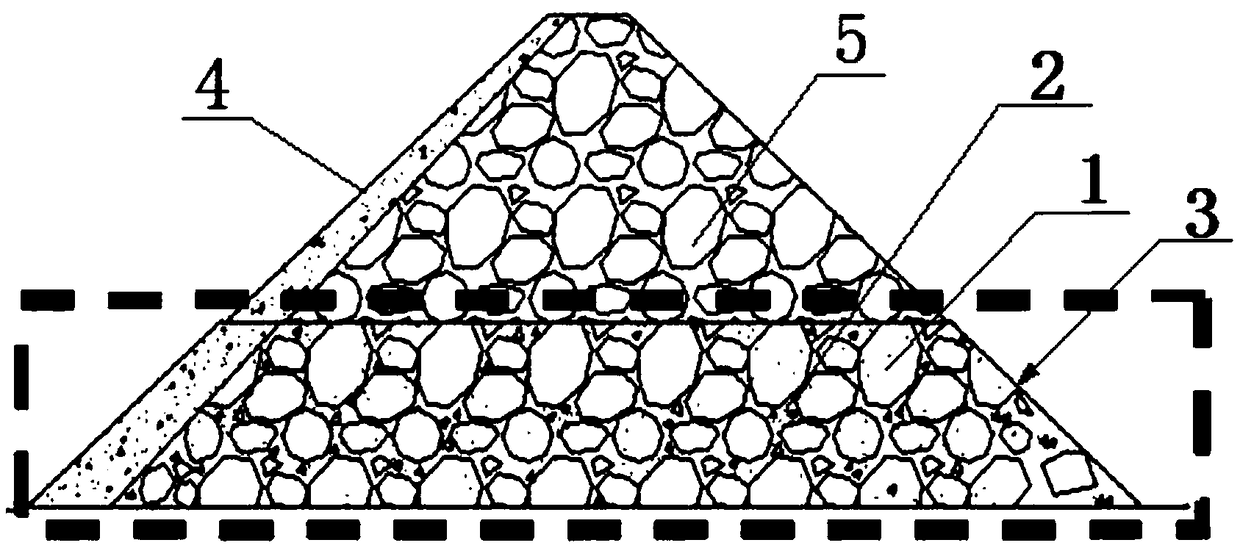

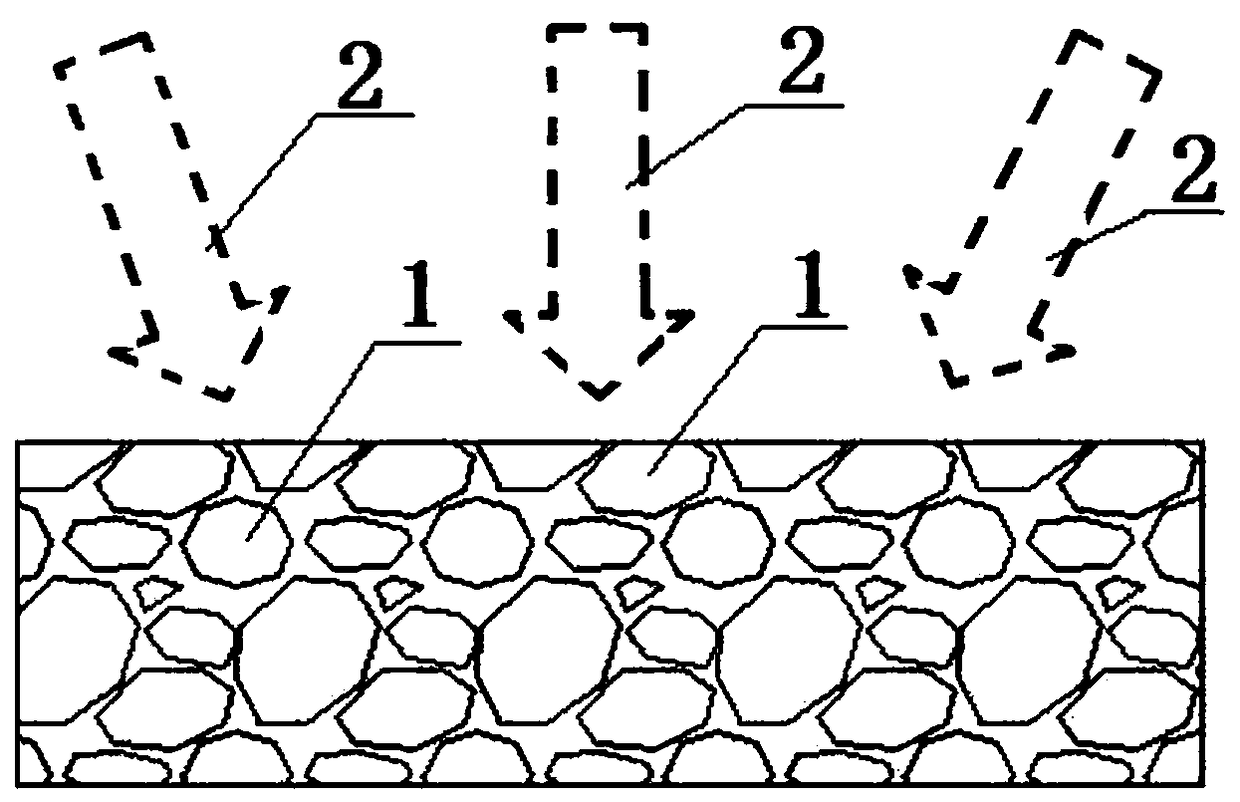

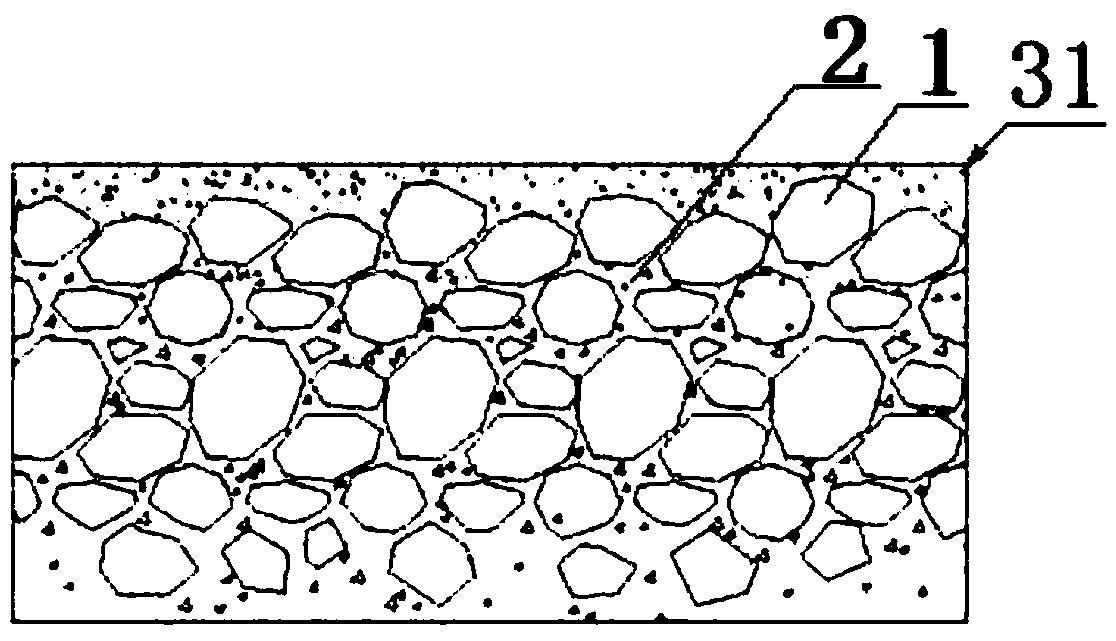

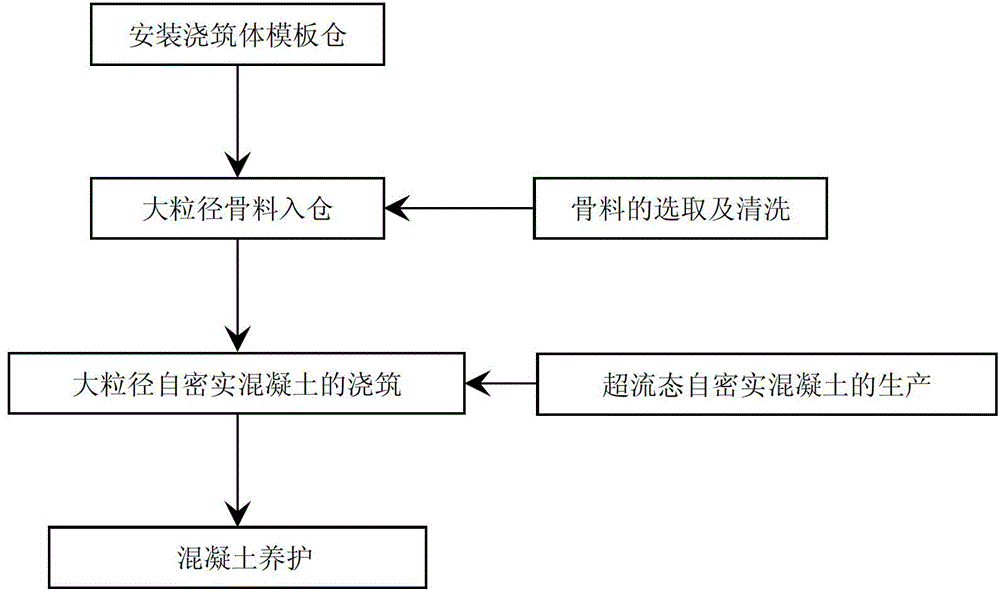

Self-compacting concrete with ultra-large particle size aggregate and its construction technology

The invention relates to a self-compact concrete with oversized-particle aggregate. The self-compact concrete is prepared by pouring large-particle-size aggregate with particle size of 100mm-1500mm and superfluid self-compact concrete slurry, wherein the superfluid self-compact concrete slurry is prepared by adding water into cement, pulverized coal ash, silica fume, dedicated superfluid additive, sand, stones and other mineral admixtures and mixing. The construction technology comprises the steps of directly placing the oversized-particle aggregate into a construction bin to form large-particle-size aggregate accumulation body with certain natural clearances, then pouring the superfluid self-compact concrete slurry on the surface of the large-particle-size aggregate, filling the clearances of the large-particle-size aggregate by means of self gravity, forming a complete, compact and low-hydration-heat concrete structure together with the large-particle-size aggregate after the superfluid self-compact concrete slurry is hardened, wherein the strength grade of the concrete can meet different design demands. The self-compact concrete with oversized-particle aggregate is not only applicable to mass concrete construction, but also applicable to reinforcing bar system engineering.

Owner:GUIZHOU HIGHWAY ENG GRP +1

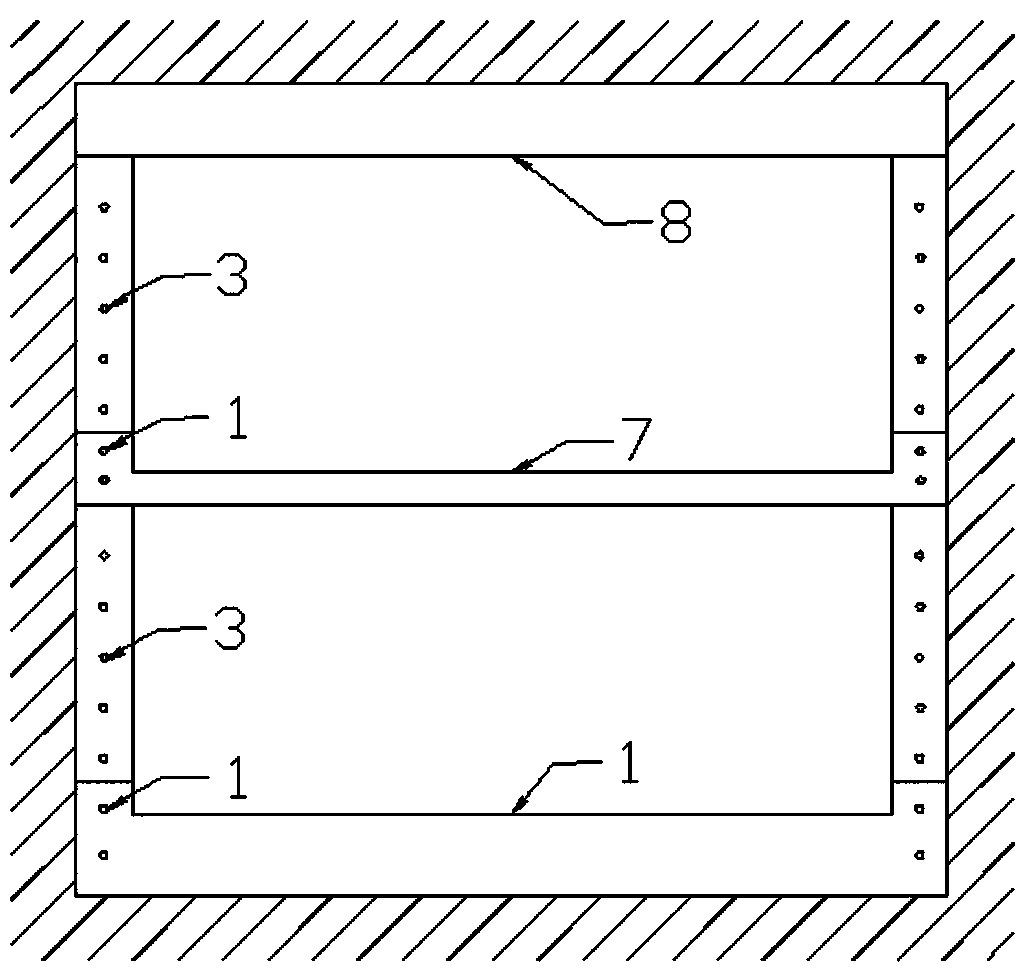

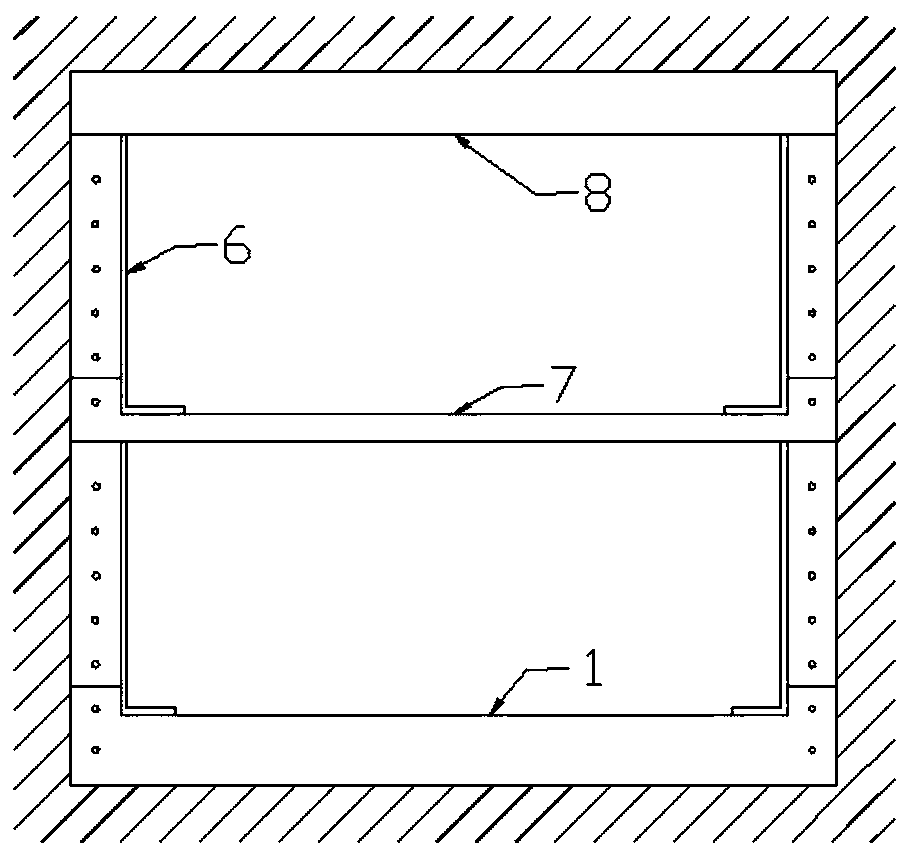

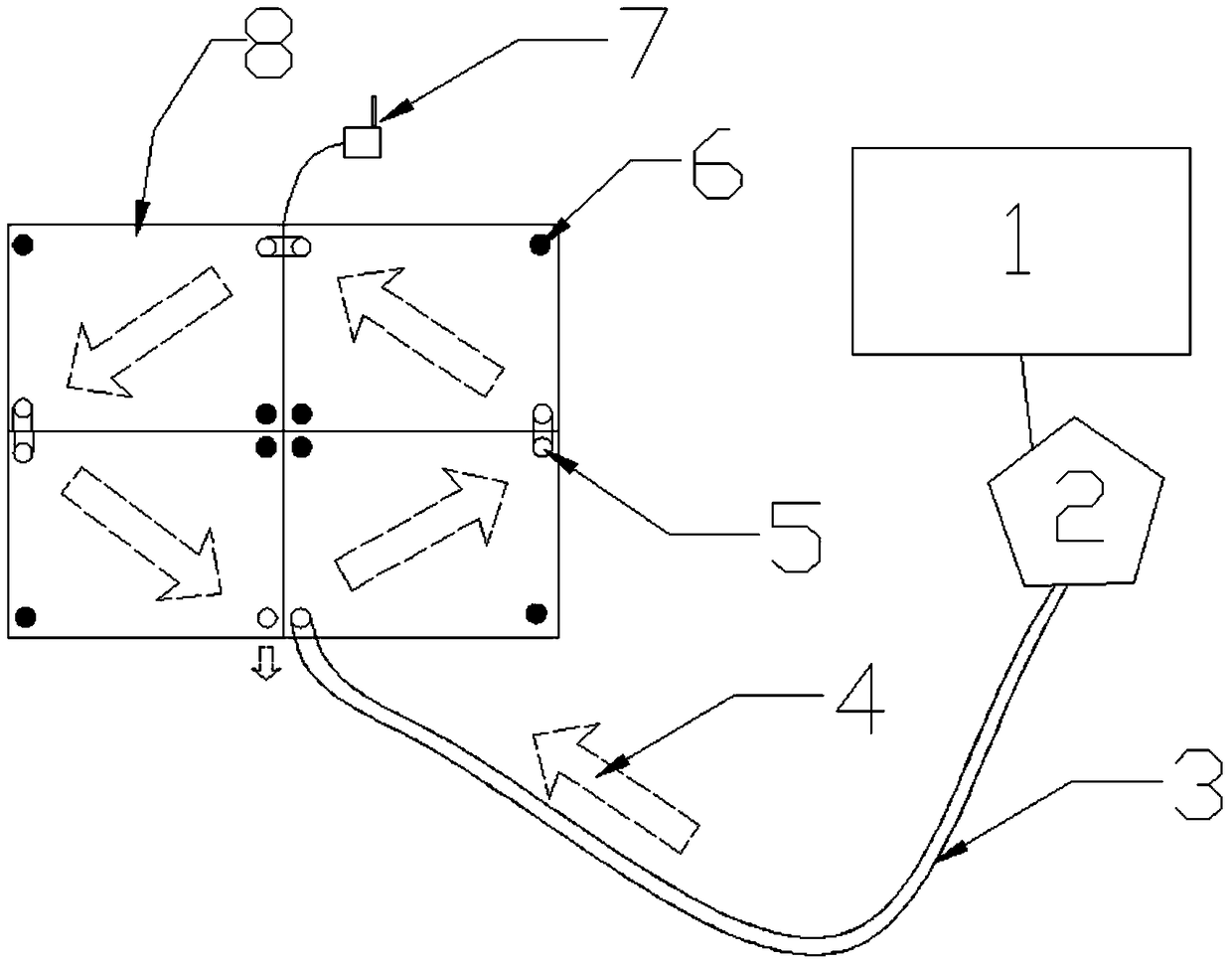

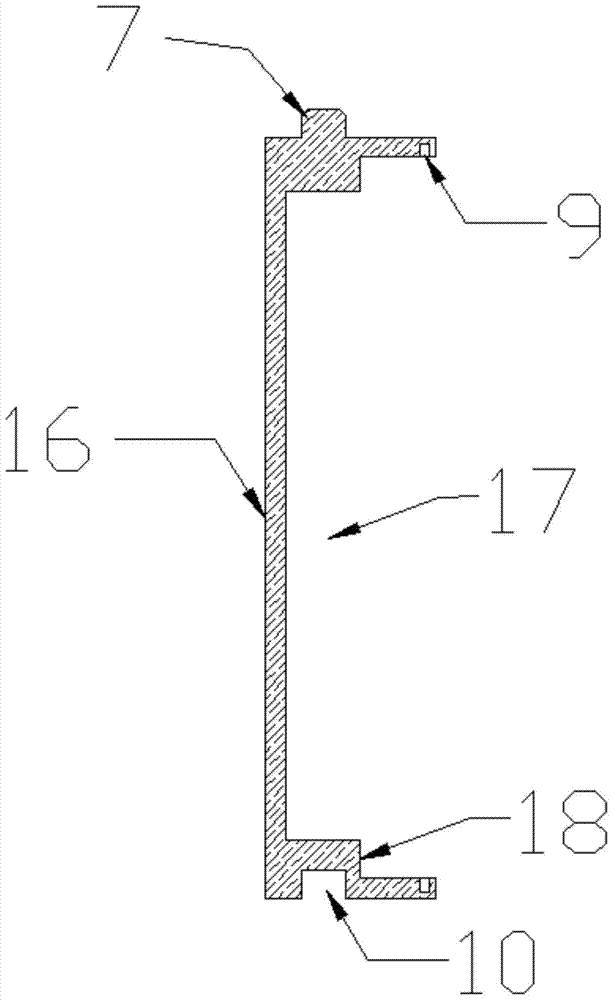

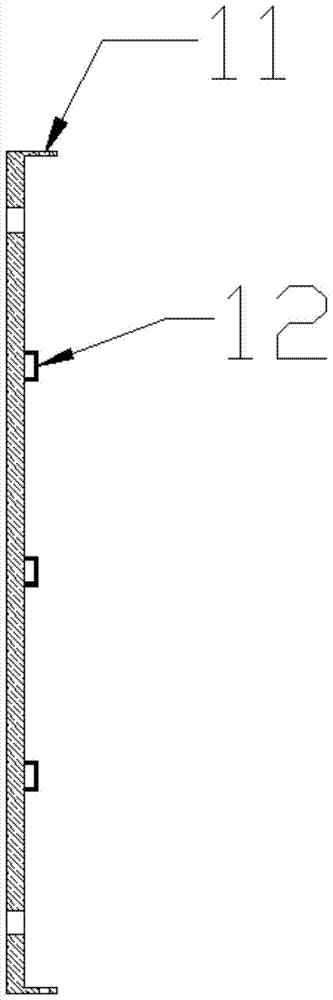

A method for preventing concrete temperature cracks in underground side wall structures

ActiveCN105669246BReduce the temperatureLower mold temperatureBulkheads/pilesTemperature controlStructural engineering

The invention discloses an underground side wall structure concrete temperature crack anticracking method. Directed at the problem of easy cracking of underground side wall structure concrete under a summer high temperature condition, low temperature airflow is introduced into a hollow structure temperature control template by a refrigerating machine of an intelligent control system, so that concrete starts to cool after entering a die, i.e. substantially lowering the concrete's temperature of entering the die. At the same time, the intelligent control system takes a measured stress value, a capillary negative pressure value and a wall center temperature value as the conditions for controlling the working mode of the refrigerating machine, so that the actual stress value of the concrete from pouring to die removal is always close to but not greater than an ultimate tensile stress value of concrete, thereby realizing effective temperature control of underground side wall concrete, and avoiding temperature cracks.

Owner:JIANGSU SOBUTE NEW MATERIALS

C80 concrete prepared from stone chips

InactiveCN112279587AImprove compactnessLower surface energySolid waste managementCalcium stoneStone dust

The invention discloses C80 concrete prepared from stone chips, the preparation materials of the concrete comprise a cementing material, coarse aggregate, a water reducing agent, water and high-calcium stone chips, the dosage of the cementing material is 580-600kg / m < 3 >, and the water-binder ratio is 0.22-0.26. The C80 concrete has the beneficial effects that the stone chips with the average particle size of less than 4.75 mm are adopted, and stone powder contained in the stone chips can fill cement particle gaps; the gel compactness is improved, the surface energy is relatively low, the dispersion is easy, and the water requirement for achieving the same liquidity is low; the problem of lack of high-quality fly ash can be solved by blending ultrafine stone powder in the stone chips andslag powder to prepare high-performance concrete; river sand is replaced with the stone chips of mine production stone to serve as fine aggregate, the problem that no high-quality river sand is used for preparing high-strength concrete in mountainous areas is solved, environmental protection and sustainable development of building materials are facilitated, and huge economic benefits are achieved.

Owner:翁源县安和混凝土有限公司

A concrete temperature control formwork and its application method

ActiveCN105715040BAchieve warmingReduce the temperatureForming/stuttering elementsTemperature controlStructural engineering

The invention discloses a concrete temperature-control mold plate and a use method thereof. The concrete temperature-control mold plate comprises a steel plate structure body, a heat-preservation material plate and a reinforced plate, wherein the steel plate structure body and the heat-preservation material plate are matched together to form a hollow structure; the heat-preservation material plate is covered by the reinforced plate; a vent interface is formed in a double-layer structure of the reinforcing plate and the heat-preservation material plate; vent interfaces can be connected through an air connecting tube so as to communicate hollow structures of adjacent temperature-control mold plates and air flow of set temperature can be conveyed into the hollow structures through air conveying tubes; air flow is subjected to heat exchange with concrete through a steel plate surface, and thus temperature regulation and control of the temperature-control mold plate to concrete can be achieved. The concrete temperature-control mold plate mainly aims to solve the problem of temperature cracks of concrete of a wall structure, particularly a long (lateral) wall structure, and the problems that temperature cracks can be easily generated as the molding temperature and the hydration temperature of concrete are increased in a high temperature environment in summer, and a structure can be damaged as concrete at an early cast stage can be frozen and cracks can be generated as the surface and inner temperature difference is too large in a severe cold environment in winter.

Owner:JIANGSU SOBUTE NEW MATERIALS

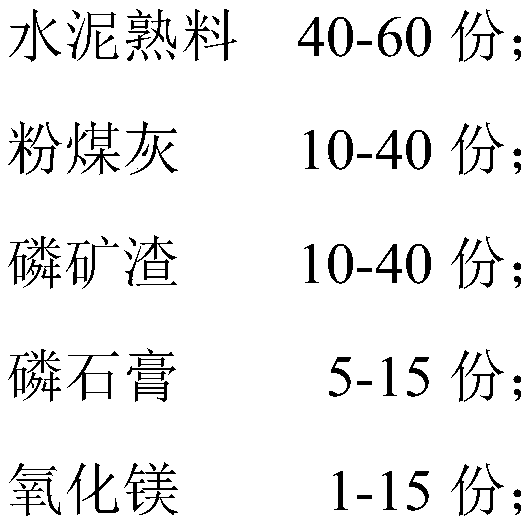

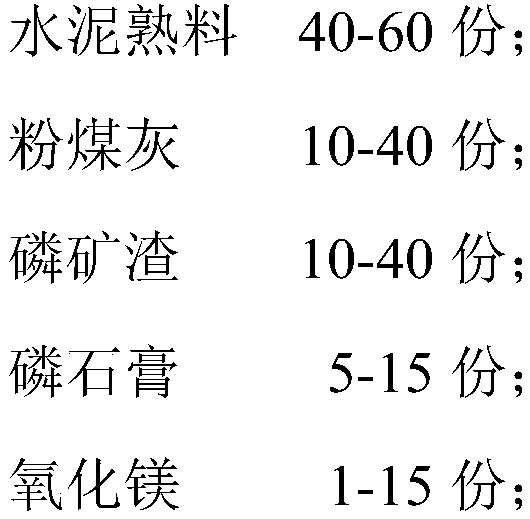

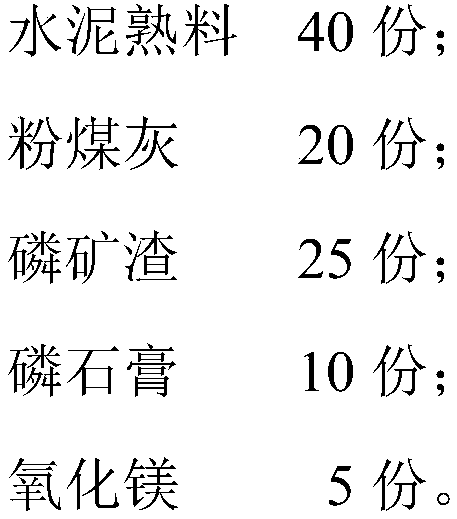

Anti-cracking cement and preparation method thereof

The invention provides anti-cracking cement, which is prepared from the following components in parts by weight: 40 to 60 parts of cement clinker, 10 to 40 parts of fly ash, 10 to 40 parts of phosphorus slag, 5 to 15 parts of phosphogypsum and 1 to 15 parts of magnesium oxide, wherein the phosphogypsum is prepared by treating phosphorite with sulfuric acid to prepare phosphoric acid, collecting solid waste residues produced in the preparation process, and calcining the solid waste residues at a high temperature of 800 to 1,000 DEG C, thus preparing the phosphogypsum.

Owner:龚家玉

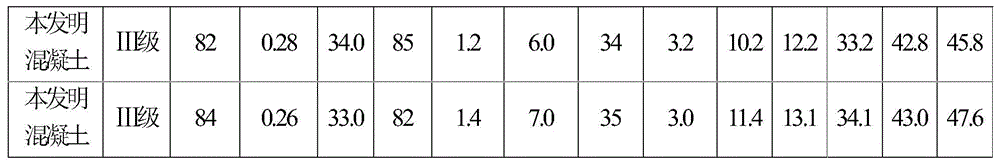

A ultra -high -mixed powder coal ash concrete

ActiveCN105731919BReduce water consumptionGuaranteed StrengthSolid waste managementTemperature controlLower grade

Owner:HUBEI GEZHOUBA TESTING +1

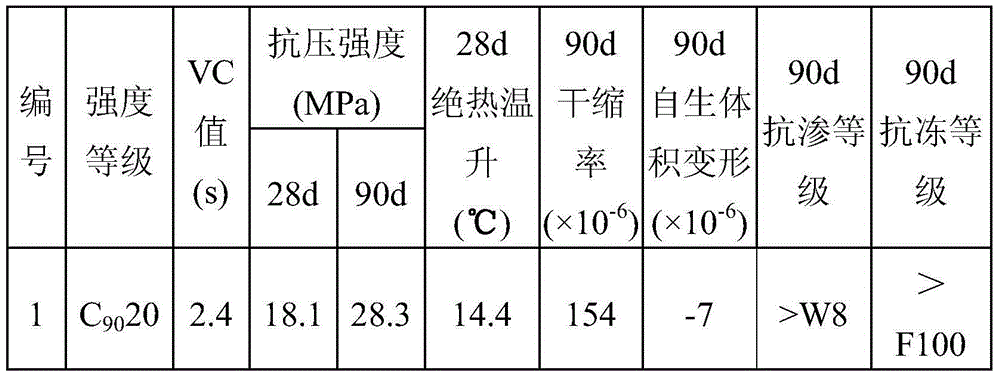

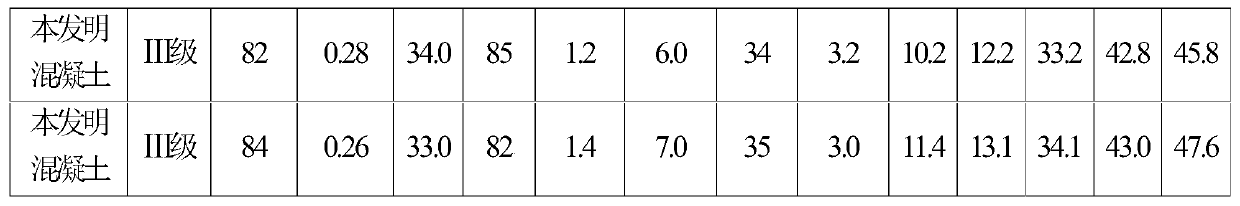

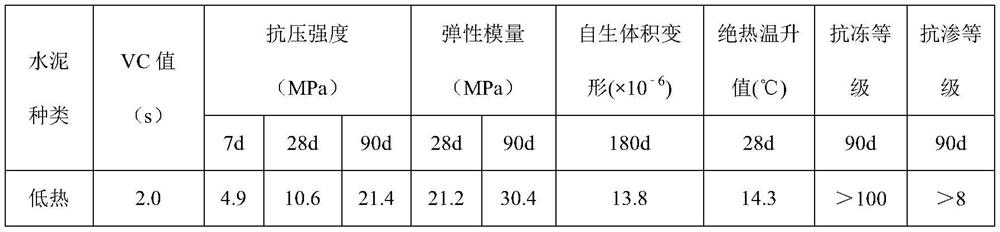

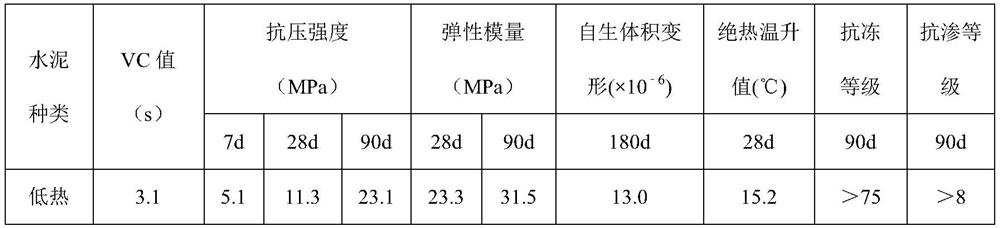

A low temperature rise, low shrinkage, high crack resistance, high durability roller compacted concrete and its preparation method

ActiveCN110885218BVC value optimizationSolve the problem of poor grindabilityRoller-compacted concreteCrack resistance

The invention relates to a low-rise, low-shrinkage, high-crack-resistance, high-durability roller compacted concrete and a preparation method thereof. All components of the roller compacted concrete are as follows in parts by weight: 60-80 parts of low heat portland cement, 89-114 parts of fly ash, 740-771 parts of sand, 1486-1514 parts of stone, 0.89-1.18 parts of water reducer share. Compared with traditional medium-heat Portland cement roller compacted concrete, the present invention has good working performance, mechanical performance and durability, and at the same time, the concrete has lower adiabatic temperature rise, smaller autogenous volume deformation and shrinkage, and even exhibits micro-expansion characteristics, and temperature control and anti-cracking capabilities Significant improvement can further simplify temperature control measures and reduce engineering costs. At the same time, it can realize construction in high temperature seasons and gradually cancel cooling water pipes in low temperature seasons. The technical and economic benefits are remarkable.

Owner:CHINA THREE GORGES CORPORATION

Multi-arch high toe wall of concrete faced rockfill dam

InactiveCN113356152ALight structureReduce volumeEarth-fill damsRock-fill damsArchitectural engineeringStructural engineering

The invention discloses a multi-arch high toe wall of a concrete faced rockfill dam. The concrete faced rockfill dam comprises a face plate, a cushion layer, a transition material, a toe plate, a toe wall, a water stop, a main rockfill area, a secondary rockfill area and a wave wall, the toe wall adopts a multi-arch shape, and each arch unit comprises a middle arch high toe wall with an arch crown facing the upstream and longitudinal supporting walls which are located at the two ends of the arch high toe wall and extend in the downstream direction, and the arch high toe walls and the longitudinal supporting walls are arranged in a covering layer and located on a bed rock. The arch high toe walls are light in structure, water pressure transmitted from the front end is transmitted to the longitudinal supporting walls, and the overall stability of the wall is guaranteed. Due to the existence of longitudinal support beams, the longitudinal rigidity is increased, and the deformation of the wall is reduced. The dam body water leakage problem caused by the fact that a traditional high toe wall deforms too much and crushes a face plate is avoided, the work amount is greatly reduced, the construction speed is higher, and investment is saved.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Machine-made sand C30 pumping concrete and preparation method thereof

InactiveCN110282934AReduce hydration temperature riseReduce shrinkage cracksRare earthUltimate tensile strength

The invention provides machine-made sand C30 pumping concrete and a preparation method thereof. The concrete is prepared in parts by weight. One cubic meter of concrete is prepared from the following components in parts by weight: 200-300 kg of P.O 42.5, 50-90 kg of fly ash, 100-180 kg of water, 800-1000 kg of machine-made sand, 900-1200 kg of broken stones, 100-200 kg of a mud blank, 8-10 kg of a water reducing agent, 32-50 kg of rare earth porcelain sand and 10-18 kg of a compound thickener. The concrete prepared with a formula provided by the invention has the advantages of strong strength, good peaceability, strong fluidity and bleeding segregation.

Owner:海南华盛混凝土有限公司

High-strength coral aggregate concrete and its preparation method

ActiveCN108218350BReduce hydration temperature riseReduce or avoid temperature cracksAluminium chlorideKaolin clay

The invention discloses high-strength coral aggregate concrete which is prepared from the following ingredients in parts by weight: 260-350 parts of low-heat marine Portland cement, 35-50 parts of flyash floating beads, 35-50 parts of mineral powder, 8-16 parts of silica fume, 8-16 parts of metakaolin, 2-6 parts of nano silicon dioxide, 2-6 parts of polyaluminum chloride, 550-679 parts of coral reef sand, 890-1000 parts of coral reef and 180-256 parts of seawater. The high-strength coral aggregate concrete has the advantages that the pelagic engineering construction cost is lowered, and environment-friendly and energy-saving requirements of civil engineering are also met.

Owner:CCCC SECOND HARBOR ENG +2

Roller Compacted Concrete Structure and Construction Method of Injecting Composite Slurry into Gravel Material

ActiveCN108643132BTake advantage ofEasy accessFoundation engineeringEarth-fill damsRoller-compacted concreteStructural engineering

The invention discloses a roller compacted concrete structure in which composite slurry material is injected into gravel material. It is composed of multi-layer composite slurry roller compacted concrete layer. The composite slurry roller compacted concrete layer is formed by vibration rolling of gravel material and surface poured composite slurry. The gravel material is excavation material with a particle size greater than or equal to 5mm. The gravel material is piled up in layers on the dam foundation, and the composite slurry is poured on the layered gravel material and randomly filled with gravel material. When the liquid level of the composite slurry is close to the top surface of the gravel material, the surface of the storehouse is compacted by vibrating rollers. A grouted roller compacted concrete structure with a uniform and stable structure is formed. The invention has the advantages of local materials, uniform and stable structure, excellent performance, fast construction speed and saving engineering cost. The invention also discloses a construction method of the roller compacted concrete structure in which the composite slurry material is injected into the stone slag material.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

A kind of low clinker cement and its preparation method and application

The invention provides a low-clinker cement and its preparation method and application. The low-clinker cement includes the following raw materials in parts by mass: 75-85 parts of blast furnace slag, 10-20 parts of gypsum, 1-10 parts of red mud, cement 2 to 5 parts of clinker, the sum of calcium, silicon and aluminum oxides in the blast furnace slag is greater than 80wt%, the content of calcium carbonate in the blast furnace slag is ≤10wt%, and the specific surface area is ≥350m 2 / kg. The present invention uses highly active blast furnace slag as the main component of cement, mixes gypsum, red mud and a small amount of cement clinker, makes full use of the alkali activity of red mud and blast furnace slag, and through the reasonable proportioning of several ash body components, Under the synergistic action of each component, the low-clinker cement with higher mechanical properties is produced by reaction, and the amount of cement clinker is reduced.

Owner:GUANGZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com