A low temperature rise, low shrinkage, high crack resistance, high durability roller compacted concrete and its preparation method

A technology of roller compacted concrete and low shrinkage, which is applied in the field of high-durability roller compacted concrete and its preparation, low shrinkage, high crack resistance, and low temperature rise. Concrete temperature difference is obvious and other problems, to achieve the effect of simplifying temperature control measures, improving crack resistance, and slowing the heat release of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

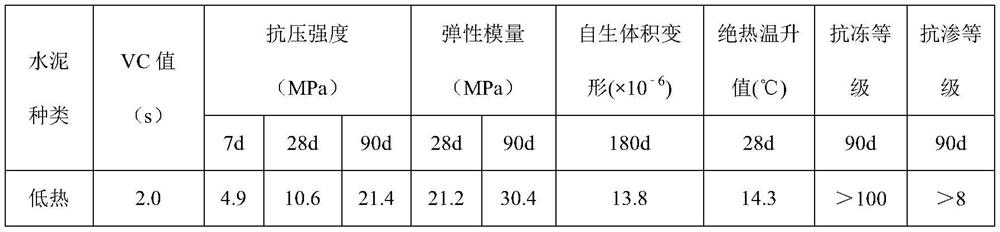

Embodiment 1

[0030] A low temperature rise, low shrinkage, high crack resistance, high durability roller compacted concrete has the following components by weight: 60 parts of low heat Portland cement, 89 parts of fly ash, 740 parts of sand, 1514 parts of stone, and water reducer 0.89 parts, 0.045 parts of air-entraining agent, 0.75 parts of shrinkage reducing agent, 82 parts of water, each part is 1kg, as shown in Table 1.

[0031] The specific surface area of the low-heat Portland cement is 332m 2 / kg, MgO content 4.7%, 3d, 7d heat of hydration are 194kJ / kg, 234kJ / kg respectively;

[0032] The alkali content of the fly ash is 0.9%; the sand is processed from limestone aggregate, and the fineness modulus is 2.71;

[0033] The particle content of d≤0.16mm in the stone is 19%, wherein the particle content of d≤0.08mm is 8%,

[0034] The stones are in three grades, big stones (40mm-80mm), medium stones (20mm-40mm), small stones (5mm-20mm), and the volume ratio is 30:40:30.

[0035] The ...

Embodiment 2

[0044] The difference is that medium-heat Portland cement is used instead of low-heat Portland cement, and the others are the same as in Example 1. The specific surface area of medium heat Portland cement is 338m 2 / kg, MgO content 4.2%, 3d, 7d heat of hydration were 239kJ / kg, 280kJ / kg.

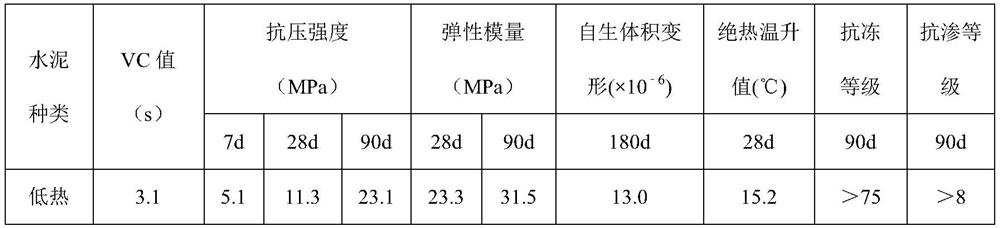

[0045] Table 3C 90 Mix ratio of 15F100W8 three-stage medium-heat Portland cement roller compacted concrete

[0046] cement fly ash sand gravel Superplasticizer air entraining agent Shrinkage reducer water 63 94 734 1501 0.94 0.047 0.75 86

[0047] Test results of thermal Portland cement RCC properties in Table 4

[0048]

[0049] It can be seen from Table 1 and Table 3 that when the site construction requirements are met, compared with the traditional medium-heat Portland cement RCC under the same conditions, the water consumption of low-heat Portland cement is reduced by 4kg / m 3 , the total amount of cementitious materials is reduced by 8kg / m 3...

Embodiment 3

[0052] The difference is that no water reducer is included, and the others are the same as in Example 1.

[0053] Field tests show that without adding water reducing agent, the mixing performance of RCC is extremely poor, it is not easy to shape, and cannot meet the construction requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com