Nondestructive measurement method for water content of roller-compacted concrete

A technology of roller compacted concrete and measurement method, which is applied to measuring devices, instruments, material analysis by electromagnetic means, etc., can solve problems such as low work efficiency, long work cycle, radioactive pollution, etc., and achieve high work efficiency and high resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

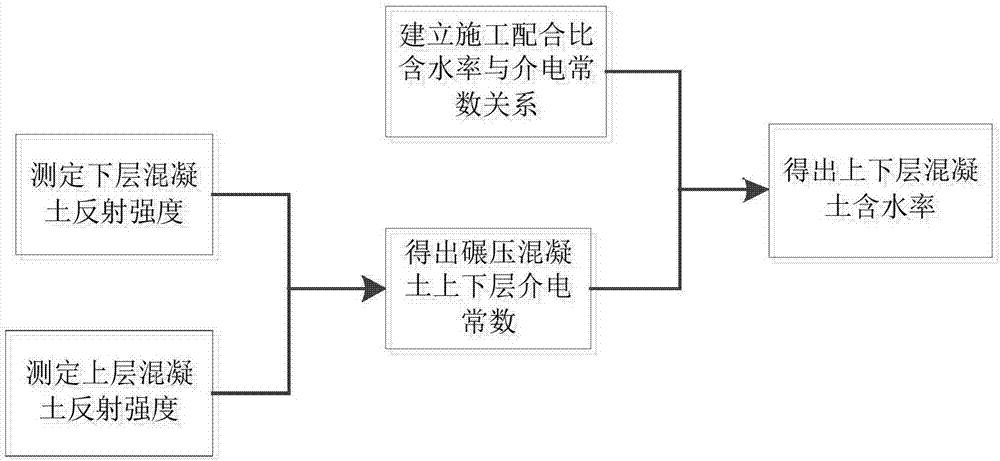

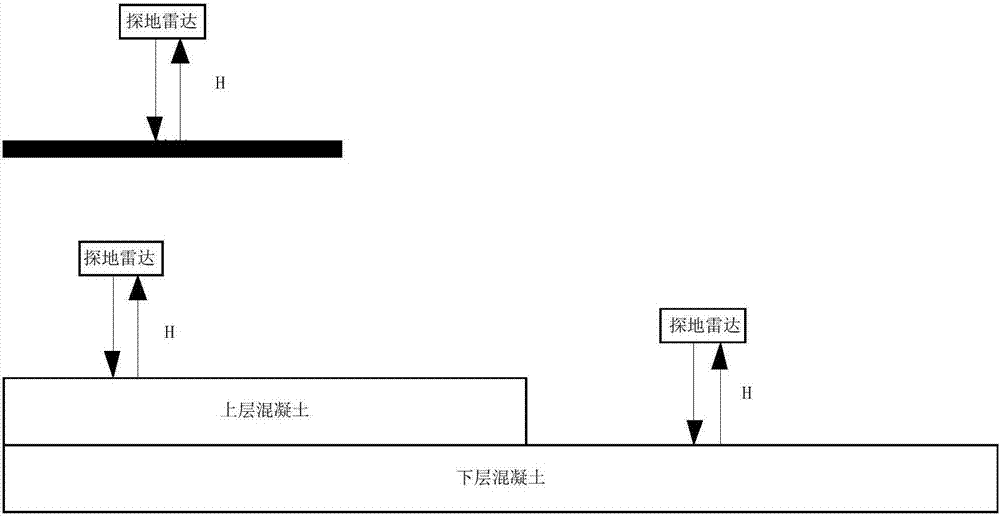

[0019] The non-destructive measurement process of the moisture content of the roller compacted concrete described in this embodiment is as follows: figure 1 As shown, the specific measurement method is as follows:

[0020] The dielectric constant of the upper and lower surface layers of RCC is obtained through the electromagnetic reflection intensity, and then the moisture content is obtained by calculating the dielectric constant; the relationship between the dielectric constant and the moisture content is:

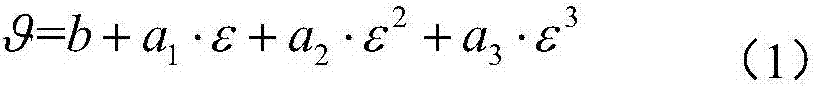

[0021]

[0022] In formula (1), is the water content, ε is the dielectric constant, b, a 1 , a 2 , a 3 is a coefficient, which is determined according to different concrete mix ratios.

[0023] The relational expression of described reflection intensity and dielectric constant is:

[0024]

[0025] In formula (2), A 0 is the reflection intensity of RCC surface, A s is the reflection intensity of the iron plate surface, and ε is the dielectric constant.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com