Boring and coring process for roller compacted concrete

A technology of roller compacted concrete and drilling core, which is applied to sampling devices, material inspection products, etc., can solve the problems of length limitation, inability to meet the requirements of engineering quality, insufficient core depth, etc., to prevent mechanical damage, and to achieve economical Benefit, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

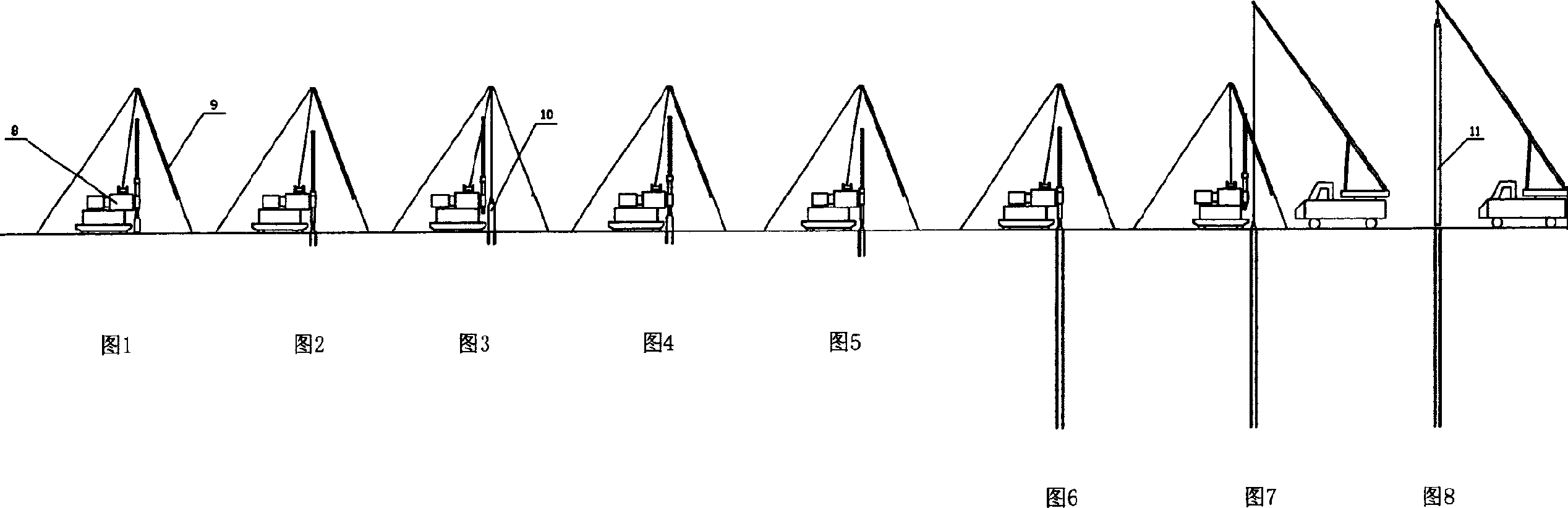

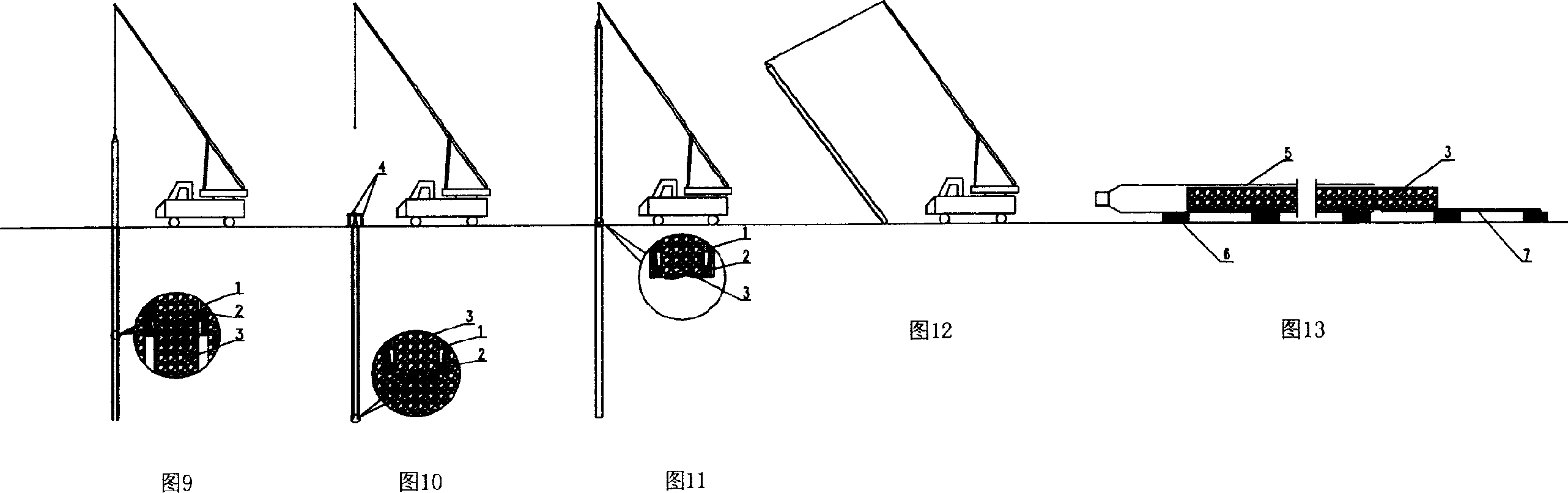

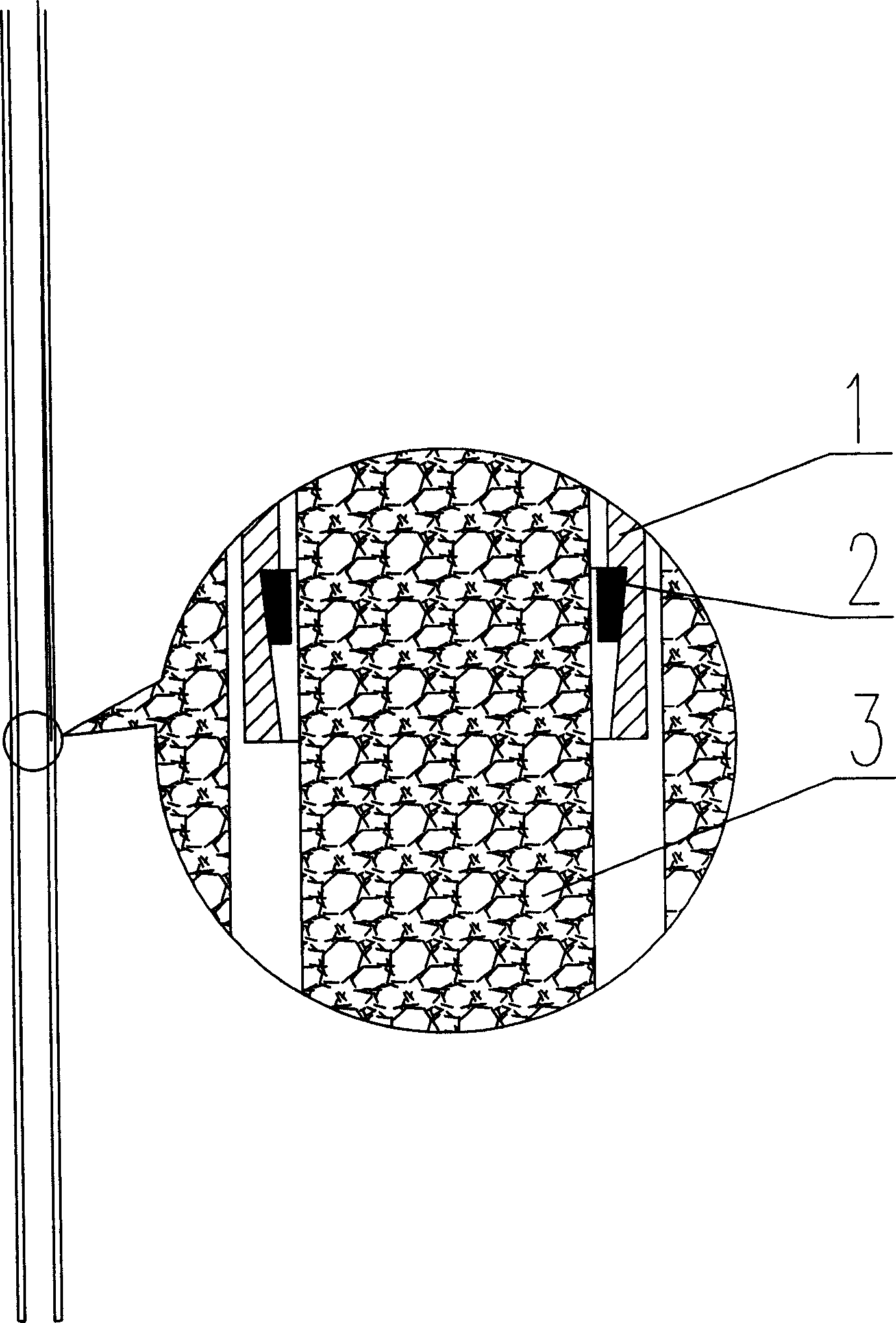

[0021] As shown in Figures 1 to 13, this embodiment is implemented by the following steps:

[0022] a. Select and install the drilling rig 8 and the drilling tower 9: In this embodiment, the SGZ-IIIA drilling rig, the SGZ-3250 pump and the ordinary tripod drilling tower are selected for conventional drilling. The concrete core 3 is pulled out, and the core pipe 5 is lifted and placed by a crane to meet the requirements of lifting a long core and stability.

[0023] b. Using single-tube drilling tool 11 for concrete drilling: according to the coring requirements, this example uses a 150mm single-tube drilling tool to take cores, and the total length of the drilling tool is 10m; due to the requirements of the drilling process, the single-tube drilling tool 11 consists of four It is composed of a short core pipe 10 with a length of 2.5m and high thread concentricity at both ends, and the accumulative straightness deviation of the drilling tool does not exceed 5mm. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com