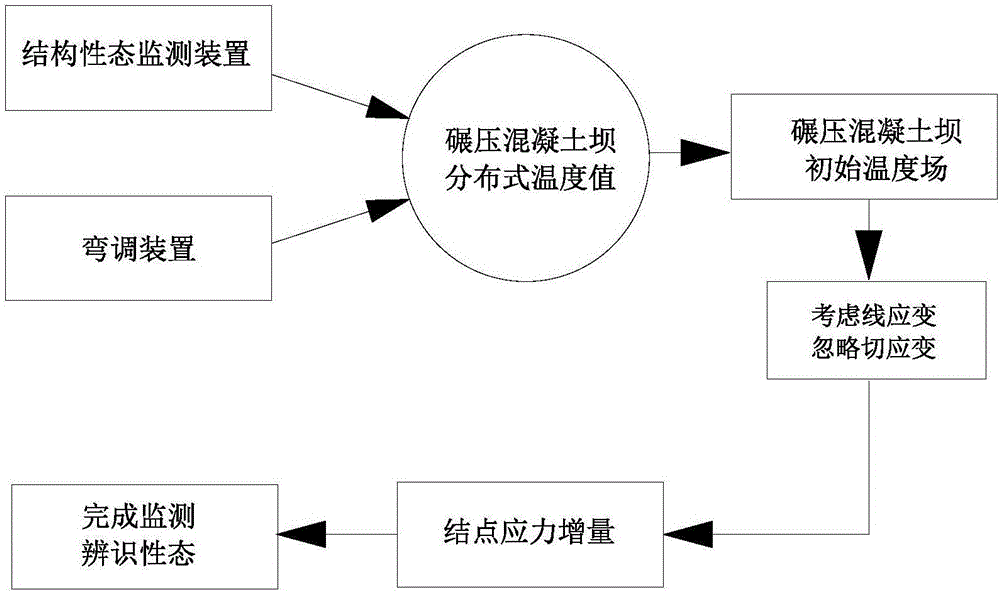

Roller compacted concrete dam structural condition monitoring system and monitoring method

A technology of roller compacted concrete, monitoring system, applied in the direction of measuring force, measuring device, measuring heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

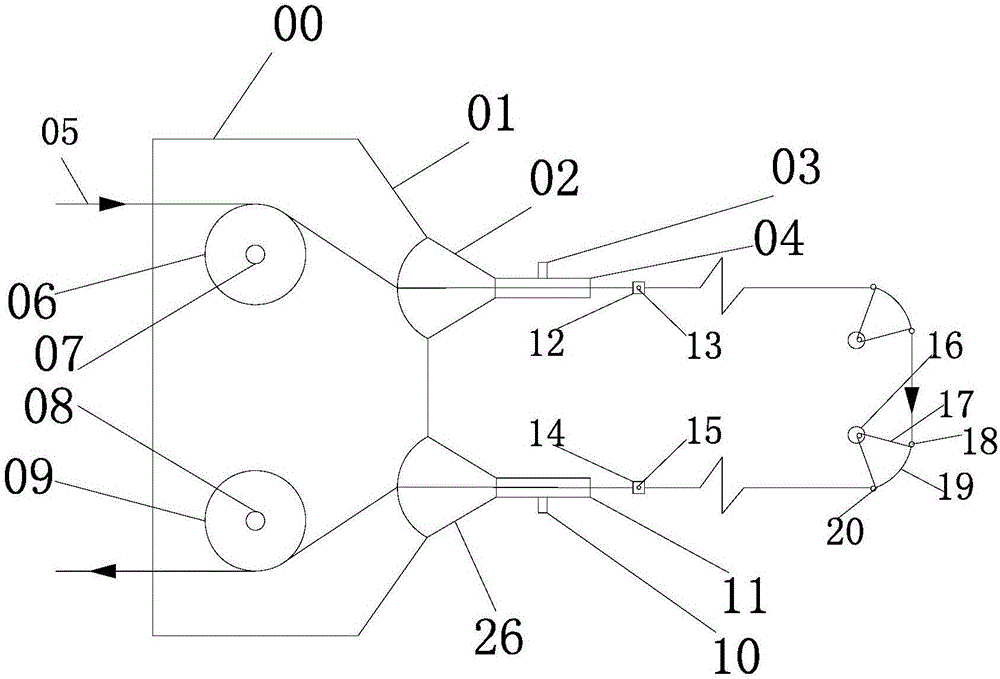

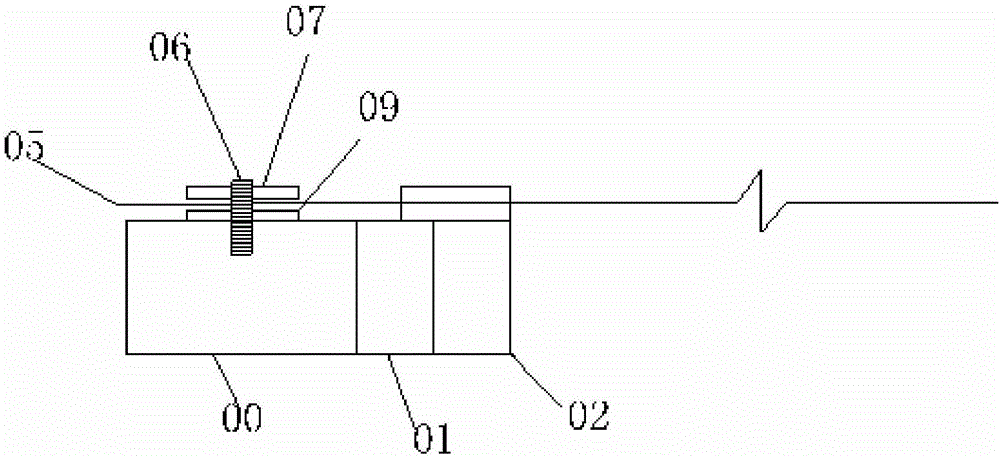

[0062] A roller compacted concrete dam is located on the middle reaches of the Jinsha River in Lijiang, Yunnan Province. The maximum dam height is 160m, and the dam crest length is 640m; the maximum length along the flow direction is 156m. The structural behavior of the dam section under the action of variable temperature loads, hydraulic loads and other factors from the construction period to the operation period is studied. During the research process, the dam foundation surface compressive stress measurement points A6-C-04 and A6-C-05 are used as typical measurement points For analysis and research, the computational domain of the 6# dam section of the RCC dam is divided into 21290 units and 26690 nodes. Figure 5 shown. Carry out the simulation calculation of the roller compacted concrete dam from the construction period to the operation period. During the calculation, according to the calculation method of the effect of the variable temperature load of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com