Four-graded roller compacted concrete suitable for water power hydraulic engineering and preparation method thereof

A technology for roller compacted concrete and water conservancy engineering, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of concrete aggregate separation, low cost, dryness, poor cohesion, etc. The effect of hydration heat temperature rise, temperature control cost reduction, and hydration temperature rise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A four-grade roller compacted concrete suitable for hydropower and water conservancy projects, including cement, fly ash, sand, gravel, water, high-efficiency water reducing agent, and air-entraining agent. The cement is 42.5 ordinary Portland cement or 42.5 medium heat Portland cement. The water demand ratio of grade II fly ash used in this example is 93.8%; the high-efficiency water reducer is a polycarboxylic acid type high-performance water reducer, and the theoretical water reduction rate is 22%; the air-entraining agent is AE air-entraining agent agent. In this embodiment, the dosage of the water reducing agent is 0.7% of the mass of the gelling material, and the dosage of the air-entraining agent is 0.05% of the mass of the gelling material.

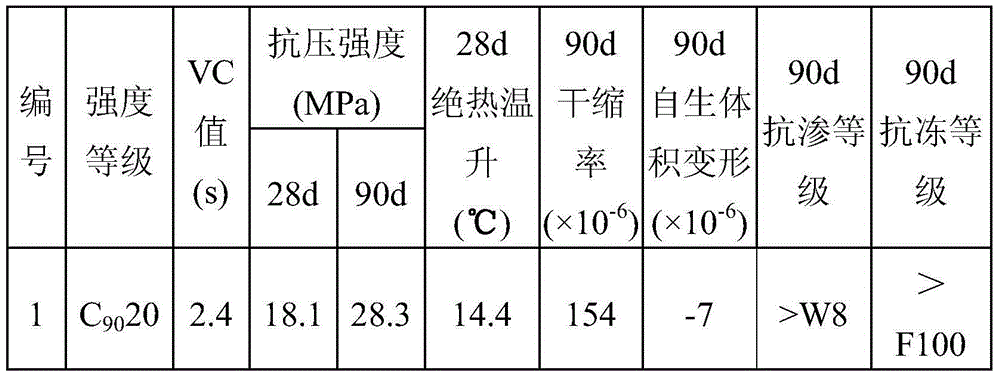

[0036] Prepare the four-graded roller compacted concrete of the present invention according to the mix ratio shown in Table 1. At the same time, according to the formula shown in Table 2, the three-grade RCC with the same...

Embodiment 2

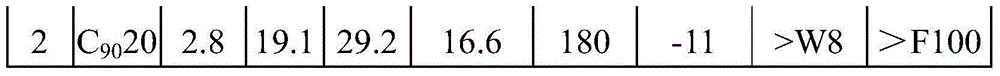

[0052] Prepare the four-graded roller compacted concrete of the present invention according to the mix ratio shown in Table 5.

[0053] Table 5C 90 20 four-grade RCC mix ratio (kg / m 3 )

[0054] serial number

strength level

cement

fly ash

water

the sand

gravel

air entraining agent

2

C 90 20

49

91

70

643

1585

1.12

0.07

[0055] The preparation method of four-graded RCC is as follows: firstly, mix cement, aggregate (sand and gravel) and fly ash according to the proportion and then dry mix for 30 seconds; then add water, water reducer and air-entraining agent according to the proportion , and mix for 3 minutes; discharge after the mixing is completed.

[0056] According to GB / T50081-2002 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete" and SL352-2006 "Test Regulations for Hydraulic Concrete" to test the VC value, compressive strength, self-gener...

Embodiment 3

[0061] Prepare the four-graded roller compacted concrete of the present invention according to the mix ratio shown in Table 7.

[0062] Table 7C 90 20 four-grade RCC mix ratio (kg / m 3 )

[0063] serial number

strength level

cement

fly ash

water

the sand

stone

air entraining agent

3

C 90 20

64

78

71

665

1563

1.14

0.071

[0064] The preparation method of the four-graded RCC is as follows: firstly, mix cement, aggregate and fly ash according to the proportion and dry mix for 30 seconds; then add water, water reducer and air-entraining agent according to the proportion, and mix for 3 minutes; After the combination is completed, the material is discharged.

[0065] According to GB / T50081-2002 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete" and SL352-2006 "Test Regulations for Hydraulic Concrete" to test the VC value, compressive strength, self-g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com