Roller-compacted concrete structure formed by pouring composite slurry into stone ballast and construction method of roller-compacted concrete structure

A technology of roller compacted concrete and construction method, which is applied in the direction of basic structure engineering, dams, buildings, etc., and can solve the problem of not being able to grasp the engineering characteristics, key technologies and operation characteristics of 300m-level high-face rockfill dams, and the environment and soil and water conservation. impact on the impact of the hydropower station’s economic index competitiveness and other issues, to achieve the effect of eliminating technological development bottlenecks, good volume stability, and ensuring structural stability and seismic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

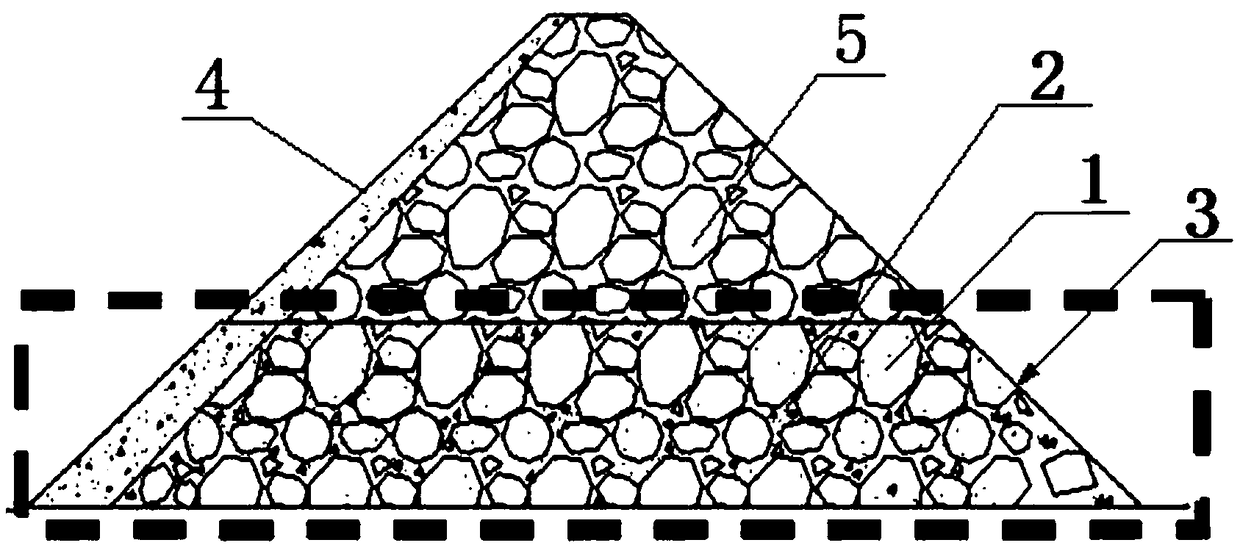

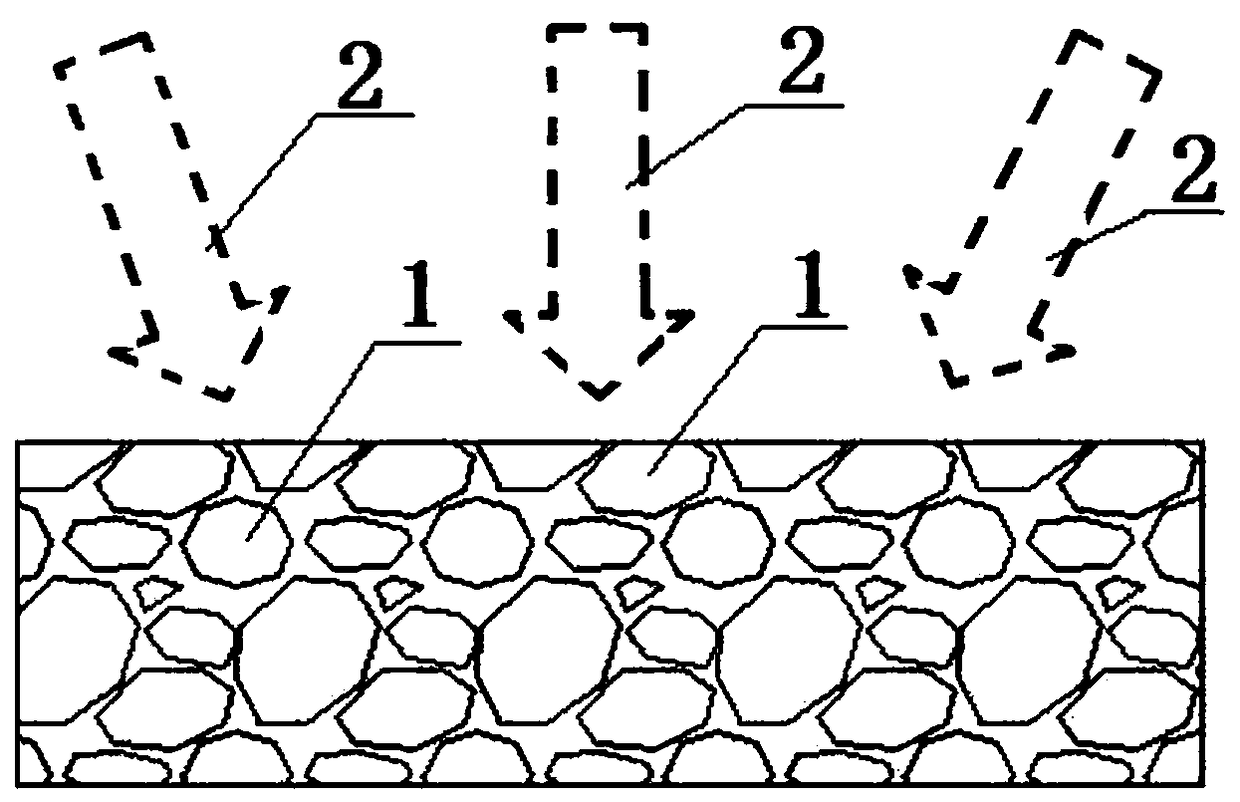

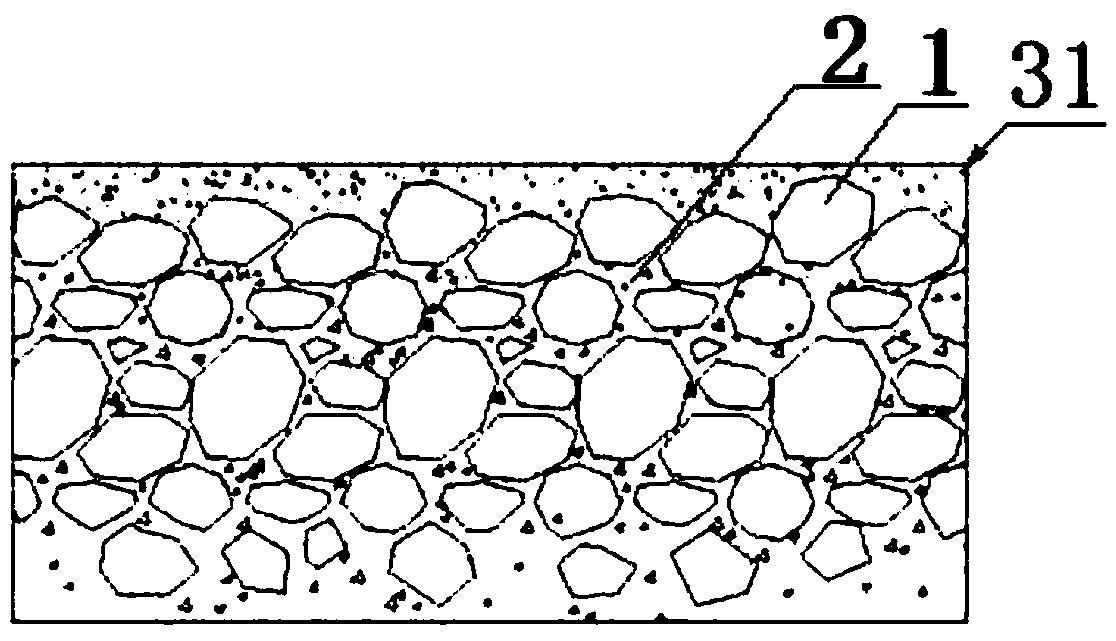

[0029] Referring to the accompanying drawings, it can be seen that the roller compacted concrete structure in which composite slurry is injected into the gravel material is characterized in that: it is composed of a multi-layer composite slurry roller compacted concrete layer 31, and the composite slurry roller compacted concrete layer is composed of gravel material 1 and The composite grout 2 poured on the surface is formed by vibratory rolling, and the gravel material 1 is excavated material with a particle size greater than or equal to 5mm; Randomly fill the gravel material on the material, and when the liquid level of the composite slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com