Concrete with ultrahigh content of mixed fly ash

A technology of fly ash and concrete, which is applied in the field of building materials, can solve the problems of restricting the development of large-volume fly ash dam concrete, and achieve the effects of controlling temperature cracks, reducing engineering costs, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

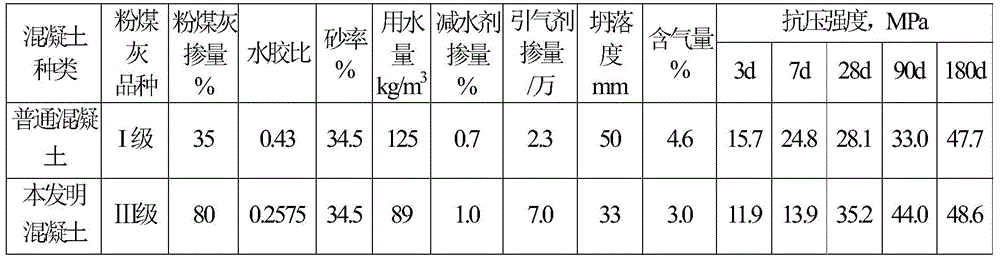

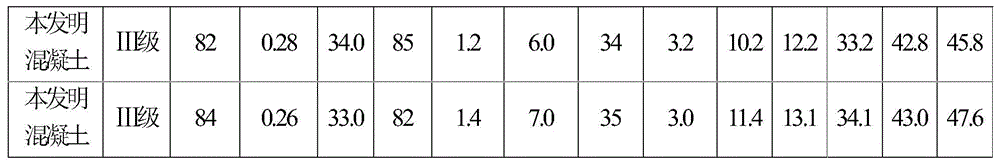

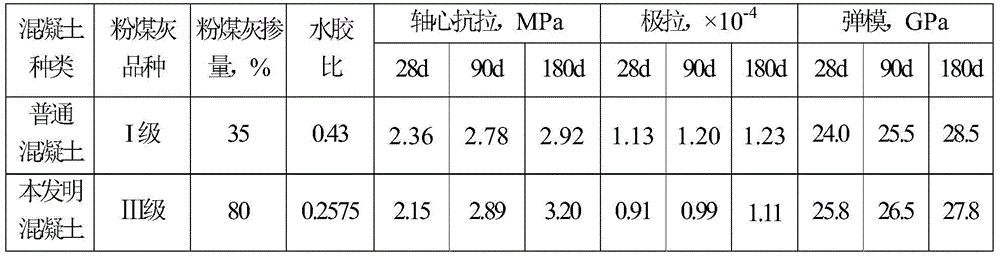

Examples

Embodiment 1

[0031] A kind of super high fly ash concrete, described concrete comprises the following components by weight:

[0032] 48 parts of cement, 272 parts of fly ash, 656 parts of sand, 1333 parts of gravel, 4.8 parts of water reducing agent, 0.26 parts of air-entraining agent, and 80 parts of water. That is, water-binder ratio: 0.25, fly ash content: 85%, water consumption 80kg / m 3 , Sand rate: 33%, superplasticizer dosage 1.5%. The concrete has a slump of 20-50mm and an air content of 3%-4%.

[0033] The cement is ordinary Portland 42.5 cement.

[0034] The fly ash is Class III fly ash required by national standards.

[0035] The water reducer is a polycarboxylate high performance water reducer.

[0036] The sand is medium sand.

[0037] The grain size of the gravel is ≤40mm.

Embodiment 2

[0039] A kind of super high fly ash concrete, described concrete comprises the following components by weight:

[0040] 60 parts of cement, 240 parts of fly ash, 696 parts of sand, 1293 parts of gravel, 3.0 parts of water reducing agent, 0.18 parts of air-entraining agent, and 90 parts of water. That is, water-binder ratio: 0.30, fly ash content: 80%, water consumption 90kg / m 3 , Sand rate: 35%, superplasticizer dosage 1.0%.

[0041] The concrete slump of the concrete is 20-50mm, and the air content is 3%-4%.

[0042] The cement is ordinary Portland 42.5 cement.

[0043] The fly ash is Class III fly ash required by national standards.

[0044] The water reducer is a polycarboxylate high performance water reducer.

[0045] The sand is medium sand.

[0046] The grain size of the gravel is ≤40mm.

Embodiment 3

[0048] A kind of super high fly ash concrete, described concrete comprises the following components by weight:

[0049] 55 parts of cement, 249 parts of fly ash, 679 parts of sand, 1317 parts of gravel, 3.65 parts of water reducing agent, 0.21 parts of air-entraining agent, and 85 parts of water. That is, water-binder ratio: 0.28, fly ash content: 82%, water consumption 85kg / m 3 , Sand rate: 34%, superplasticizer dosage 1.2%.

[0050] The concrete slump of the concrete is 20-50mm, and the air content is 3%-4%.

[0051] The cement is ordinary Portland 42.5 cement.

[0052] The fly ash is Class III fly ash required by national standards.

[0053] The water reducer is a polycarboxylate high performance water reducer.

[0054] The sand is medium sand.

[0055] The grain size of the gravel is ≤40mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com