A method for preventing concrete temperature cracks in underground side wall structures

A technology of concrete temperature and side wall structure, which is applied in the field of concrete crack control and concrete construction. It can solve the problems of concrete temperature cracks, difficulty in reducing concrete mold temperature, and rise in concrete temperature, so as to reduce hydration temperature rise and improve volume stability. The effect of shortening the time of temperature change history

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

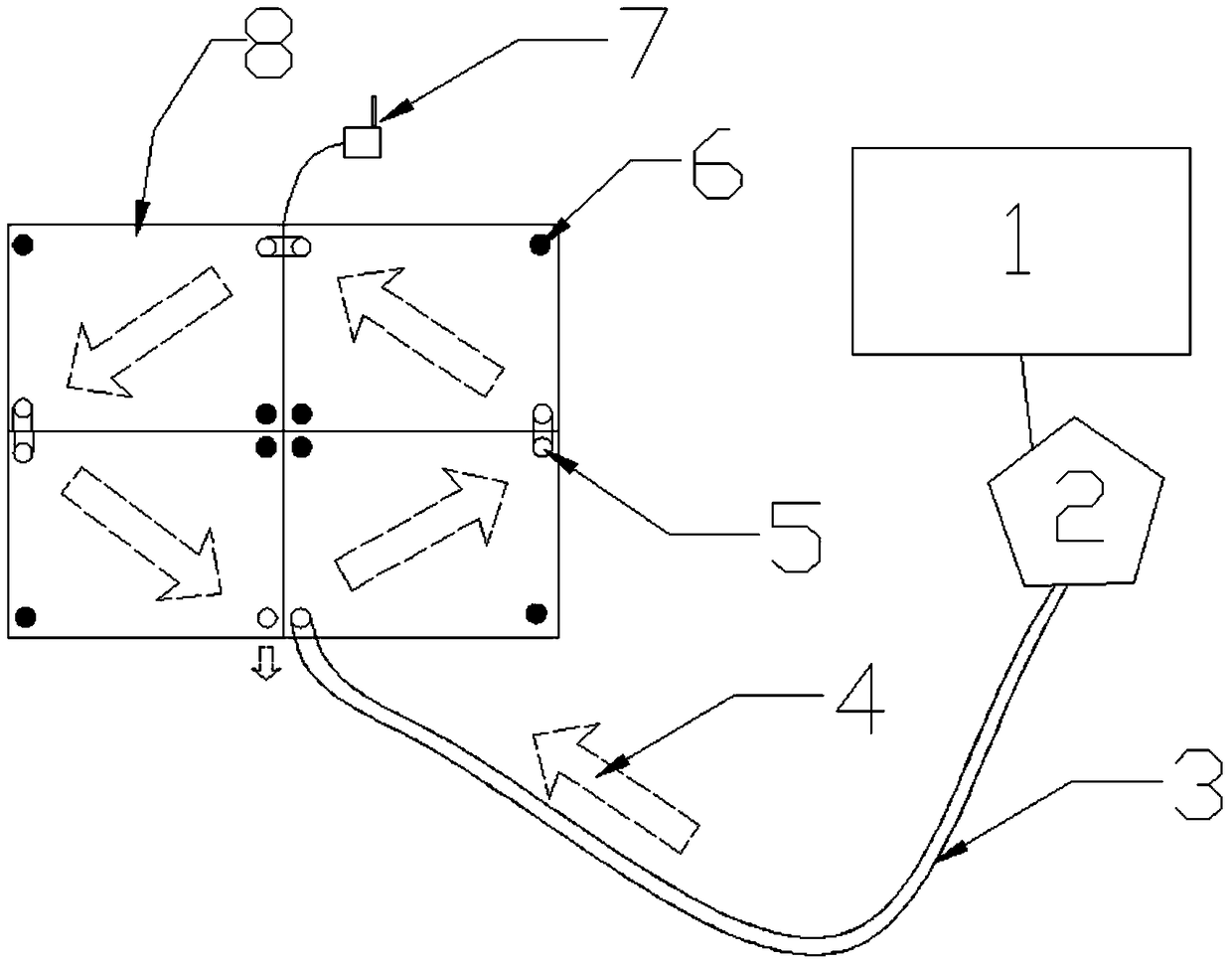

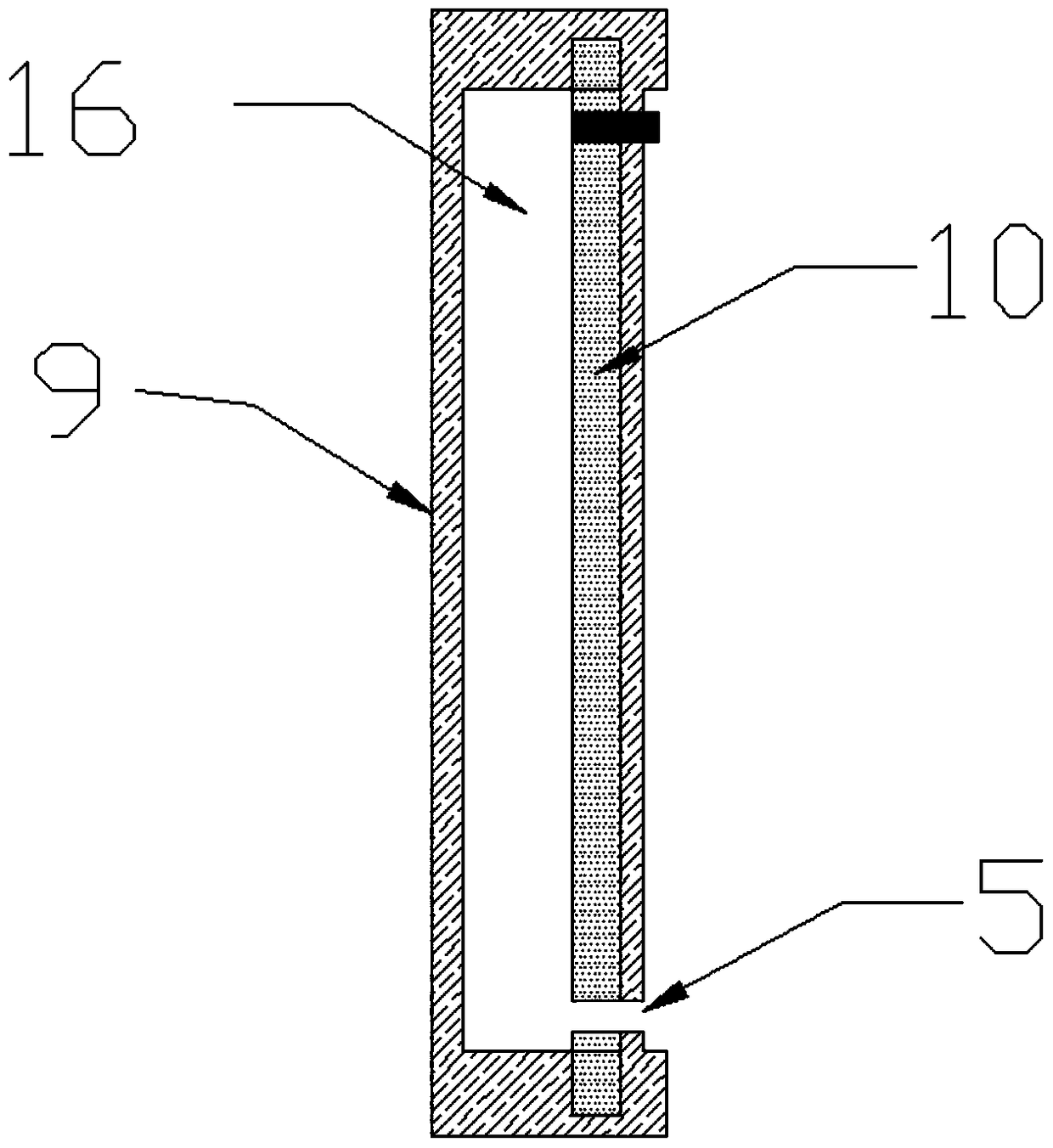

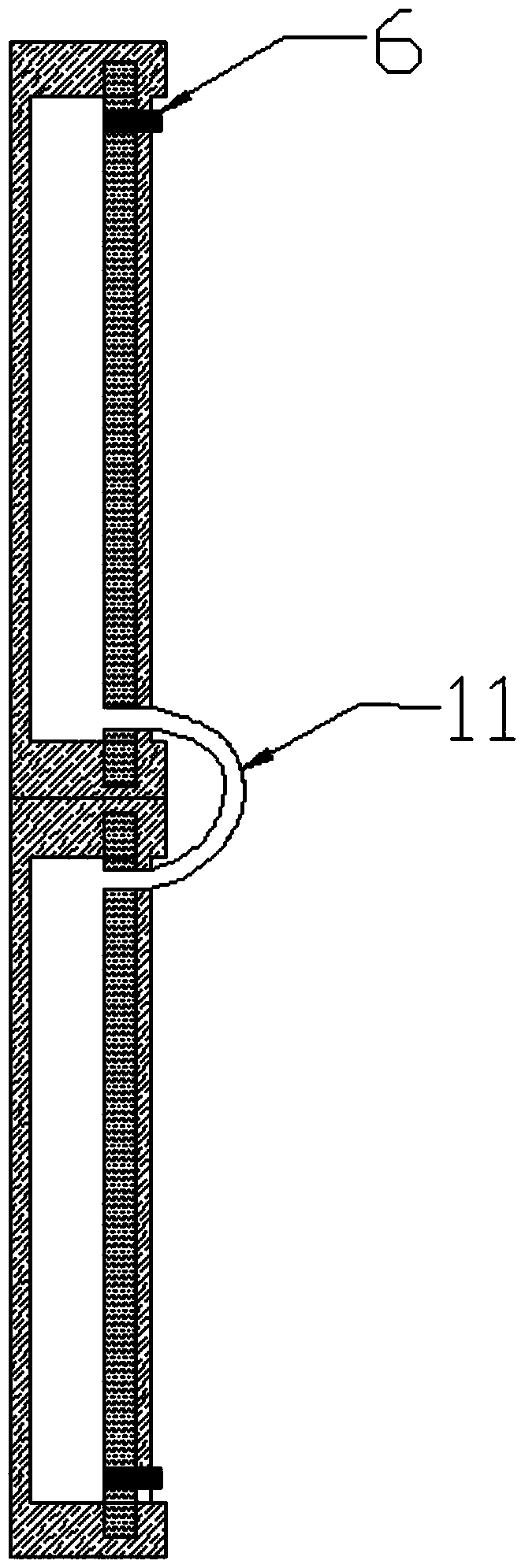

Method used

Image

Examples

Embodiment

[0042] An underground side wall structure with a thickness of 80cm, a height of 6m, a single pouring length of 20m, and an ambient temperature of 34.2°C is used for pouring construction of C40 concrete. The initial setting time is 10 hours, and the hydration temperature rise is 33.5°C. The engineering results show that the side walls are severely cracked, with one temperature crack every 0.8 to 1.5 meters; after that, the temperature of the concrete entering the mold is controlled at 31.5°C, the initial setting time is 10.5h, and the hydration temperature rise is 33.2°C. The engineering results show that the side walls are severely cracked, with one temperature crack every 1.0 to 1.6 meters; the technical results of the two constructions show that in the high temperature environment in summer, The engineering effect of this project is that the concrete only reduces the mold entry temperature by about 5°C, and only reduces the initial mold entry temperature. Under the premise of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com