Feeding device for amorphous alloy ribbons

A technology of amorphous alloy and feeding device, which is applied in the directions of thin material handling, transportation and packaging, and winding strips, etc. It can solve the problems of operator hazards and affecting the quality of amorphous cores, so as to eliminate the impact of product quality, Improve work efficiency and avoid mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

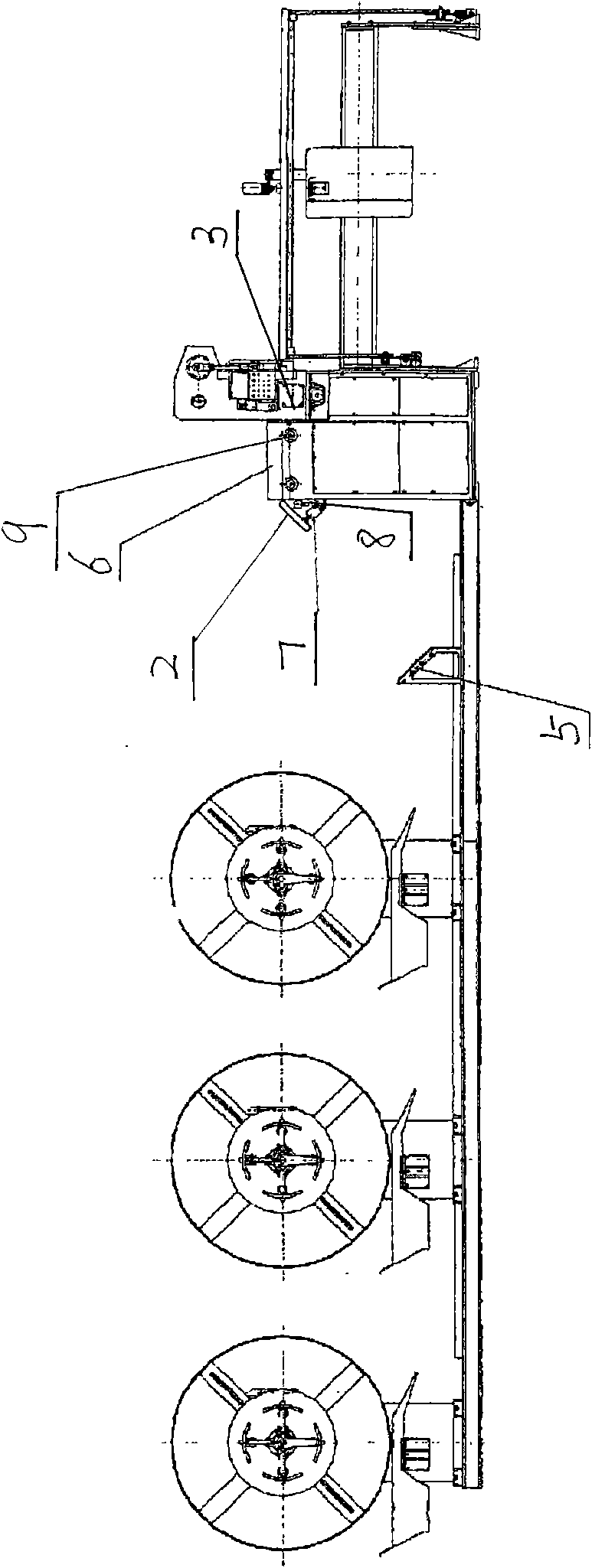

[0018] like figure 1 Shown, the present invention provides a kind of amorphous alloy ribbon feeding device, comprises the feed passage that is used to convey amorphous alloy thin ribbon, and described feed passage is arranged in turn by the distributing frame 5 and on the frame The vibrator 1, the feeding frame 6 and the upper and lower feeding rollers 3 distributed in sequence constitute the vibrator. The vibrator is provided with a vibrating tank 2, and the vibrating tank is connected with a vibrating drive mechanism to drive its vibration.

[0019] The vibration driving mechanism may include a vibration cylinder 7 and a pressure regulating valve 8 of the vibration cylinder, the front part of the bottom surface of the vibration tank is hinged with the frame, and the rear part of the bottom surface of the vibration tank is connected to the cylinder, thereby passing the cylinder Drive the vibrating tank to vibrate and shake off the debris on the steel belt. To avoid damage ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com