Automated multi-station production line for disc parts

A disc-like parts and production line technology, applied in the field of automatic production equipment, can solve the problems of taking up a lot of space, material accumulation, and the need to change machine tools, etc., and achieve the effect of small time, zero inventory, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

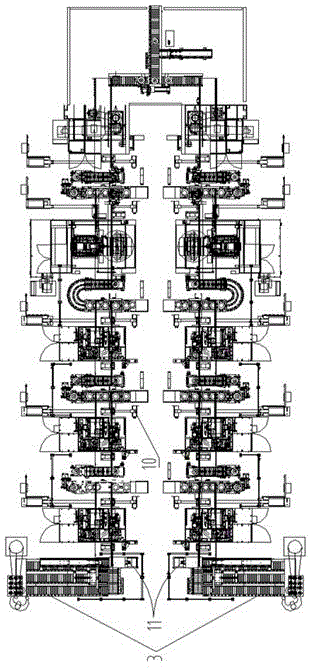

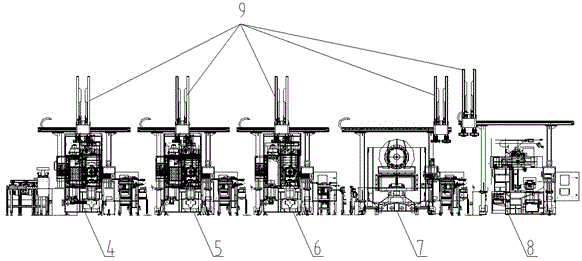

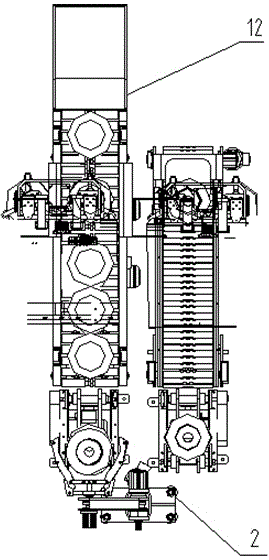

[0025] Such as Figures 1 to 4 As shown, the automatic multi-station production line for disk parts includes a logistics roller table system for connecting each processing unit of the production line. The logistics roller table system includes a workpiece turning device 2 for realizing automatic turning during material operation. On the surface, the feeding channel 3 is placed at the feeding position of the first numerically controlled lathe 4, and also includes the first numerically controlled lathe 4, the second numerically controlled lathe 5, and the third numerically controlled lathe 6 arranged in series. Afterwards, a machining center 7 and a double-sided lathe 8 are arranged in series, all of which are sequentially connected to other parts through a logistics roller table, and also include a truss manipulator system 9, which includes several The truss manipulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com