System for preparing water by seawater distillation

A seawater and evaporator technology, which is applied in the system field of producing high-purity water by low-temperature multi-effect seawater distillation method, can solve the problems of large investment, many equipment, complicated maintenance, etc., and achieves the effect of less investment, good benefit and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

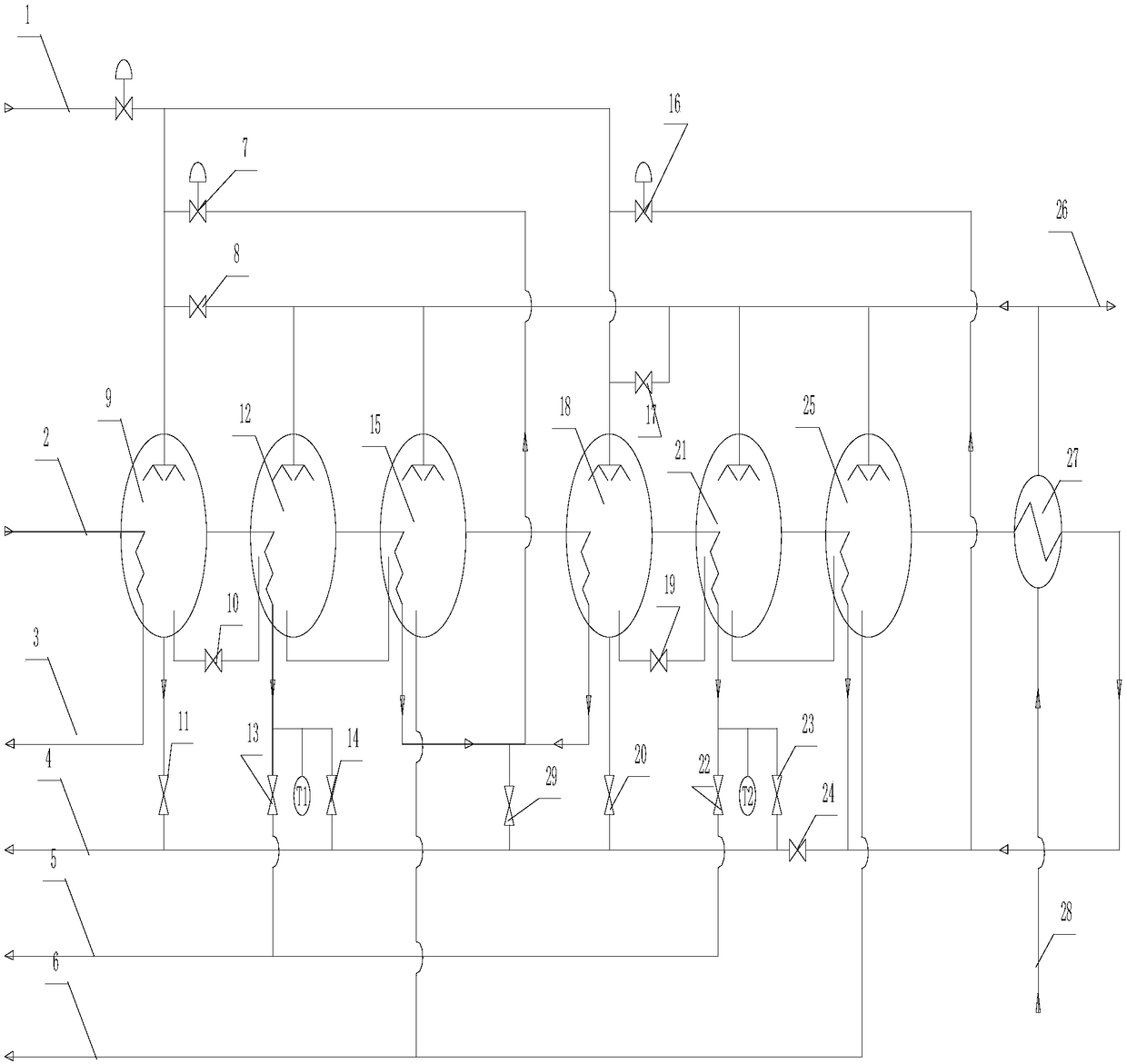

[0033] A system for producing water by seawater distillation, the system includes two evaporation groups, the evaporation groups need to be connected in series, adopt a single operation mode, close valves 7, 11, 13, 16, 20 and 22, open valves 8, 10, 14, 29, 17, 19, 23 and 24 valves. After the raw seawater is preheated in the condenser, it enters the first, middle and non-evaporator shells of each evaporation group respectively, and sprays on the heat exchange tubes. A part of the raw seawater is heated and evaporated and enters the adjacent next-effect evaporator tube side. , the remaining concentrated seawater enters the tube side of the next effect evaporator for further evaporation and concentration, and finally is discharged into the concentrated seawater pipeline by the final effect evaporator of each evaporation group. In the same evaporation group, the condensed water in the tube side of the neutralized evaporator and the seawater condenser enters the primary product wa...

Embodiment 2

[0035] A system for producing water by seawater distillation, the system includes 4 evaporation groups, the evaporation groups need to be connected in series, adopt the one-time operation mode, close the valves 7, 11, 13, 16, 20 and 22, open the valves 8, 10, 14, 29, 17, 19, 23 and 24 valves. After the raw seawater is preheated in the condenser, it enters the first, middle and non-evaporator shells of each evaporation group respectively, and sprays on the heat exchange tubes. A part of the raw seawater is heated and evaporated and enters the adjacent next-effect evaporator tube side. , the remaining concentrated seawater enters the tube side of the next effect evaporator for further evaporation and concentration, and finally is discharged into the concentrated seawater pipeline by the final effect evaporator of each evaporation group. In the same evaporation group, the condensed water in the tube side of the neutralized evaporator and the seawater condenser enters the primary ...

Embodiment 3

[0037] A system for producing water by seawater distillation, the system includes 6 evaporation groups, the evaporation groups need to be connected in series, adopt the one-time operation mode, close the valves 7, 11, 13, 16, 20 and 22, open the valves 8, 10, 14, 29, 17, 19, 23 and 24 valves. After the raw seawater is preheated in the condenser, it enters the first, middle and non-evaporator shells of each evaporation group respectively, and sprays on the heat exchange tubes. A part of the raw seawater is heated and evaporated and enters the adjacent next-effect evaporator tube side. , the remaining concentrated seawater enters the tube side of the next effect evaporator for further evaporation and concentration, and finally is discharged into the concentrated seawater pipeline by the final effect evaporator of each evaporation group. In the same evaporation group, the condensed water in the tube side of the neutralized evaporator and the seawater condenser enters the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com