A kind of manufacturing method of ag-mec electrical contact and its integrated assembly

A manufacturing method and technology of electrical contacts, which are applied in the direction of improving process efficiency, improving energy efficiency, and additive processing, etc., can solve problems such as inability to achieve production, and achieve improved electrical conductivity, reduced production costs, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

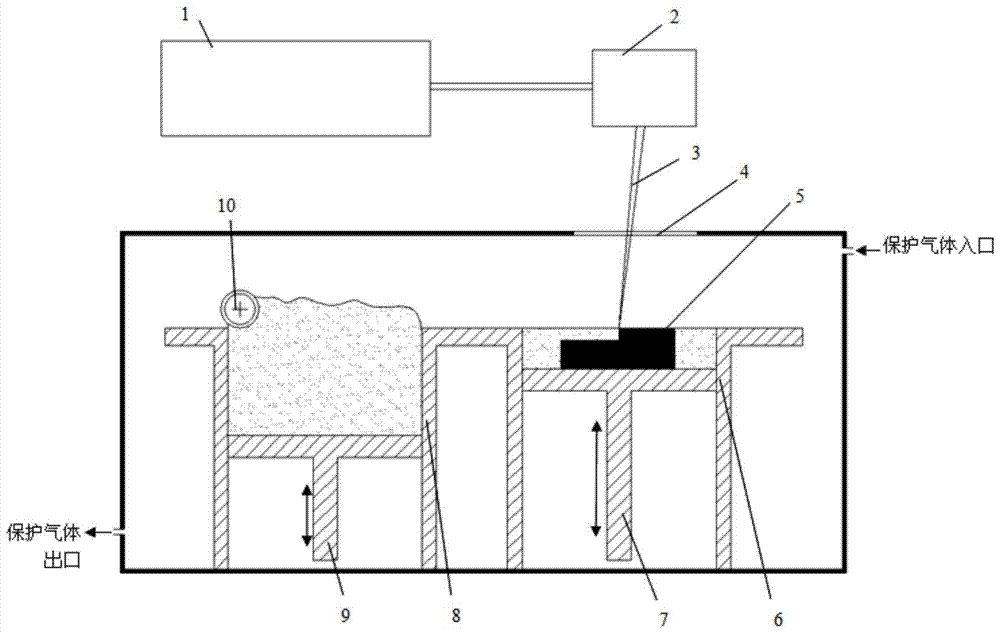

Method used

Image

Examples

Embodiment 1

[0024] Taking the printing of Ag60WC40 electrical contacts and their integrated components as an example

[0025] In the first step, silver and tungsten carbide powders are prepared respectively, the tungsten carbide powder is pretreated by electroless silver plating, and the silver-tungsten carbide mass ratio is 60:40 to make silver-tungsten carbide composite powder.

[0026] In the second step, the silver-tungsten carbide composite powder is made of a polymer with a particle size of 1μm coated silver-tungsten carbide composite powder. Load the coated silver-tungsten carbide composite powder into the powder cylinder of the 3D printer.

[0027] The third step is to establish a three-dimensional model of the Ag60WC40 electrical contact and its integrated components, and use selective laser sintering technology to 3D print the Ag60WC40 electrical contact and its integrated components. The laser power is 13W and the scanning speed is 1800mm / s , the scanning distance is 0.1 mm, ...

Embodiment 2

[0029] Taking the printing of Ag50WC50 electrical contacts and their integrated components as an example

[0030] In the first step, silver and tungsten carbide powders are prepared respectively, and the tungsten carbide powder is pretreated by electroless silver plating, and the silver-tungsten carbide mass ratio is 50:50 for powder mixing to make silver-tungsten carbide composite powder.

[0031] In the second step, the silver-tungsten carbide composite powder is made into a film-coated silver-tungsten carbide composite powder with a particle size of 10 μm by using a high molecular polymer as a binder. Load the coated silver-tungsten carbide composite powder into the powder cylinder of the 3D printer.

[0032] The third step is to establish a three-dimensional model of the Ag50WC50 electrical contact and its integrated components, and use selective laser sintering technology to 3D print the Ag50WC50 electrical contact and its integrated components. The laser power is 14W and...

Embodiment 3

[0035]Taking the printing of Ag35WC65 electrical contacts and their integrated components as an example

[0036] In the first step, silver and tungsten carbide powders are prepared respectively, and the tungsten carbide powder is pretreated by composite electroplating silver, and the silver-tungsten carbide mass ratio is 35:65 to mix the powder to make silver-tungsten carbide composite powder.

[0037] In the second step, the silver-tungsten carbide composite powder is made into a film-coated silver-tungsten carbide composite powder with a particle size of 50 μm by using a high molecular polymer as a binder. Load the coated silver-tungsten carbide composite powder into the powder cylinder of the 3D printer.

[0038] The third step is to establish a three-dimensional model of the Ag35WC65 electrical contact and its integrated components, and use selective laser sintering technology to 3D print the Ag35WC65 electrical contact and its integrated components. The laser power is 15W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com