Patents

Literature

61results about How to "Satisfy grinding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

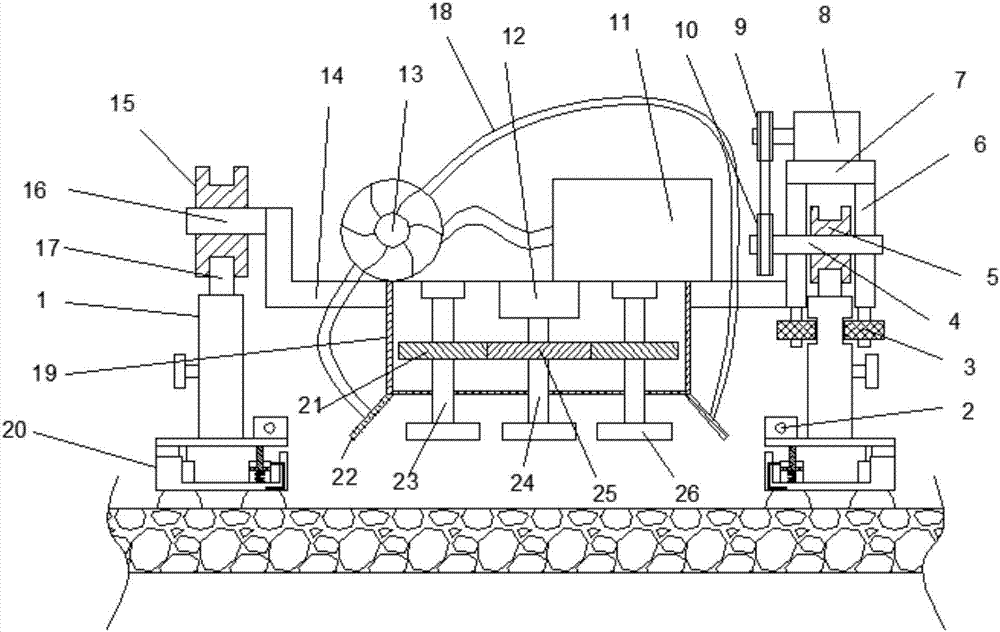

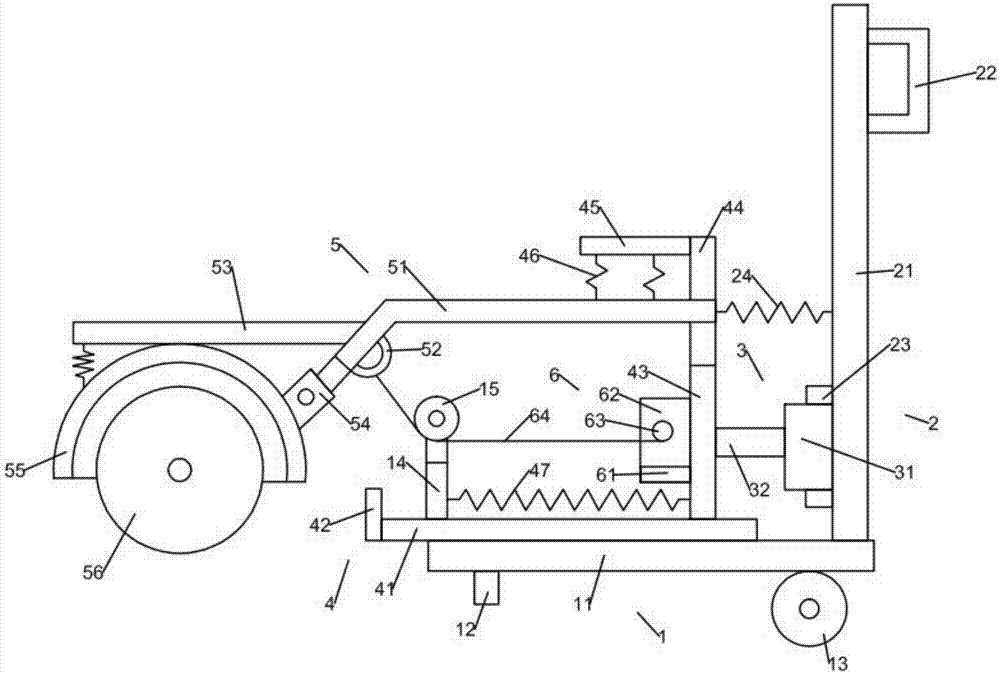

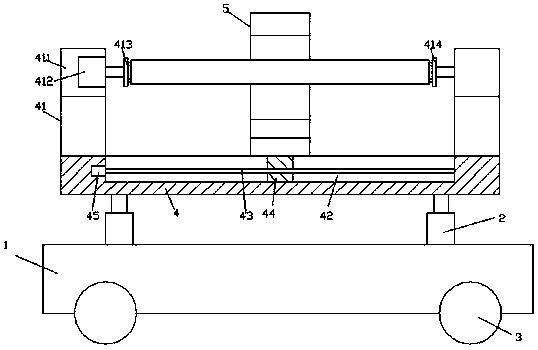

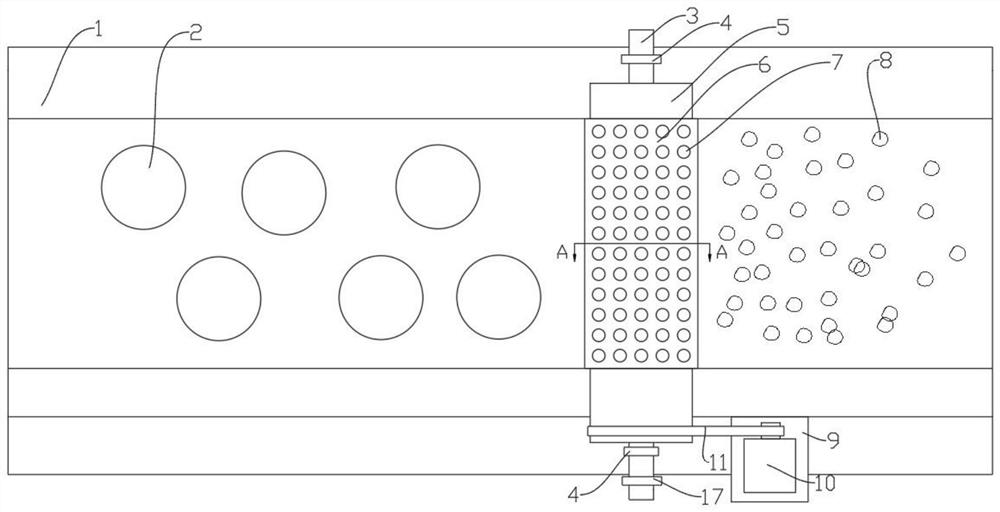

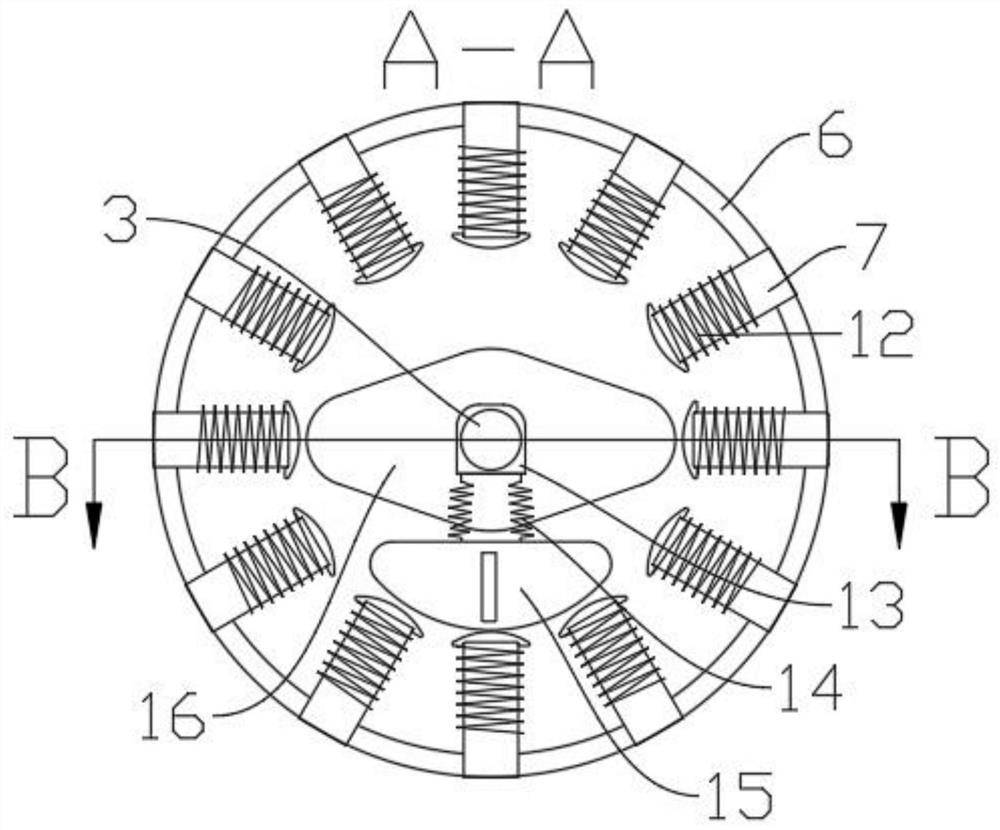

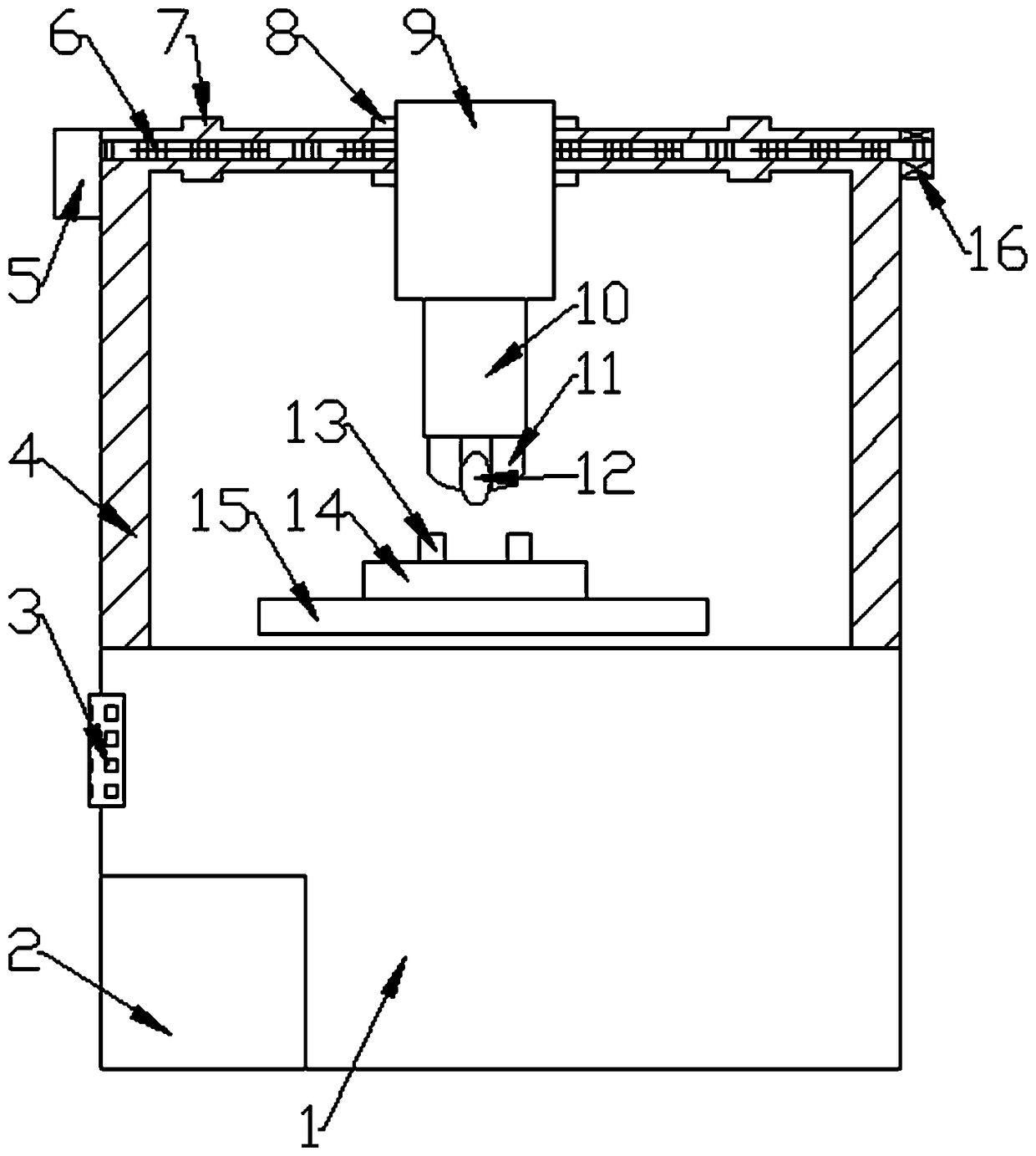

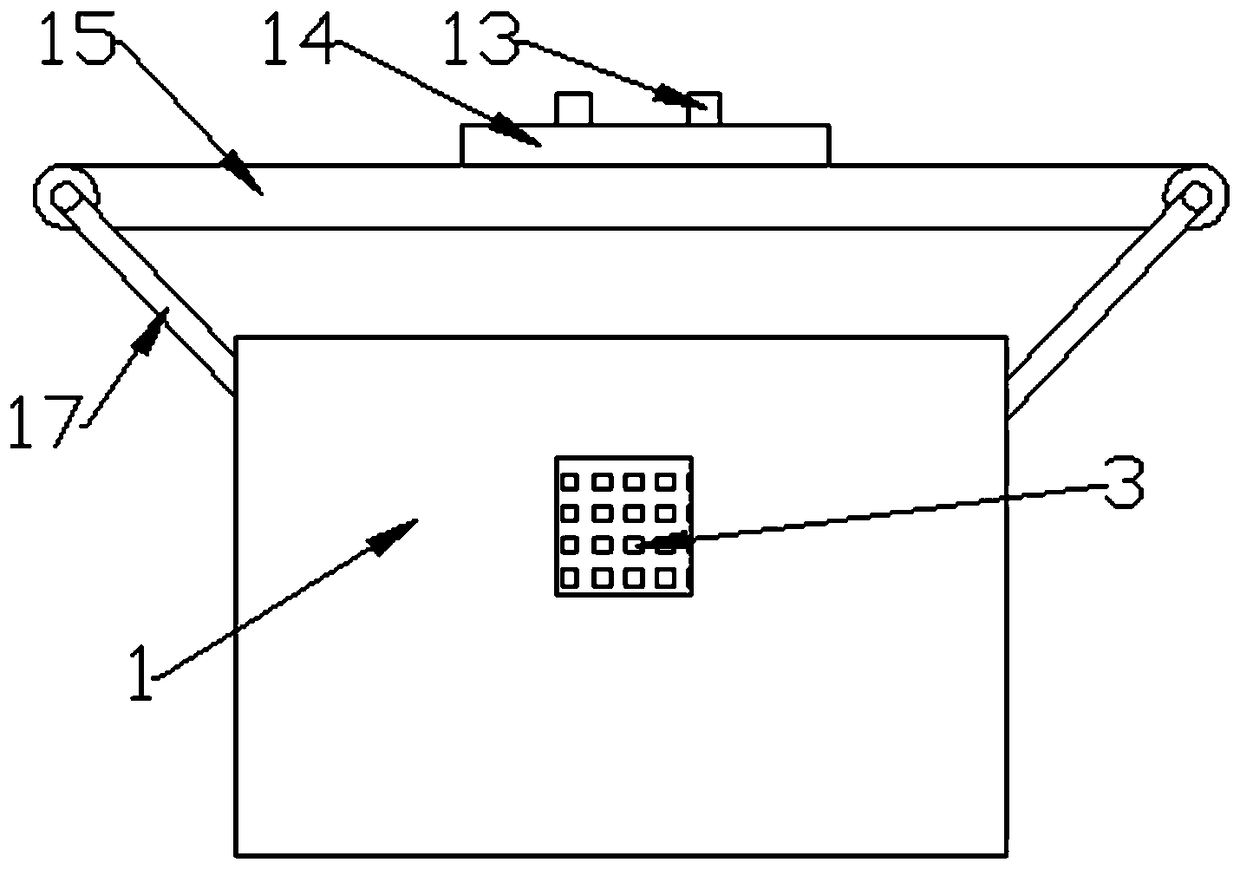

Polishing device for dustless building grounds

InactiveCN107097110AReasonable structureInnovative designGrinding carriagesGrinding work supportsAgricultural engineeringDrive shaft

The invention discloses a polishing device for dustless building grounds. The polishing device comprises an extension column; the upper end of the extension column is connected with limiting bars; the upper end of the limiting bar on the left side is connected with a driven walking wheel; the middle part of the driven walking wheel is connected with a driven shaft; the upper end of the limiting bar on the right side is connected with a driving walking wheel; the middle part of the driving walking wheel is connected with a driving shaft; limiting frames are connected to two ends of the driving shaft; the upper ends of the limiting frames are connected with a mounting plate; the upper end of the mounting plate is connected with a walking motor; the left end of the walking motor is connected with a driving belt wheel; the lower end of the driving belt wheel is connected with a driven belt wheel through a belt; a walking frame is connected between the driven shaft and the limiting frame on the left side; the middle part of the walking frame is connected with a driving box; the lower end of the driving box is connected with a dust sucking cover; and the lower end of the extension column is connected with a fixed base. The polishing device satisfies the polishing demands on the building grounds, prevents workers from being supported by a polishing machine to polish, reduces the labor intensity of construction workers, meanwhile, improves the polishing efficiency of the building grounds, and is high in practicability.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

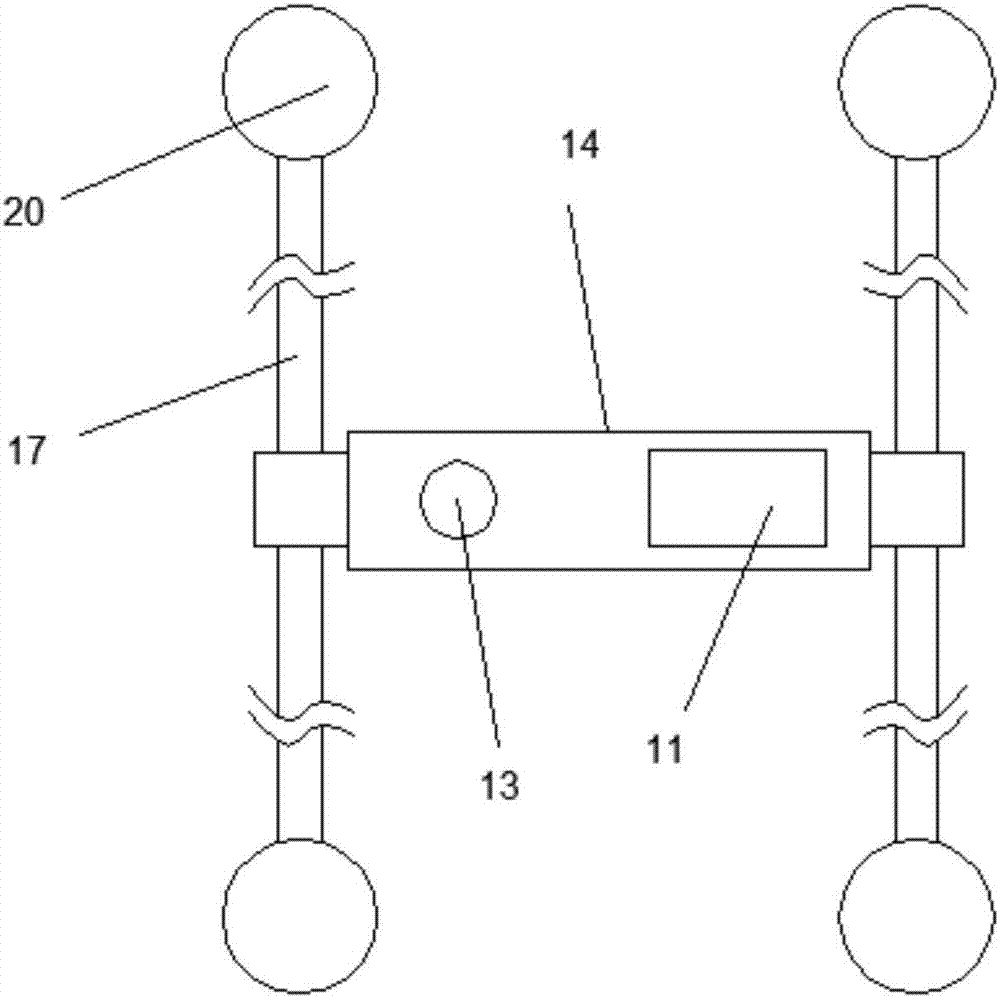

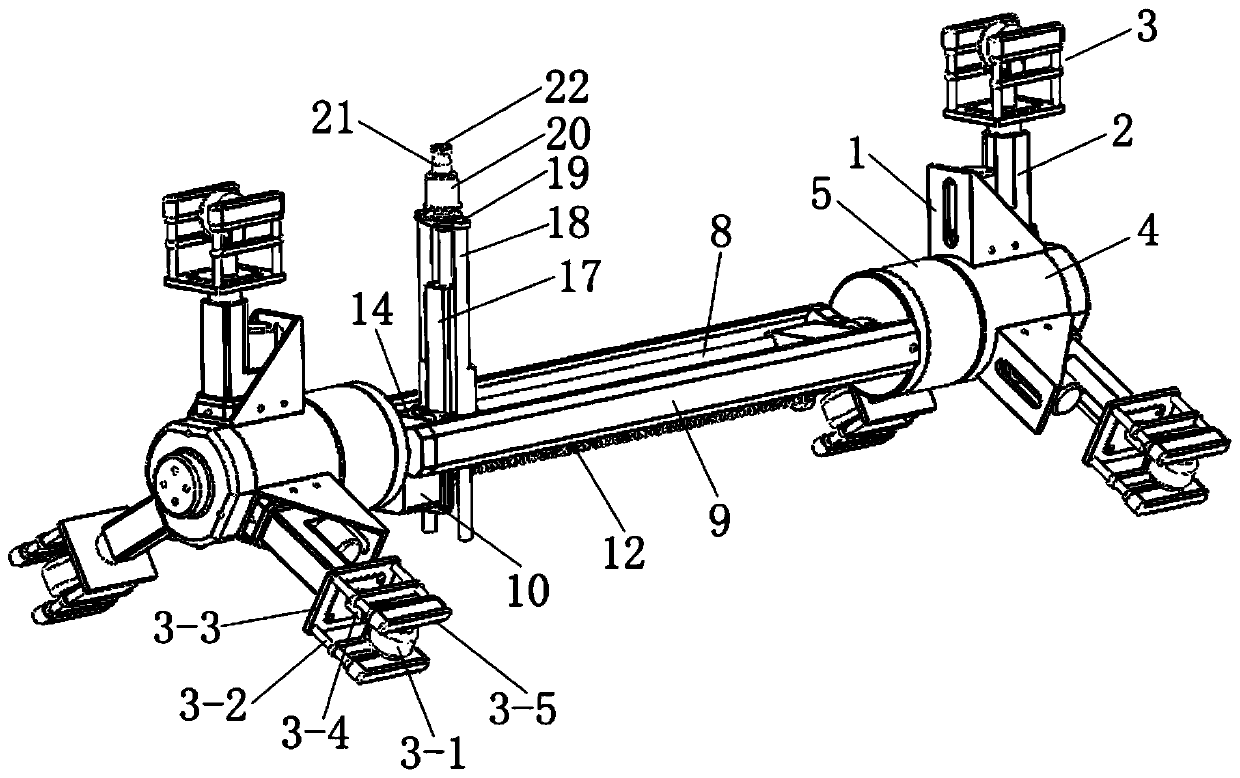

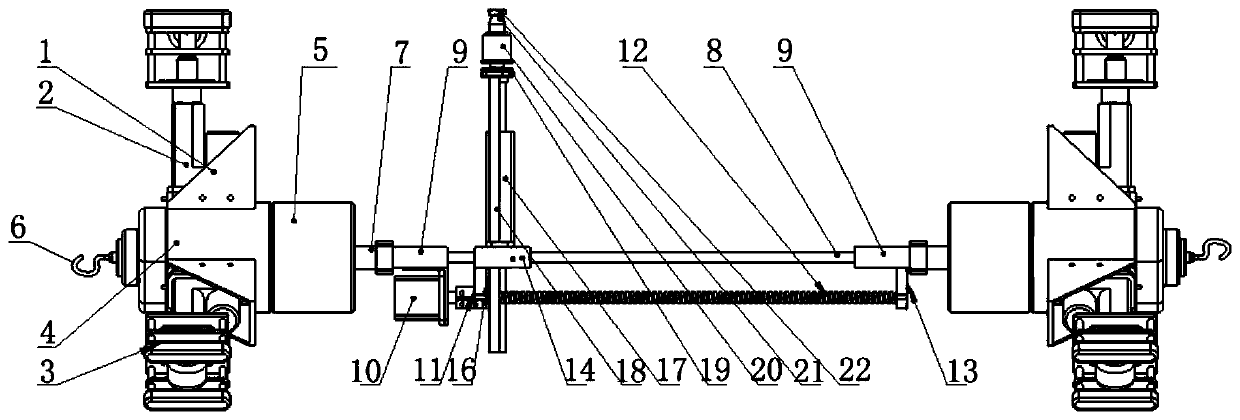

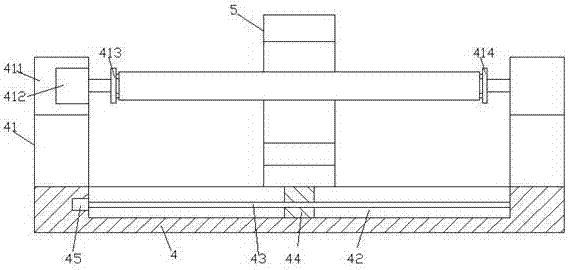

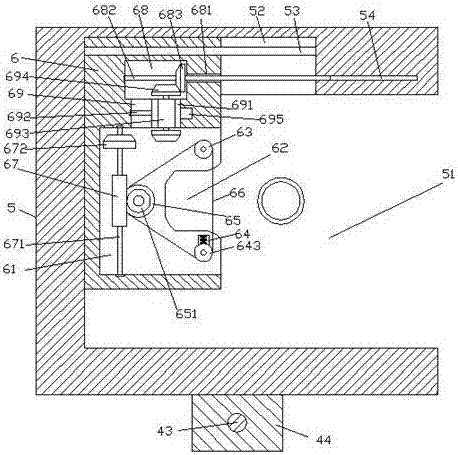

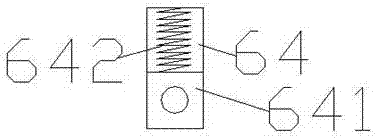

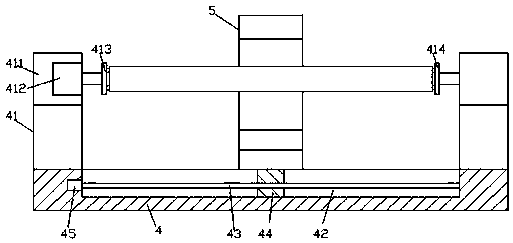

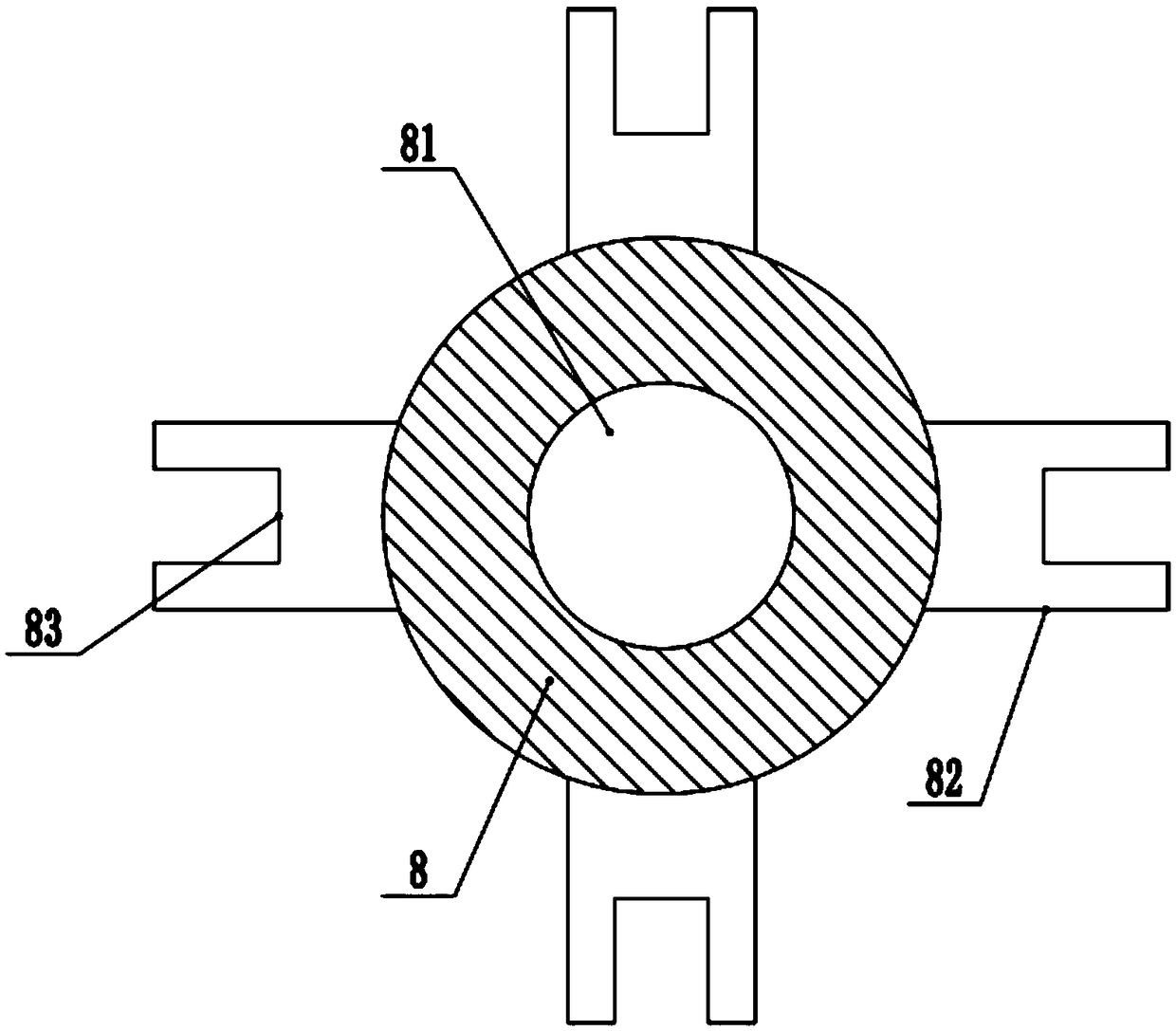

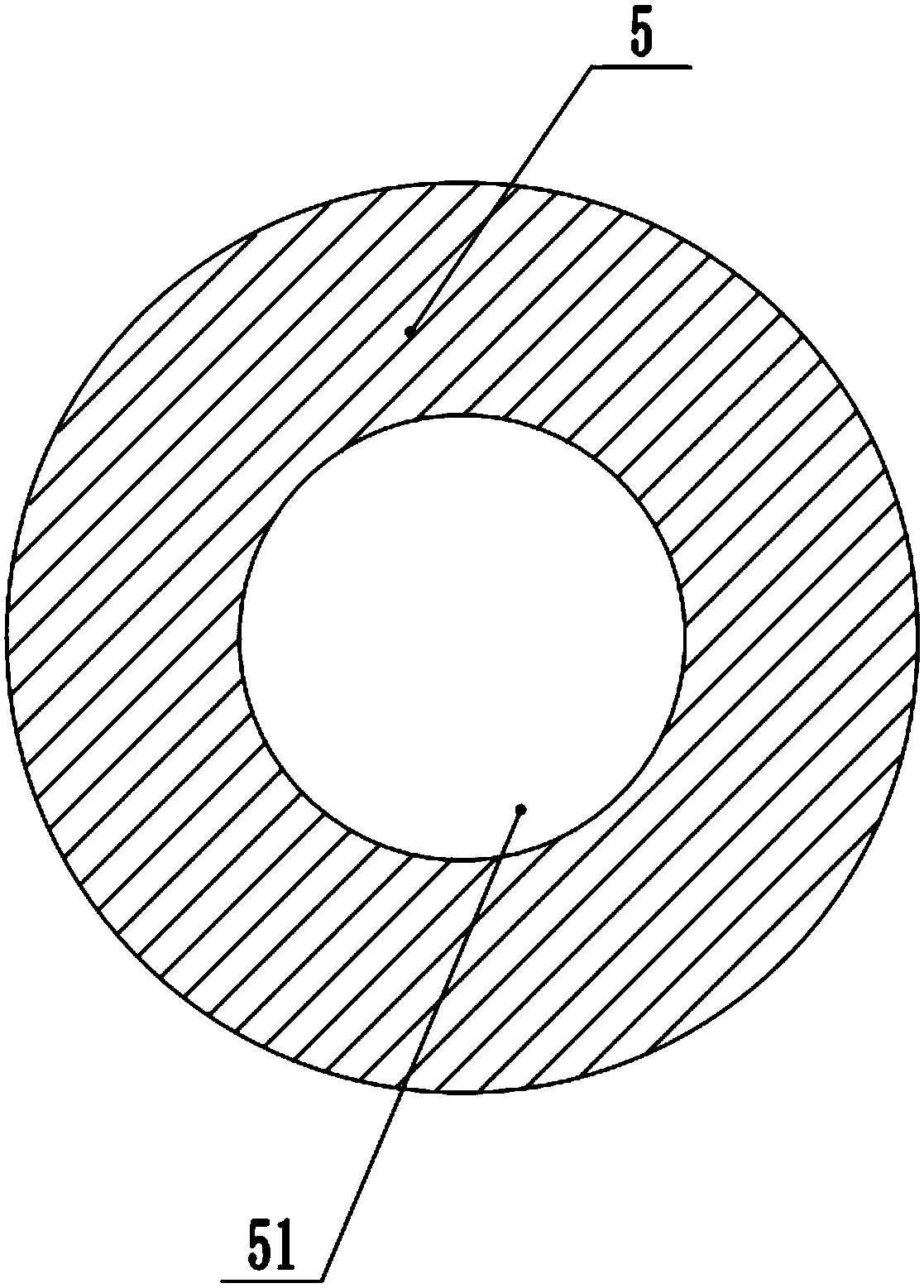

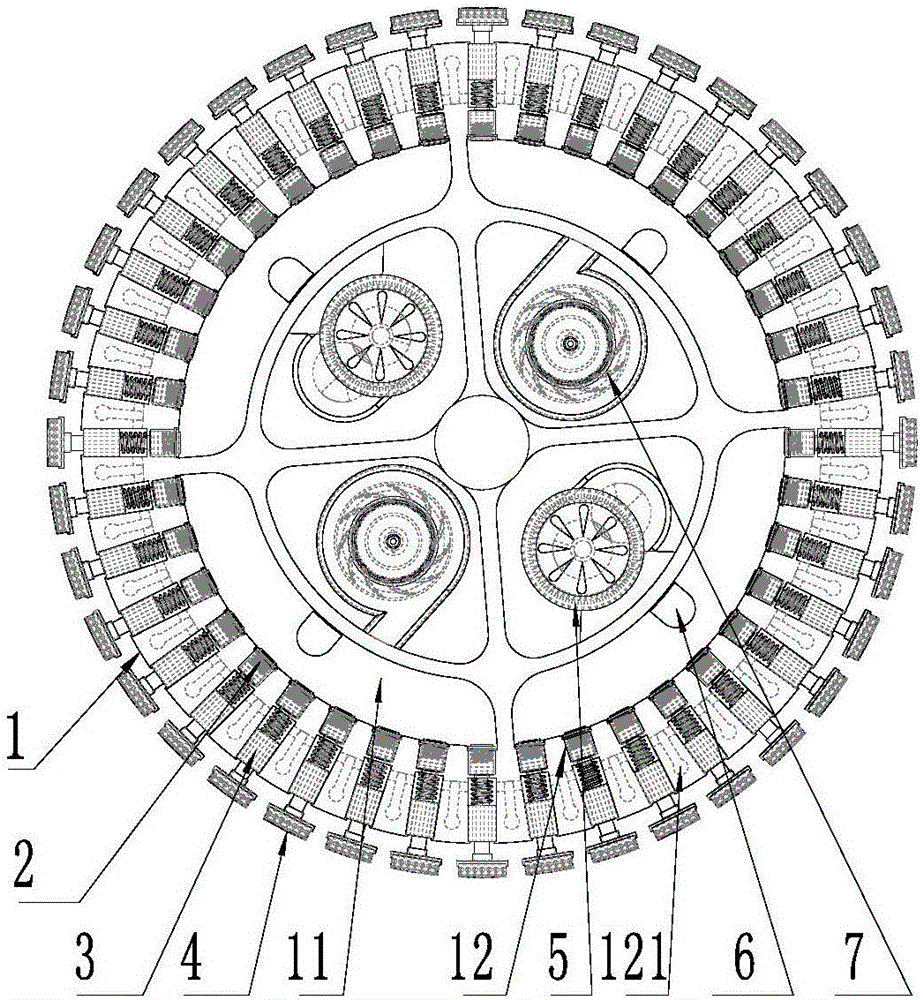

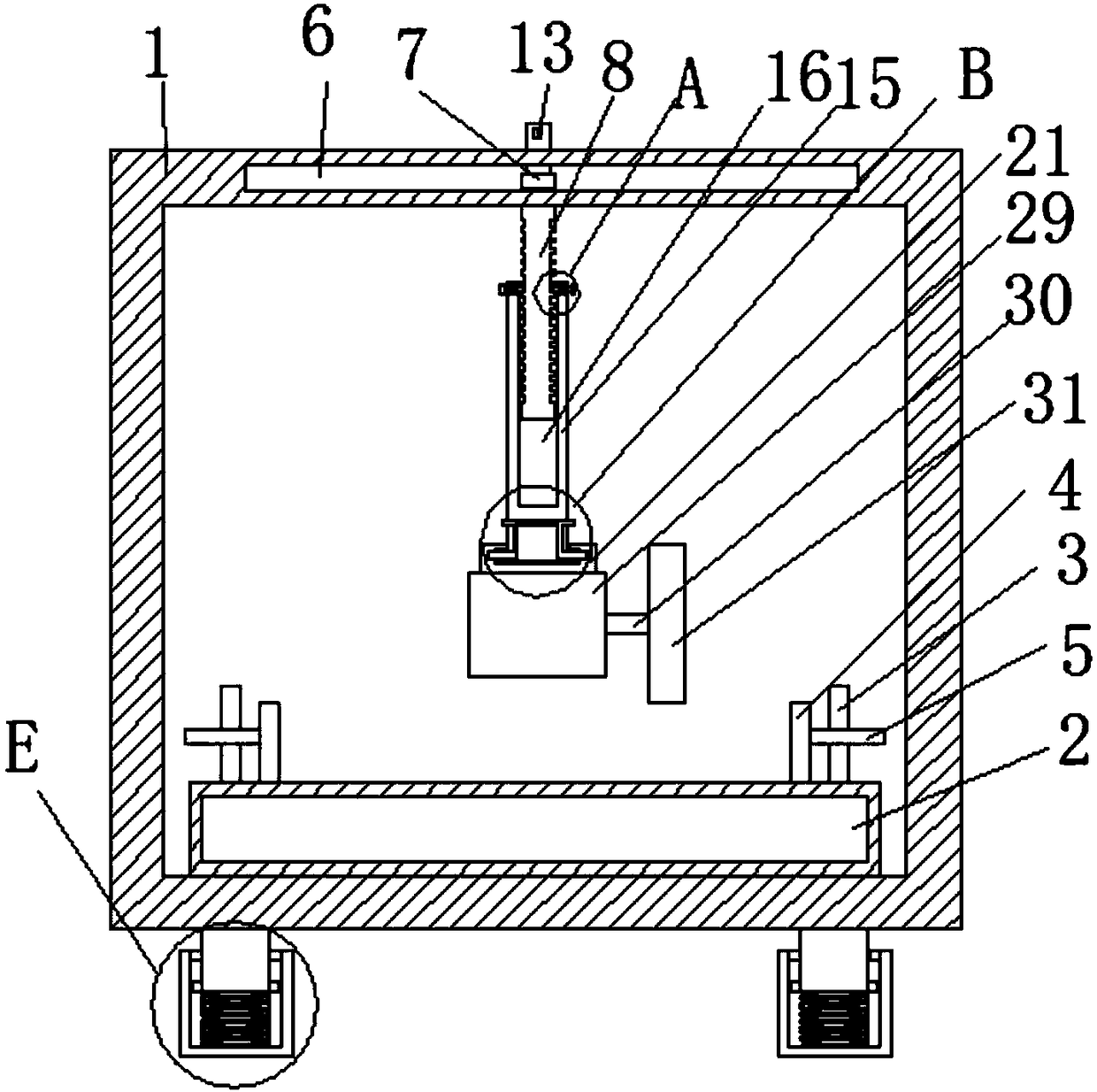

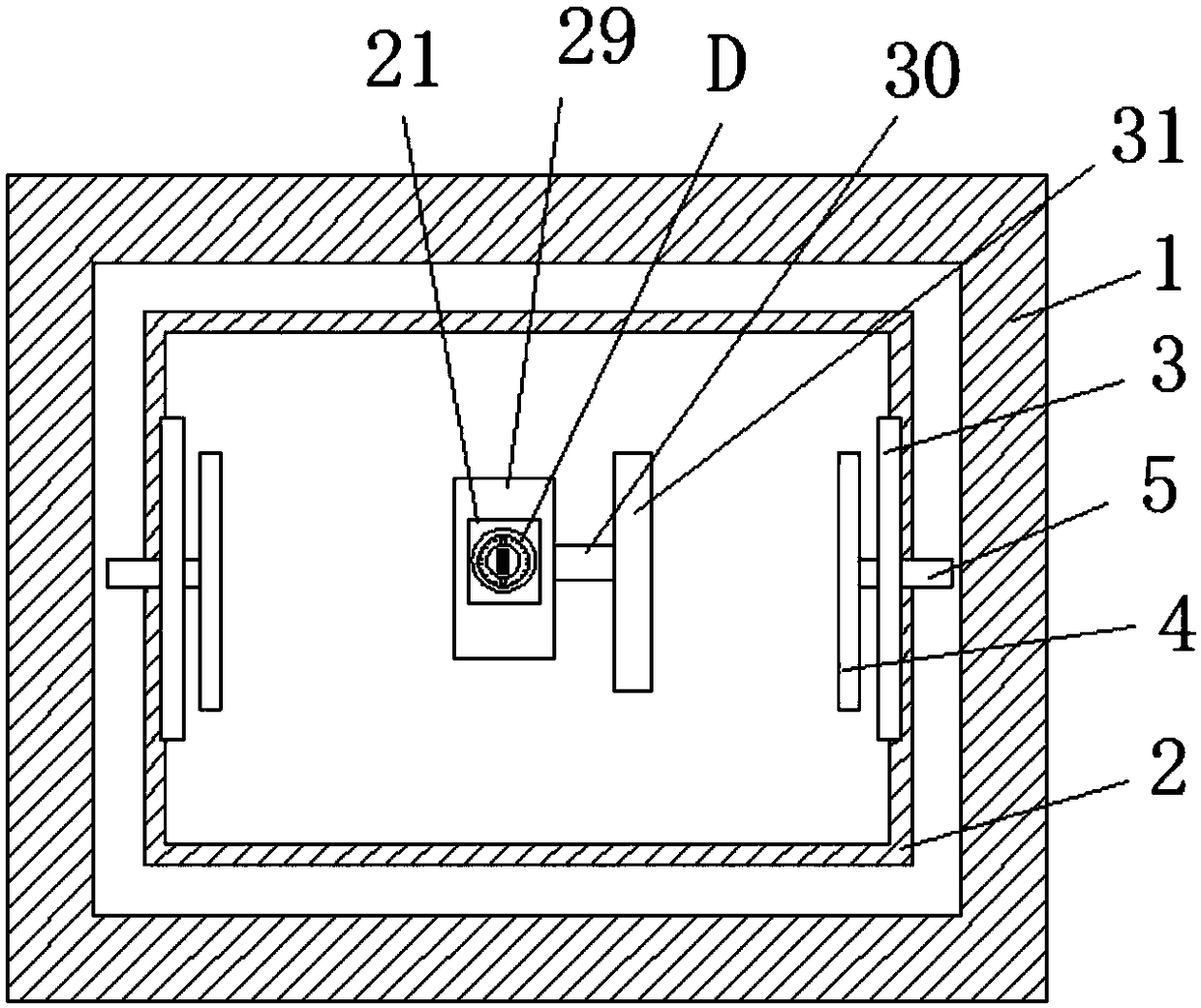

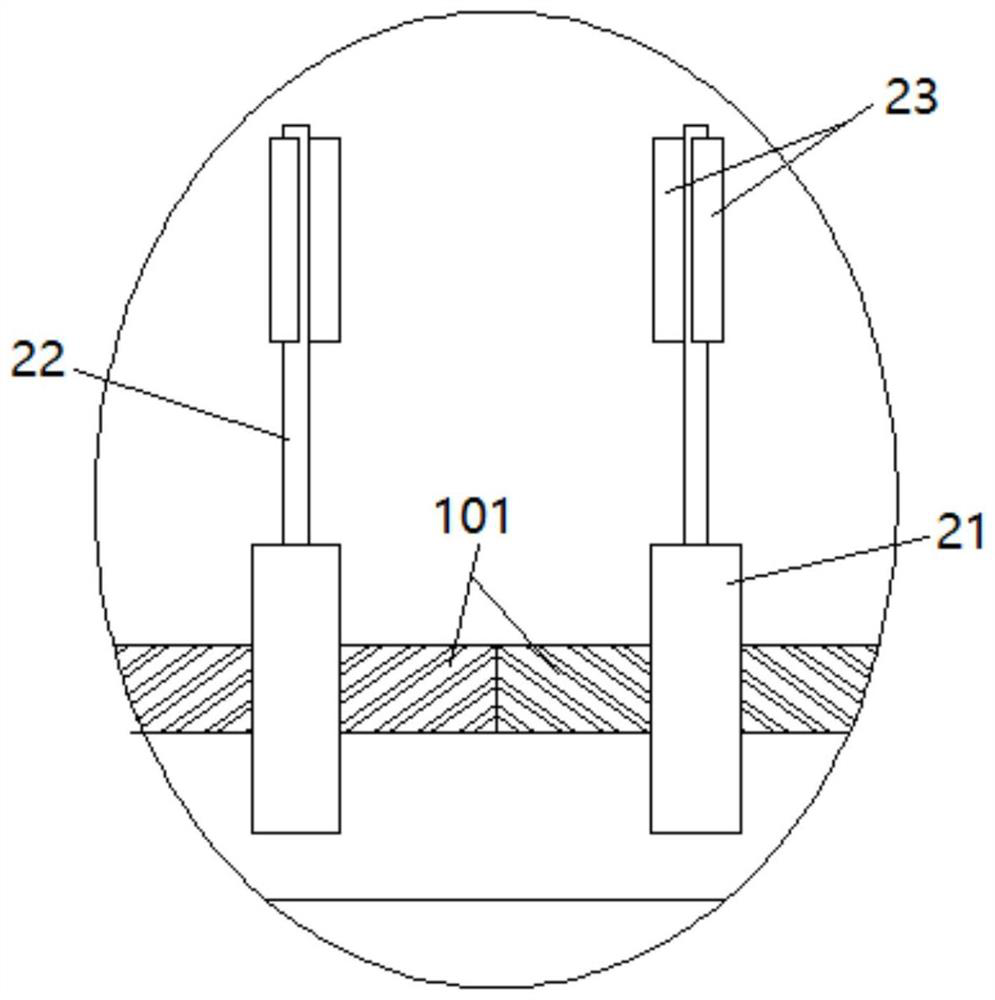

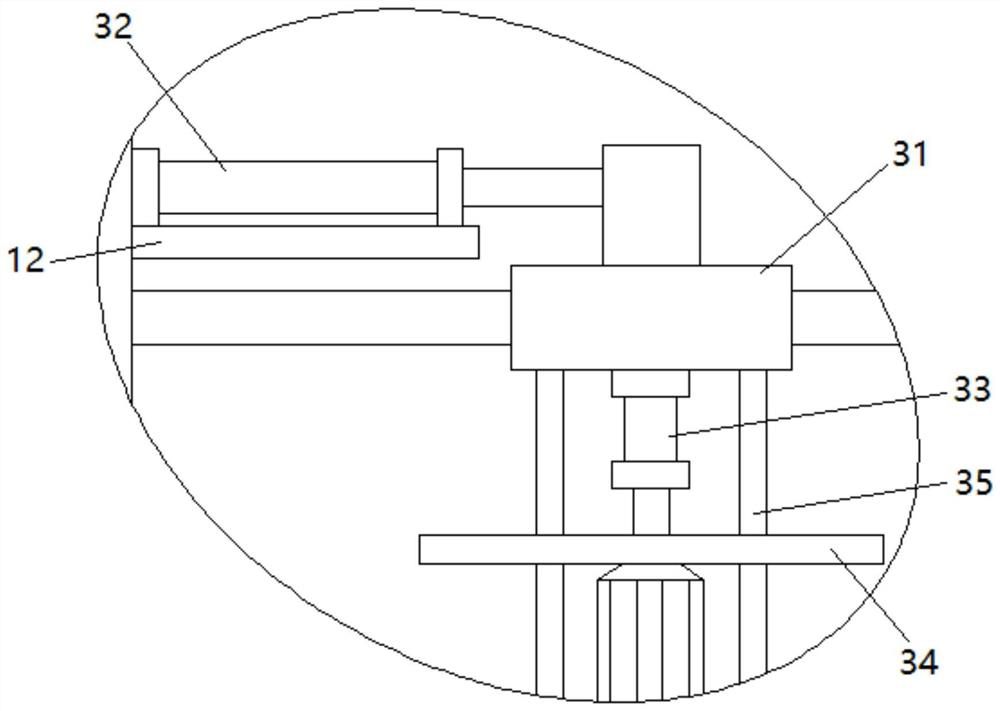

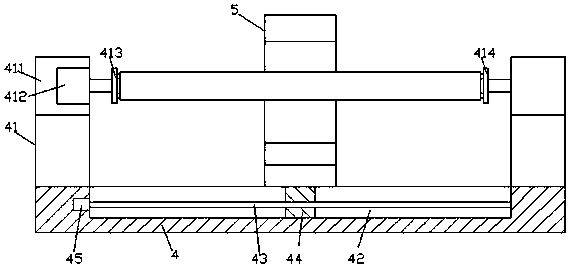

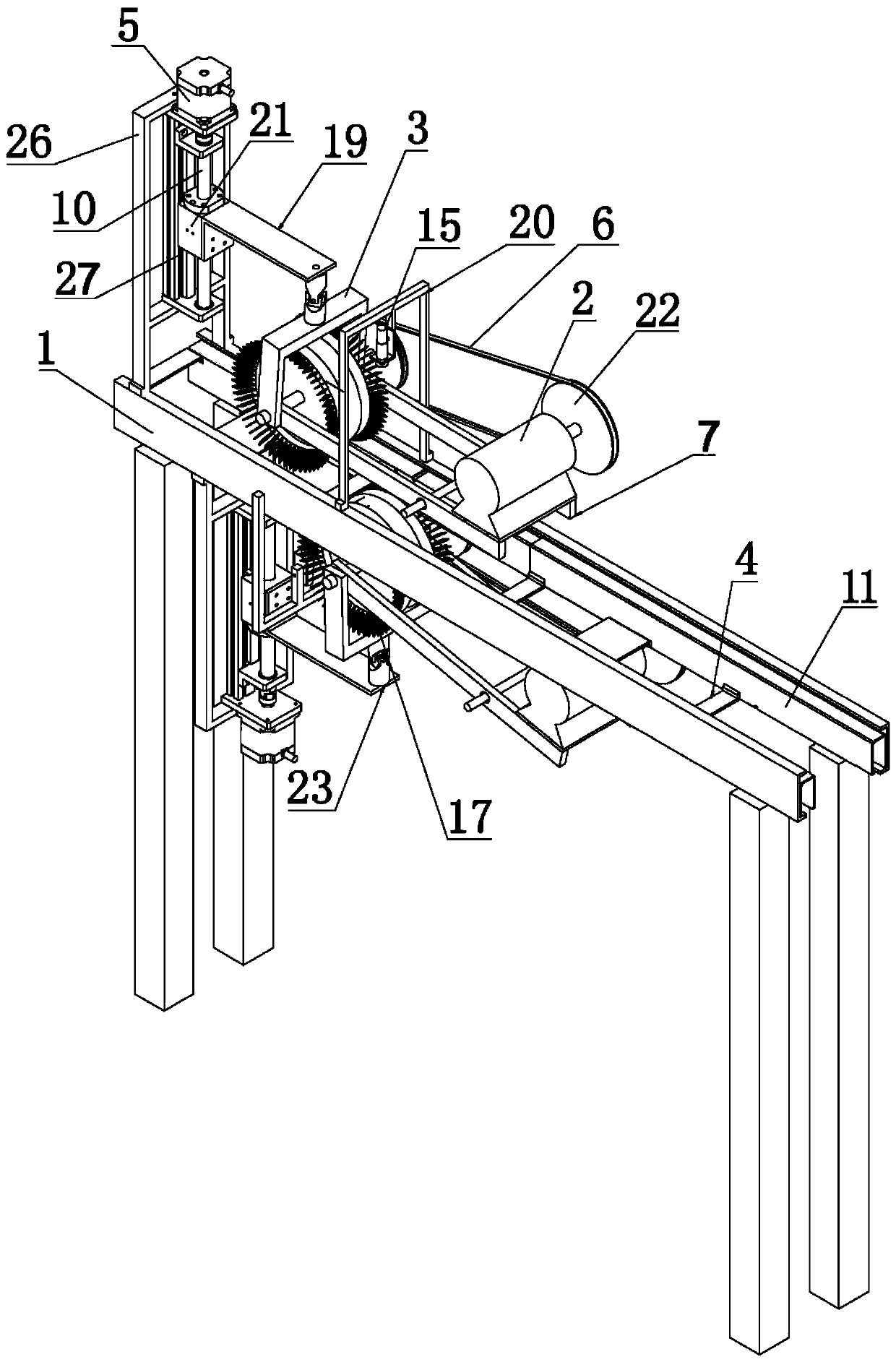

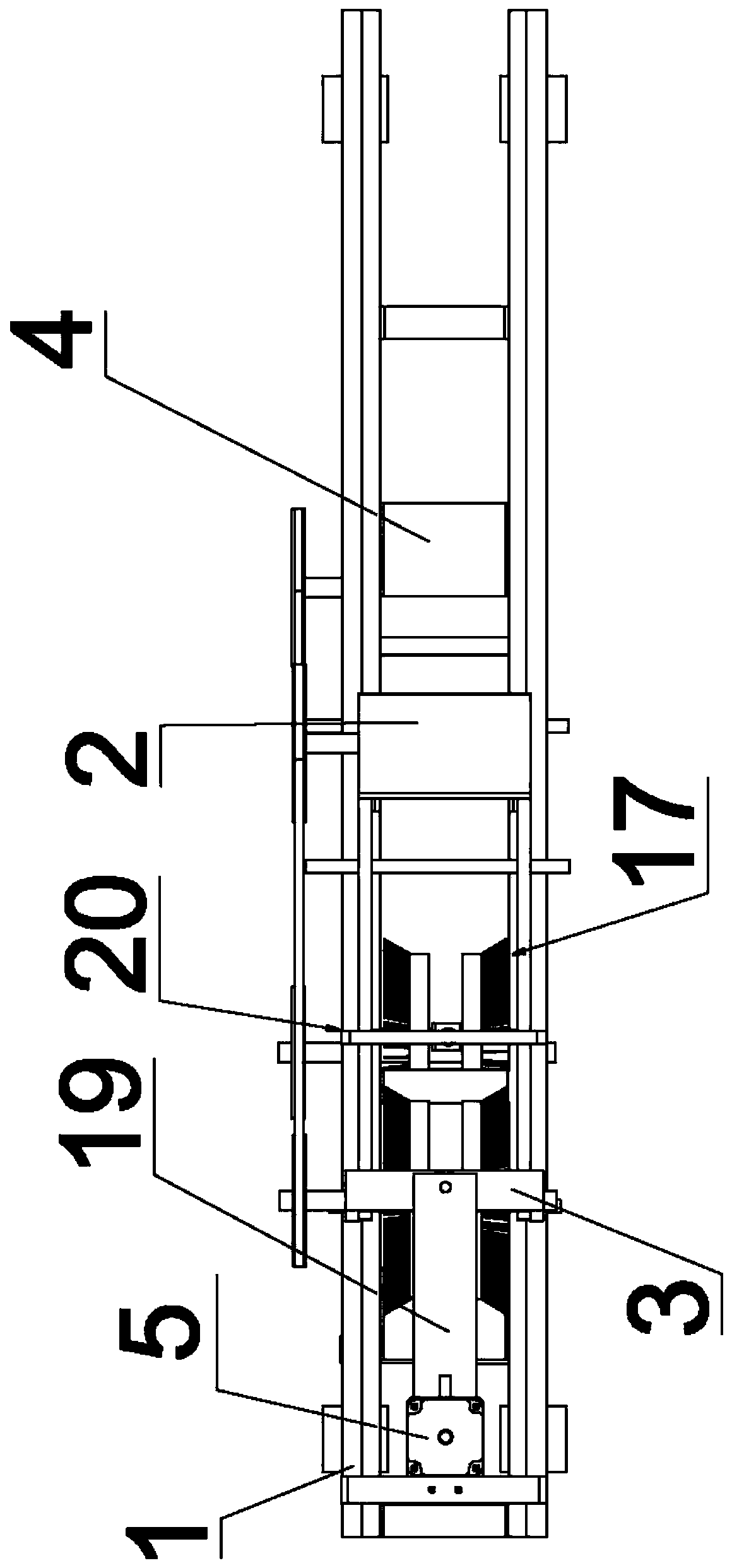

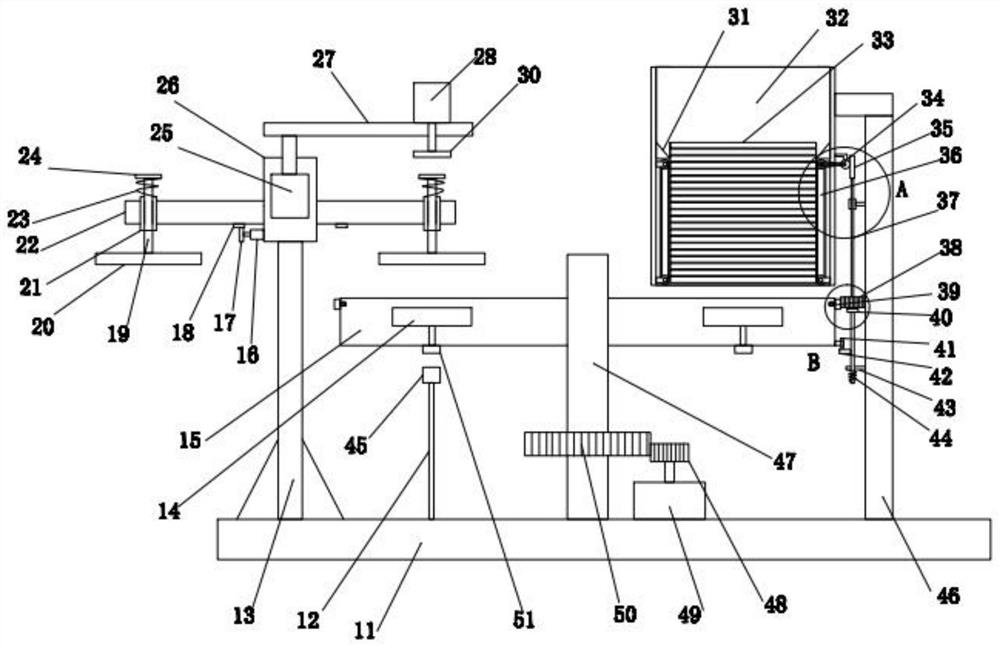

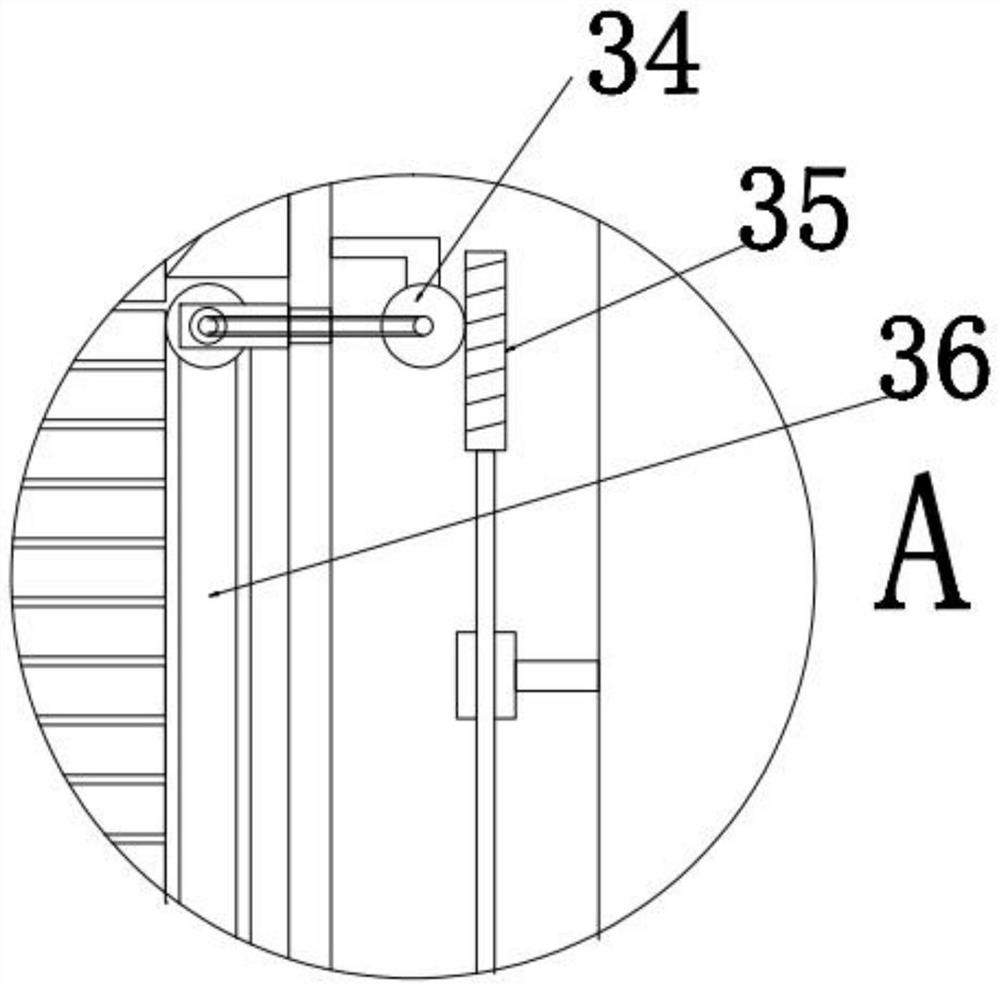

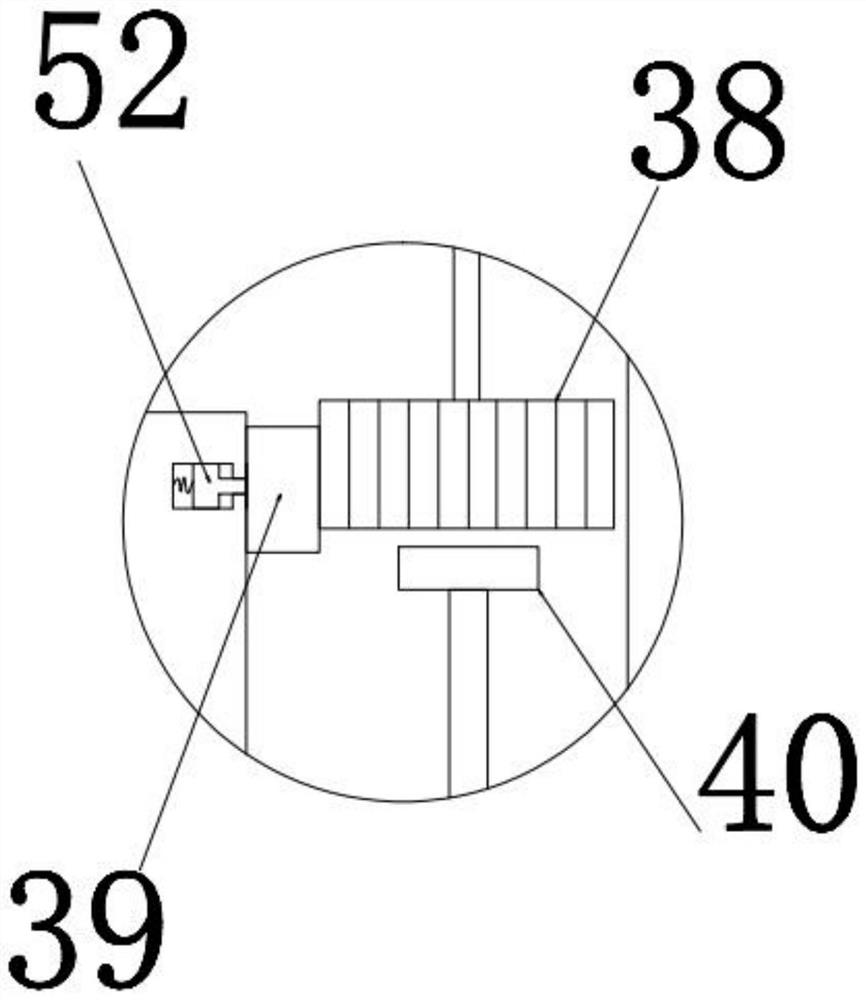

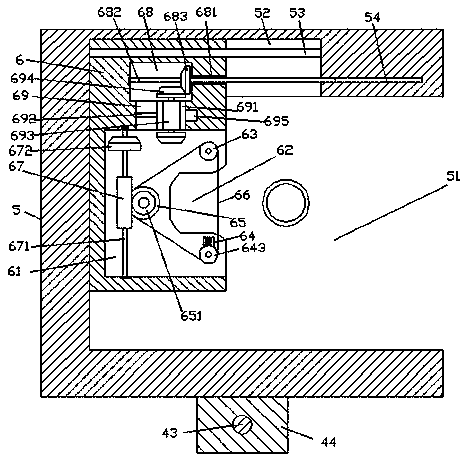

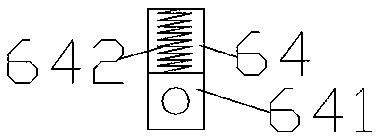

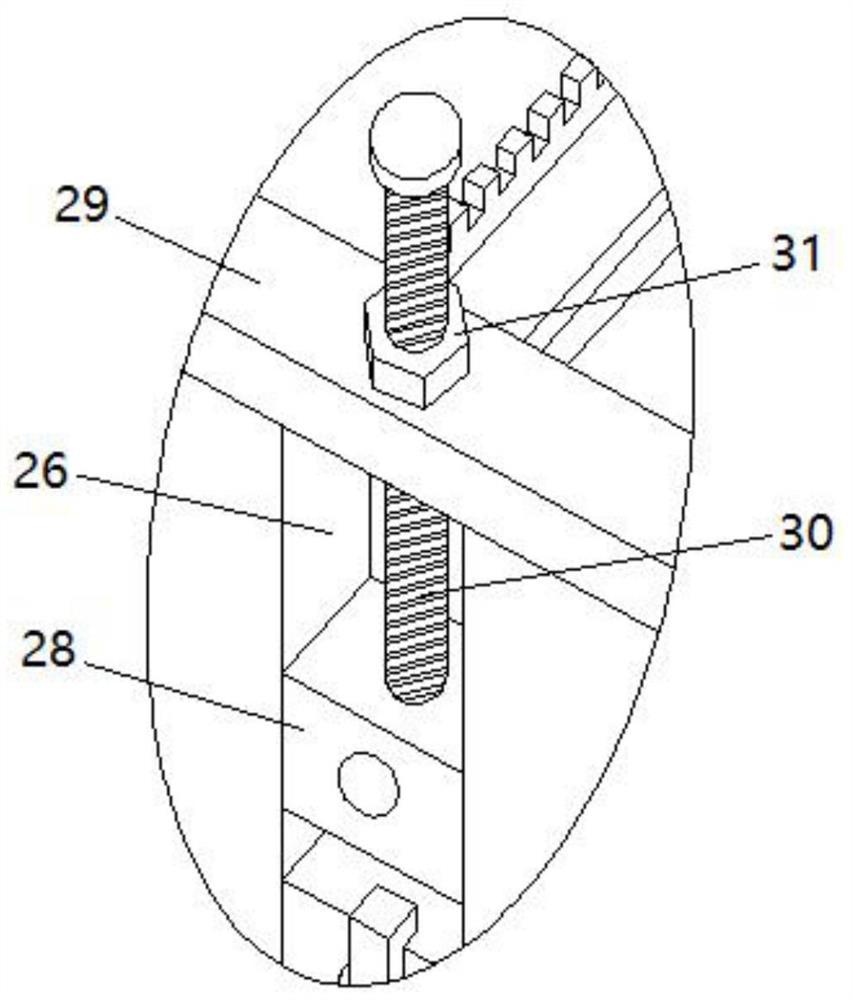

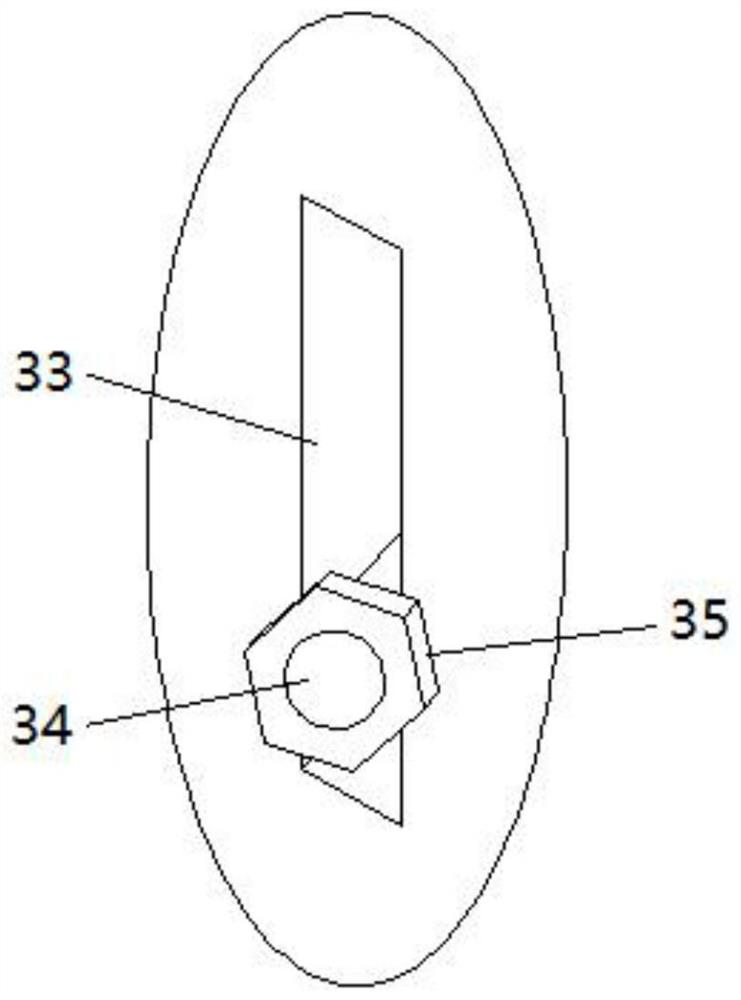

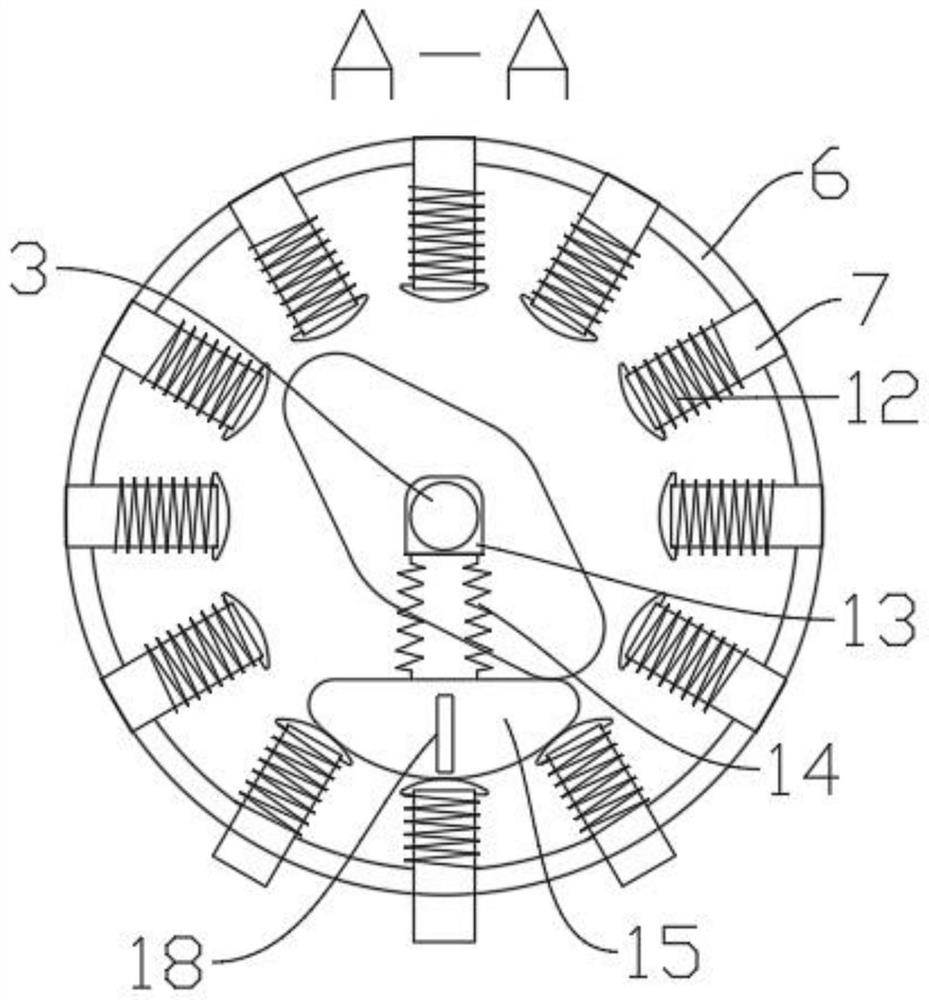

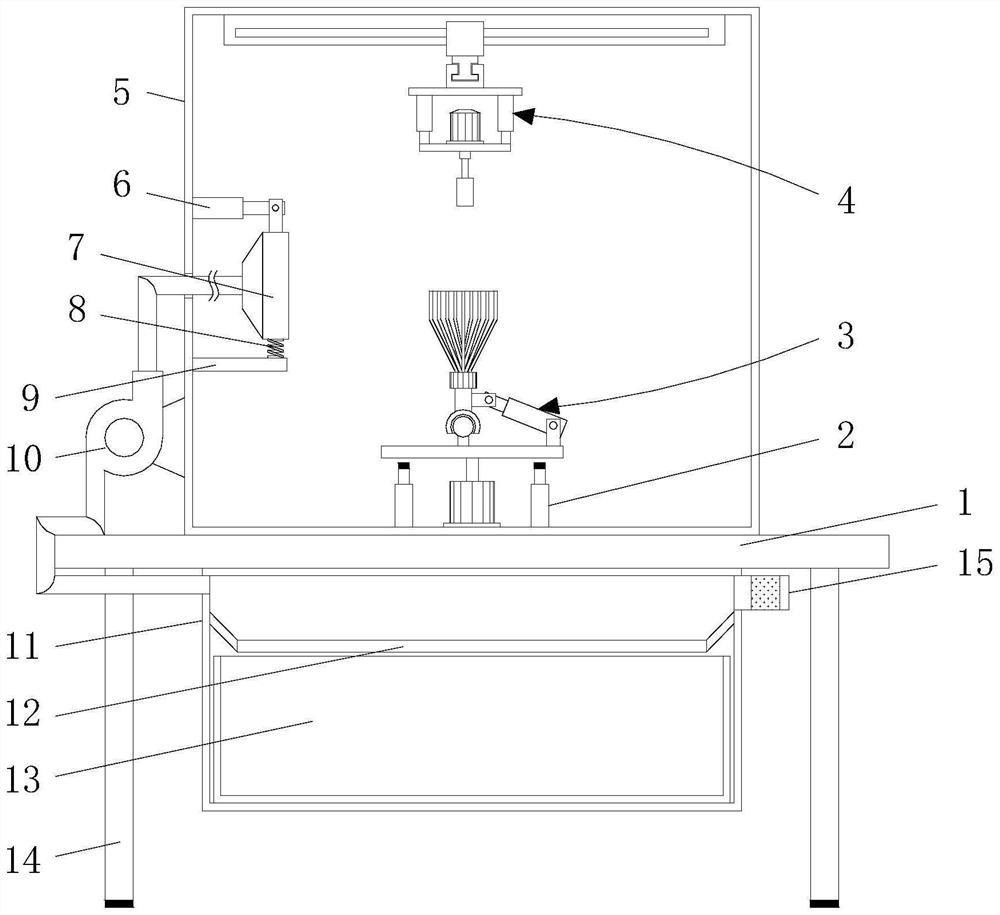

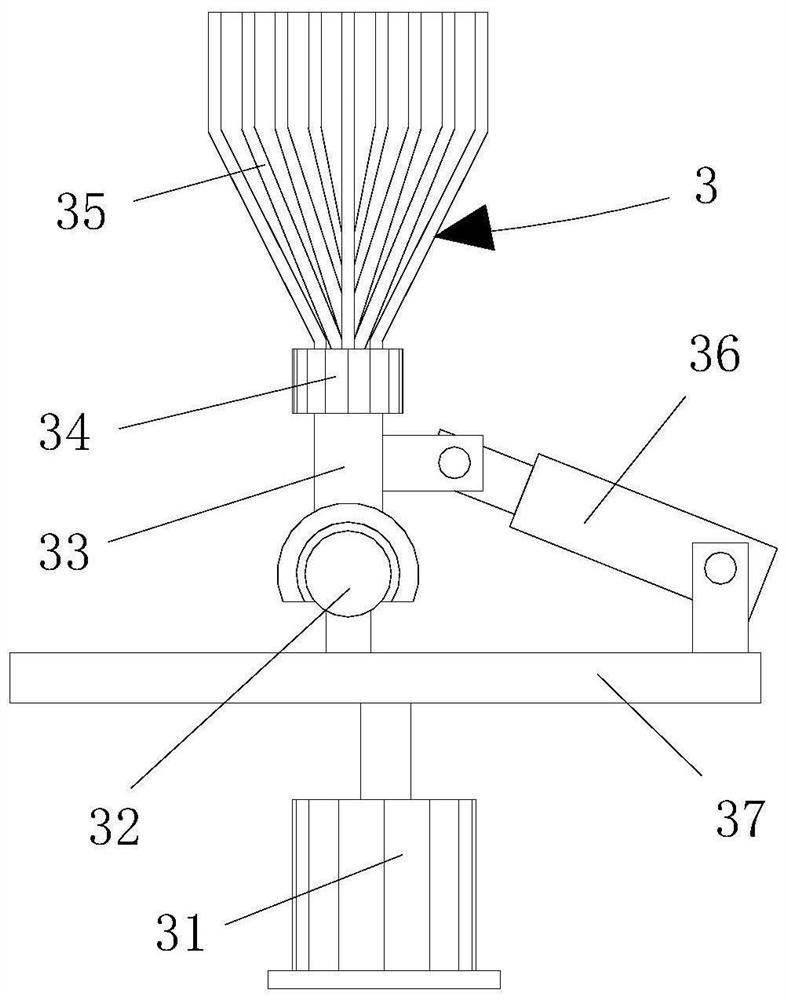

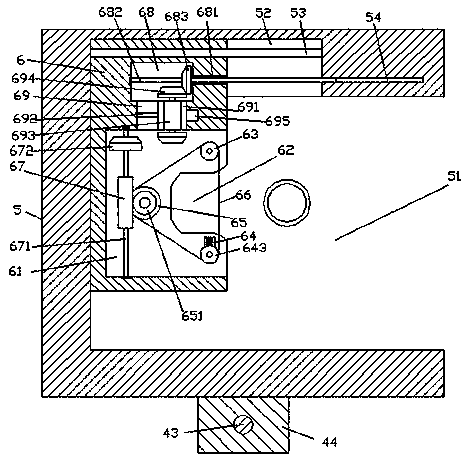

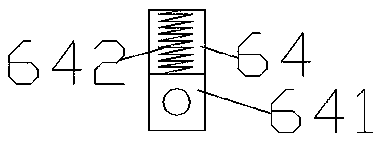

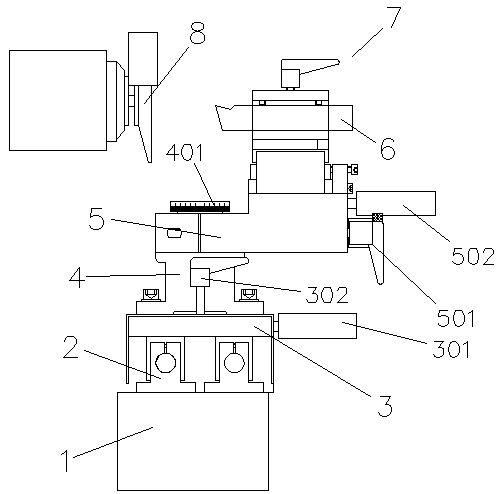

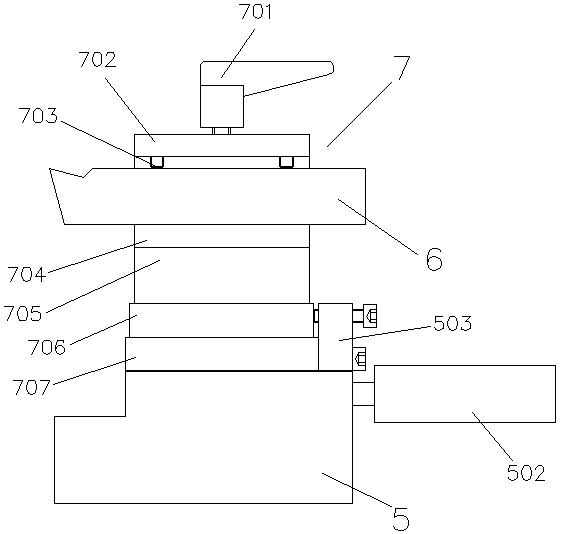

Spiral pipe inner wall weld joint grinding device

InactiveCN110421201AMeet the needs of welding seam grindingSatisfy grinding needsMilling machinesMilling equipment detailsSelf lockingEngineering

The invention relates to a spiral pipe inner wall weld joint grinding device. The spiral pipe inner wall weld joint grinding device comprises pipeline supporting mechanisms at the two ends, a rotary feeding mechanism and a grinding and executing mechanism, wherein each pipeline supporting mechanism comprises a central supporting seat and a plurality of movable supporting legs capable of self-locking, the movable supporting legs are evenly spaced along the circumferential direction and are arranged on the central supporting seat in a telescopic manner, the rotary feeding mechanism comprises anaxial sliding rod, a rotary servo driving device, a screw rod mechanism and an axial stepping motor, wherein the axial sliding rod and the screw rod mechanism are correspondingly arranged between thepipeline supporting mechanisms at the two ends in the axial direction, the axial sliding rod is driven to rotate through the rotary servo driving device, the screw rod mechanism is driven and controlled by an axial stepping motor, the grinding and executing mechanism is movably arranged on the axial sliding rod through a moving platform and is driven to move in the axial direction through the screw rod mechanism, and the grinding and executing mechanism is provided with a telescopic adjusting structure. According to the spiral pipe inner wall weld joint grinding device, mechanical grinding ofspiral welding joints on the inner wall of a spiral pipe can be realized, the stability is high, and the accuracy is good.

Owner:DONGHUA UNIV

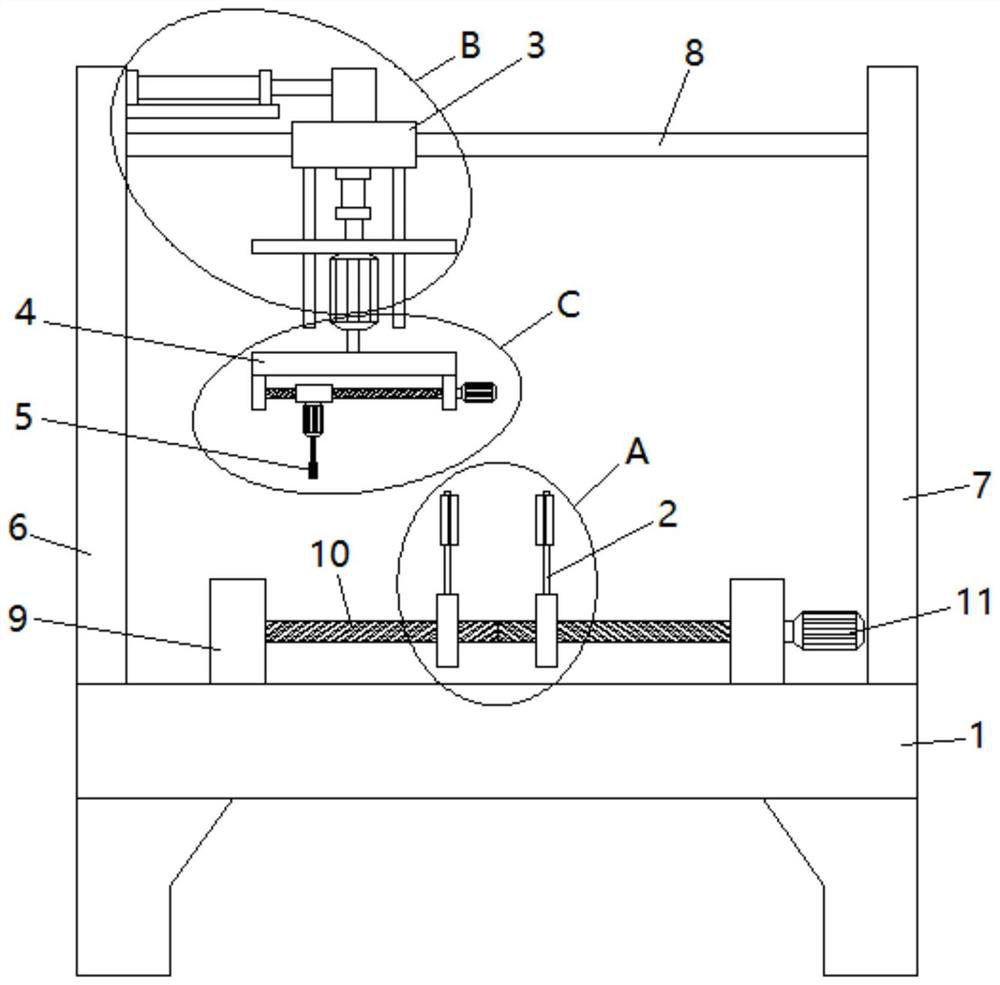

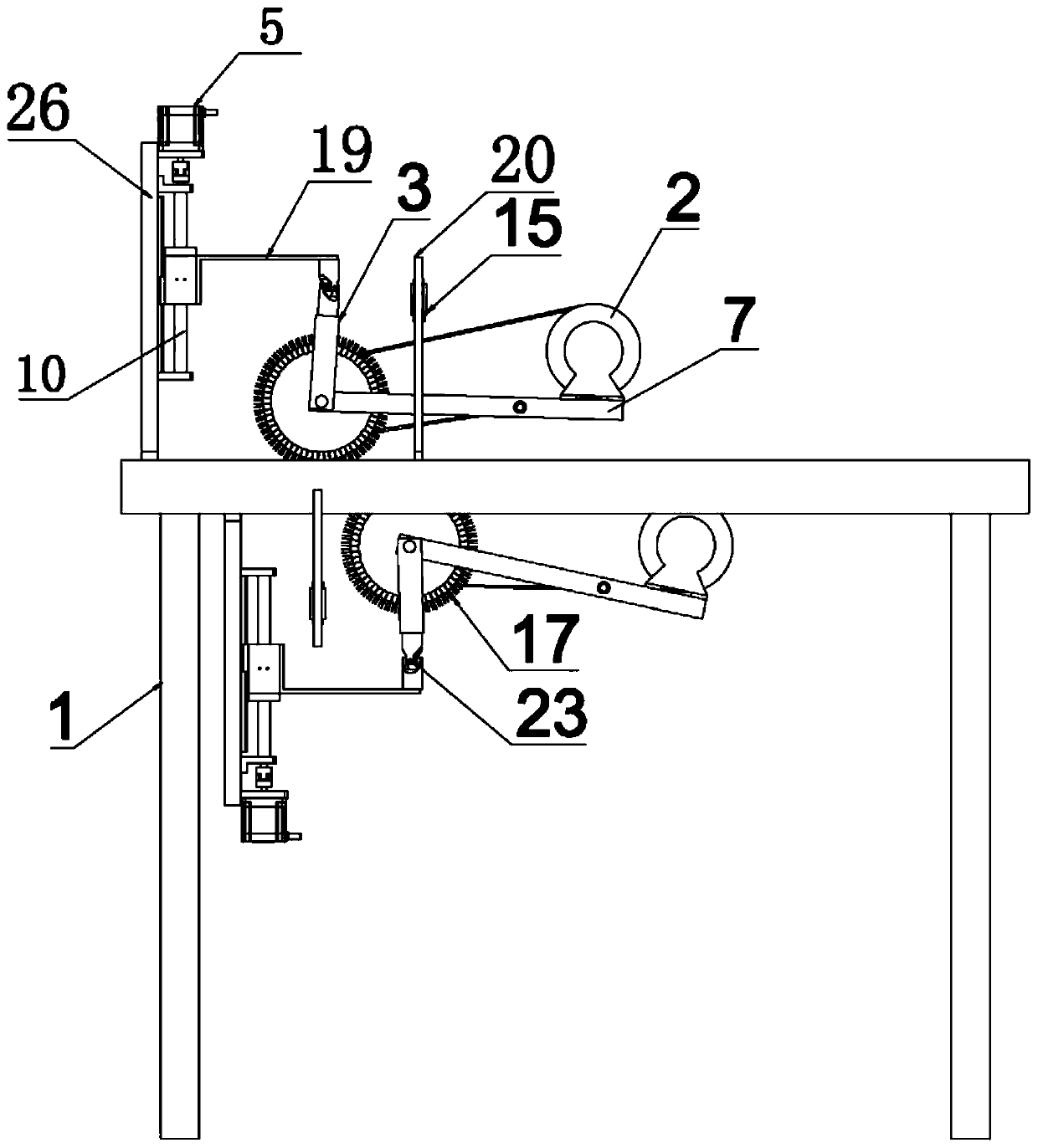

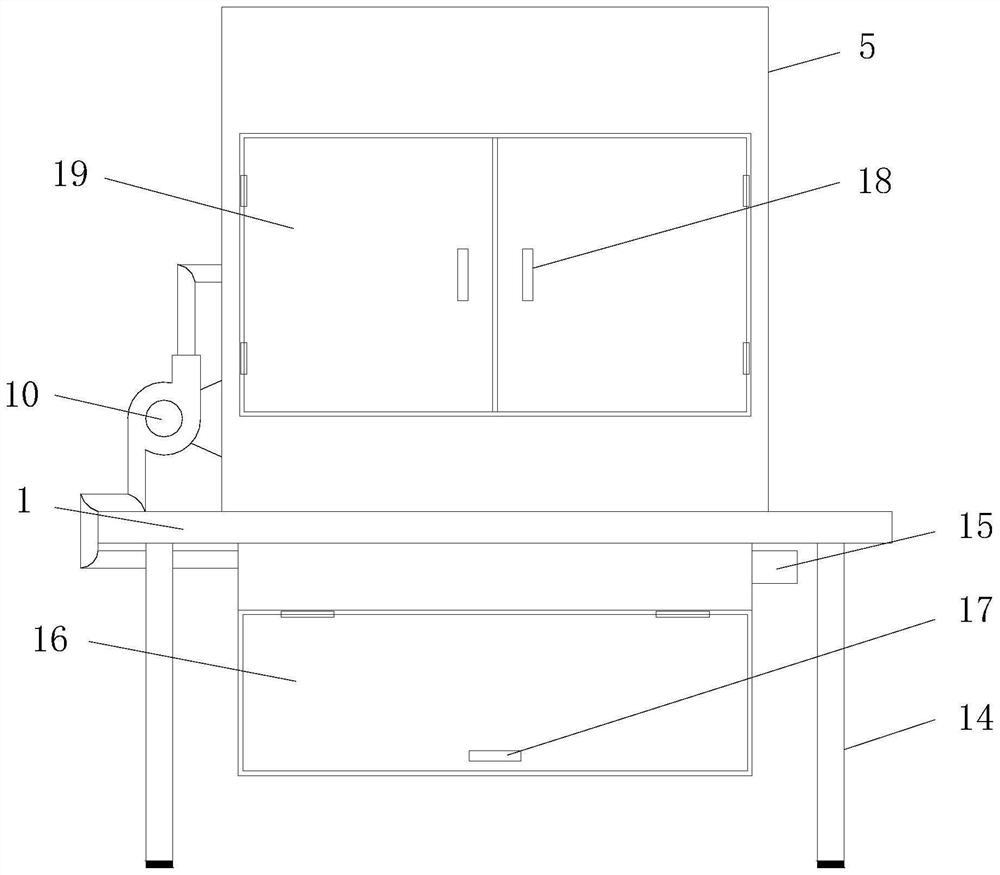

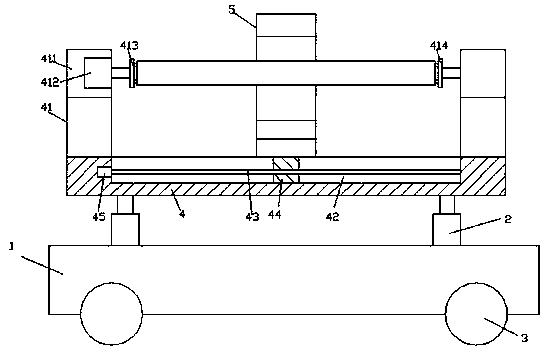

Welding seam polishing equipment of belt-type stainless steel pipe

InactiveCN106985039ARealize automatic controlAdjustable tension controlGrinding carriagesBelt grinding machinesAutomatic controlMotor drive

The invention discloses welding seam polishing equipment of a belt-type stainless steel pipe. The welding seam polishing equipment comprises a base frame and a polishing supporting frame arranged on the base frame; a containing groove is formed in the end face of the front side of the polishing supporting frame; a first sliding groove formed in a front-and-back extending manner is formed in the rear side of the top wall in the containing groove; a guide rod arranged in a front-and-back extending manner is arranged in the first sliding groove; a threaded hole extending to the front side is formed in the inner wall of the front side of the first sliding groove; the guide rod is slidingly matched with a polishing mechanism extending downwards; and a bottom extending section of the polishing mechanism stretches into the containing groove. The welding seam polishing equipment is simple in structure, reasonable in design, and low in manufacturing cost and maintenance cost; automatic control on switching of polishing transmission and movement control on the polishing mechanism can be realized, leftward and rightward movement work of the polishing supporting frame can be realized simultaneously, and the polishing requirements of different positions of a welding seam of the stainless steel pipe can be met; in addition, when a rotating motor drives the stainless steel pipe to rotate for achieving omnibearing welding seam polishing, the polishing efficiency is improved.

Owner:FOSHAN JINHAI HUIHUANG STAINLESS STEEL

Welding line polishing equipment of stainless steel pipes

ActiveCN107695835ARealize automatic controlAdjustable tension controlGrinding carriagesBelt grinding machinesMotor driveAutomatic control

The invention discloses welding line polishing equipment of stainless steel pipes. The equipment comprises a base frame, and a polishing support frame arranged on the base frame; an accommodating tankis formed in the front side end surface of the polishing support frame; a first slide groove extending front and back is formed in the back side of the top wall in the accommodating tank; a guide rodextending front and back is arranged in the first slide groove; a thread hole extending to the front side is formed in the inner wall of the front side of the first slide groove; the guide rod is slidingly matched and connected with a polishing mechanism downwards extending; and the bottom extension section of the polishing mechanism extends into the accommodating tank. The equipment is simple instructure, reasonable in design and low in manufacturing cost and maintenance cost, can realize automatic control of switching between polishing and transmission and mobile control of the polishing mechanism, meanwhile, can realize left-right moving work of the polishing support frame, and satisfies the polishing demands of different welding line positions of the stainless steel pipes; and in addition, when a rotating motor drives the stainless steel pipes to rotate to realize comprehensive welding line polishing, the polishing efficiency is improved.

Owner:NINGXIA DEXING & HENGTONG PIPE IND

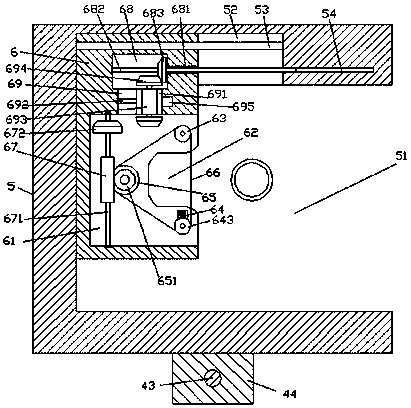

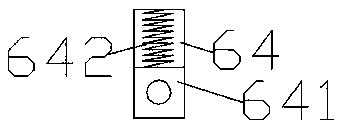

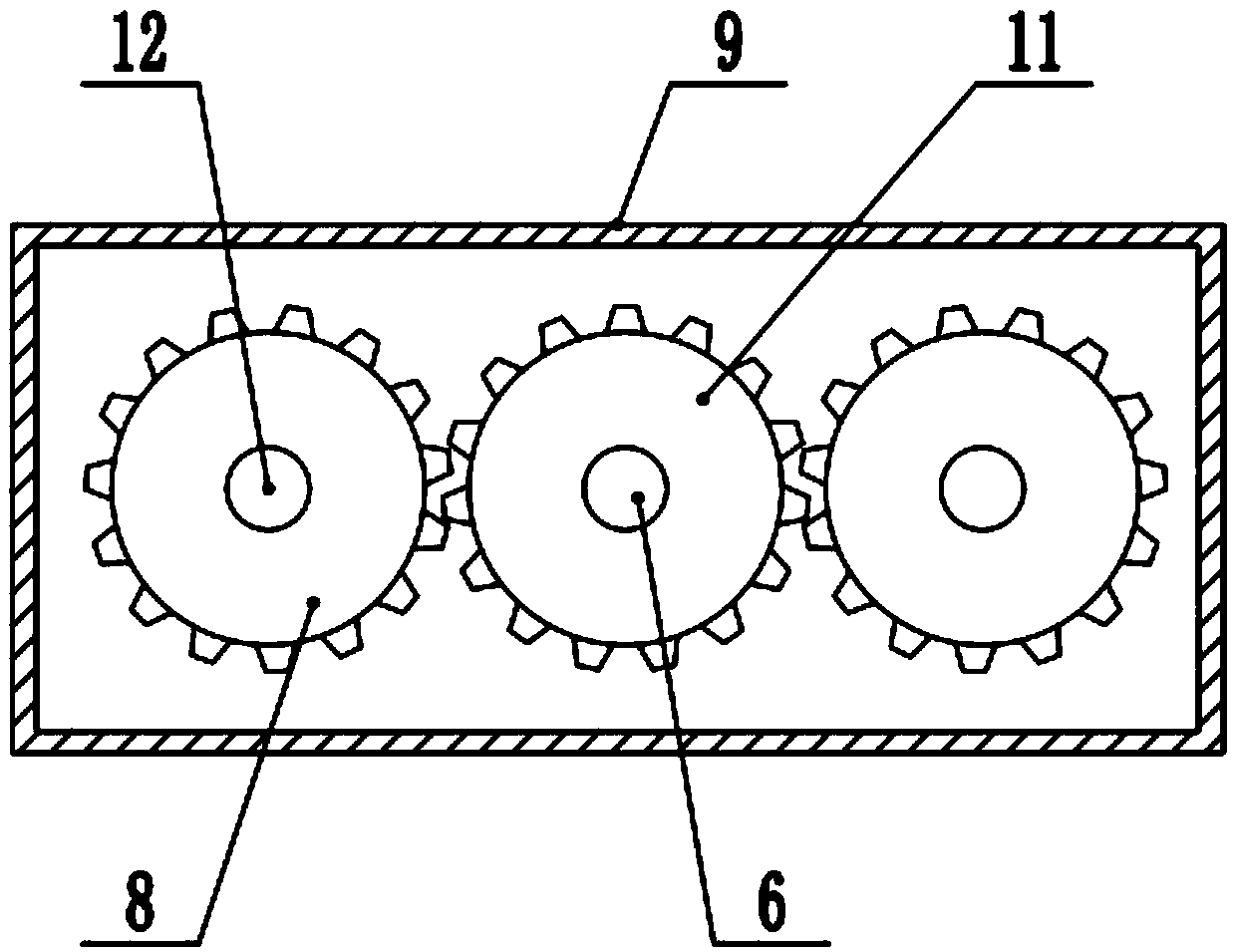

A machine for grin and repairing weld seam for welding automobile pipe fittings

InactiveCN108890480AReasonable structureInnovative designGrinding carriagesGrinding drivesDrive shaftGear wheel

A machine for grin and repairing weld seam for welding automobile pipe fittings Including bottom plate, A support frame is connecte to that left side of the upper end of the bottom plate, A left end of that support frame is connecte with a feeding box, An upper and low ends of that inlet tank are connecte with a fixing frame, A material inlet roll is arranged in that middle of the fix frame, At that right end of the support frame, A rotary screw is arranged inside the fixed cylinder, A rotary gear is connected with the middle part of the outer side of the rotary screw, A low end of that rotarygear is meshed with a drive gear, At that left end of the drive gear, a drive shaft is connecte with the left end of the driving shaft, a drive motor is connecte with the left end of the driving shaft, a slider is connecte with the middle part of the rotating screw, a guide block is uniformly connected with the outer side of the slider, a mounting groove is connected with the outer side of the guide block, a connecting rod is connected with the middle part of the mounting groove, a tie rod is connected with the right end of the connecting rod, a grinding wheel frame is connected with the middle part of the grinding wheel frame, and a grinding wheel is connected with the middle part of the grinding wheel frame. The invention realizes the adjustment of the distance between the grinding wheels and meets the needs of grinding the end faces of automobile pipe fittings with different diameters.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

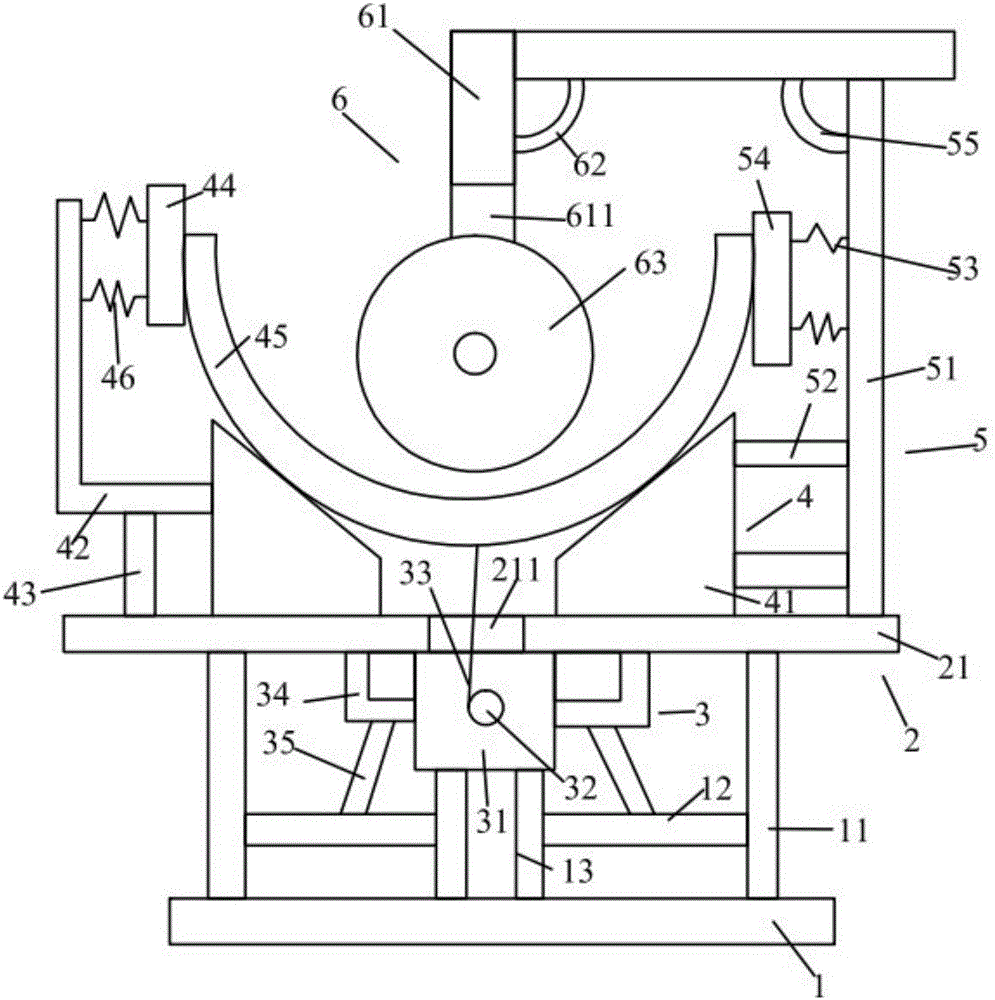

Board section fixed grinding equipment applicable to the field of furniture processing

ActiveCN106625078AEffectively fixedFixed grinding is effectiveGrinding carriagesGrinding work supportsElectric machineEngineering

The invention discloses board section fixed grinding equipment applicable to the field of furniture processing. The board section fixed grinding equipment comprises a base plate, a support device, a supporting device, a fixed device, a first grinding device, a lifting device, a second grinding device, a first motor device and a second motor device, a first supporting block and a first idler wheel are arranged on the base plate, the support device comprises a first cross rod, a first supporting rod, a first cross plate, a first locating frame, a first support, a first spring, a second cross rod, a first abutting-leaning rod, a first abutting-leaning plate and a first bent rod, the support device comprises a abutting- wheel, a second abutting- leaning rod, a first vertical rod, a curving plate, a second vertical rod, a first location rod, a second spring, and a third spring, the fixed device comprises a second cross plate, a second supporting rod, and a third supporting rod, and the first grinding device comprises a first motor, a first output shaft, a second support, a fourth supporting rod, a rotating rod, a first grinding wheel and a first bracing wire. According to the board section fixed grinding equipment applicable to the field of furniture processing, effective fixation can be conducted on a panel when the panel is grinded, so that the grinding is more accurate.

Owner:GUANGZHOU LANGU HOUSEHOLD TECH CO LTD

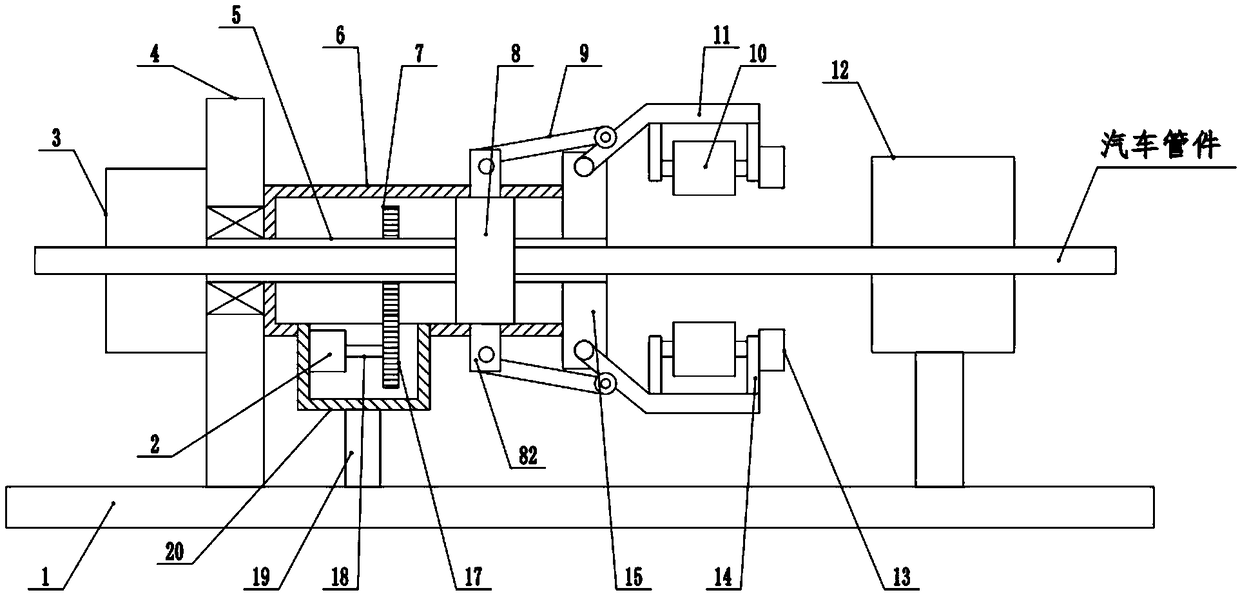

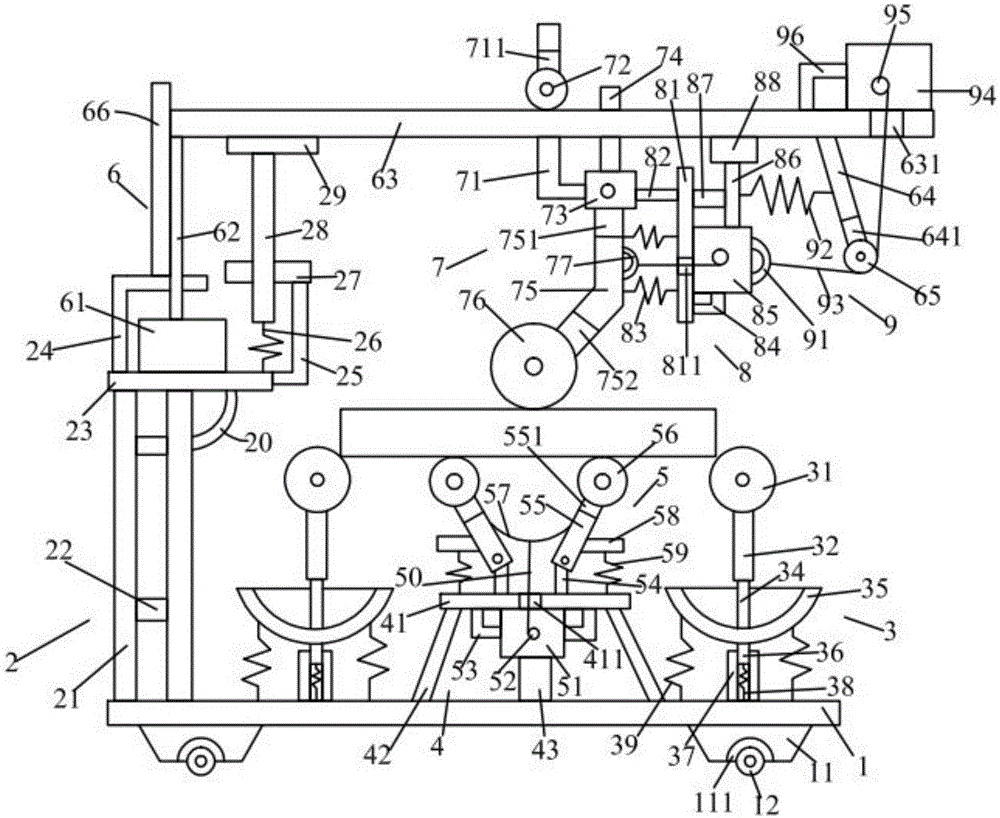

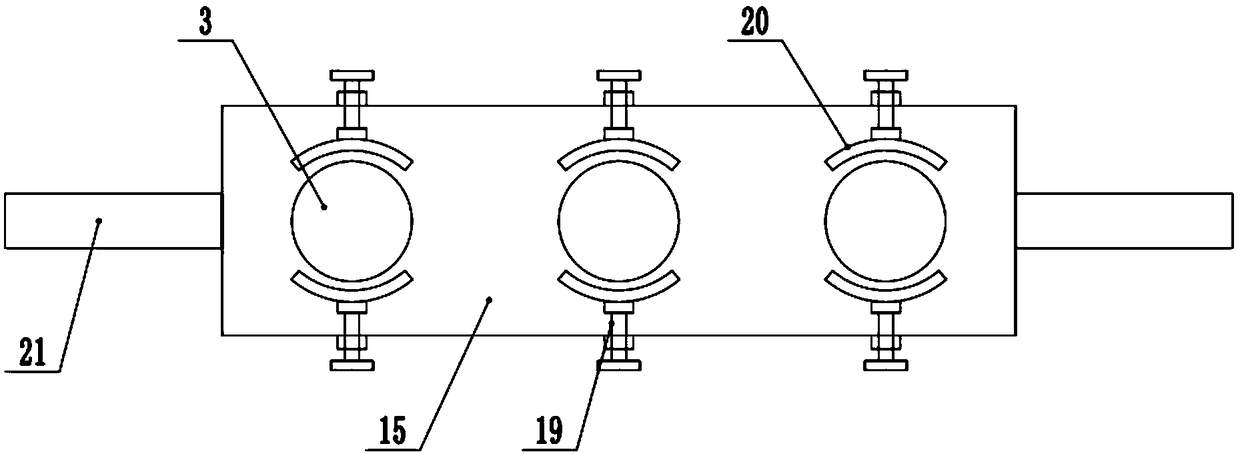

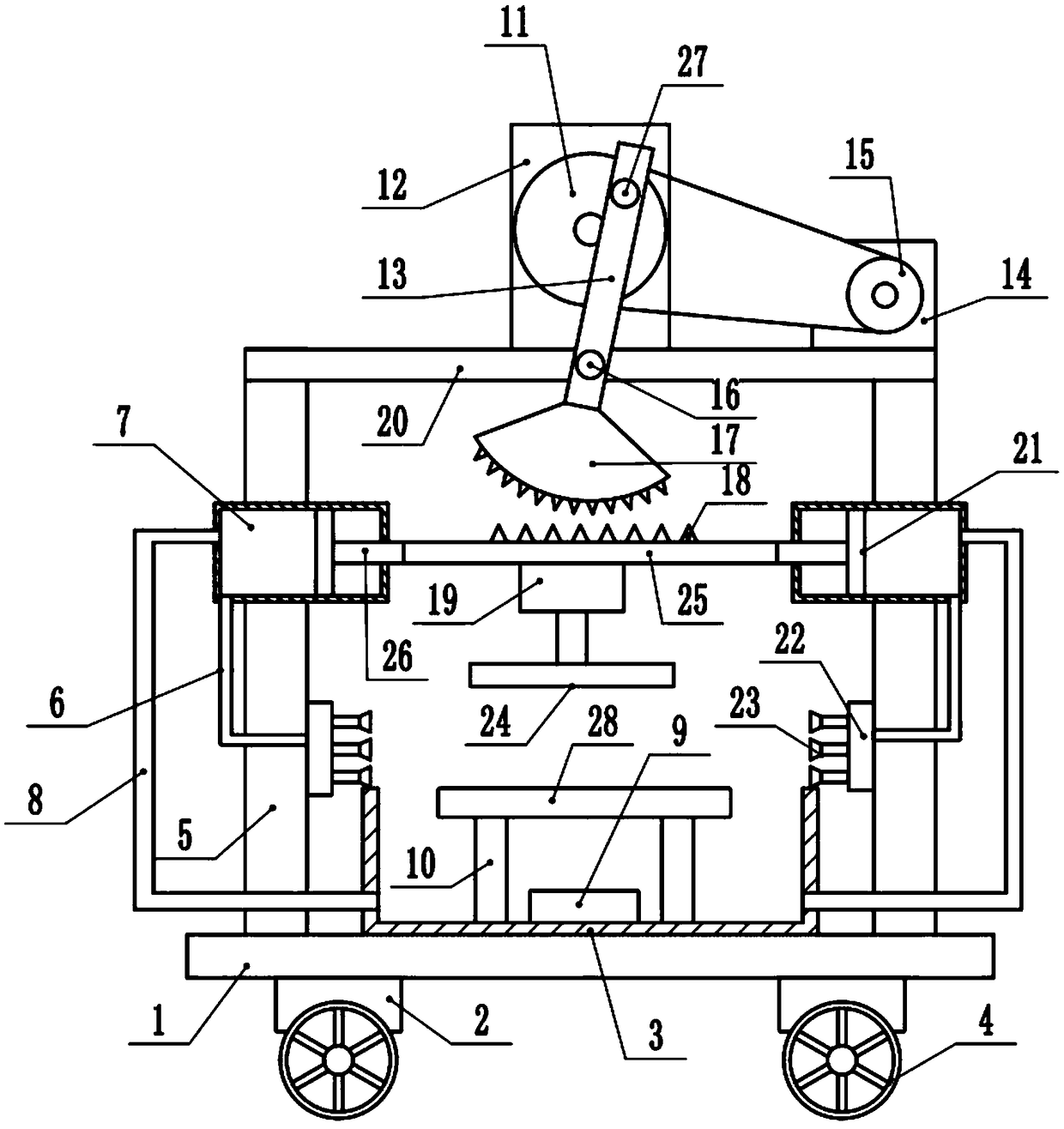

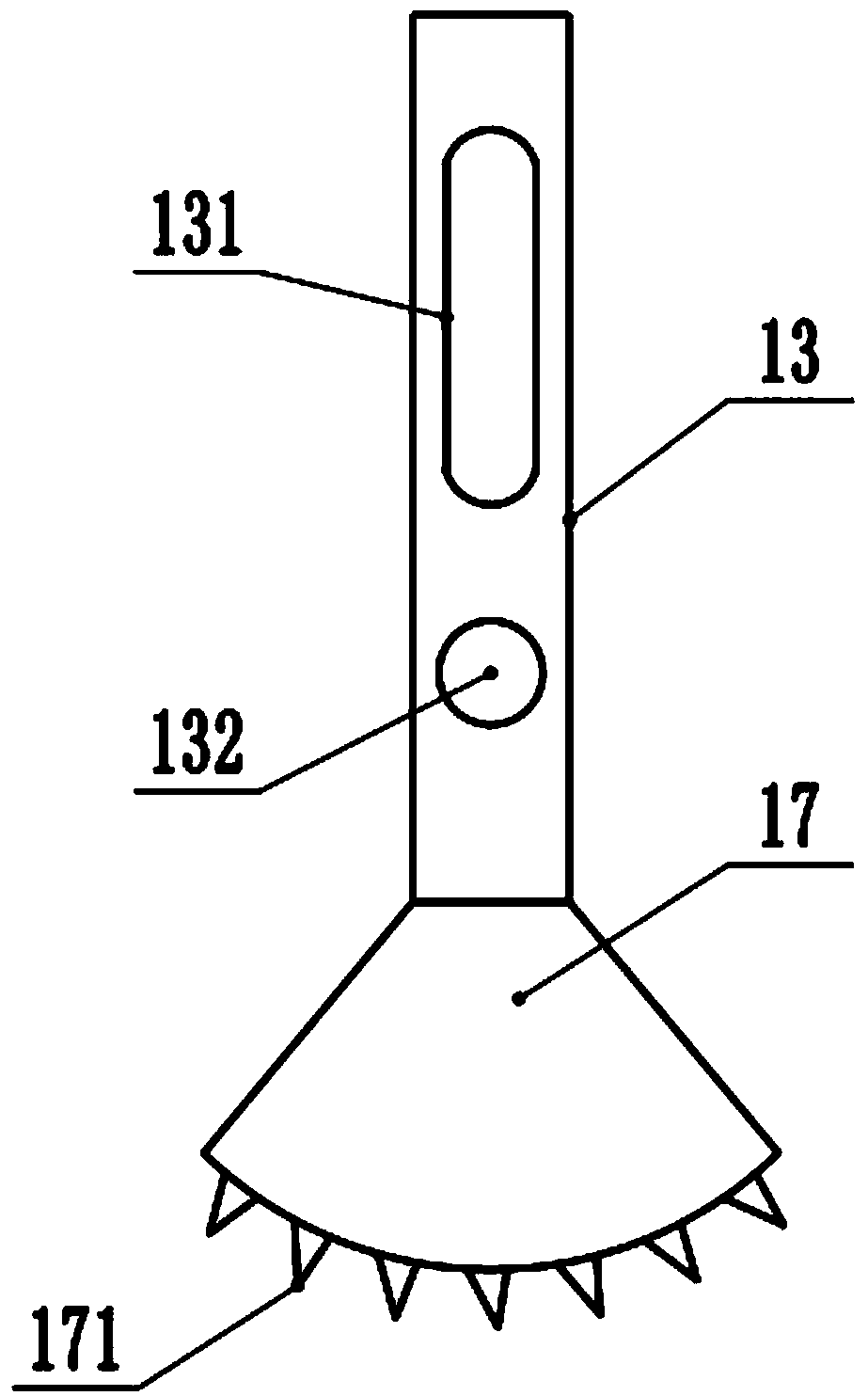

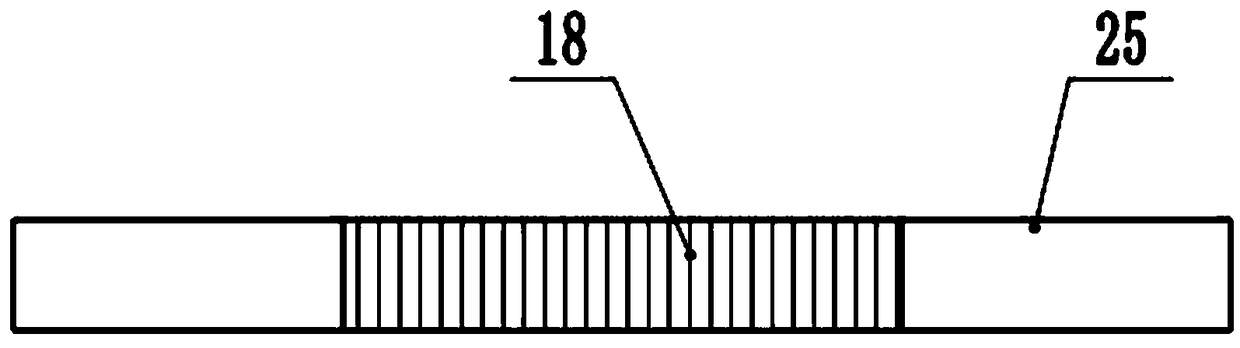

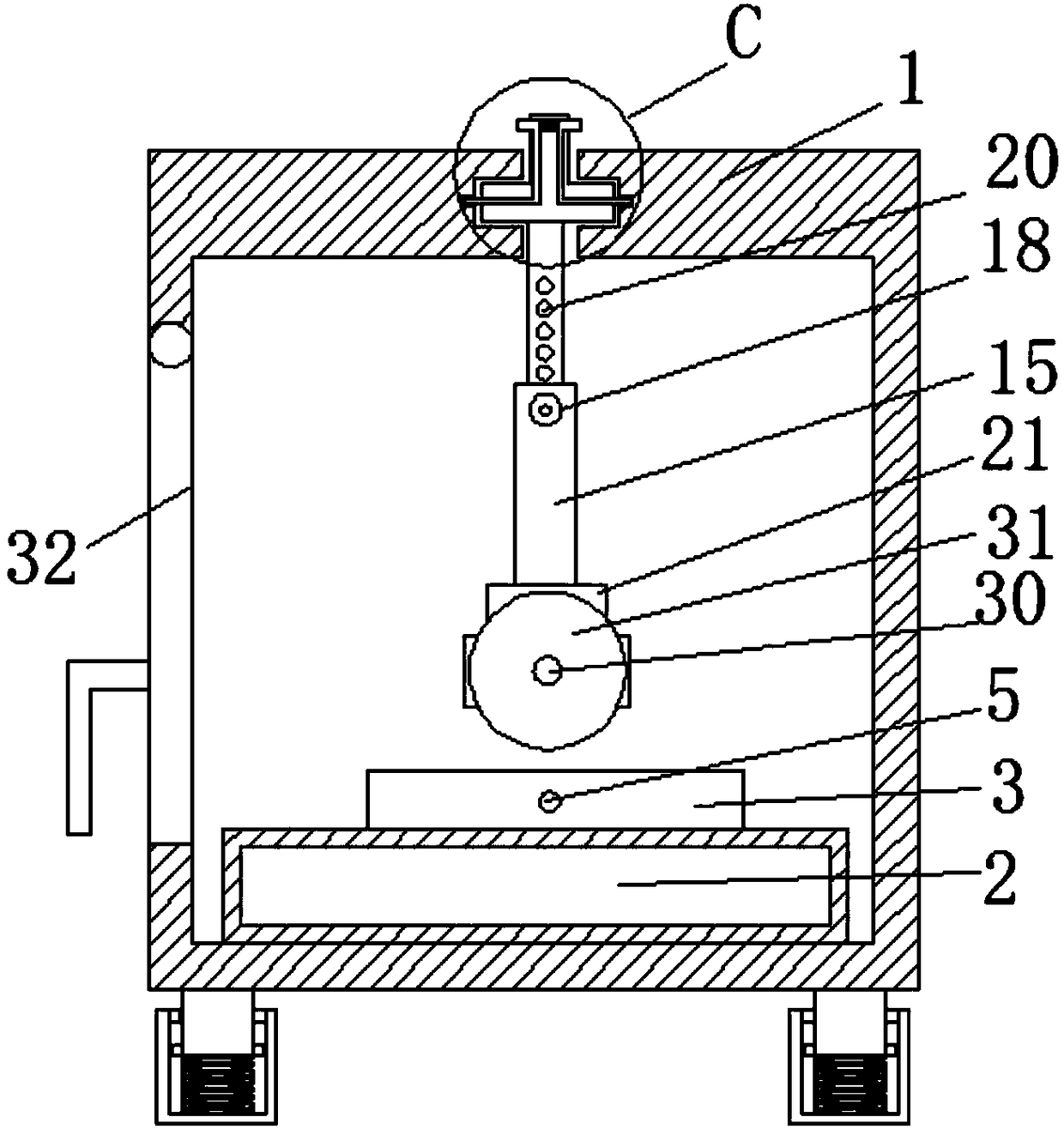

A burr polishing device for cutting the inner wall of an automobile pipe fitting

InactiveCN108890486AImprove grinding efficiencyReduce labor intensityEdge grinding machinesGrinding carriagesDrive wheelPipe fitting

A burr polishing device for cutting inner wall of automobile pipe fitting including workbench, At both side of that lower end of the workbench are connecte support legs, A support frame is connecte onboth sides of that upper end of the work table, A cross beam is arranged in the middle of the support frame, A drive box is connected to the middle of the beam, A drive motor is connected to the upper end of the drive box, A low end of that drive motor is connected with a rotary shaft, A drive wheel is connected with the middle part of the rotary shaft, a driven wheel is engaged at both ends of the drive wheel, a polishing shaft is connected at the lower end of the driven wheel, a polishing head is connected at the bottom end of the polishing shaft, a fixing plate is connected between the lower ends of the support frame, a pipe groove is arranged at the middle part of the fixing plate, a clamping plate is connected at the upper end of the pipe groove, and fastening screws are connected atboth ends of the clamping plate. The invention not only reduces the labor intensity of the worker when polishing, but also improves the polishing efficiency of the automobile pipe fittings, meets thepolishing needs of a large number of automobile pipe fittings, and avoids setting a plurality of motors through the driven wheels, reduces the manufacturing cost, and is worth popularizing and using.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

Grinding wheel with array-type region grinding function

The invention provides a grinding wheel with an array-type region grinding function. The grinding wheel comprises a grinding wheel body. One or more sliding rigid or semirigid abrasive blocks are arranged on the circumference of the edge of the grinding wheel body. The abrasive blocks slide in the radial direction of the grinding wheel body. Through the structure, the grinding wheel with the array-type region grinding function can always maintain balanced grinding pressure on a ground region as a traditional grinding belt do. When the shaft array interval radian is small, and the telescopic travel of a polishing and grinding module is increased, the multiple abrasive blocks can simultaneously act within a certain region range, and the grinding balance is maintained in a large range. The working linear speed can reach hundreds of meters per second or over, rapid cooling can be achieved, and the service life is long.

Owner:广州市合联科技发展有限公司

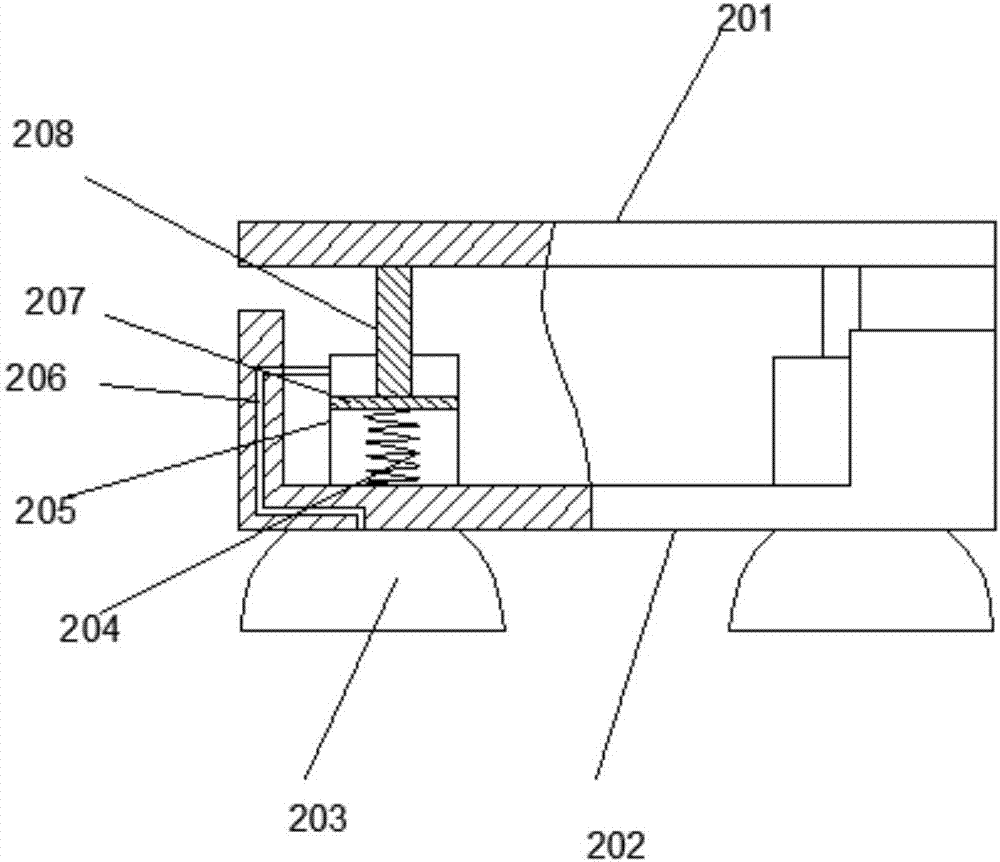

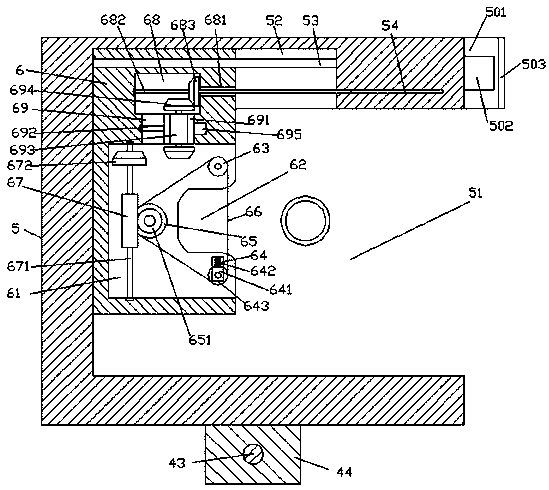

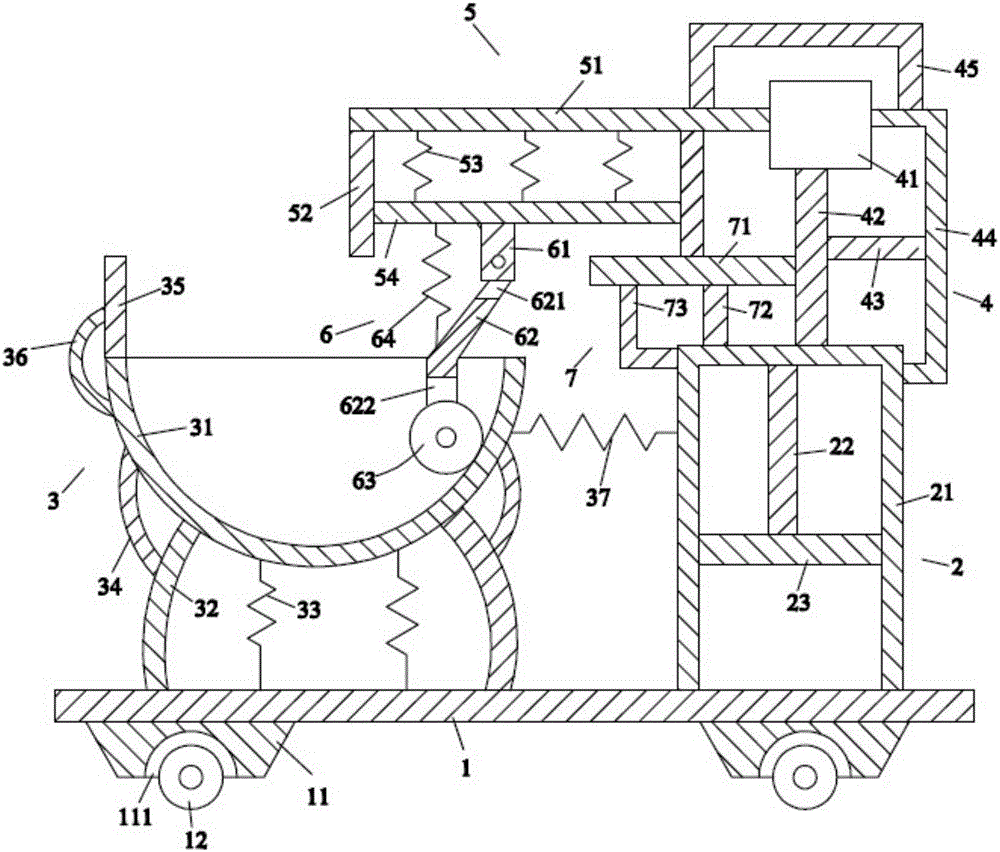

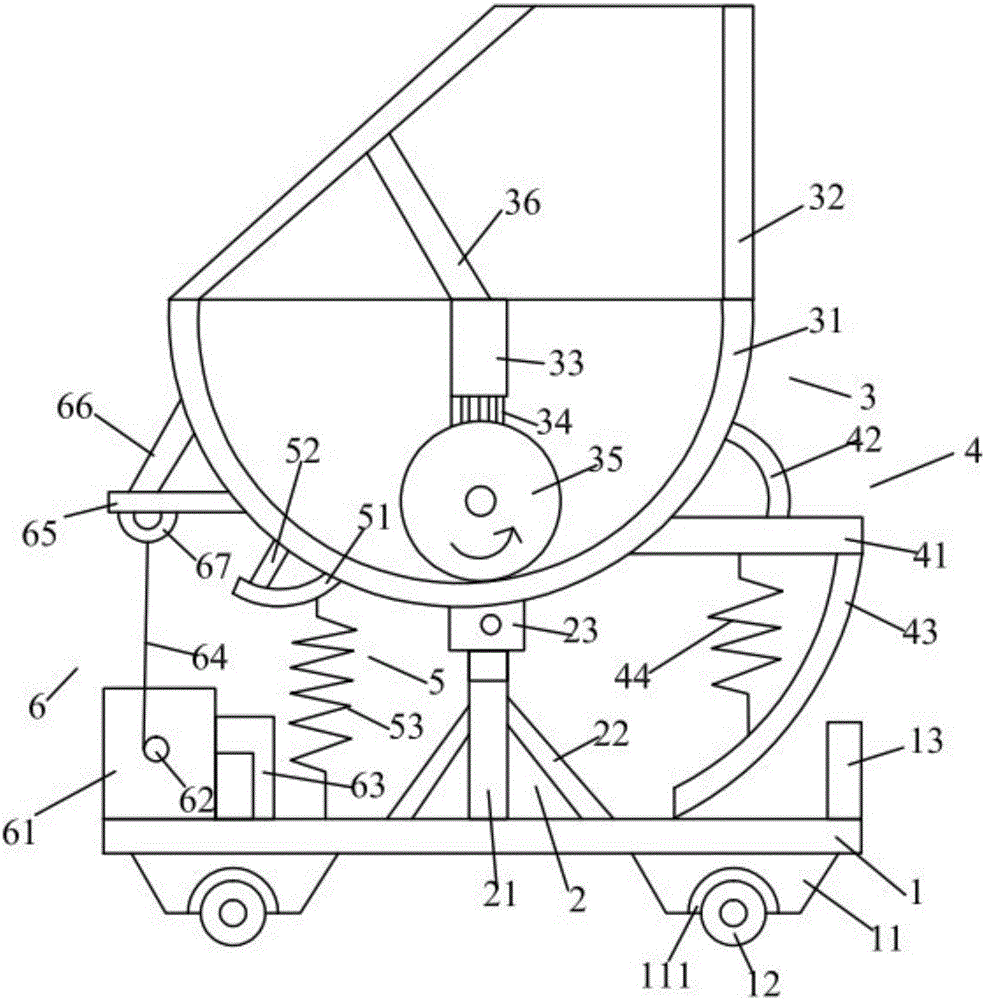

Automobile firmware surface polishing treatment device

InactiveCN108972268ASatisfy grinding needsReasonable structureGrinding carriagesGrinding drivesEngineeringPiston rod

The invention discloses an automobile firmware surface polishing treatment device. The automobile firmware surface polishing treatment device comprises a base, both sides of the upper end of the baseare provided with a support frame, the top end of the support frame is provided with a horizontal frame, the middle of the upper end of the horizontal frame is provided with a fixing plate, the middleof the front end of the fixing plate is provided with a driven belt pulley, the front end of the driven belt pulley is provided with a rotary column, the middle of the horizontal frame is provided with a fixing column, the front end of the fixing column is connected in a hinged mode with a swing frame, and the lower end of the swing frame is provided with a swing wheel; the middle of the supportframe is provided with a drainage cylinder inside which pistons are arranged, piston rods are arranged between the pistons, a guide plate is arranged between the piston rods, the lower end of the guide plate is provided with a polishing motor, and the lower end of the polishing motor is connected with a polishing head; the inside of the lower end of the support frame is provided with a diversion cavity outside which a spray pipe is connected. The automobile firmware surface polishing treatment device achieves swinging of the polishing head to expand the polishing range, and meanwhile, by blow-cooling the polishing head through the drainage cavity, prolongs the service life of the polishing head, thereby meeting the polishing requirement of automobile firmware.

Owner:合肥岑遥新材料科技有限公司

Adjustable high efficiency grinding device

ActiveCN108436709APrevent splashAvoid pollutionGrinding carriagesGrinding drivesSlide plateEngineering

The invention discloses an adjustable high efficiency grinding device. The adjustable high efficiency grinding device comprises a shell which is arranged in a hollow manner; a containing plate is arranged in the shell, and is provided with two fixed plates arranged in parallel; the containing plate is further provided with two clamping plates which are located between the two fixed plates; threaded rods are connected in the fixed plates in a threaded manner, and are rotationally connected with the clamping plates; the side wall of the shell is provided with an opening communicating with the interior, and a cover plate is rotationally connected to the opening position; the side wall of the upper side of the shell is provided with a strip-shaped opening communicating with the interior; the inner walls of the two sides of the strip-shaped opening are each provided with a slide groove; a T-shaped sliding plate is further arranged in the strip-shaped opening; the upper end of the T-shaped sliding plate extends to the exterior of the shell, and the T-shaped sliding plate is in sliding connection with the slide grooves; and the T-shaped sliding plate is of a hollow structure. The adjustable high efficiency grinding device can be used for grinding articles all dimensionally, and is wide in applicability and high in work efficiency.

Owner:江苏富乐德石英科技有限公司

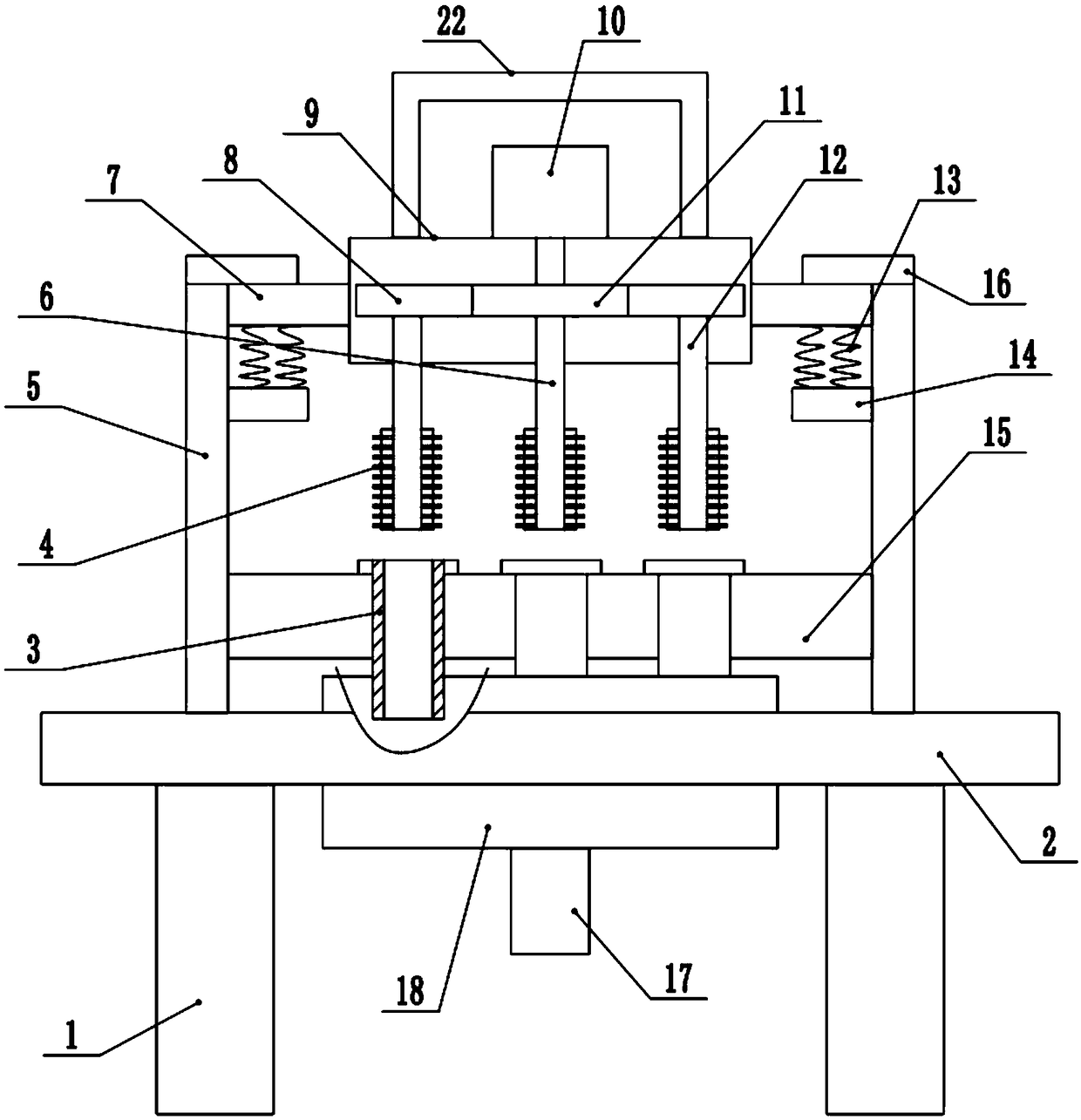

Grinding device for side wall and end face of bearing ring

PendingCN113319660AMeet the needs of grindingEasy to operateGrinding carriagesRevolution surface grinding machinesEngineeringWorkbench

The invention discloses a grinding device for the side wall and the end face of a bearing ring. The grinding device comprises a workbench, two clamping mechanisms, a transverse moving and lifting mechanism, a rotating mechanism and a grinding mechanism, wherein the two clamping mechanisms can correspondingly clamp the bearing ring from the two sides of the outer portion or correspondingly expand the bearing ring from the two sides of the inner portion, and the distance between the two clamping pieces is adjustable; the transverse moving and lifting mechanism can drive the rotating mechanism and the grinding mechanism to transversely move and lift; the grinding mechanism is arranged at the eccentric position of the rotating mechanism and driven by the rotating mechanism to rotate, and the distance between the grinding mechanism and the center position of the rotating mechanism is adjustable; and the grinding mechanism can grind the inner wall, the outer wall, the upper end face and the lower end face of the bearing ring in the circumferential direction. The grinding device is simple in structure, small in occupied space, low in cost, easy and convenient to operate, high in working efficiency, capable of meeting the requirement for grinding the bearing rings with different diameters and suitable for grinding the small and medium-sized bearing rings.

Owner:安徽省肥东宏达轴承配件有限公司

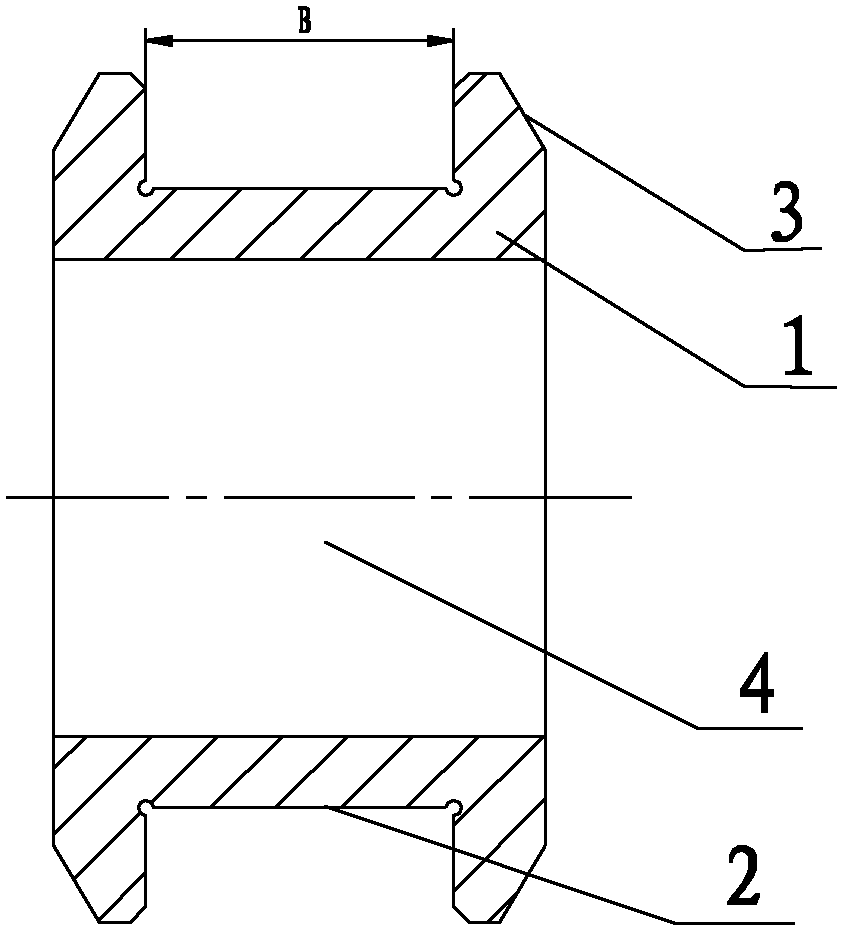

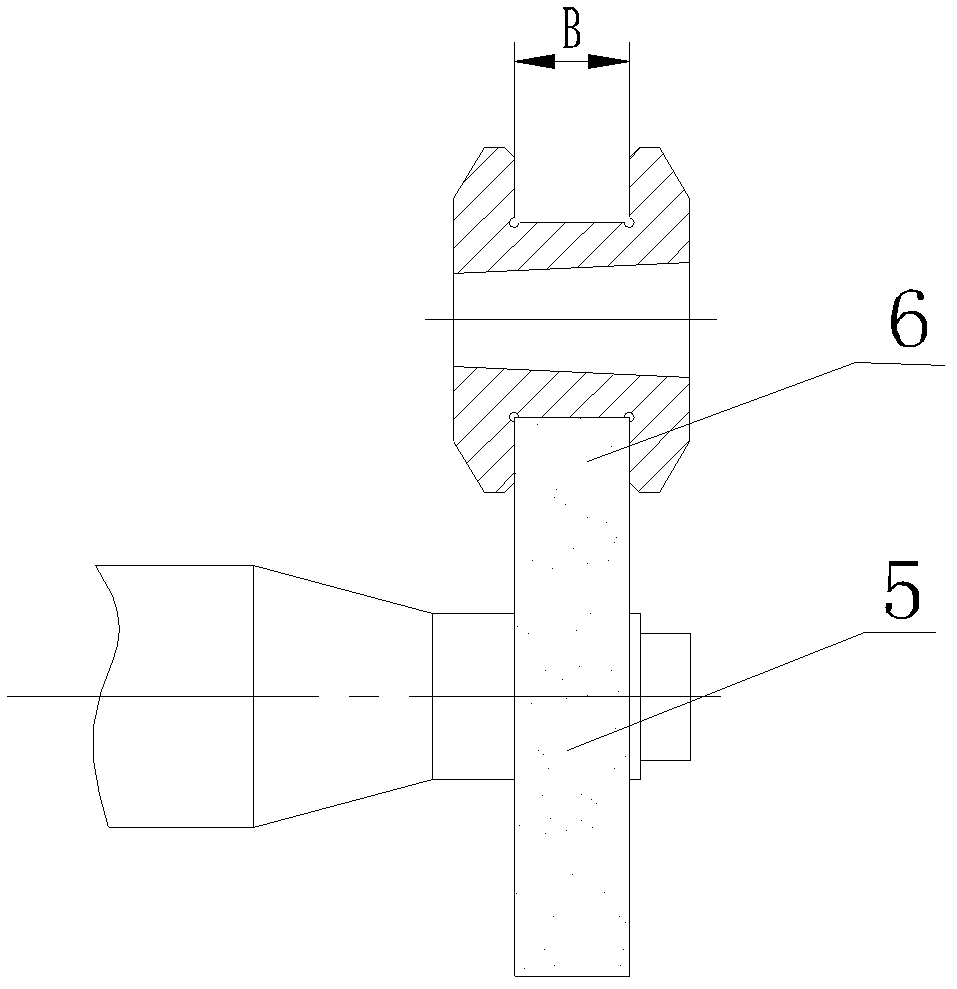

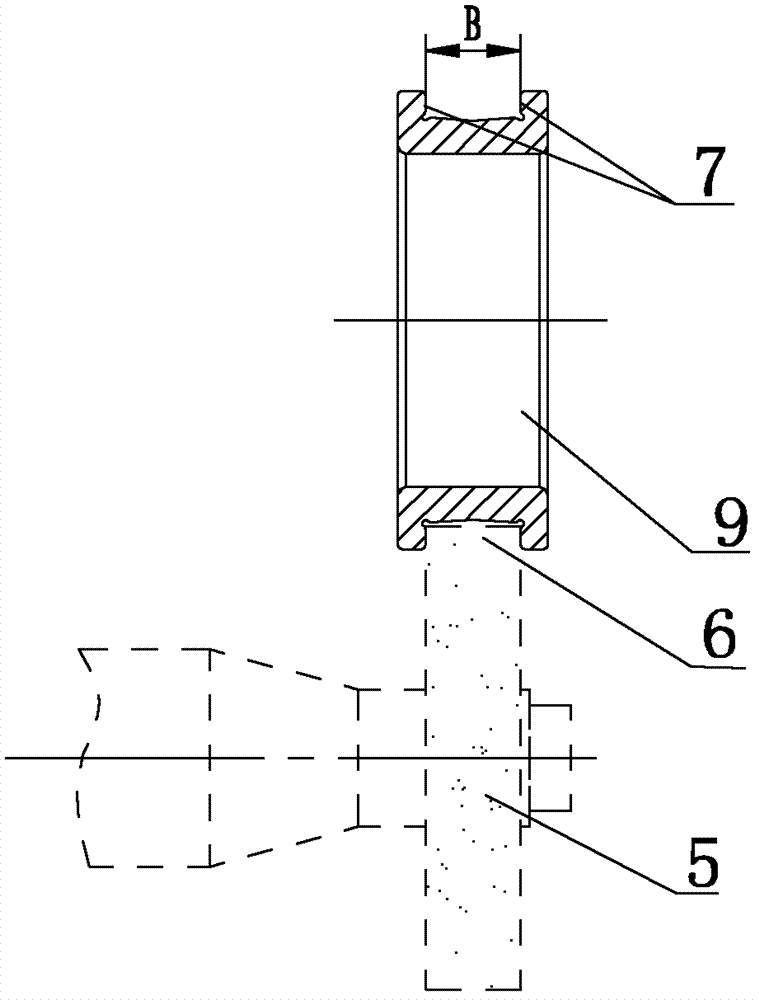

Grinding wheel grinding roller

InactiveCN103084980AOvercoming Width Dimension ErrorsImprove machining accuracyAbrasive surface conditioning devicesEngineeringGrinding wheel

The invention discloses a grinding wheel grinding roller for grinding a grinding wheel which is used for grinding stop edges of inner-ring roller path and outer-ring roller path of a short cylindrical bearing. Front projection of the grinding roller is H-shaped, a central hole (4) is reserved at the center of a gyration, an annular groove (2) is arranged on the middle portion of an outer ring, a grinding wheel grinding position (6) is arranged in the groove (2), and the width B of the groove (2) is identical to the width B of a dressed grinding wheel (5) and the width B of the roller paths with grinded stop edges of the grinding wheel (5). Via the grinding wheel dressed by the grinding roller, two stop edges on the inner-ring, outer-ring roller paths can be grinded after one-step positioning, the quality problem that width error of an inner ring and the outer ring is duplicated on the grinded width of the stop edges is solved, and full automatic production can be realized.

Owner:LUOYANG LUOLING BEARING SCI & TECH

Stainless steel pipe grinding device

ActiveCN107695836ARealize automatic controlAdjustable tension controlBelt grinding machinesGrinding work supportsTransmission switchingMotor drive

The invention discloses a stainless steel pipe grinding device. The stainless steel pipe grinding device comprises a base frame and a grinding supporting frame arranged on the base frame; a containinggroove is formed in the front side end face of the grinding supporting frame, a first sliding groove extending front and back is formed in the rear side of the inner top wall of the containing groove, a guide rod which extends front and back is arranged in the first sliding groove, a thread hole extending towards the front side is arranged on the inner wall of the front side of the first slidinggroove, a grinding mechanism which extends downwards is in sliding fit connection to the guide rod, and the bottom extension segment of the grinding mechanism extends into the containing groove. The stainless steel pipe grinding device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost and capable of automatically controlling grinding transmission switching and grinding mechanism moving control, the grinding supporting frame can move left and right for work, the grinding needs of a stainless steel pipe at the different welding line positions can be met, in addition, a rotating motor drives a stainless steel pipe to achieve comprehensive welding line grinding, and meanwhile, grinding efficiency is improved.

Owner:昆山赫斯顿精密五金机械有限公司

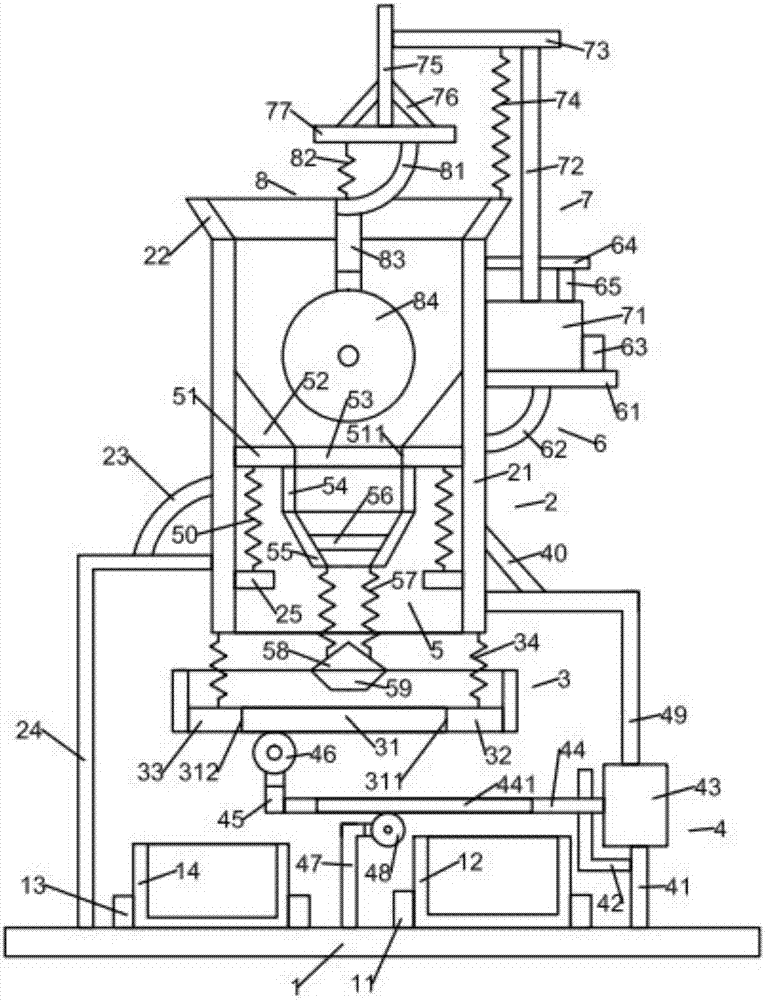

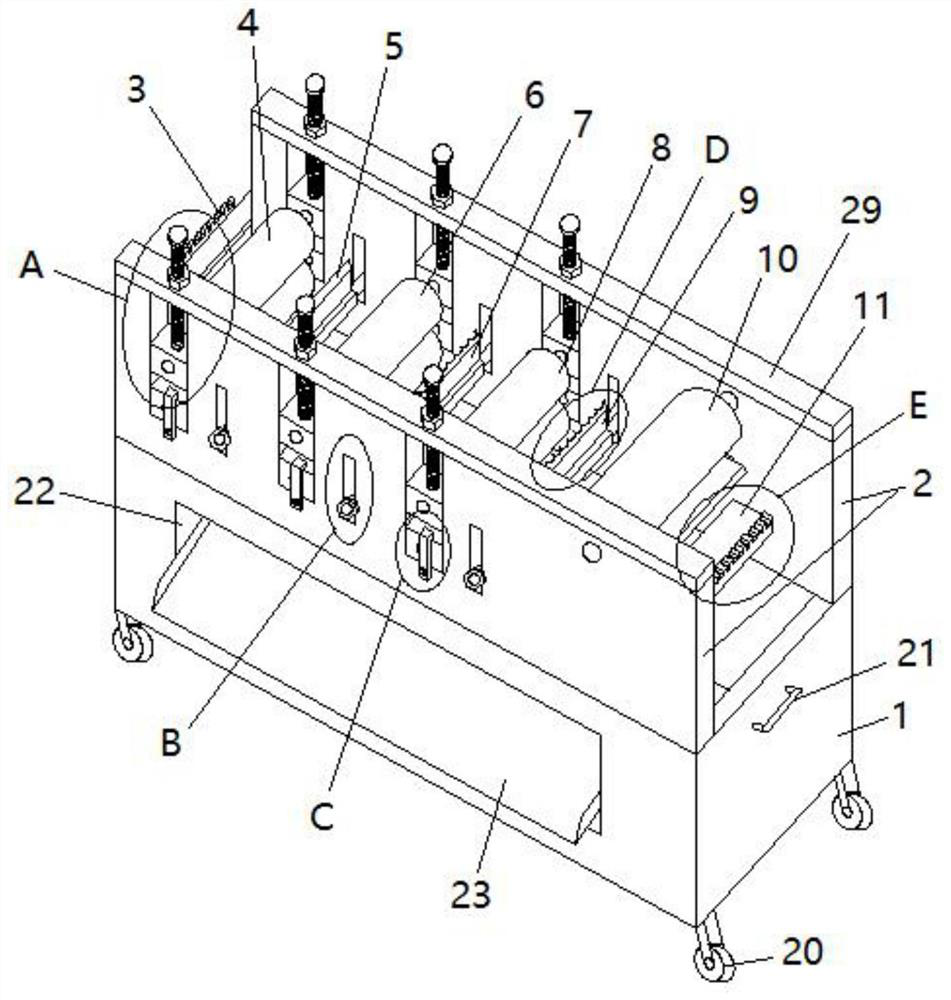

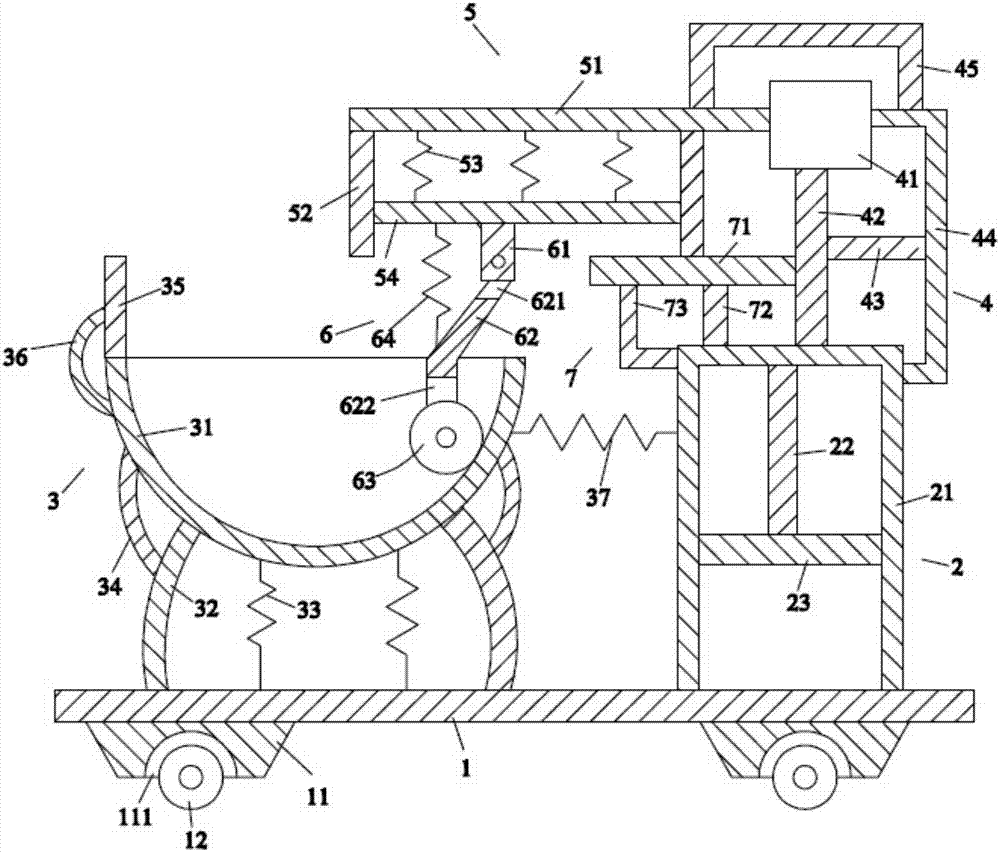

Resource-saving mechanical solid raw material grinding system for chemical industry production

ActiveCN106975557AMeet the needs of grindingGrind fullyGrain treatmentsChemical industryResource saving

A resource-saving mechanical solid raw material grinding system for chemical industry production comprises a bottom plate, a frame device, a filter device, a supporting device, a concentrating device, a fixing device, an electric cylinder device and a grinding device; a first recycling box, first positioning blocks, a second recycling box and second positioning blocks are arranged on the bottom plate, the frame device comprises a frame, a feeding frame, a first fixing rod, a first support and first fixing blocks, the filter device comprises a collection frame, a first filter net, a second filter net and first springs, the supporting device comprises a first supporting rod, a second support, a first electric cylinder, a first pushing rod, a first vertical rod, a first roller, a third support, a second roller, a fourth support and a second fixing rod, and the concentrating device comprises a moving plate, a third filter net, concentrating bocks, a concentrating frame, a discharging frame, a fourth filter net, a second spring, a connecting block, a hammering block and third springs; solid raw materials can be sufficiently ground, the grinding efficiency is high, and grinding is uniform.

Owner:广西田阳智蓝环保科技有限责任公司

Control method for workpiece automatic grinding

InactiveCN110900338AMeet processing needsSave human effortAutomatic grinding controlGrinding feedersControl signalControl engineering

The invention relates to a control method for workpiece automatic grinding. The control method comprises the following steps: 1) setting a workpiece distance range by a user; 2) reading sensor distance information, and calculating whether a workpiece reaches specific position or not; 3) controlling signal transmission, performing lead screw motor positive rotation, moving a grinding wheel towardsthe workpiece by certain height to reach a position capable of being grinded; 4) feeding back distance information by a sensor, and calculating whether the workpiece leaves the specific position or not; 5) controlling signal transmission, performing lead screw motor negative rotation, moving the grinding wheel in a direction reverse to the workpiece, leaving the position capable of being grinded,and returning to the original position; and 6) continuously reading sensor distance information, thereby accomplishing once workpiece automatic grinding control. The control method for workpiece automatic grinding can automatically grind positive and negative surfaces of the workpieces, meets processing needs in the modern plant, saves a great deal of labor power, reduces labor cost, and greatly improves working efficiency.

Owner:ZHEJIANG SCI-TECH UNIV

Traditional Chinese medicine grinding machine with high practicability

InactiveCN106378248AEasy to useImprove grinding efficiencyGrain treatmentsEngineeringChinese herbology

The invention discloses a traditional Chinese medicine grinding machine with high practicability. The traditional Chinese medicine grinding machine with the high practicability comprises a bottom plate, a bracket device, a frame body device, a fixed device, a moving device, a grinding device and a supporting device; a first fixed block and a first roller are arranged on the bottom plate; the bracket device comprises a first bracket, a first vertical rod and a first transverse rod; the frame body device comprises a frame body, a first bending rod, a first spring, a second bending rod, a baffle, a third bending rod and a second spring; the fixed device comprises an electric cylinder, a first supporting rod, a second transverse rod, a second bracket and a third bracket; the moving device comprises a third transverse rod, a positioning plate, a third spring and a moving plate; the grinding device comprises a second fixed block, a rotating frame, a grinding wheel and a fourth spring; the supporting device comprises a transverse plate, a second supporting rod and a fourth bracket. According to the traditional Chinese medicine grinding machine with the high practicability, traditional Chinese medicines can be ground automatically; the grinding efficiency is high and the grinding speed is high; the automation degree is high; the requirements on traditional Chinese medicine grinding can be met very well; the grinding effect is good.

Owner:周末

Highway pavement grinding equipment in highway engineering field

A highway pavement grinding equipment in the field of highway engineering, comprising a bottom plate device, a gripping device arranged on the bottom plate device, an electric cylinder device arranged on the gripping device, a moving device arranged on the bottom plate, A grinding device and a motor device arranged on the moving device. The invention can quickly grind the road surface, has high grinding efficiency, is simple to operate, is convenient to use, does not need manual force, has low labor intensity, and is suitable for popularization and application. One time grinding, the grinding effect is good, and the height of the grinding wheel can be adjusted at the same time, so as to adjust the depth of the road surface grinding, which can meet the needs of different road surface grinding.

Owner:方彐云

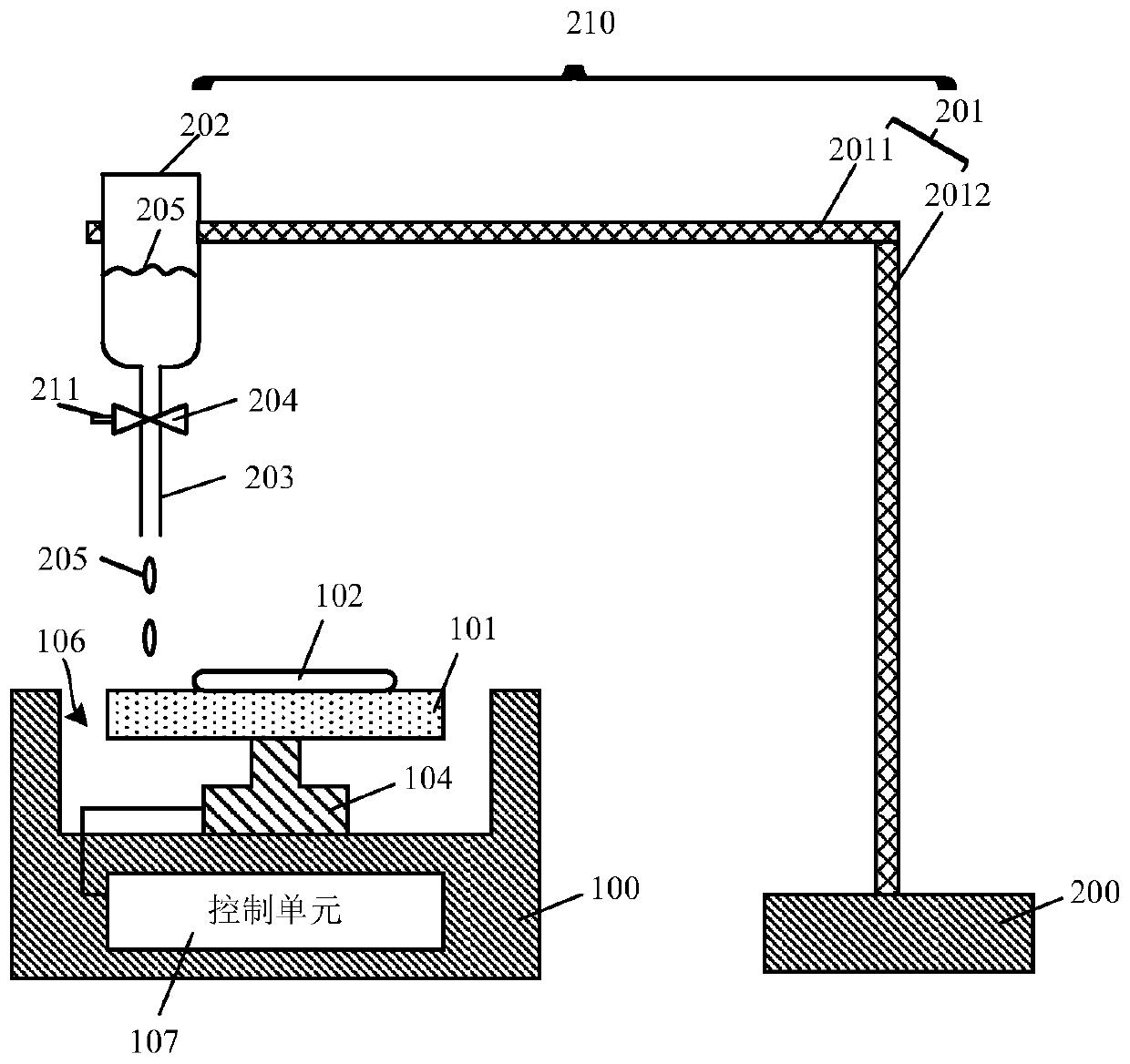

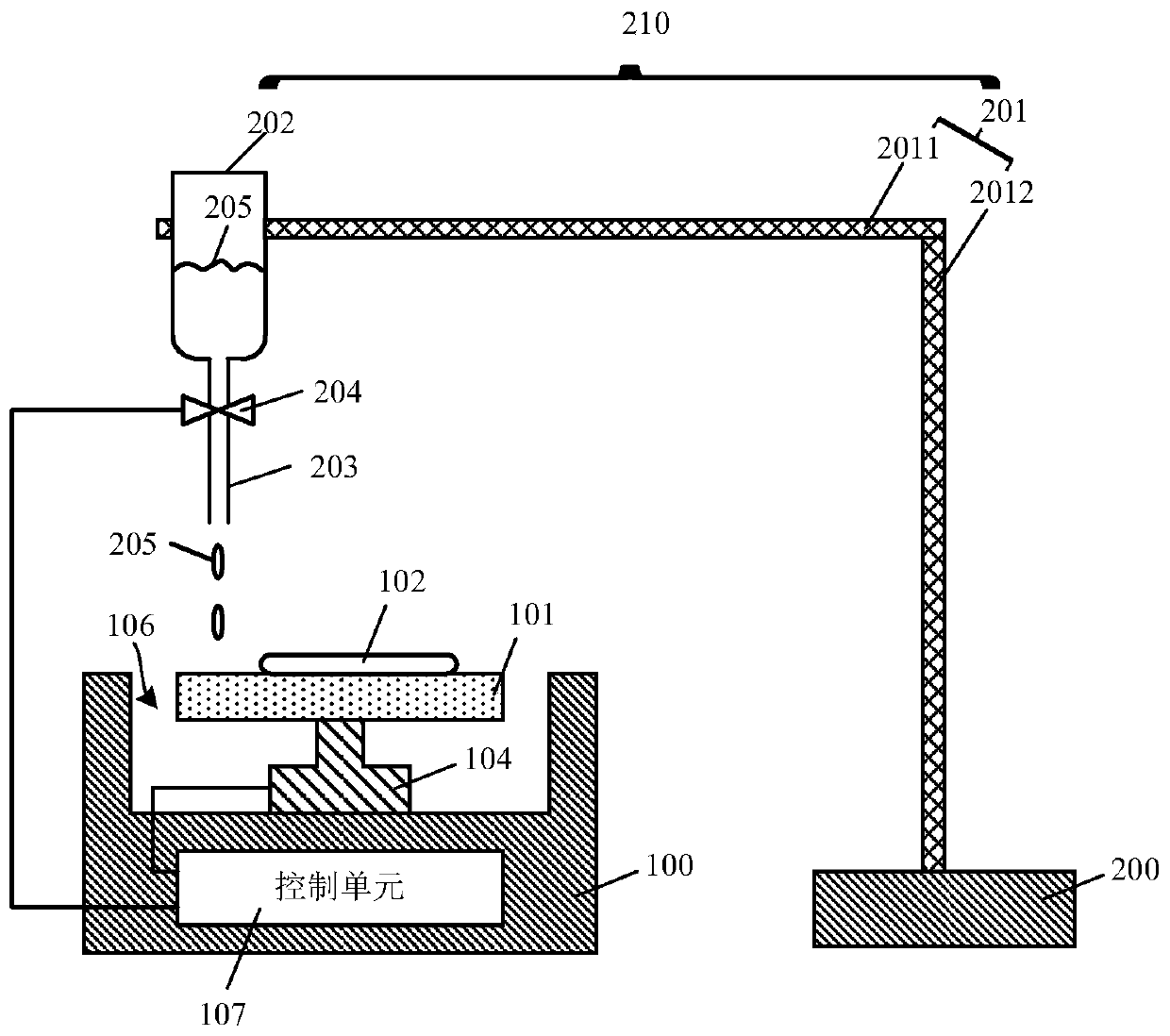

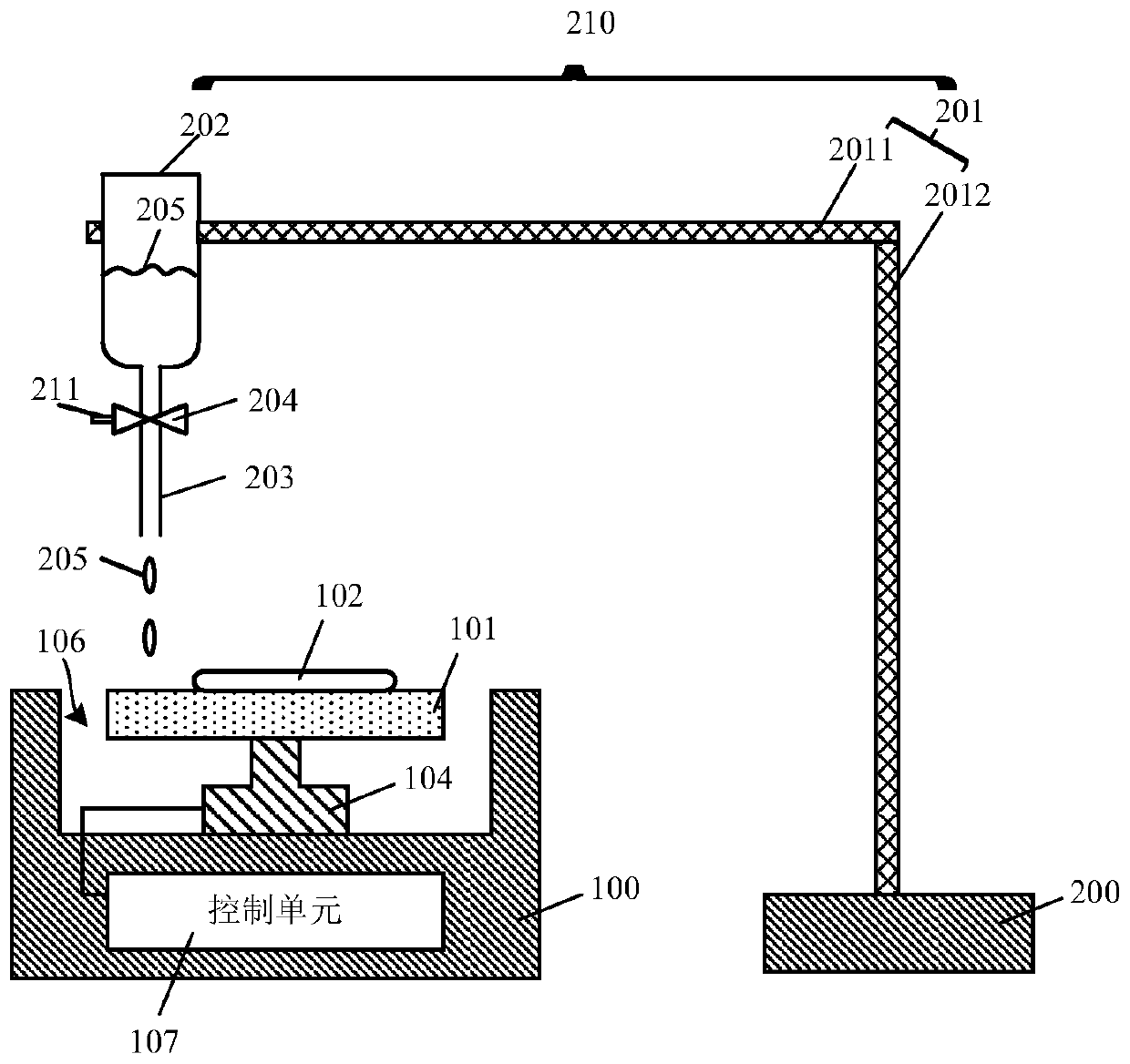

Invalid wafer grinding device

PendingCN111152128AImprove grinding uniformityImprove uniformityLapping machinesGrinding/polishing apparatusWaferEngineering

The invention provides an invalid wafer grinding device. The invalid wafer grinding device comprises a grinding table provided with a grinding surface and used for grinding the to-be-ground surface ofan invalid wafer, and a grinding fluid automatic dripping unit used for evenly dripping grinding fluid onto the grinding surface of the grinding table when the grinding table carries out grinding onthe to-be-ground surface of the invalid wafer. The grinding fluid automatic dripping unit can evenly drip the grinding fluid onto the grinding surface of the grinding table when the grinding table carries out grinding on the to-be-ground surface of the invalid wafer. Thus, the invalid wafer grinding device can accurately control the dripping rate and dripping quantity of the grinding fluid to prevent waste of the grinding fluid through manual dripping and can improve the grinding evenness of the invalid wafer. When the reverse side of the invalid wafer needs to be pressed during grinding, an operator or an inspector can press the reverse side of the invalid wafer with the two hands so as to improve the grinding evenness of the invalid wafer.

Owner:YANGTZE MEMORY TECH CO LTD

Efficient grinding equipment for cement production in construction field

InactiveCN106607118ASimple structureGrinding thoroughly and effectivelyGrain treatmentsBristleArchitectural engineering

The invention discloses efficient grinding equipment for cement production in the construction field. The efficient grinding equipment comprises a base plate, a support device, a frame body device, a first elastic device, a second elastic device and a motor device. The base plate is provided with first supporting blocks, first sliding wheels and first limiting rods. The support device comprises a first supporting rod, first fixing rods and a first fixing block. The frame body device comprises a frame body, a feeding box, a second fixing rod, brush bristles, a grinding wheel and a third fixing rod. The first elastic device comprises a fourth fixing rod, a first bent rod, an elastic rod and a first spring. The second elastic device comprises a second bent rod, a fifth fixing rod and a second spring. The motor device comprises a motor, an output shaft, a fixing rack, a bracing wire, a connecting ring located above the bracing wire, a sixth fixing rod and a seventh fixing rod. The efficient grinding equipment is simple in structure, cement raw materials can be ground effectively and thoroughly, and the grinding effect is good.

Owner:GUANGZHOU SONGBIN ENG TECH CO LTD

Polishing device and method for communication shell machining

PendingCN114393493AImprove work efficiencySatisfy grinding needsGrinding carriagesPolishing machinesPhysicsEngineering

The polishing device comprises a base and a rotating column rotationally arranged in the middle of the upper end of the base, the lower end of the rotating column is connected with a rotating driving part used for driving the rotating column to rotate so as to achieve station switching, and a rotating disc used for containing workpieces is coaxially arranged at the upper end of the rotating column; a plurality of magnetic adsorbers used for conducting auxiliary positioning on workpieces are distributed in the rotating disc in an array mode, signal receivers used for starting the magnetic adsorbers are arranged at the bottoms of the magnetic adsorbers, and a fixing rod is arranged at the upper end of the base. And one-by-one feeding by operators is not needed, automatic feeding can be carried out, fixing is carried out in cooperation with an electromagnetic adsorption positioning mode, and the working efficiency is effectively improved.

Owner:芜湖仅一轻量化科技有限公司

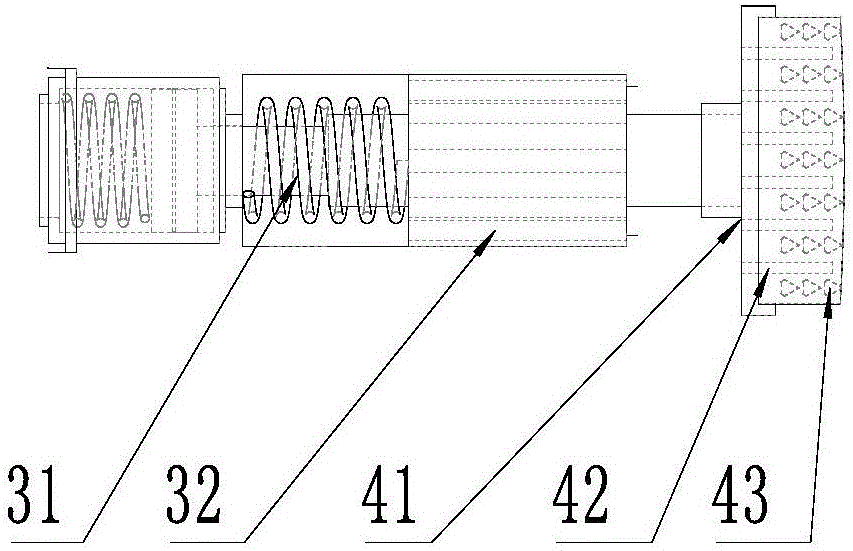

Belt type stainless steel pipe welding line grinding device

ActiveCN107695838AExtended service lifeRealize automatic controlBelt grinding machinesAutomatic grinding controlPipe weldingMotor drive

The invention discloses a belt type stainless steel pipe welding line grinding device. The belt type stainless steel pipe welding line grinding device comprises a base frame and a grinding supportingframe arranged on the base frame; a containing groove is formed in the front side end face of the grinding supporting frame, a first sliding groove extending front and back is formed in the rear sideof the inner top wall of the containing groove, a guide rod which extends front and back is arranged in the first sliding groove, a thread hole extending towards the front side is arranged on the inner wall of the front side of the first sliding groove, a grinding mechanism which extends downwards is in sliding fit connection to the guide rod, and the bottom extension segment of the grinding mechanism extends into the containing groove. The belt type stainless steel pipe welding line grinding device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost and capable of automatically controlling grinding transmission switching and grinding mechanism moving control, the grinding supporting frame can move left and right for work, the grinding needs of a stainless steel pipe at the different welding line positions can be met, in addition, a rotating motor drives a stainless steel pipe to achieve comprehensive welding line grinding, and meanwhile, grinding efficiency is improved.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

Bamboo skin polishing device

InactiveCN112935961AImprove comfortImprove securityEdge grinding machinesWood feeding arangementsRough surfacePolishing

The invention discloses a bamboo skin polishing device which comprises a cabinet body and two side plates. A feeding mechanism, a discharging mechanism, a first-stage conveying roller, a second-stage conveying roller, a third-stage conveying roller, a first-stage polishing tool, a second-stage polishing tool, a third-stage polishing tool and a fourth-stage polishing tool are arranged between the two side plates; the first-stage conveying roller, the second-stage conveying roller and the third-stage conveying roller comprise upper rotating rollers and lower rotating rollers; adjustable gaps allowing bamboo skins to pass through are formed between the upper rotating rollers and the lower rotating rollers; the rotating speeds of the lower rotating rollers of the first-stage conveying roller, the second-stage conveying roller and the third-stage conveying roller are sequentially increased; the first-stage polishing tool, the second-stage polishing tool and the third-stage polishing tool all comprise height-adjustable tool rests; blades are fixed onto the tool rests; a plurality of arc-shaped grooves are formed in cutting edges of the blades of the second-stage polishing tool and the third-stage polishing tool respectively; the fourth-stage polishing tool comprises a rotating roller; a groove is formed in one side of the rotating roller in the length direction of the rotating roller; and a planer tool is fixedly installed on the inner wall of the groove. According to the bamboo skin polishing device provided by the invention, the smooth surface and the rough surface of the bamboo skin can be flat, the overall thickness is consistent, the bamboo skin has a smooth cambered surface, manual weaving is facilitated, and the comfort level and the safety in the using process are improved.

Owner:唐满结

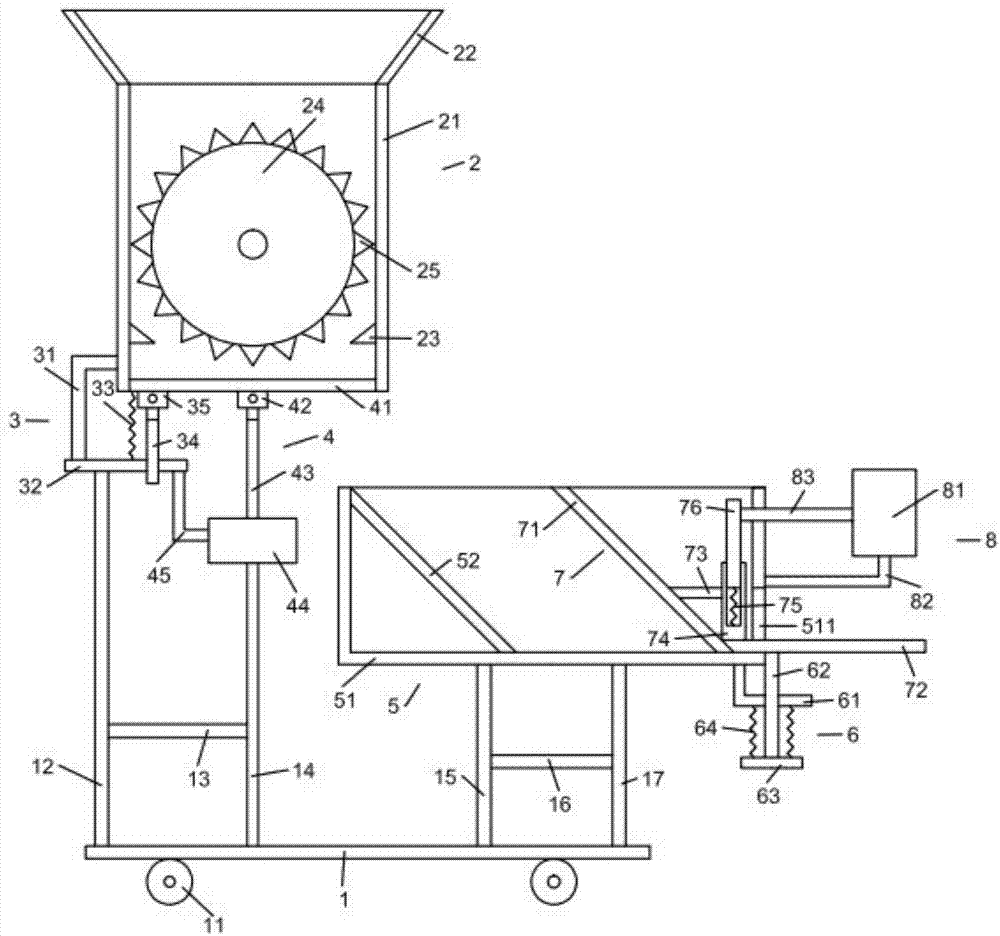

Multi-specification tablet grinding device and using method thereof

ActiveCN113559975AGood for crushing and grindingMeet the needs of grindingGrain treatmentsMechanical engineeringPhysics

The invention discloses a multi-specification tablet grinding device and a using method thereof. The multi-specification tablet grinding device comprises a conveying frame used for conveying tablets, wherein the conveying frame is rotationally connected to a hollowed smashing roller, the smashing roller is connected to a driving mechanism, an adjusting shaft is arranged in the smashing roller, the two ends of the adjusting shaft are rotationally connected to the conveying frame, the smashing roller is provided with a plurality of medicine smashing holes which are uniformly spaced and annularly arranged, a smashing needle is slidably connected in each medicine smashing hole, the smashing needles are connected to the smashing roller through reset springs, a plurality of cams which are distributed side by side are arranged between the smashing needles, the cam is fixedly arranged on an adjusting shaft in a sleeve mode, the adjusting shaft is further rotationally connected to a rotating sleeve, the rotating sleeve is connected to an extrusion platform through an extrusion spring, and the bottom end of the extrusion platform makes contact with the smashing needles. The multi-specification tablet grinding device can conduct multi-specification tablet grinding work, can effectively prevent tablets from being attached to the smashing needles in the grinding process, and prevents the situations such as tablet splashing in the grinding process.

Owner:王予安

Traditional Chinese medicine grinding machine high in practicability

The invention provides a traditional Chinese medicine grinding machine high in practicability. The traditional Chinese medicine grinding machine comprises a bottom plate, a bracket device, a frame body device, a fixed device, a movable device, a grinding device and a supporting device. The bottom plate is provided with a first fixing block and a first idler wheel; the bracket device comprises a first bracket, a first vertical rod and a first transverse rod; the frame body device comprises a frame body, first bent rods, first springs, second bent rods, a baffle, a third bent rod and a second spring; the fixed device comprises an electric cylinder, a first supporting rod, a second transverse rod, a second bracket and a third bracket; the mobile device comprises a third transverse rod, positioning plates, third springs and a mobile plate; the grinding device comprises a second fixing block, a rotary frame, a grinding wheel and a fourth spring; and the supporting device comprises a transverse plate, a second supporting rod and a fourth bracket. By means of the traditional Chinese medicine grinding machine high in practicability, traditional Chinese medicine can be ground automatically, grinding efficiency is high, grinding is rapid, the automated degree is high, the traditional Chinese medicine grinding requirement can be met quite well, and the grinding effect is good.

Owner:王杨

Fast grinder for metal materials for 3D printing

Disclosed is a fast grinder for metal materials for 3D printing. The fast grinder comprises a bottom plate, a support plate device, a motor device, a concentration device, a support device and a grinding structure. The bottom plate is provided with a first support rod, a first transverse rod and a second support rod. The support plate device comprises a support plate. The motor device comprises a motor, an output shaft, a bracing wire, a first support and a first fixed rod. The concentration device comprises a support block, a second support, a first vertical rod, a first spring, a first abutting plate and a concentration plate. The support device comprises a third support rod, a second transverse rod, a second spring, a second abutting plate, a first bent rod and a transverse plate located above the third support rod. The grinding structure comprises a second vertical rod, a second bent rod located on the right side of the second vertical rod, and a grinding wheel located below the second vertical rod. The fast grinder can grind the metal materials for 3D printing fast and effectively, and the grinding efficiency is high.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

Ultrafine powder grinding preparing system for mineral production

The invention relates to an ultrafine powder grinding preparing system for mineral production. The ultrafine powder grinding preparing system for mineral production comprises a base plate, a first shell device, a connecting device, a baffle device, a second shell device, a movement plate device, a grinding device and an electric cylinder device; the first shell device comprises a first shell, a feeding frame, a triangular block, a smashing wheel and smashing teeth; the connecting device comprises a first support, a third transverse rod, a first spring, a first vertical rod and a first connecting block; the baffle device comprises a baffle, a second connecting block, a first pushing rod, a first electric cylinder and a second support; the second shell device comprises a second shell and an inclined plate; the movement plate device comprises a third support, a movement plate, a fourth transverse rod and a second spring; the grinding device comprises a first grinding plate, a second grinding plate, a fixing rod, a positioning rod, a third spring and a second push rod; and the electric cylinder device comprises a second electric cylinder, a fixing support and a third pushing rod. By means of the ultrafine powder grinding preparing system, mineral can be sufficiently smashed and ground, the grinding efficiency is high, and grinding is sufficient.

Owner:辰溪成金石业有限公司

Polishing device for sensor machining

InactiveCN112091775AImprove sanding effectMeet regulatory needsGrinding drivesGrinding machinesElectric machineryPolishing

The invention discloses a polishing device for sensor machining. The polishing device comprises a workbench and a protective cover, a dust collecting case is fixedly connected to the middle end of thebottom of the workbench, a material baffle is fixedly connected to the upper end of an inner cavity of the dust collecting case, meanwhile, a dust collecting box is slidably connected to the bottom of the inner cavity of the dust collecting case, the protective cover is fixedly connected to the middle end of the top of the workbench, a clamping mechanism is arranged at the bottom of an inner cavity of the protective cover, meanwhile, the clamping mechanism comprises a first motor, an adjusting ball rod, a binding rod, an adjusting screw, clamping rods, a first electric telescopic rod and a first supporting plate. According to the polishing device, the clamping mechanism is arranged, the clamping rods can clamp and fix sensors of different sizes, moreover, a polishing head can polish different parts of the sensors, a polishing mechanism is arranged so that the requirement for polishing the different types of sensors and the different parts of the sensors can be met, the polishing effect of the polishing device is effectively improved, and great convenience is brought to the use of people.

Owner:江西艾斯欧匹精密智造科技有限公司

A belt type stainless steel pipe weld seam grinding equipment

ActiveCN107695838BRealize automatic controlAdjustable tension controlBelt grinding machinesAutomatic grinding controlTransmission switchingArchitectural engineering

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

Turning tool feeding device for grinding turning tool

InactiveCN108214121AImprove grinding qualityImprove grinding efficiencyGrinding carriagesGrinding drivesEngineeringGrinding wheel

A turning tool feeding device for grinding a turning tool comprises a horizontally arranged working platform and a sliding rail, and the sliding rail is arranged on the working platform and is parallel to the wheel face of a grinding wheel. The sliding rail is slidably provided with a sliding base. The sliding base is provided with a rotary shaft perpendicular to the working platform. A fixed table capable of rotating around the rotary shaft is arranged at the top of the rotary shaft and is provided with a turning tool clamping mechanism used for clamping the turning tool. According to the turning tool feeding device, the rotary shaft drives the turning tool clamping mechanism to rotate in a certain angle of the horizontal plane, the sliding rail drives the turning tool clamping mechanismto slide in a direction so as to adjust the position of the turning tool clamping mechanism relative to the grinding wheel, thus the curved surface of the turning tool can also be ground, rotation adjustment and sliding adjustment are both achieved manually through a handle, in this way, an operator can conduct adjustment and operation conveniently in real time, and grinding quality and efficiencyare improved.

Owner:LUOYANG INST OF SCI & TECH

Assembly line type hardware product polishing equipment

InactiveCN108747708AMeet the needs of grindingProtect the safety of useGrinding carriagesGrinding machinesHydraulic cylinderArchitectural engineering

The invention discloses assembly line type hardware product polishing equipment which comprises a worktable, a protecting box, a transmission lead screw, two buffer blocks, a hydraulic telescopic rod,an elliptical polishing head, a special-shaped clamping device and a supporting rod, wherein the workable is placed on the lower part of the whole equipment; a hydraulic cylinder is connected to thetransmission lead screw by penetrating the protecting box; a connecting block is connected to the hydraulic cylinder and is mounted on the protecting box; the buffer blocks are symmetrically mounted above the protecting box; the hydraulic telescopic rod is mounted at the lower end of the hydraulic cylinder and is placed in the protecting box; a transmission connector is mounted at the lower end ofthe hydraulic telescopic rod; the elliptical polishing head is mounted on the transmission connector; a conveyer belt wheel is mounted above the worktable by penetrating the protecting box; a main driving box is arranged at the bottom end of the worktable; and a control switch is inlaid onto the left side wall of the worktable. The assembly line type hardware product polishing equipment is easy and convenient to use and operate and high in practicality.

Owner:盐城国刀刀具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com