Invalid wafer grinding device

A technology of grinding device and wafer, applied in grinding device, grinding machine tool, grinding/polishing equipment, etc., to achieve the effect of improving uniformity, avoiding waste of grinding liquid and improving grinding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

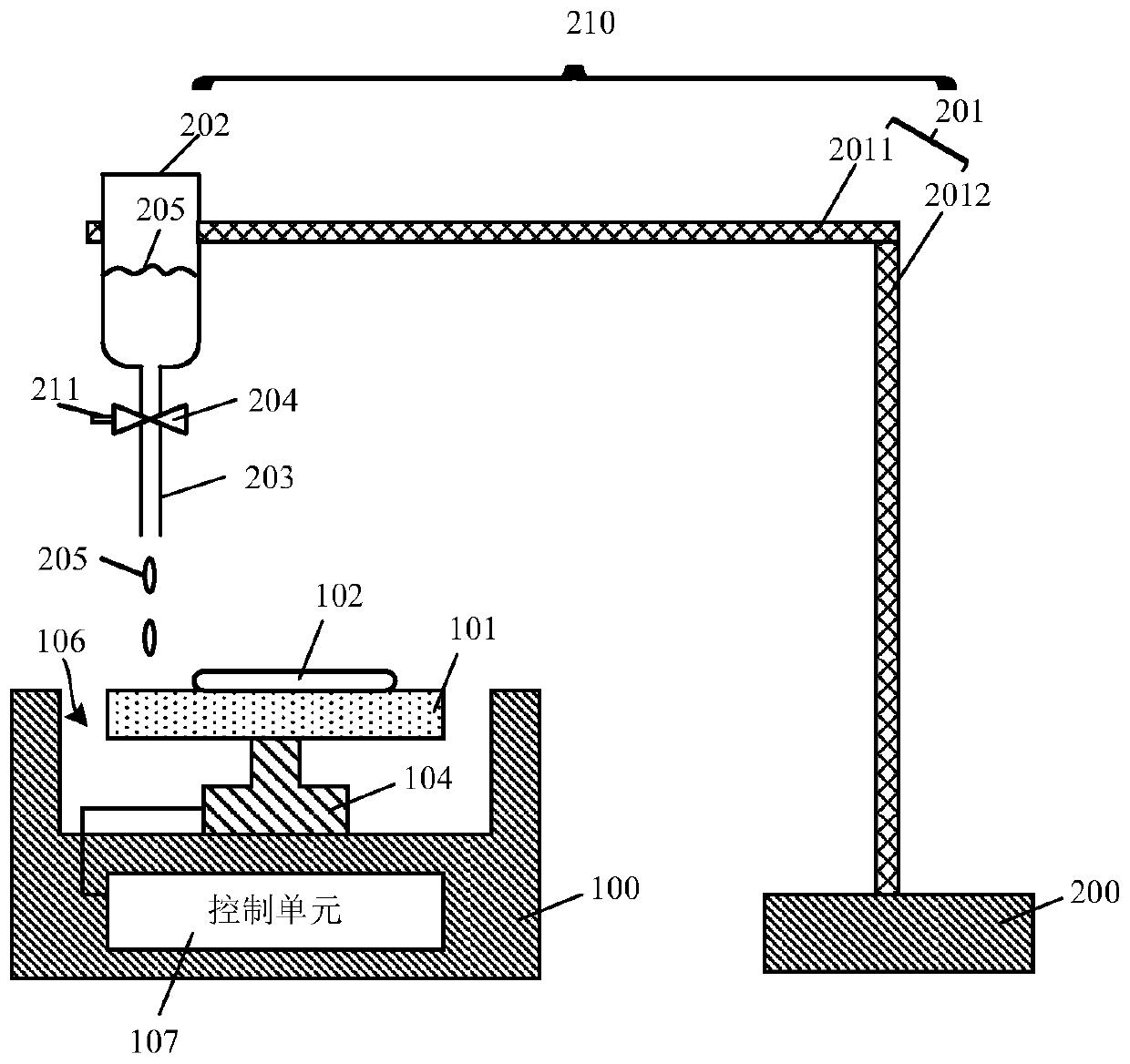

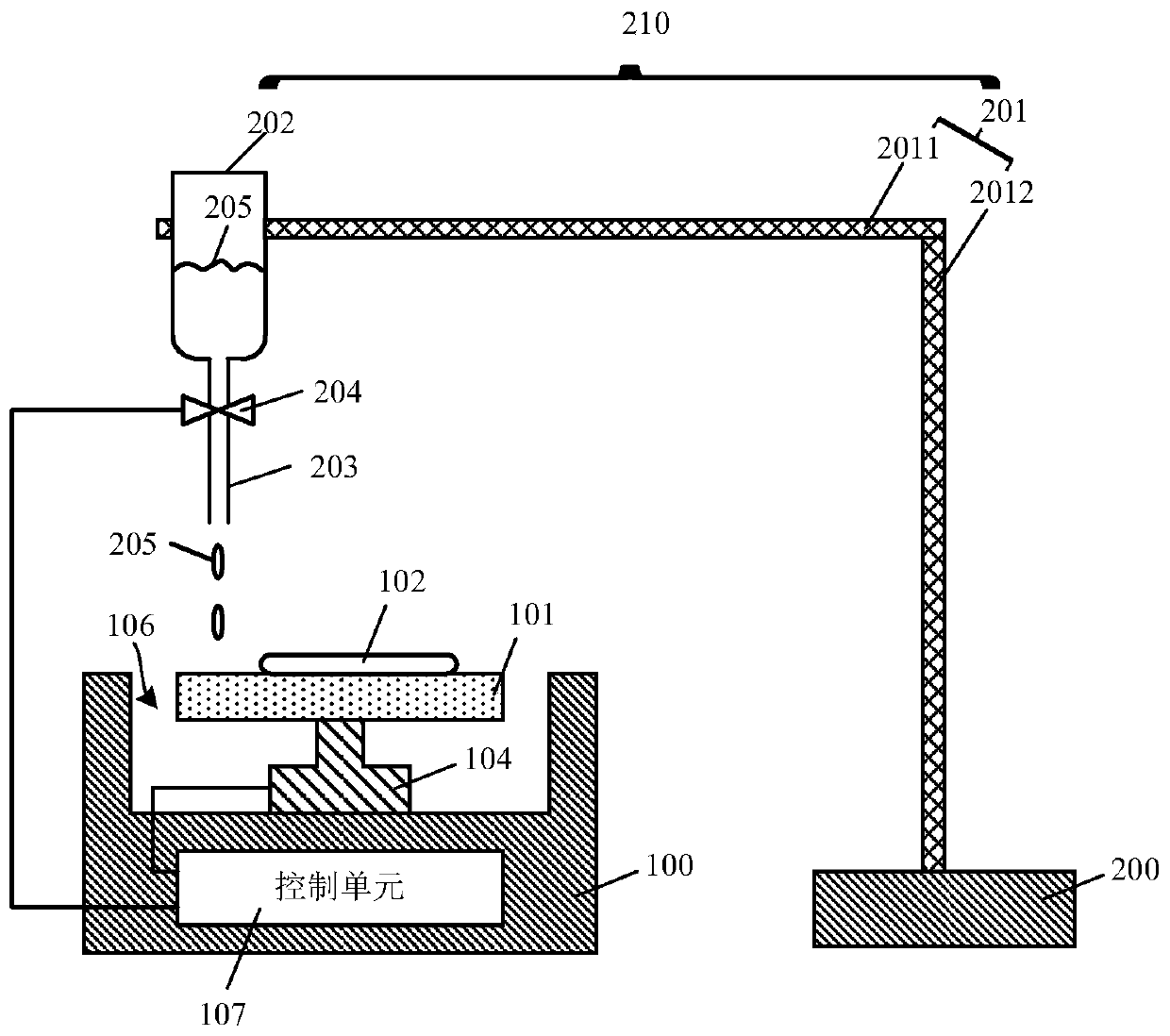

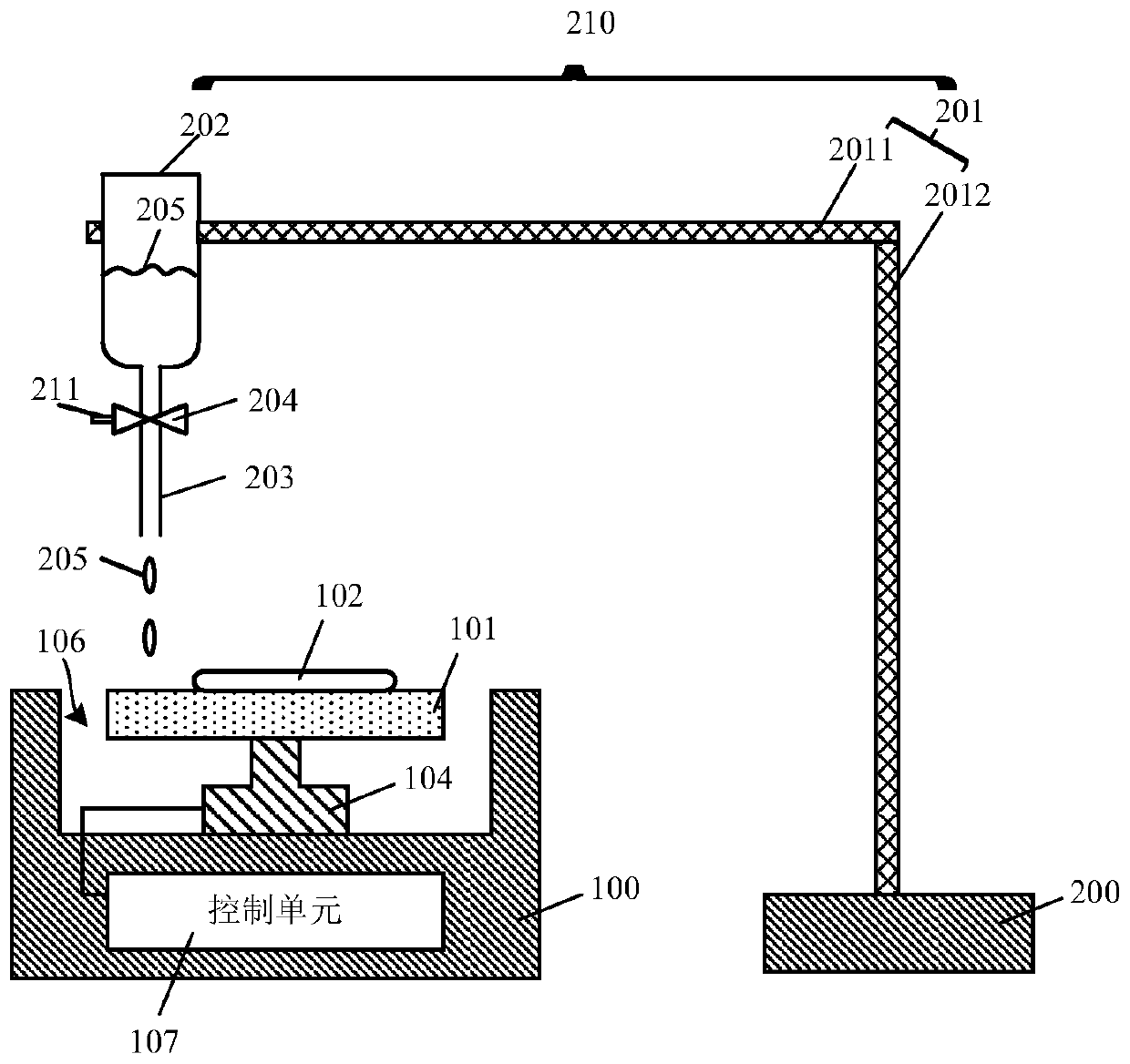

[0034] As mentioned in the background art, when the existing invalid wafer grinding device grinds the invalid wafer, it is easy to cause problems such as uneven grinding and great waste of polishing fluid.

[0035] The study found that when using the existing invalid wafer grinding device to grind the invalid wafer, the grinding fluid is manually added, and the amount of grinding fluid added and the flow rate of the grinding fluid are difficult to control, which easily leads to waste of grinding fluid and insufficient grinding. In addition, one hand needs to be used to press the back of the failed wafer during grinding, and the other hand is required to add the grinding liquid, which is not conducive to grinding with both hands, and further affects the uniformity of grinding the failed wafer.

[0036]For this reason, the present invention provides a kind of failure wafer grinding device, comprises: grinding table, and described grinding table has grinding surface, is used for g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com