Floating sensing grinding head device and constant force grinding method

A technology of grinding head and floating joint, applied in grinding/polishing safety device, grinding frame, grinding bed, etc., can solve the problems of inability to offset, grinding pressure influence, grinding uniformity defect, etc., to achieve grinding Good uniformity, constant pressing force and good grinding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

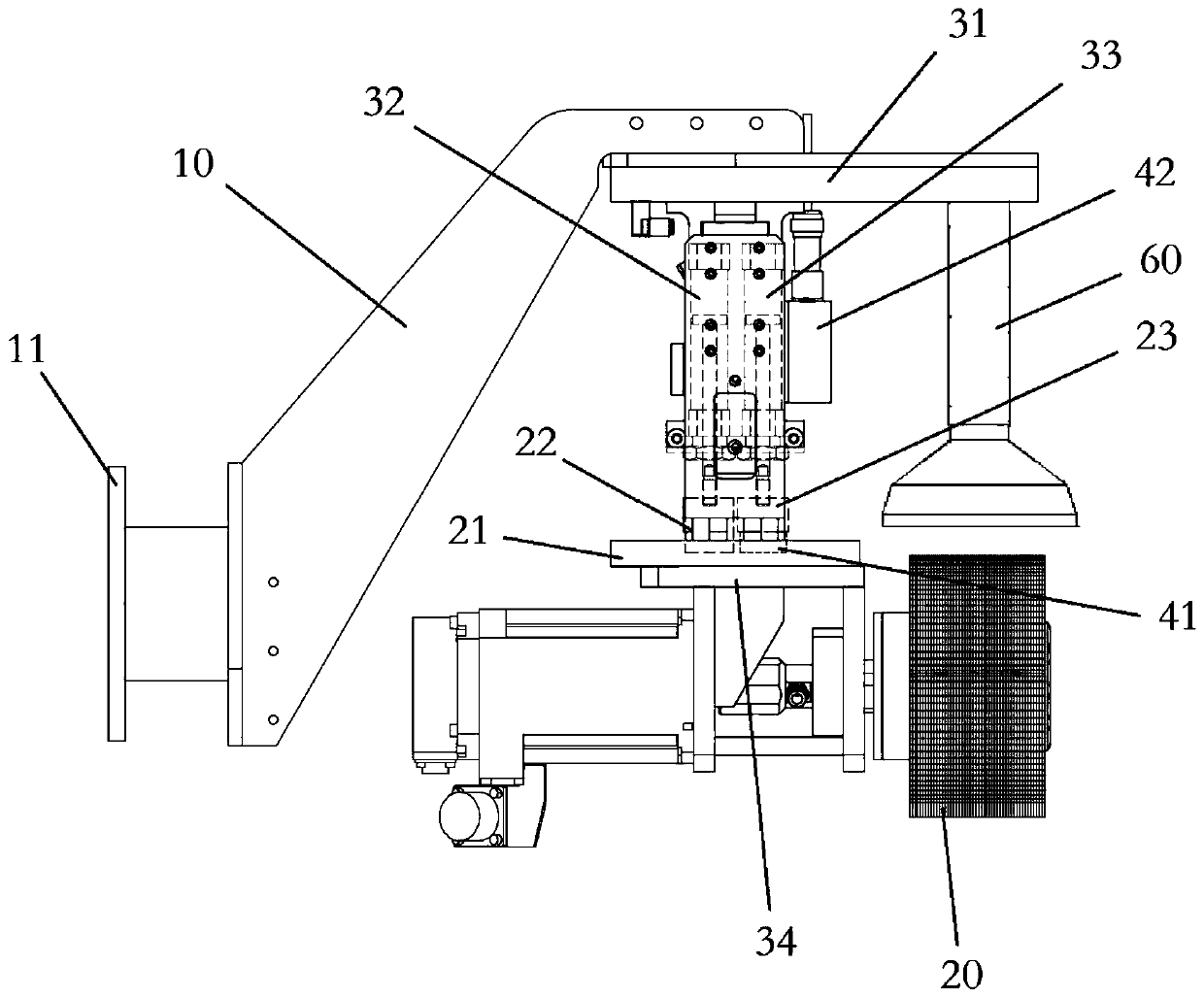

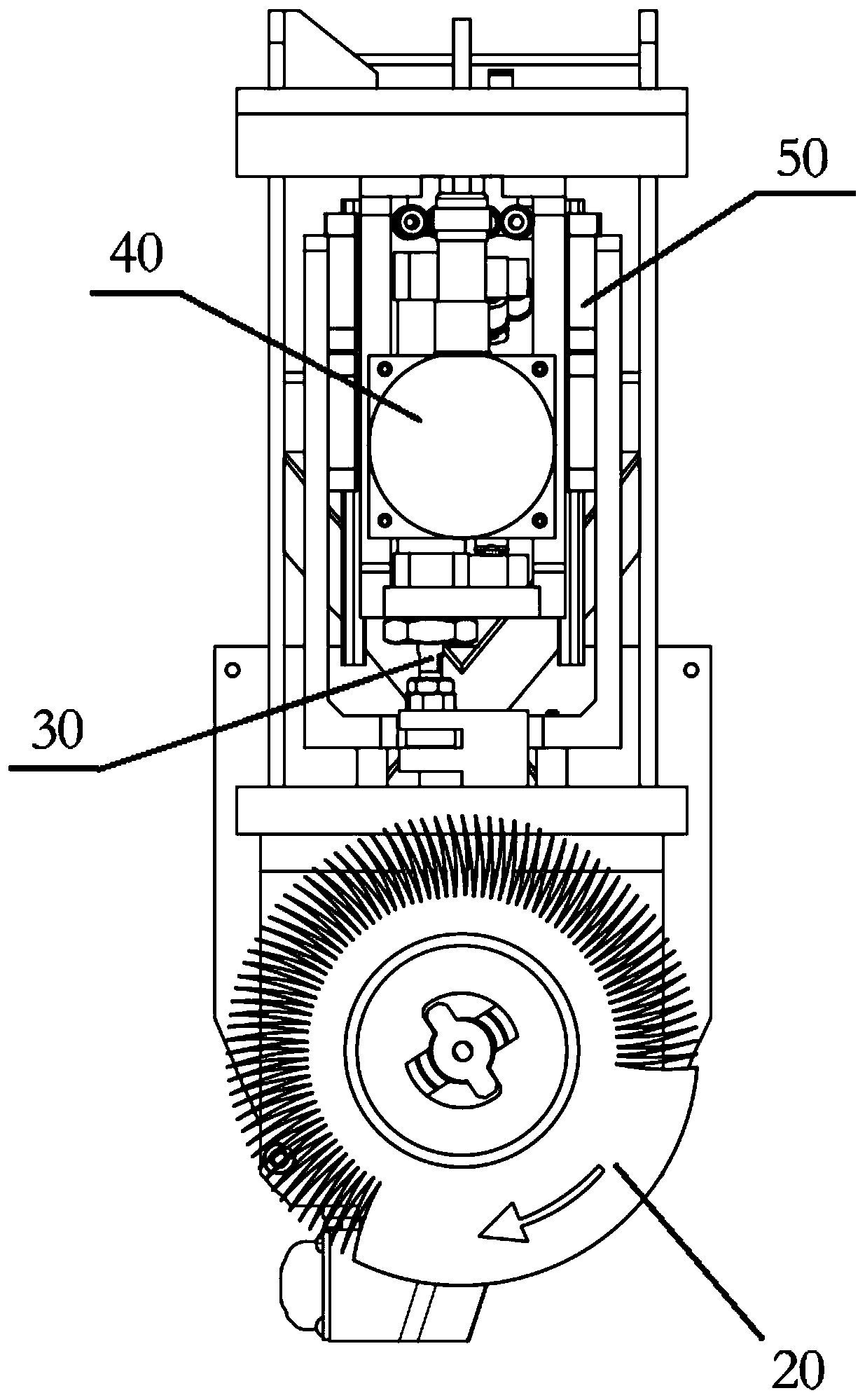

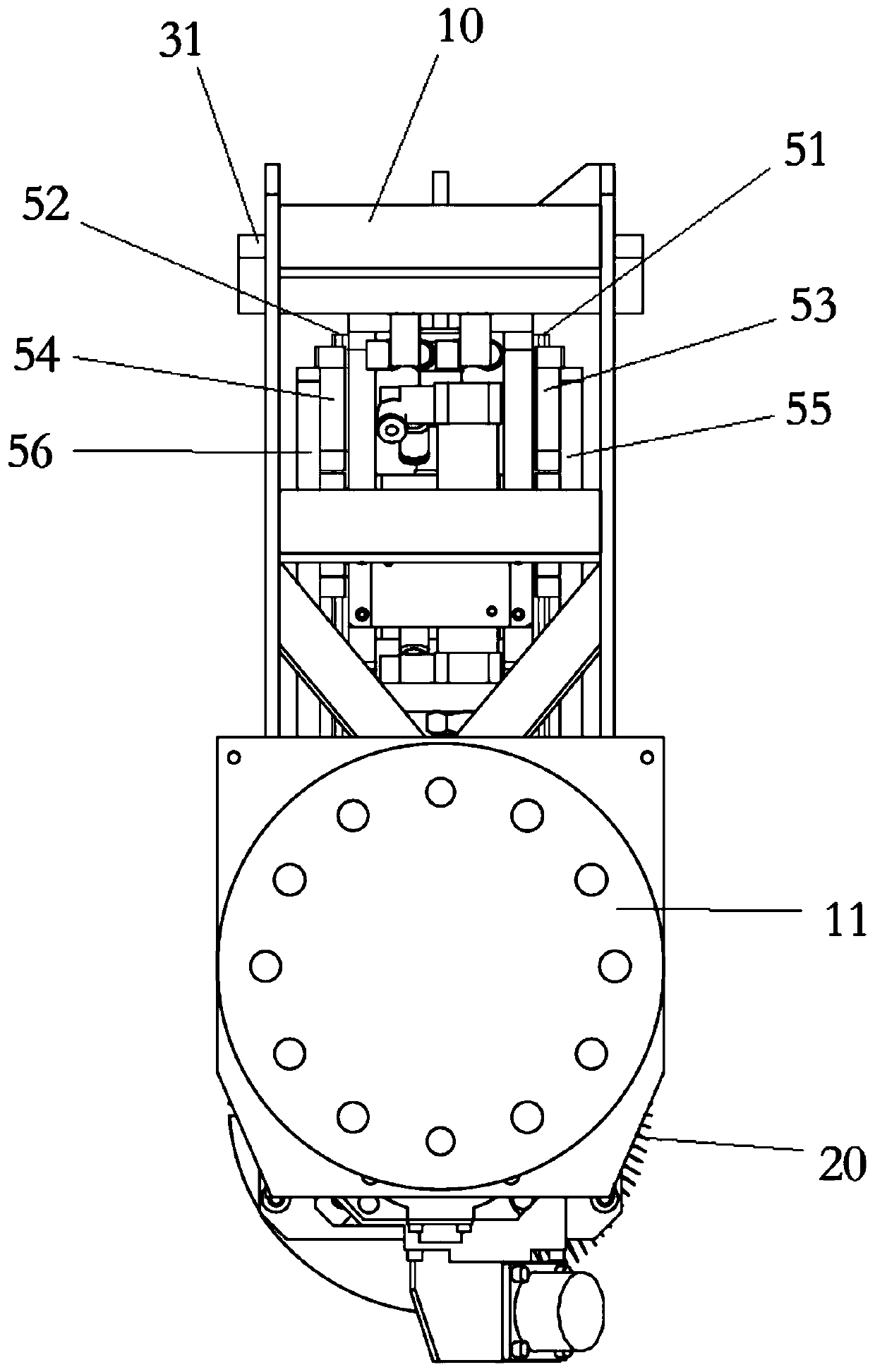

[0046] A floating sensing grinding head device, such as figure 1 As shown in -3, it includes a grinding head frame body 10, a grinding machine 20, a two-way floating assembly 30, a floating sensing assembly 40, a controller, a double slide rail assembly 50 and a dust discharge duct 60.

[0047] The grinding head frame body 10 is arranged at the execution end of the manipulator, which can switch the grinding position synchronously following the preset grinding track of the manipulator, wherein the grinding head frame body 10 is provided with a flange structure 11 for forming a connection with the execution end of the manipulator. Strong connections.

[0048] The two-way floating assembly 30 includes an upper fixed connection plate 31, a forward driver 32, a reverse driver 33, and a lower floating connection plate 34. The upper fixed connection plate 31 is arranged on the grinding head frame 10, and the lower floating connection plate 34 is arranged on the forward direction. Th...

Embodiment 2

[0057] This embodiment provides a floating sensing constant force grinding method, such as figure 1 As shown in -3, it includes a grinding machine 20, a grinding head frame body 10, a forward drive 32 and a reverse drive 33 located on the grinding head frame body 10, a load cell 41, a position sensor 42 and a controller, wherein the grinding machine 20 The grinding head frame body 10 is installed on the driving end of the manipulator, and the grinding machine 20 is positioned at the driving end of the forward driver 32 and the reverse driver 33, the grinding method comprises the following steps:

[0058] Set the grinding trajectory of the end of the manipulator during the grinding process;

[0059] Obtain the current coordinate position signal of the grinding machine on the grinding track through the measurement of the position sensor 42, and convert it into a first electrical signal and transmit it to the controller;

[0060] Measure and obtain the weight signal of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com