Patents

Literature

46 results about "Backdrive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

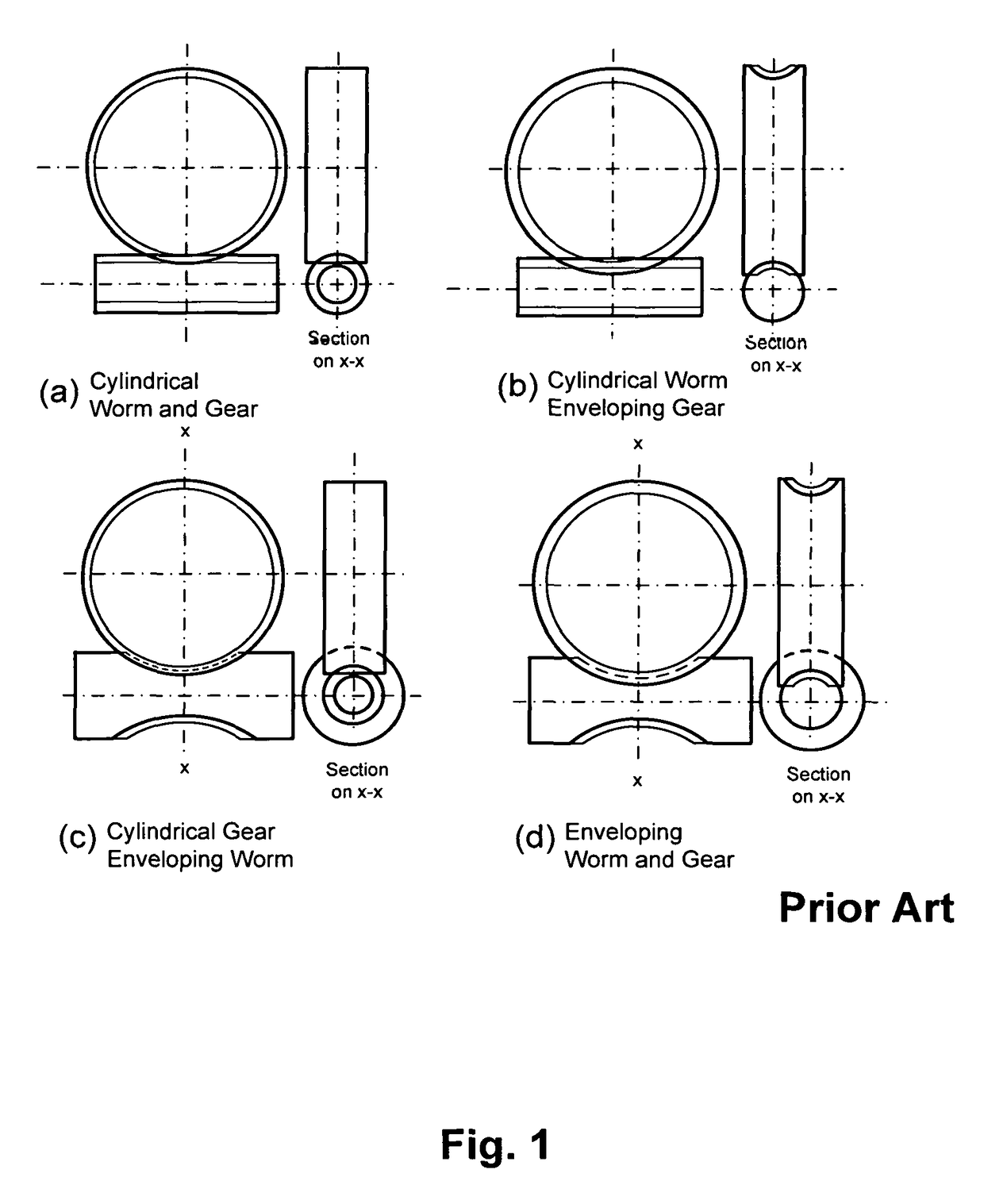

A backdrive is a component used in reverse to obtain its input from its output. This extends to many concepts and systems from thought based to practical mechanical applications. Not every system can be backdriven. A DC electrical generator can be implemented by backdriving a DC electric motor, however a worm drive works only in one direction.

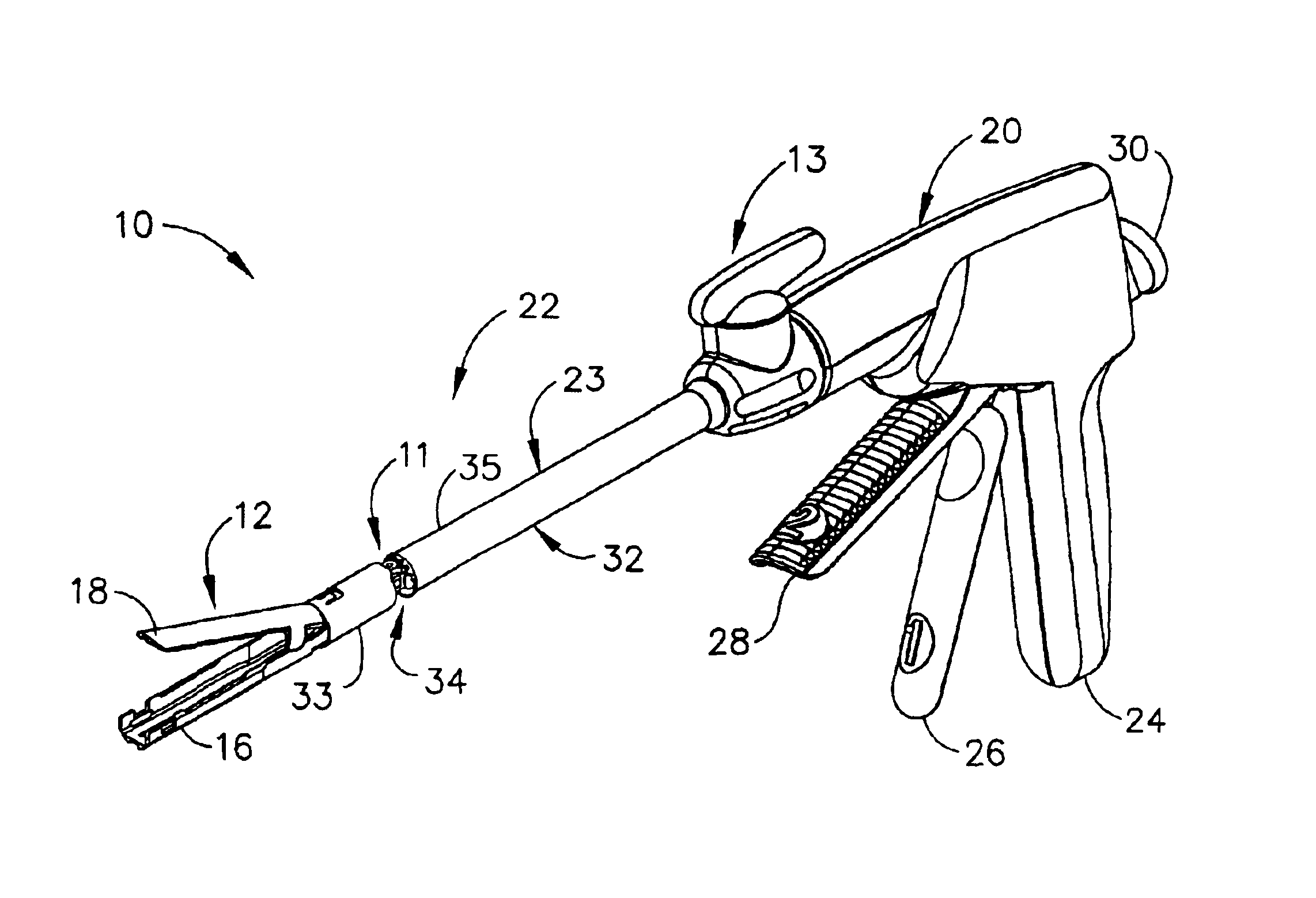

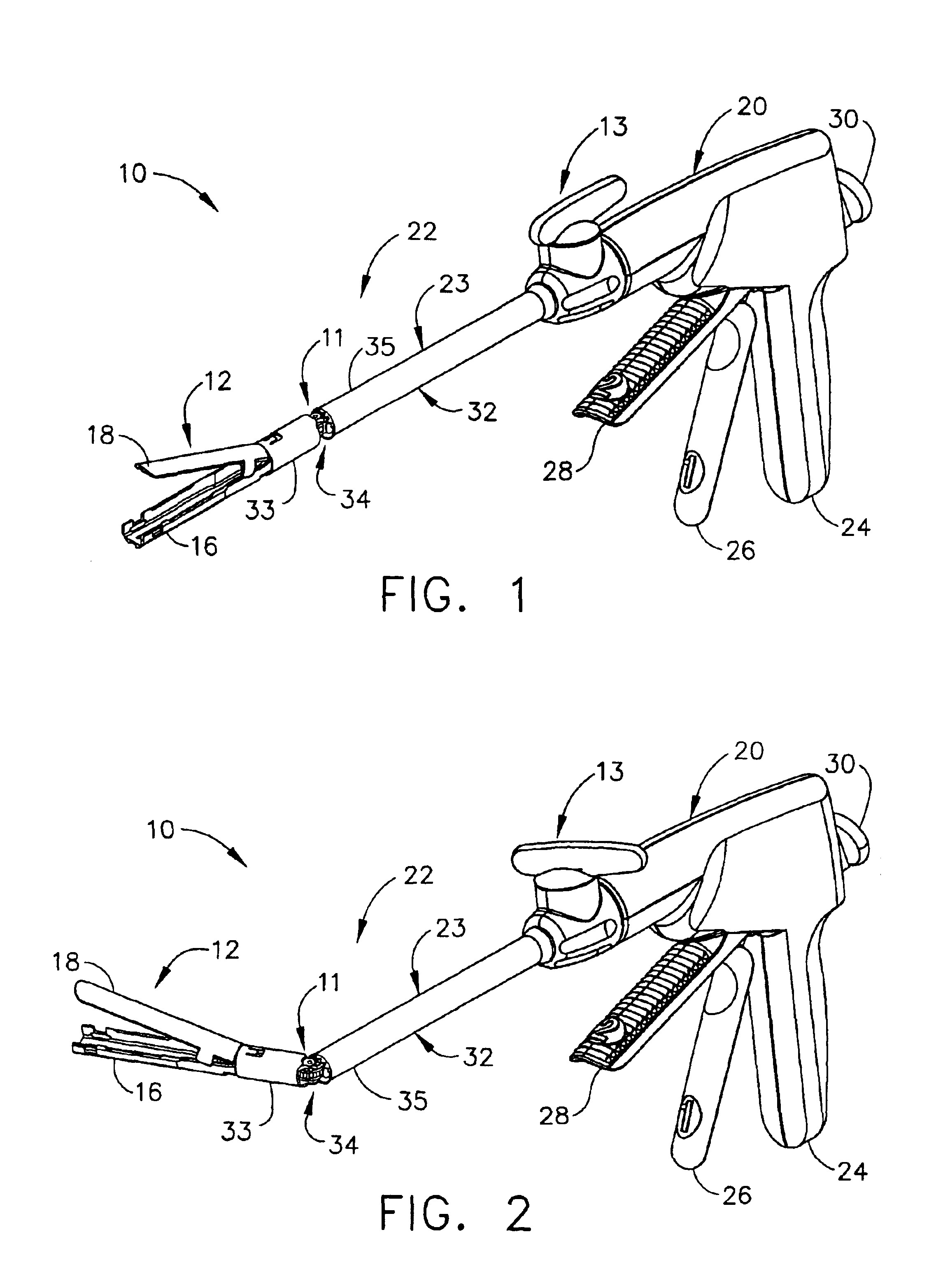

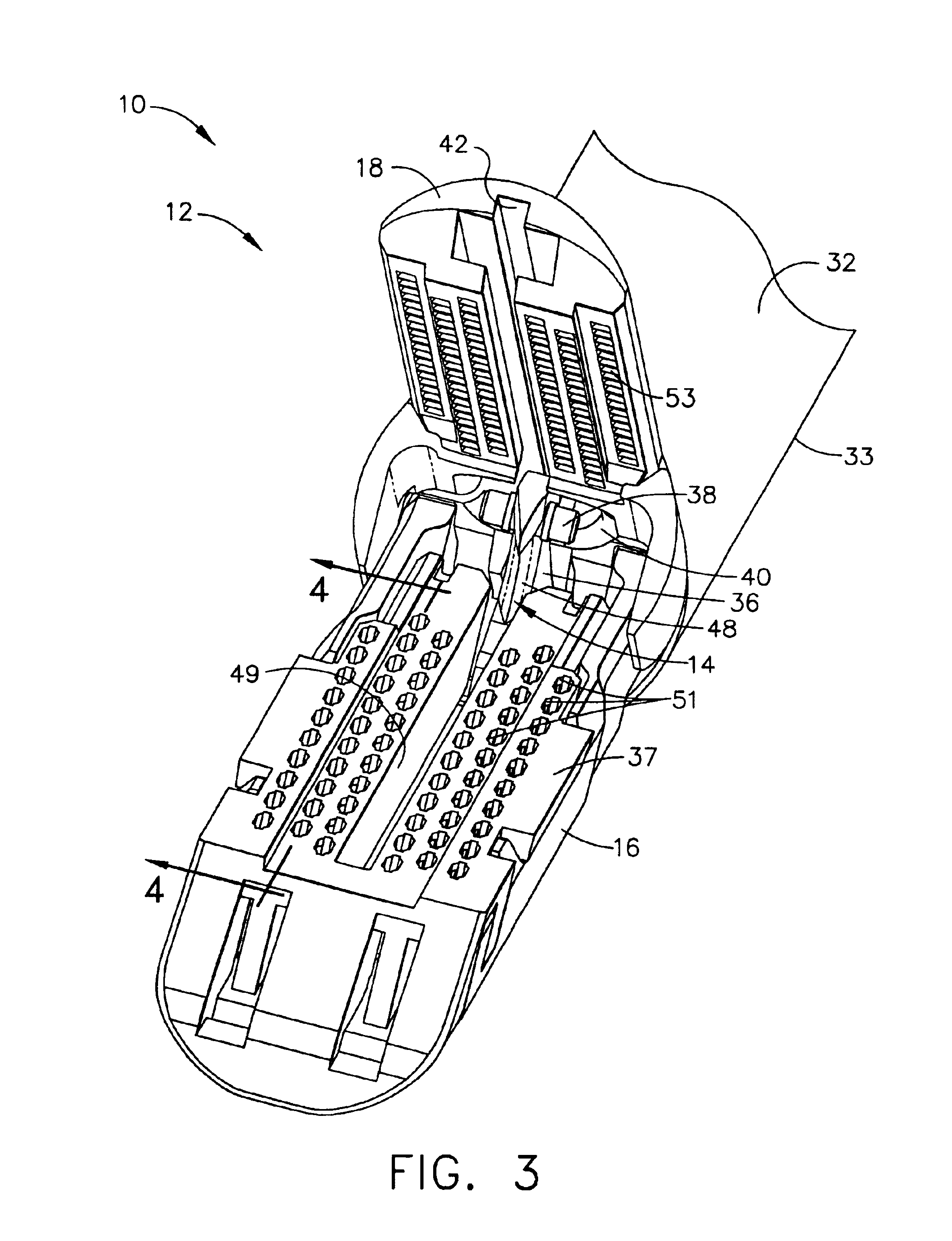

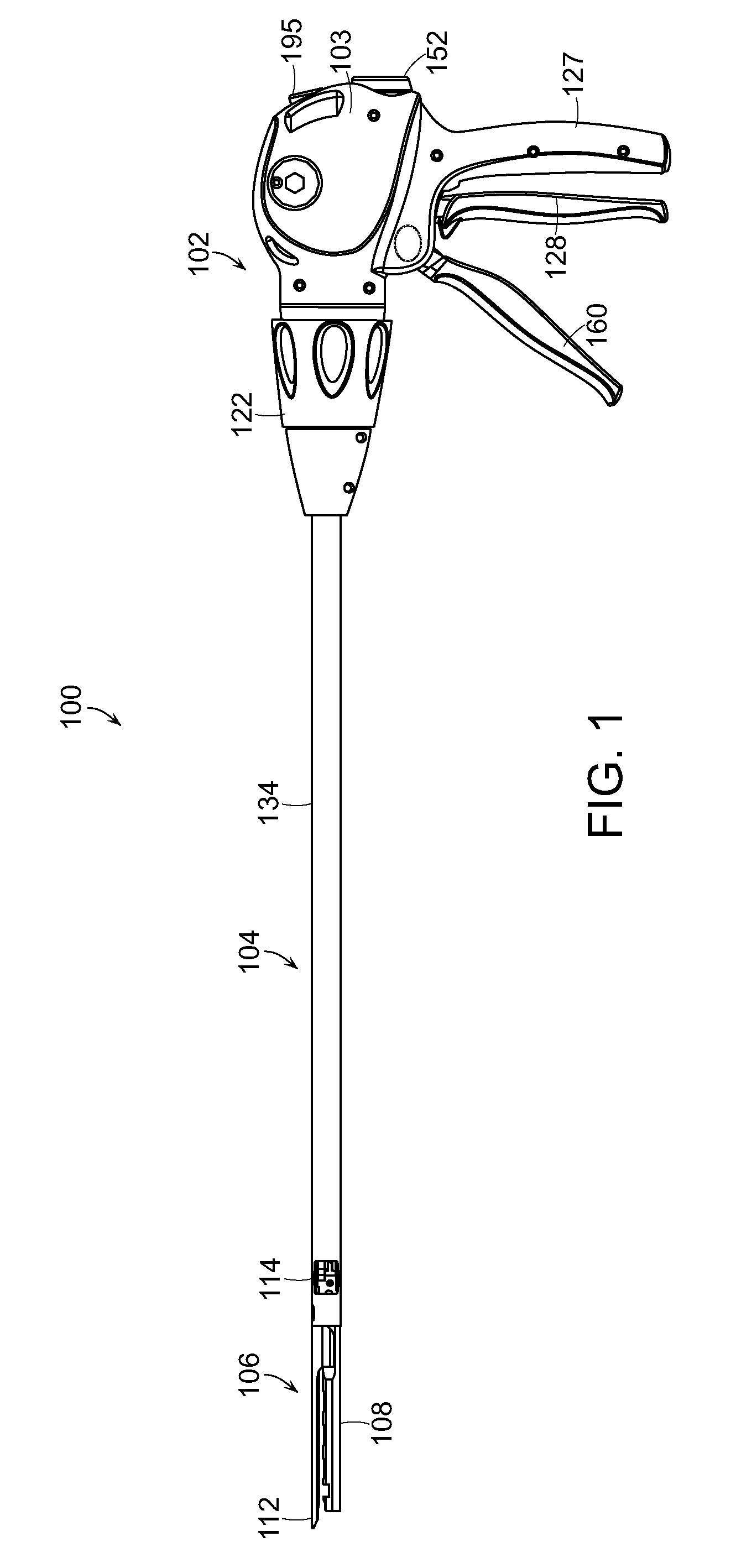

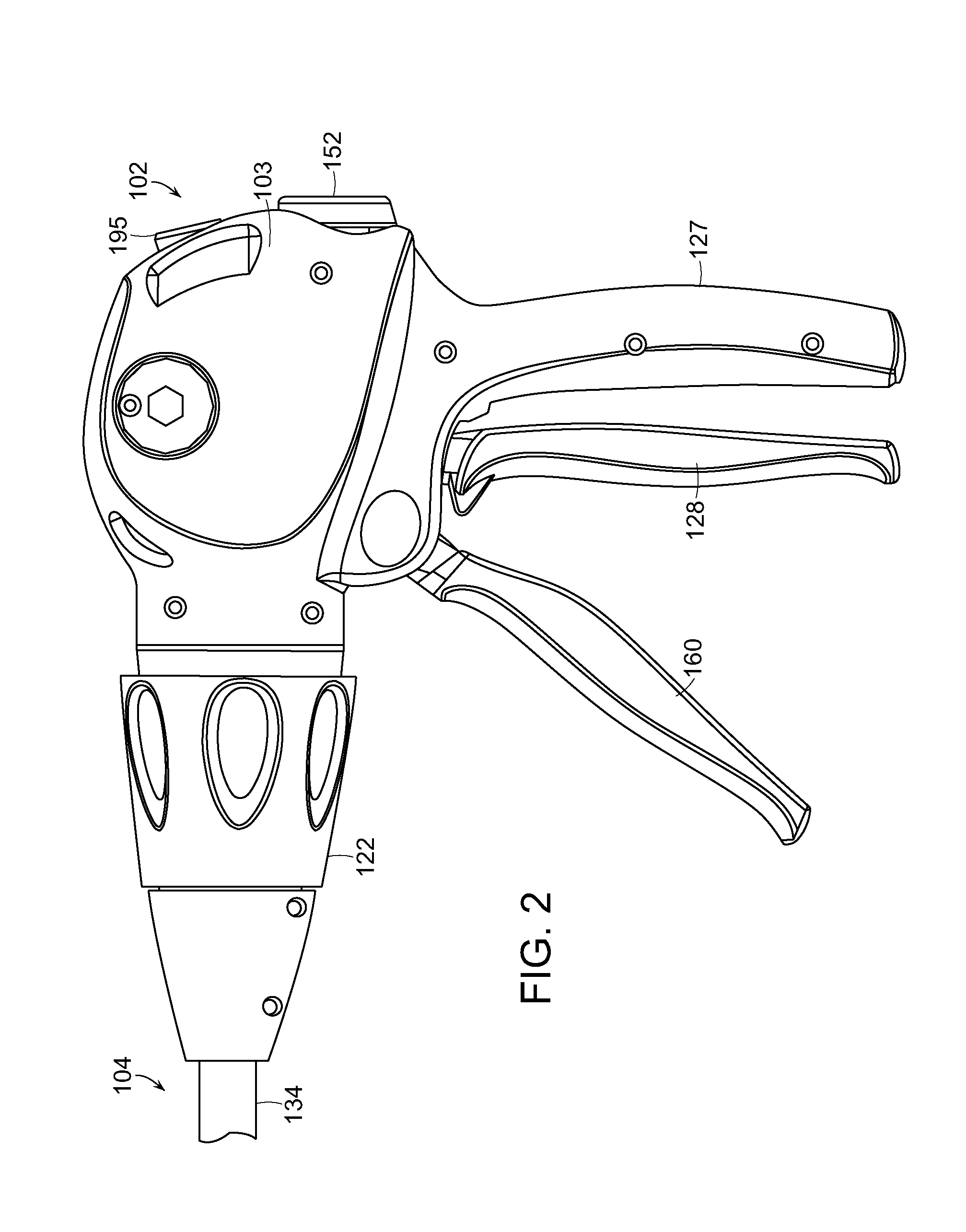

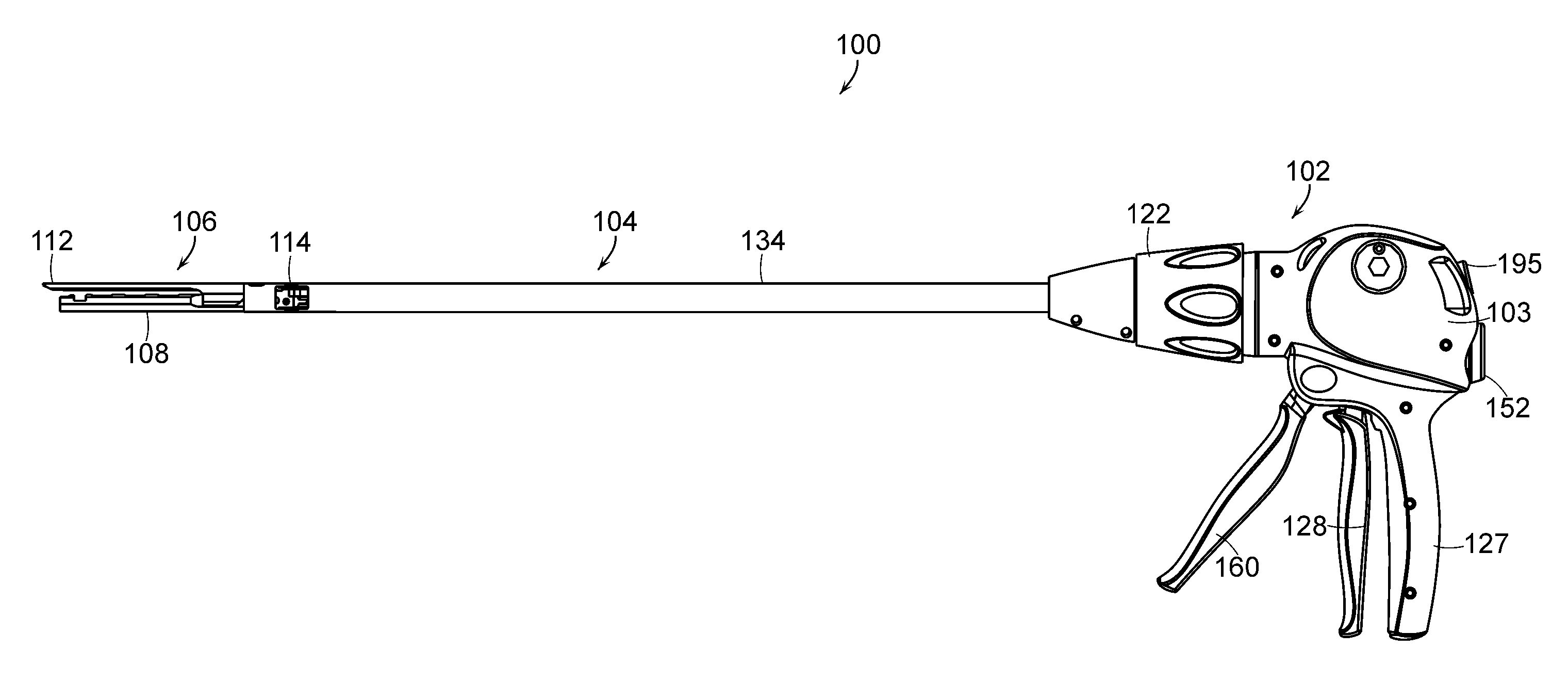

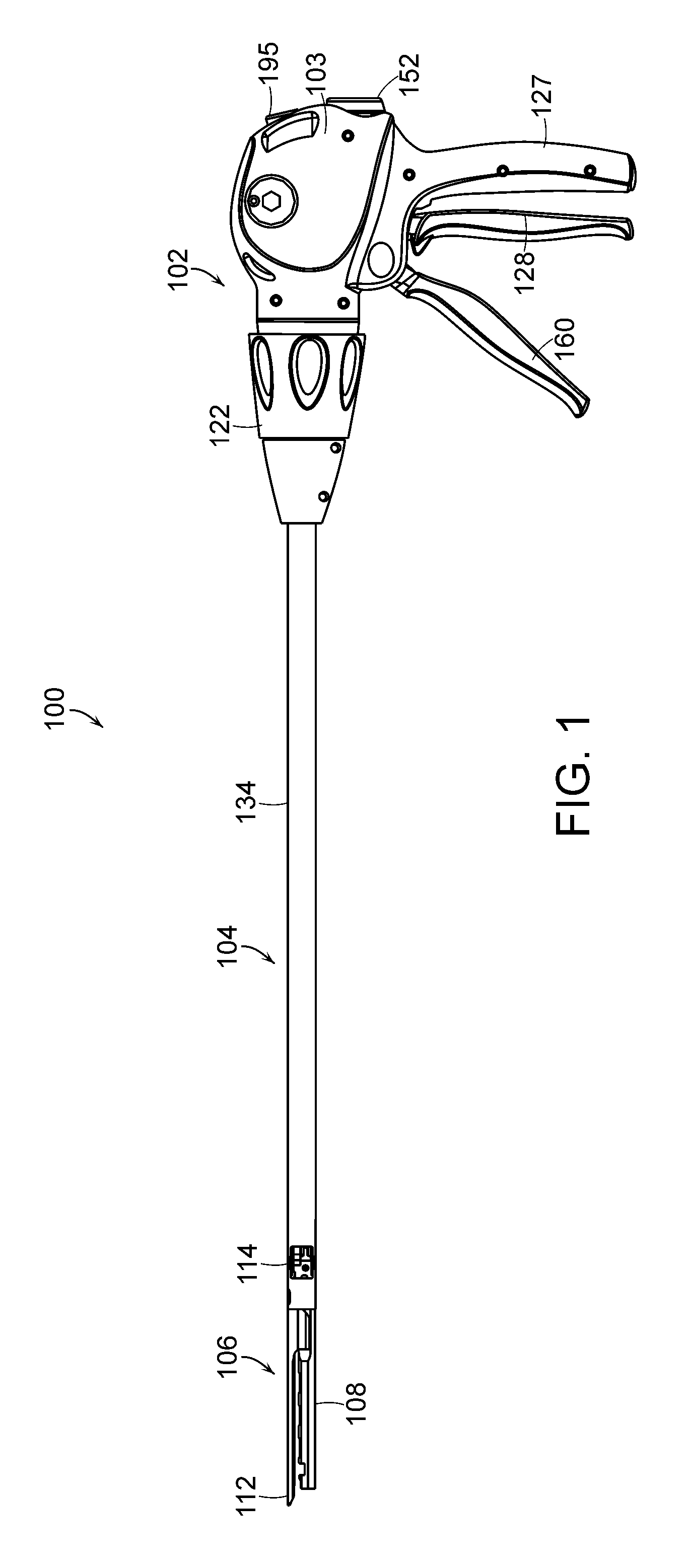

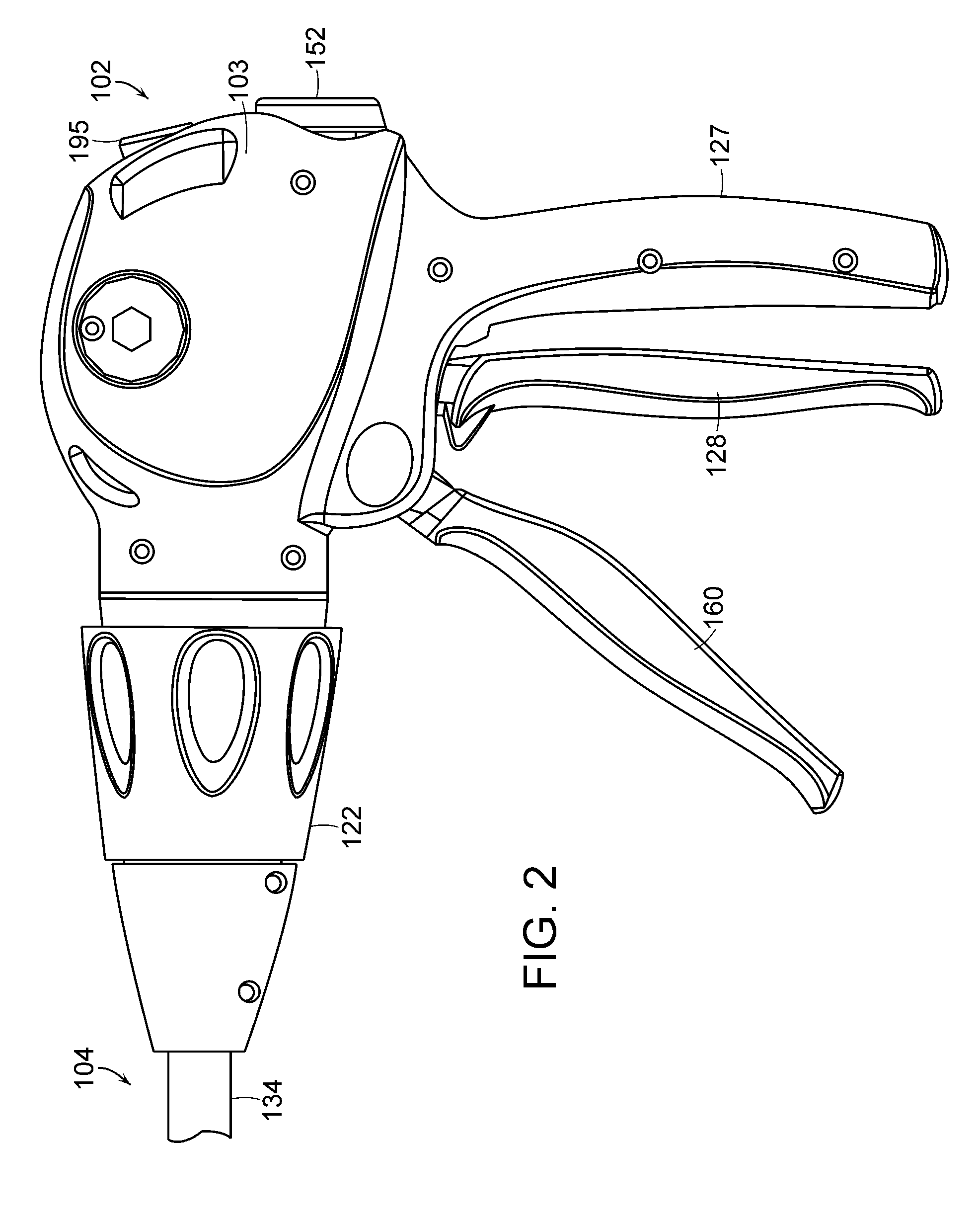

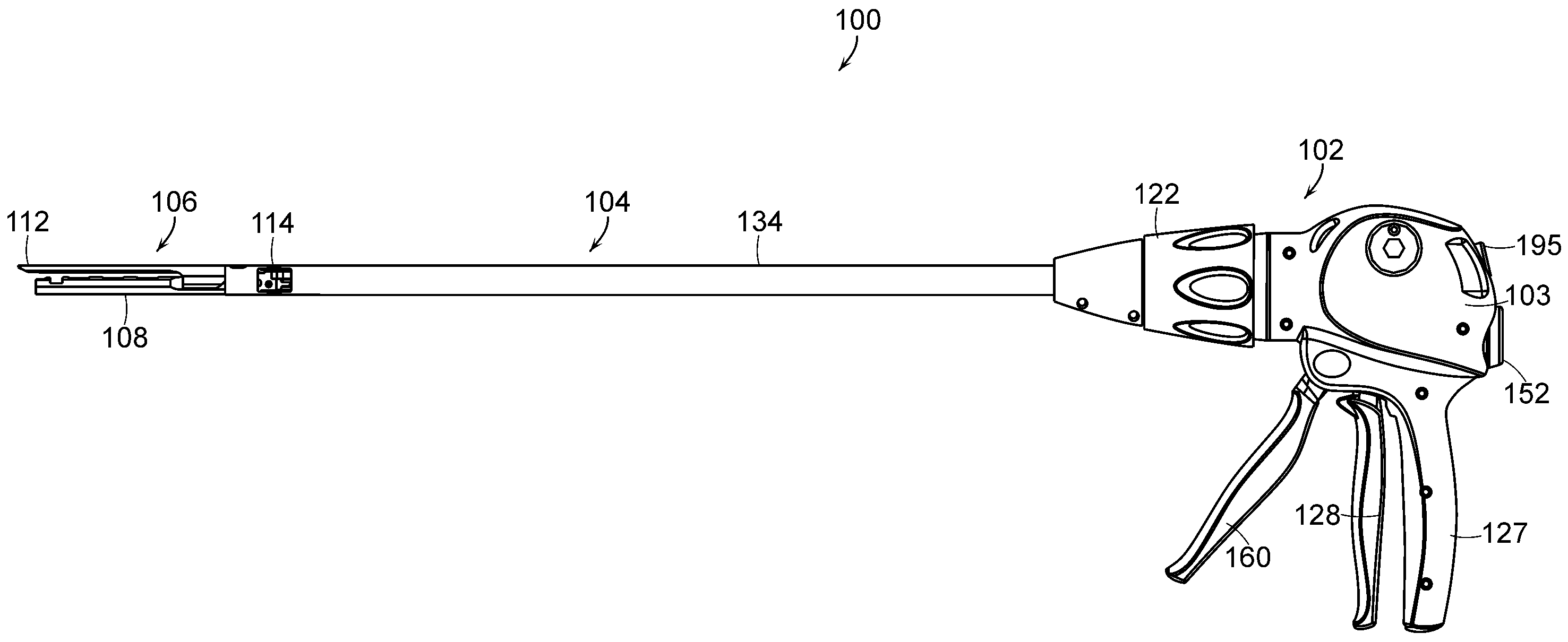

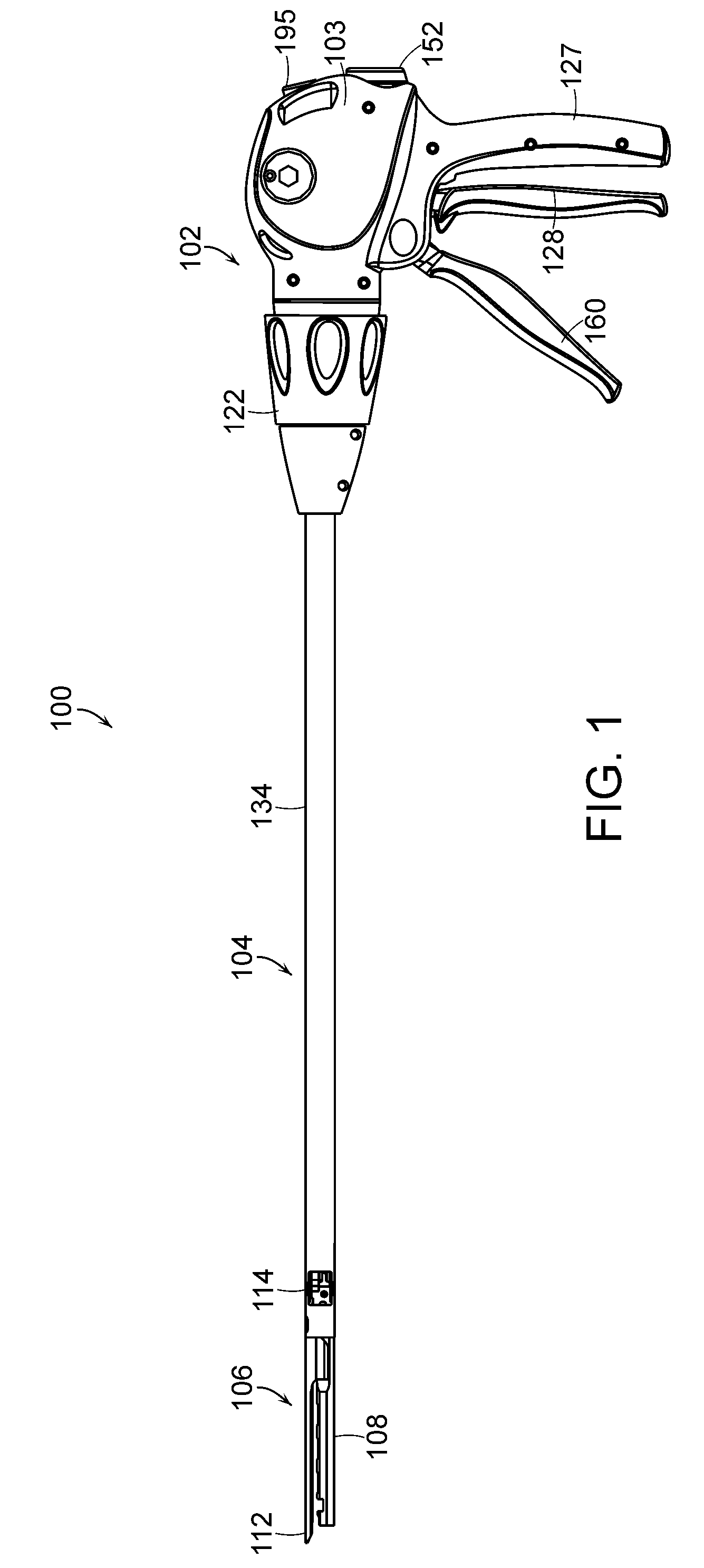

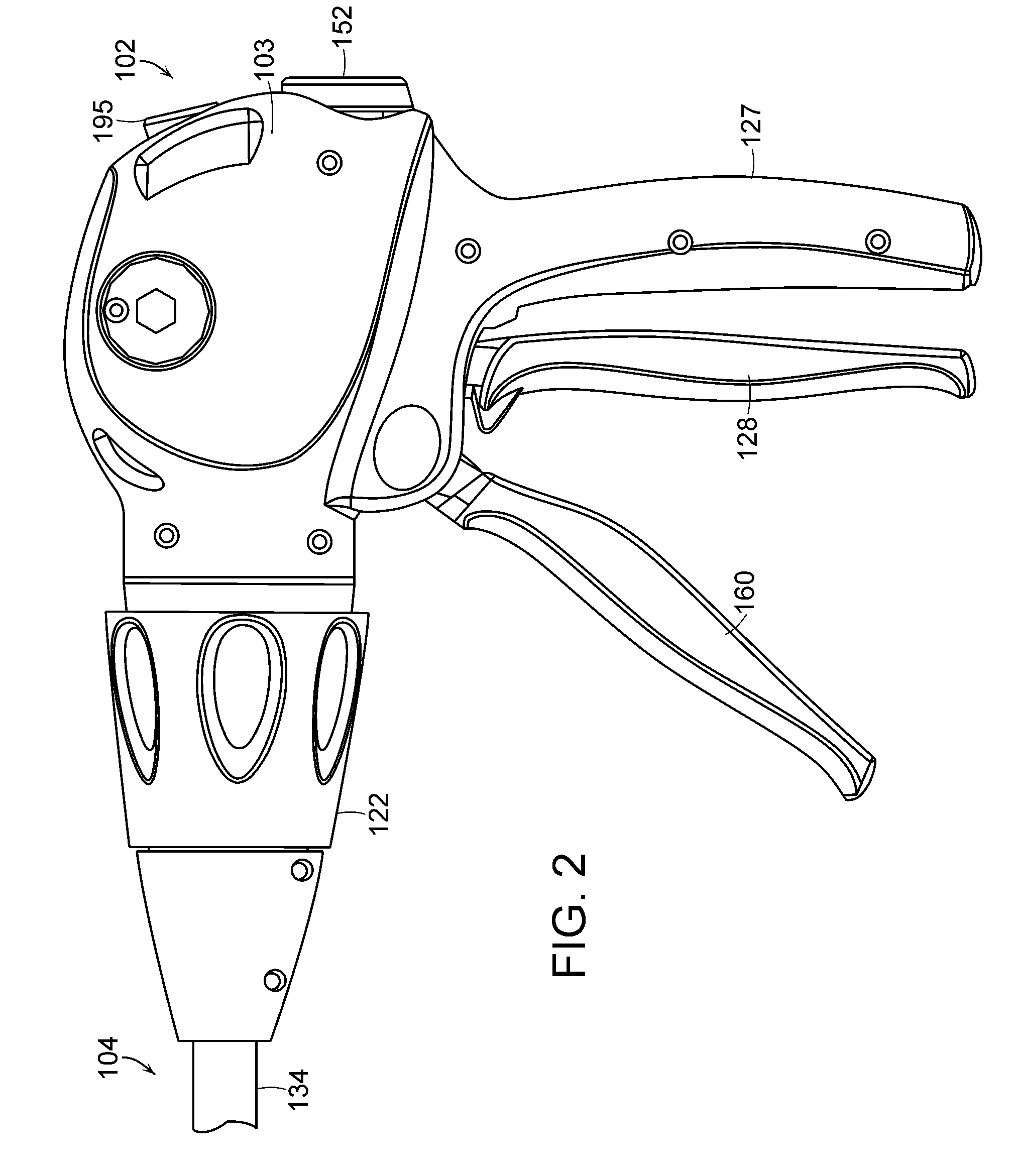

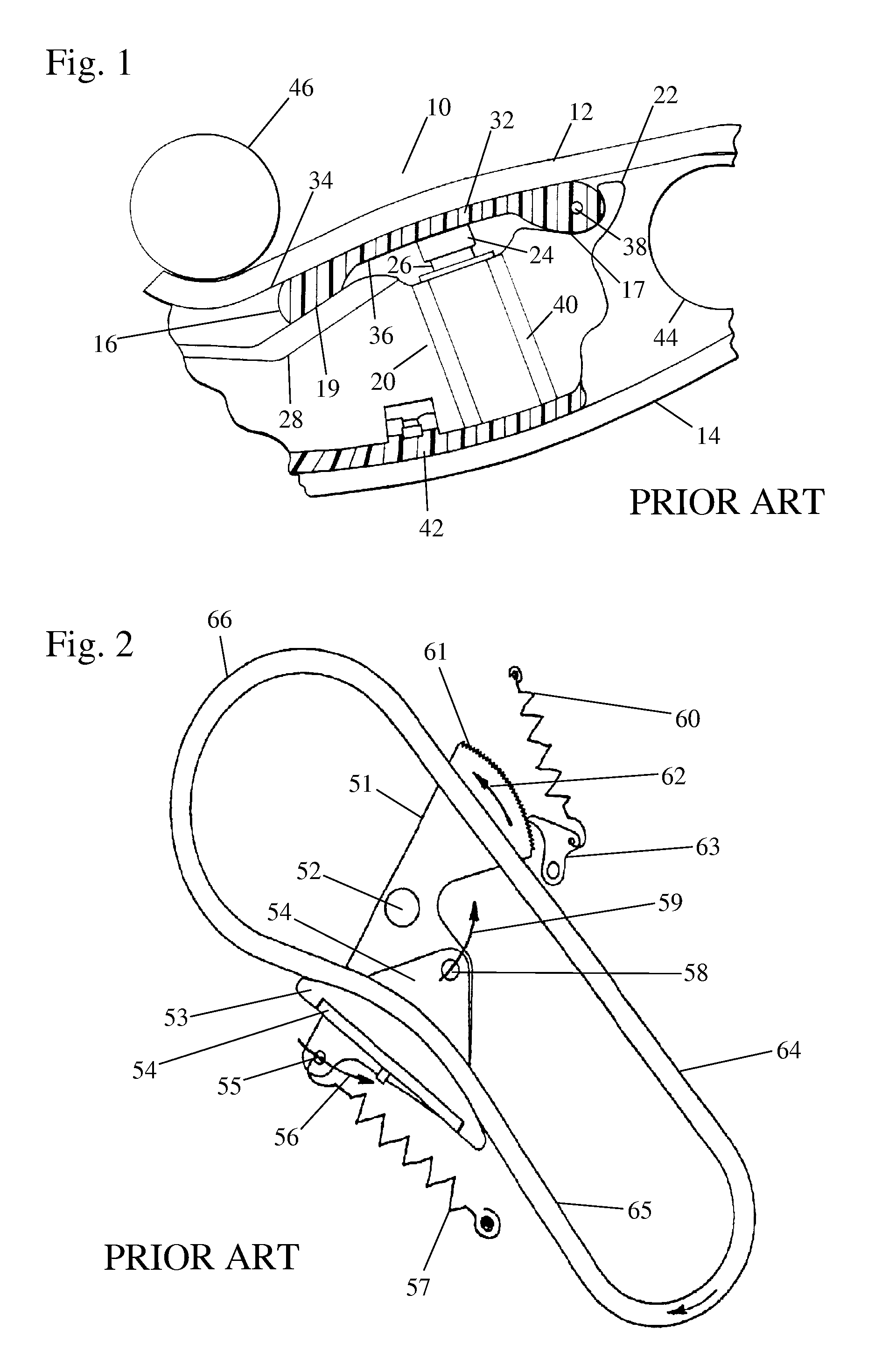

Surgical instrument with a lateral-moving articulation control

InactiveUS6981628B2Complicate amountComplicate directionSuture equipmentsStapling toolsEngineeringTarsal Joint

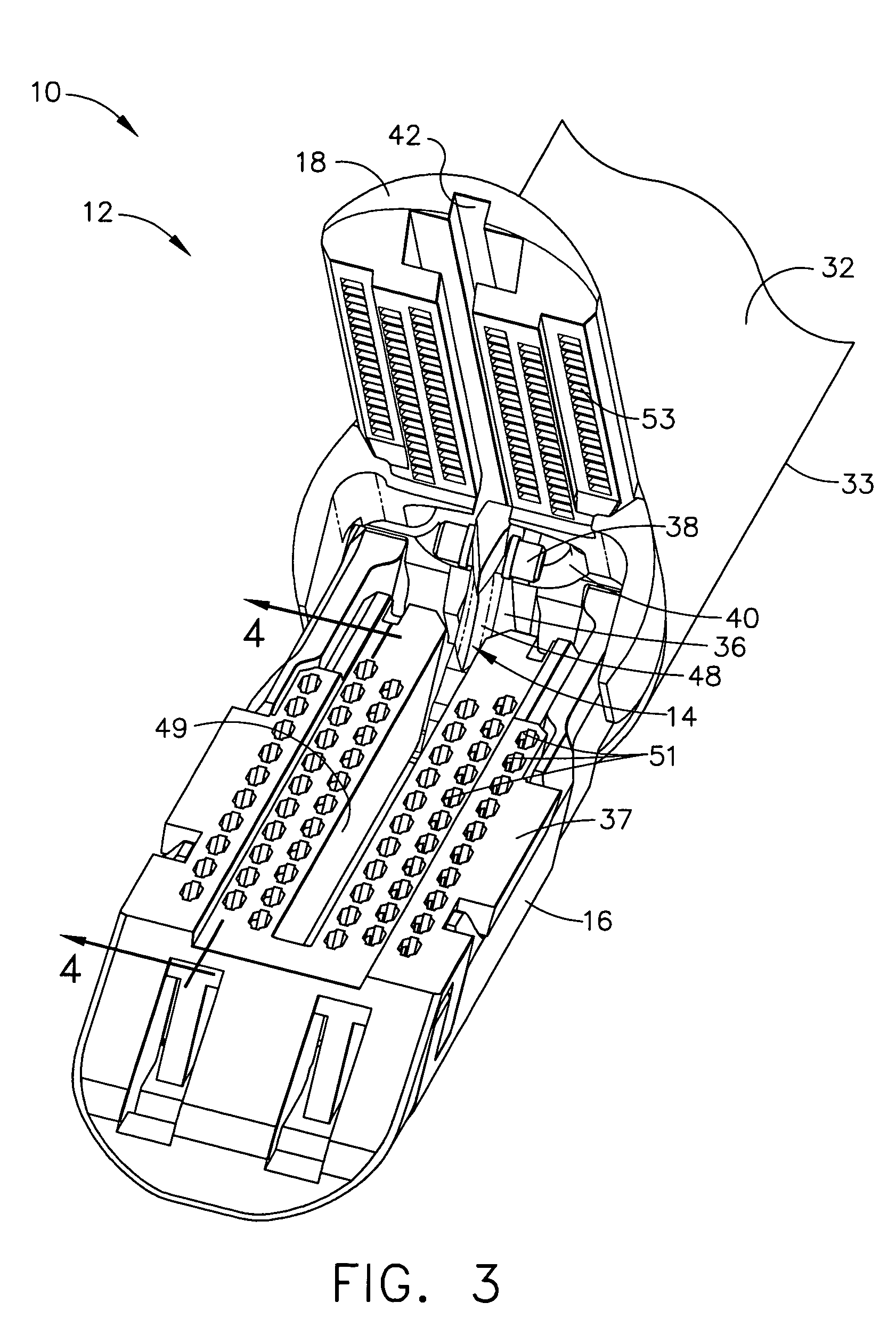

An articulating surgical instrument suited for endoscopic use includes a lateral articulation control into a handle portion that provides an intuitive visual and tactile indication to the clinician as to the amount and direction of articulation of an end effector at a distal end of a shaft. Lateral movement of a lateral control actuator is converted into a longitudinal motion or a rotational motion transferred by the shaft to an articulation mechanism. A version of a lateral articulation control for a rotationally driven articulation mechanism incorporates an articulation backdrive lockout that prevents forces on the end effector from causing the selected amount of articulation from being changed.

Owner:CILAG GMBH INT

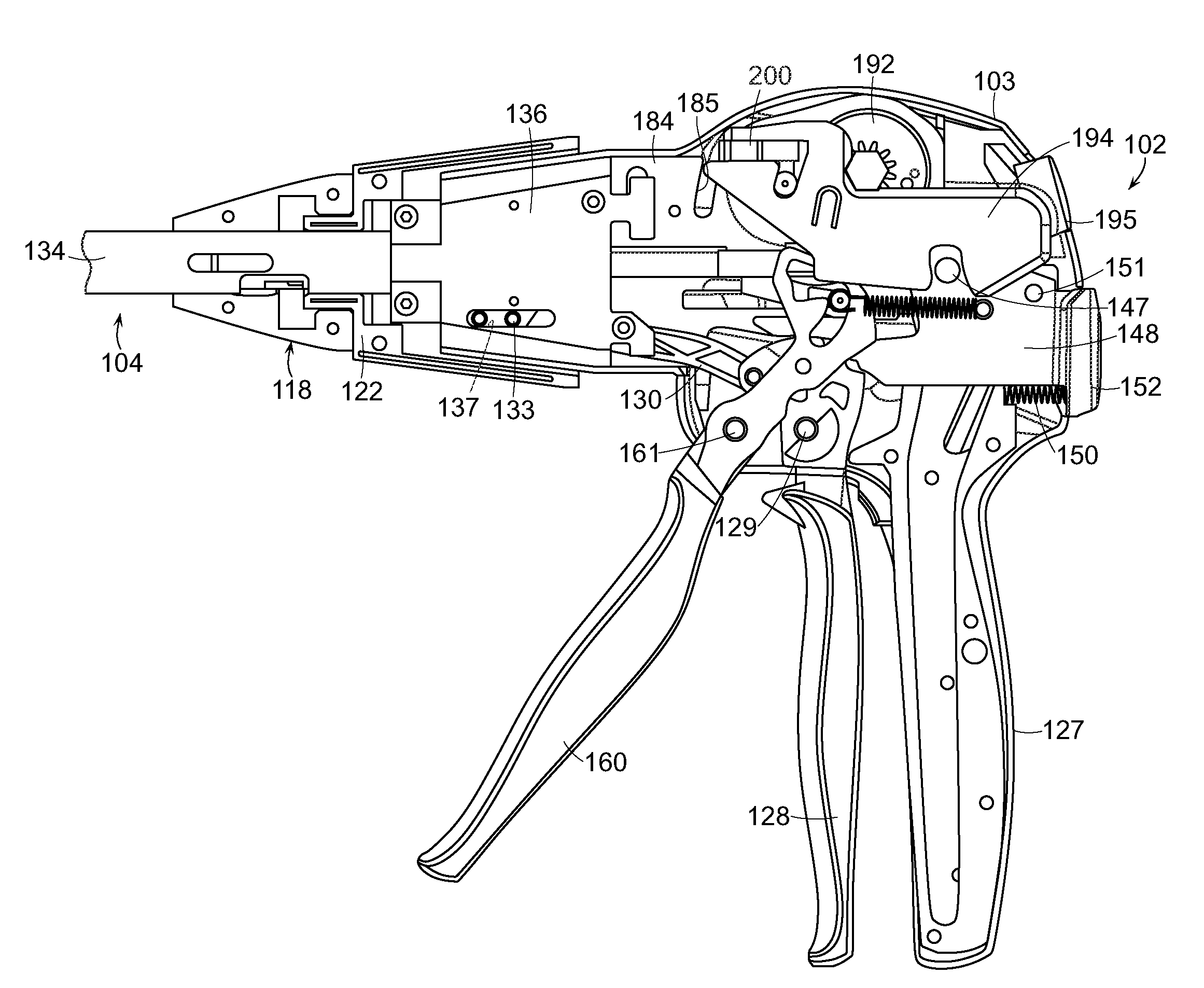

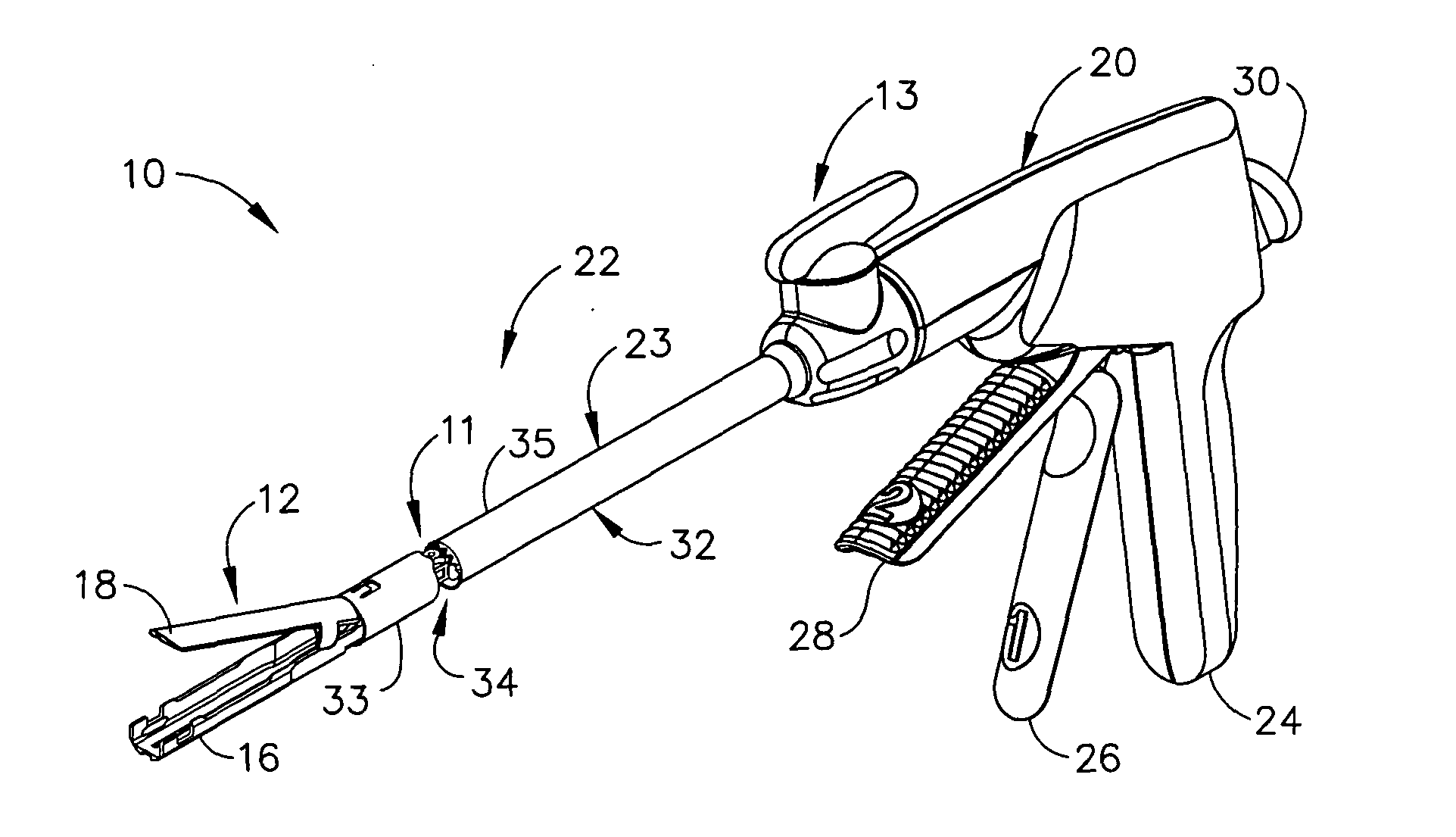

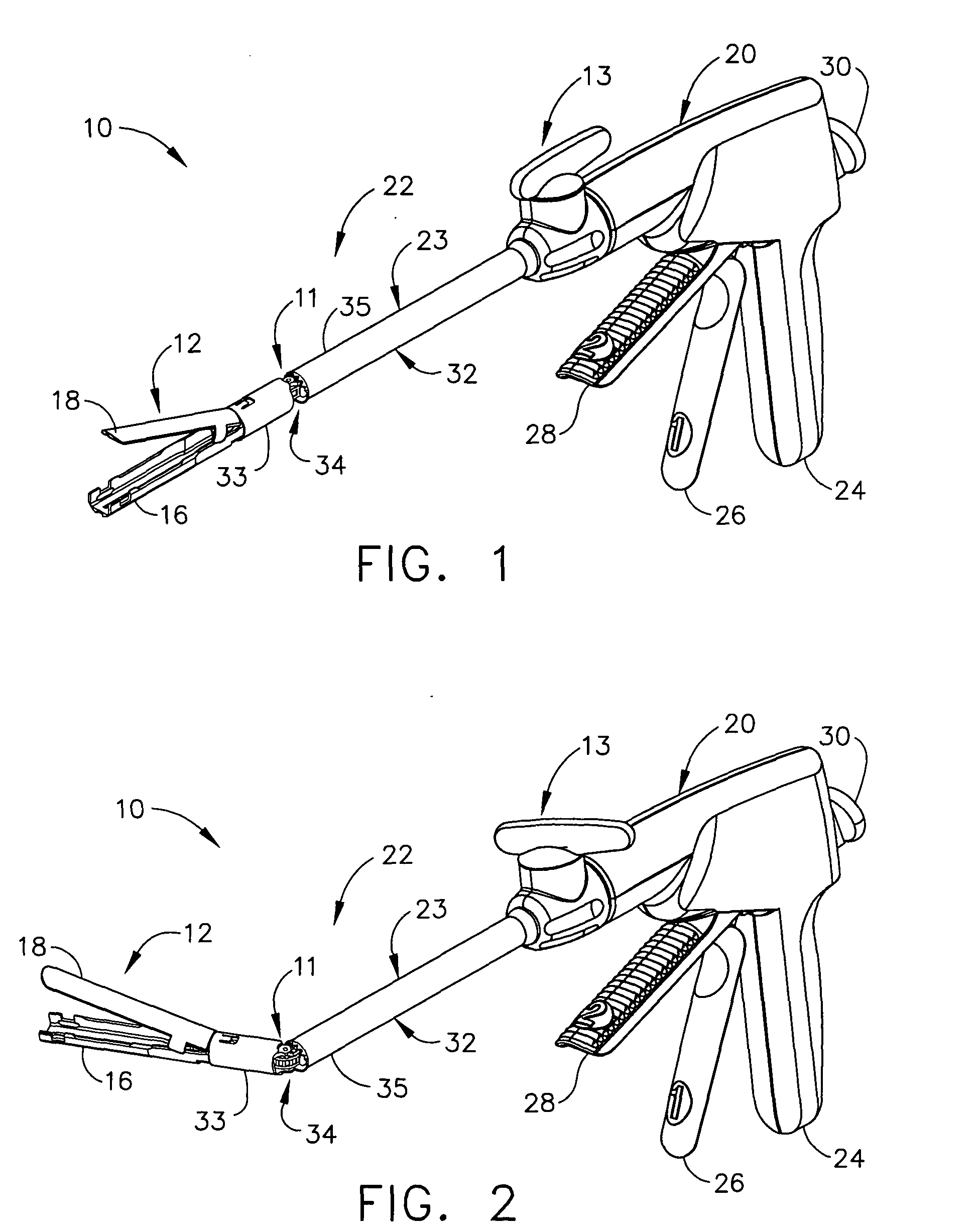

Surgical stapling instrument with a geared return mechanism

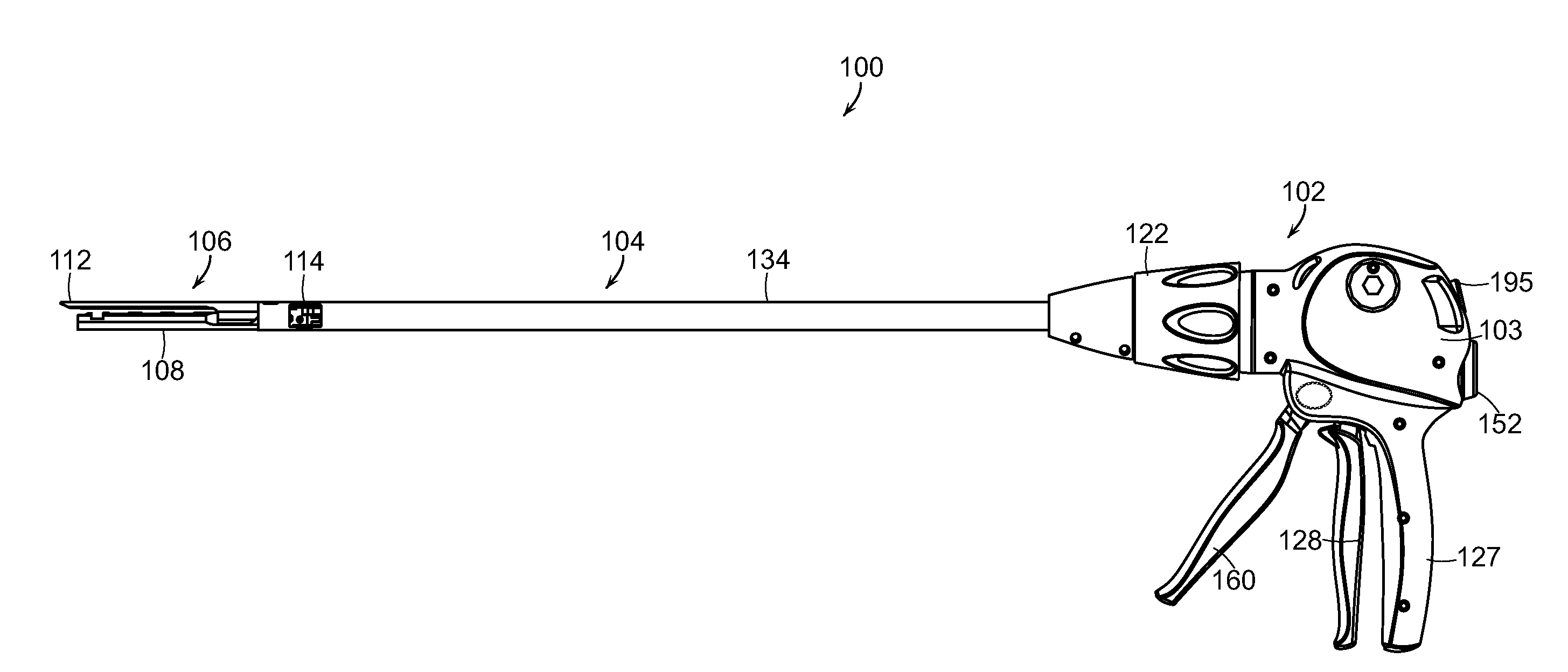

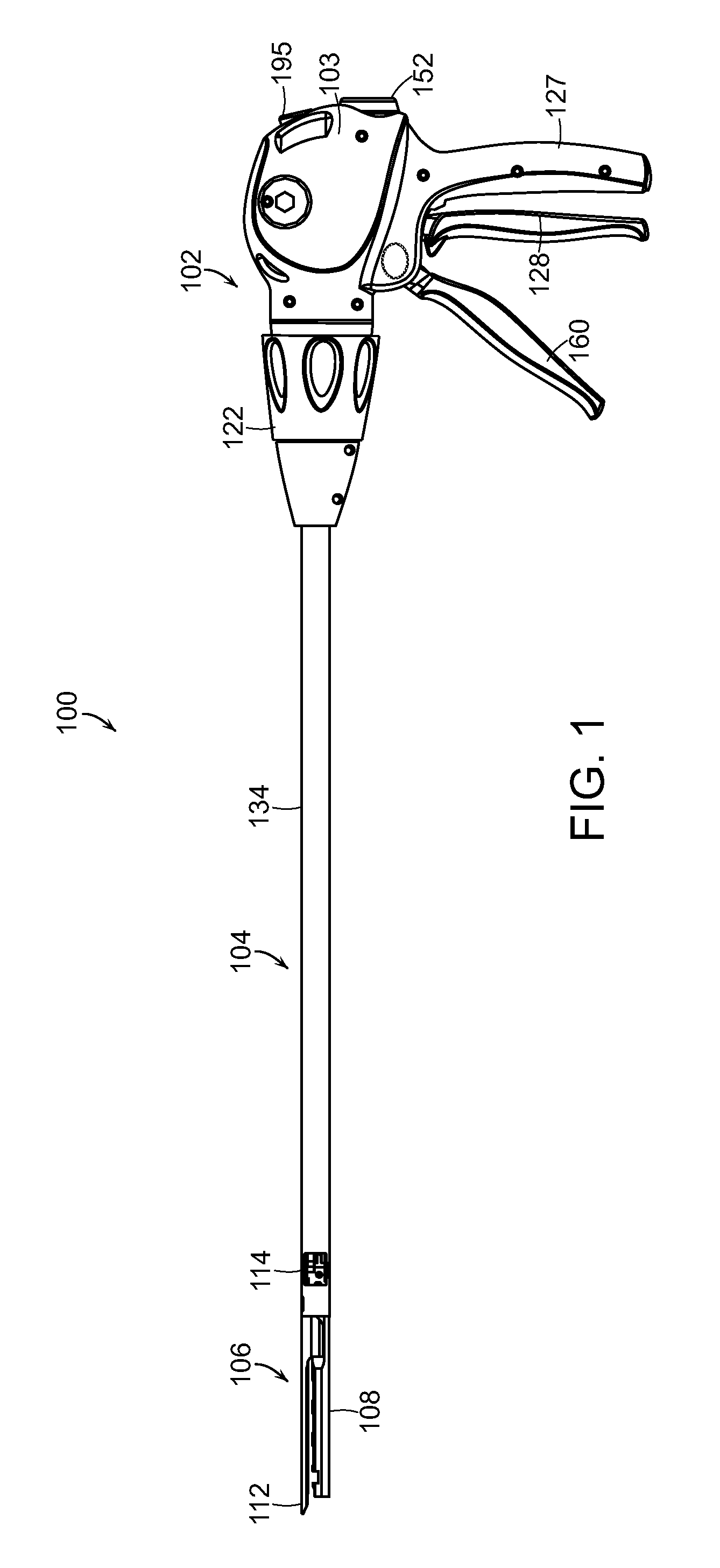

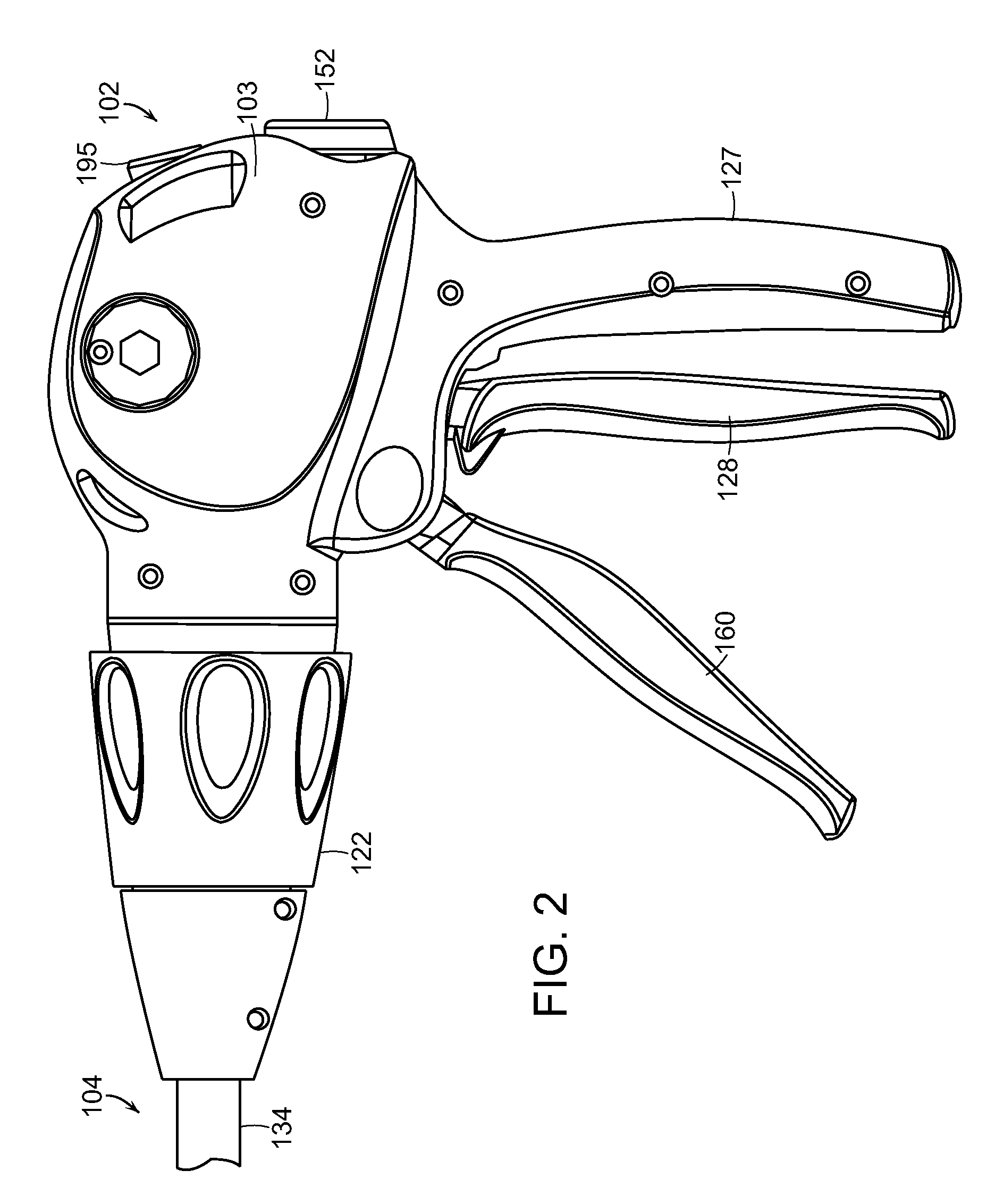

A surgical instrument including a firing drive configured to selectively advance a firing member and / or cutting member relative to an end effector and, in addition, a reversing drive configured to selectively retract the firing member and / or cutting member relative to the end effector. The firing drive can include a pawl which can be selectively engaged with the firing member in order to advance the firing member, wherein the pawl can be disengaged from the firing member when the reversing drive is engaged with the firing member. The reversing drive can include a gear train having a first gear operably engaged with the firing member and, in addition, a second gear operably engaged with the first gear, wherein the second gear can be selectively operable with the trigger such that an actuation of the trigger can retract the firing member and / or cutting element via the first and second gears.

Owner:CILAG GMBH INT

Surgical instrument with a lateral-moving articulation control

InactiveUS20050006430A1Complicate amountComplicate directionSuture equipmentsStapling toolsEngineeringSacroiliac joint

An articulating surgical instrument suited for endoscopic use includes a lateral articulation control into a handle portion that provides an intuitive visual and tactile indication to the clinician as to the amount and direction of articulation of an end effector at a distal end of a shaft. Lateral movement of a lateral control actuator is converted into a longitudinal motion or a rotational motion transferred by the shaft to an articulation mechanism. A version of a lateral articulation control for a rotationally driven articulation mechanism incorporates an articulation backdrive lockout that prevents forces on the end effector from causing the selected amount of articulation from being changed.

Owner:CILAG GMBH INT

Surgical Stapling Instrument With A Geared Return Mechanism

A surgical instrument including a firing drive configured to selectively advance a firing member and / or cutting member relative to an end effector and, in addition, a reversing drive configured to selectively retract the firing member and / or cutting member relative to the end effector. The firing drive can include a pawl which can be selectively engaged with the firing member in order to advance the firing member, wherein the pawl can be disengaged from the firing member when the reversing drive is engaged with the firing member. The reversing drive can include a gear train having a first gear operably engaged with the firing member and, in addition, a second gear operably engaged with the first gear, wherein the second gear can be selectively operable with the trigger such that an actuation of the trigger can retract the firing member and / or cutting element via the first and second gears.

Owner:CILAG GMBH INT

Surgical stapling instrument with a firing member return mechanism

A surgical instrument including a firing drive configured to selectively advance a firing member and / or cutting member relative to an end effector and, in addition, a reversing drive configured to selectively retract the firing member and / or cutting member relative to the end effector. In various embodiments, the surgical instrument can further include a switch including relatively movable first and second portions, wherein the first portion can be configured to operably disengage the firing drive from the firing member and, in addition, operably engage the reversing drive with the firing member. In at least one embodiment, the second portion can include a handle extending therefrom which can be motivated by the surgeon in order to engage the second portion with the first portion and move the first portion into position.

Owner:CILAG GMBH INT

Surgical stapling instrument with a geared return mechanism

A surgical instrument including a firing drive configured to selectively advance a firing member and / or cutting member relative to an end effector and, in addition, a reversing drive configured to selectively retract the firing member and / or cutting member relative to the end effector. The firing drive can include a pawl which can be selectively engaged with the firing member in order to advance the firing member, wherein the pawl can be disengaged from the firing member when the reversing drive is engaged with the firing member. The reversing drive can include a gear train having a first gear operably engaged with the firing member and, in addition, a second gear operably engaged with the first gear, wherein the second gear can be selectively operable with the trigger such that an actuation of the trigger can retract the firing member and / or cutting element via the first and second gears.

Owner:CILAG GMBH INT

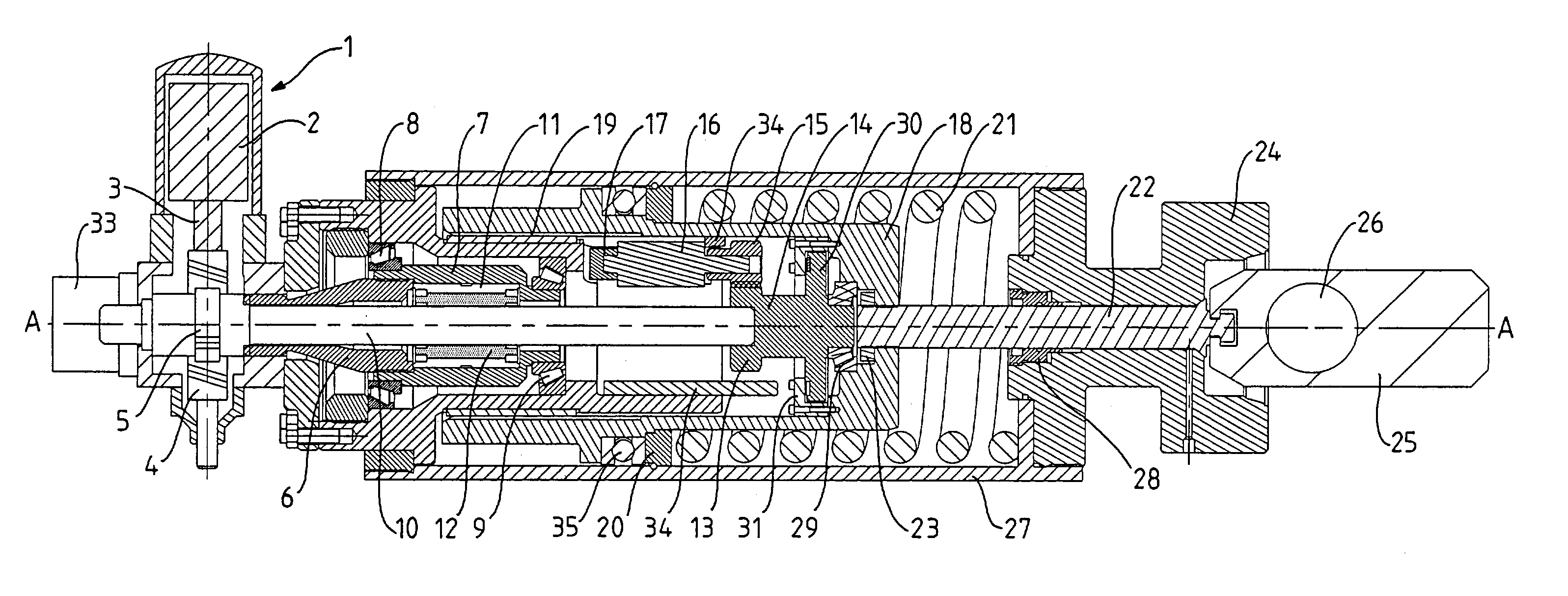

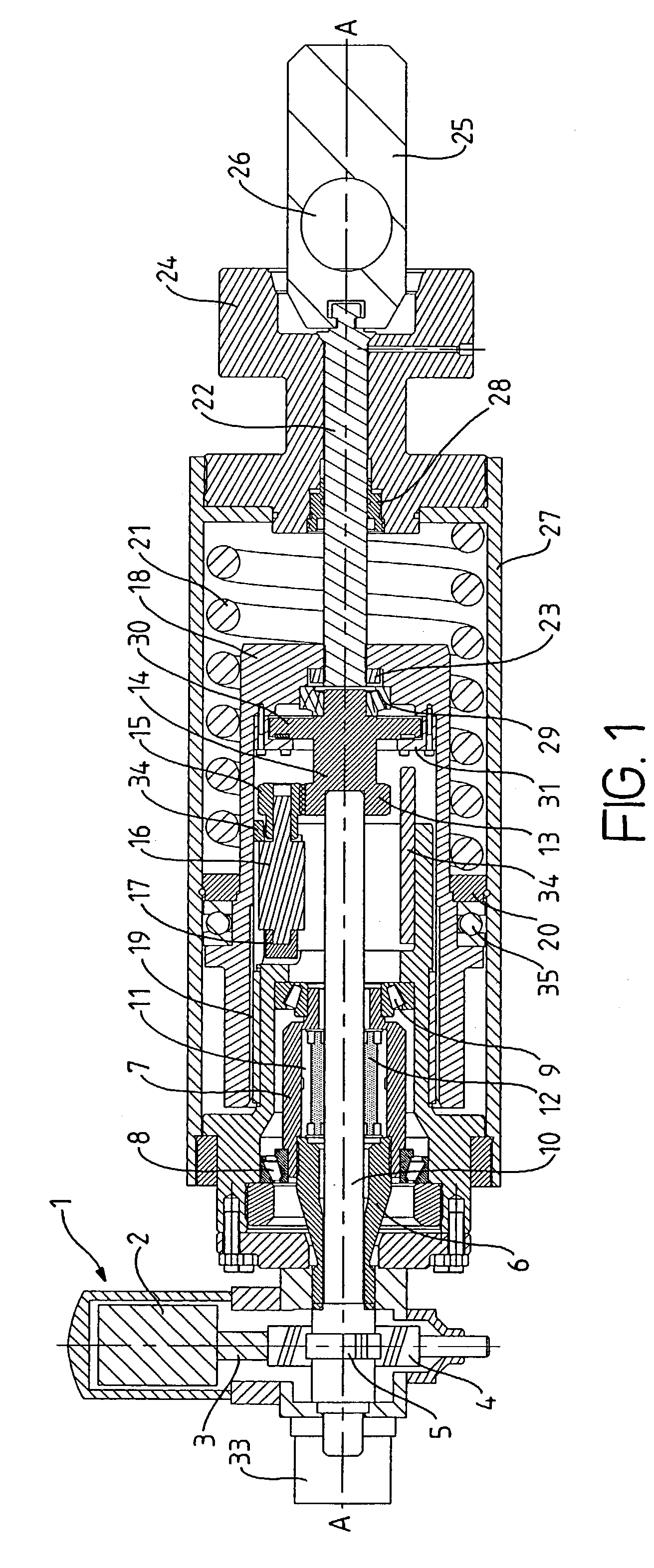

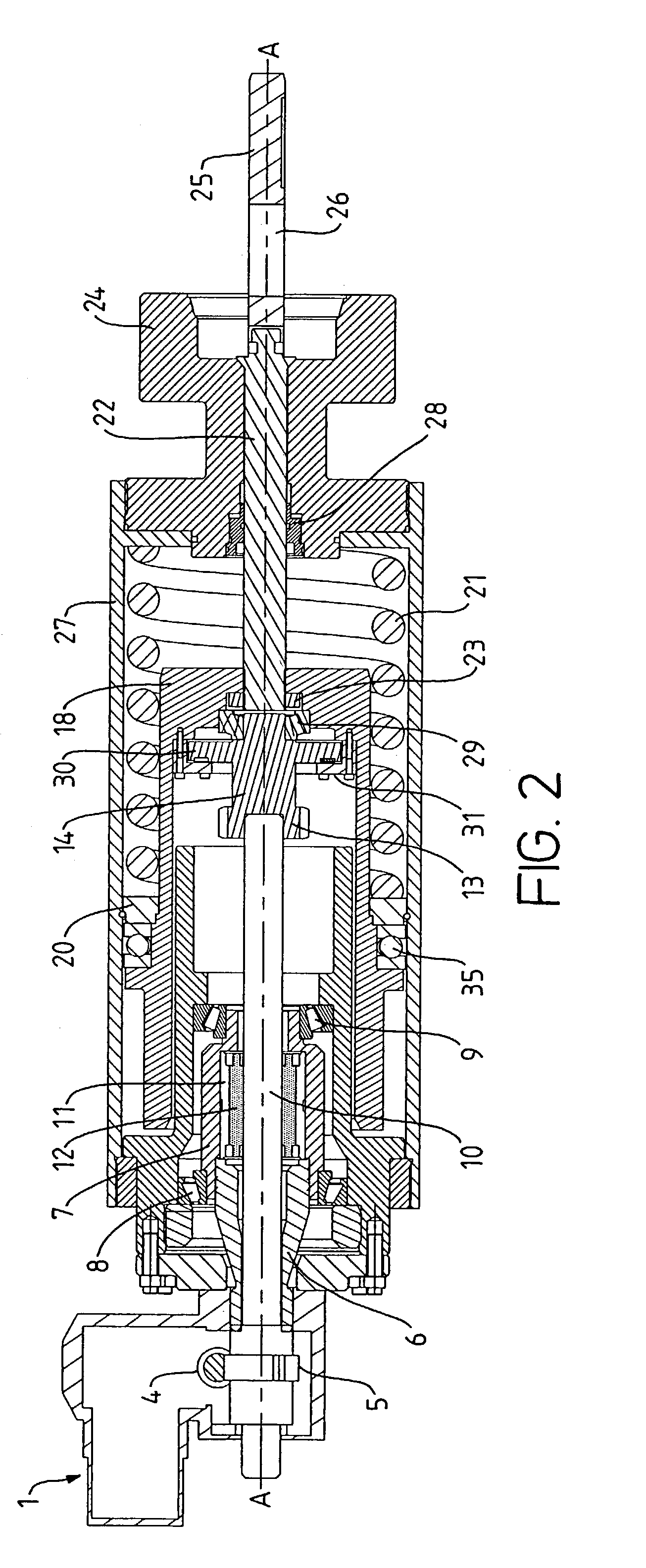

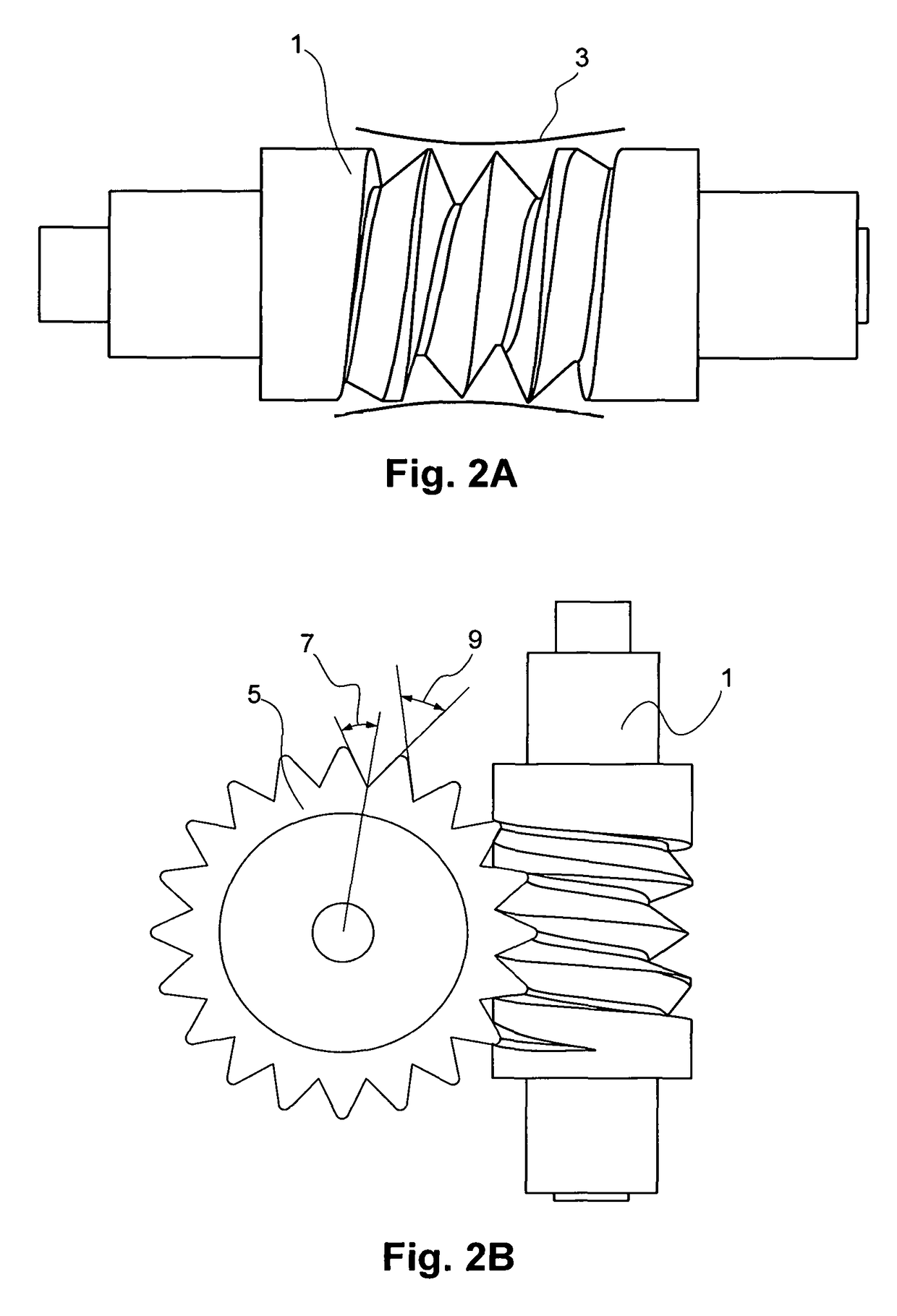

Linear actuators

InactiveUS6981428B2Prevent rotationOperating means/releasing devices for valvesToothed gearingsLinear motionControl theory

A linear actuator comprises rotary motion producing means (1,2,3,4,5); linear motion producing means (6,7,10,11,12) coupled with the rotary motion producing means for converting rotary motion to linear motion; a driven member (18) movable linearly by the linear motion providing means from a first position to a second position; and backdrive means (22) for returning the driven member to the first position. The arrangement is such that the linear motion producing means includes torque reaction means (13,15,16,17) which, in normal operation, is in an activated condition and provides a torque reaction path to enable the driven member to be moved from the first to the second position but which, in the event of a fault, is in a de-activated condition so that it no longer provides the torque reaction path and the back-drive means can move the driven member to the first position, without disengaging the rotary motion producing means from the linear motion producing means.

Owner:BAKER HUGHES ENERGY TECH UK LTD

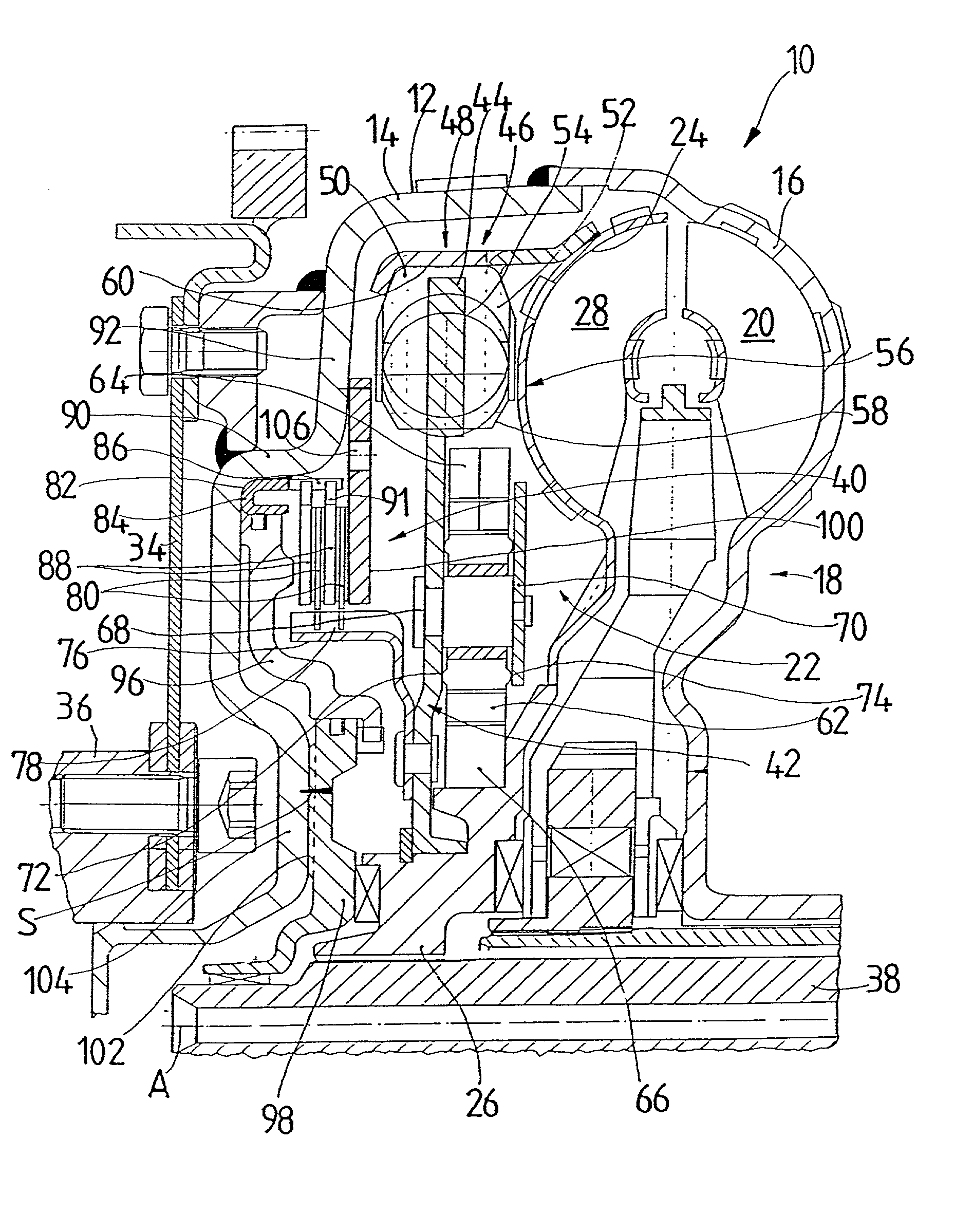

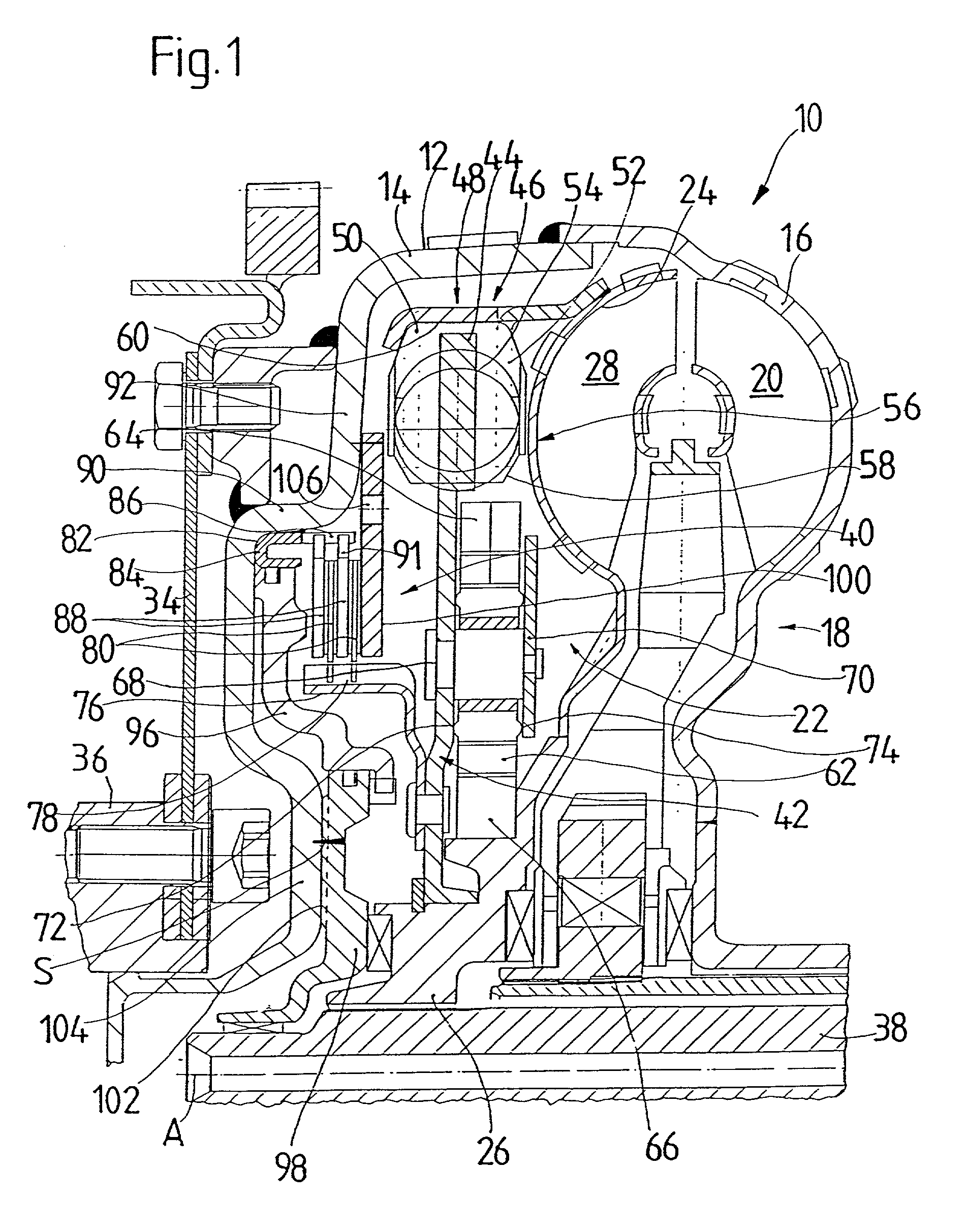

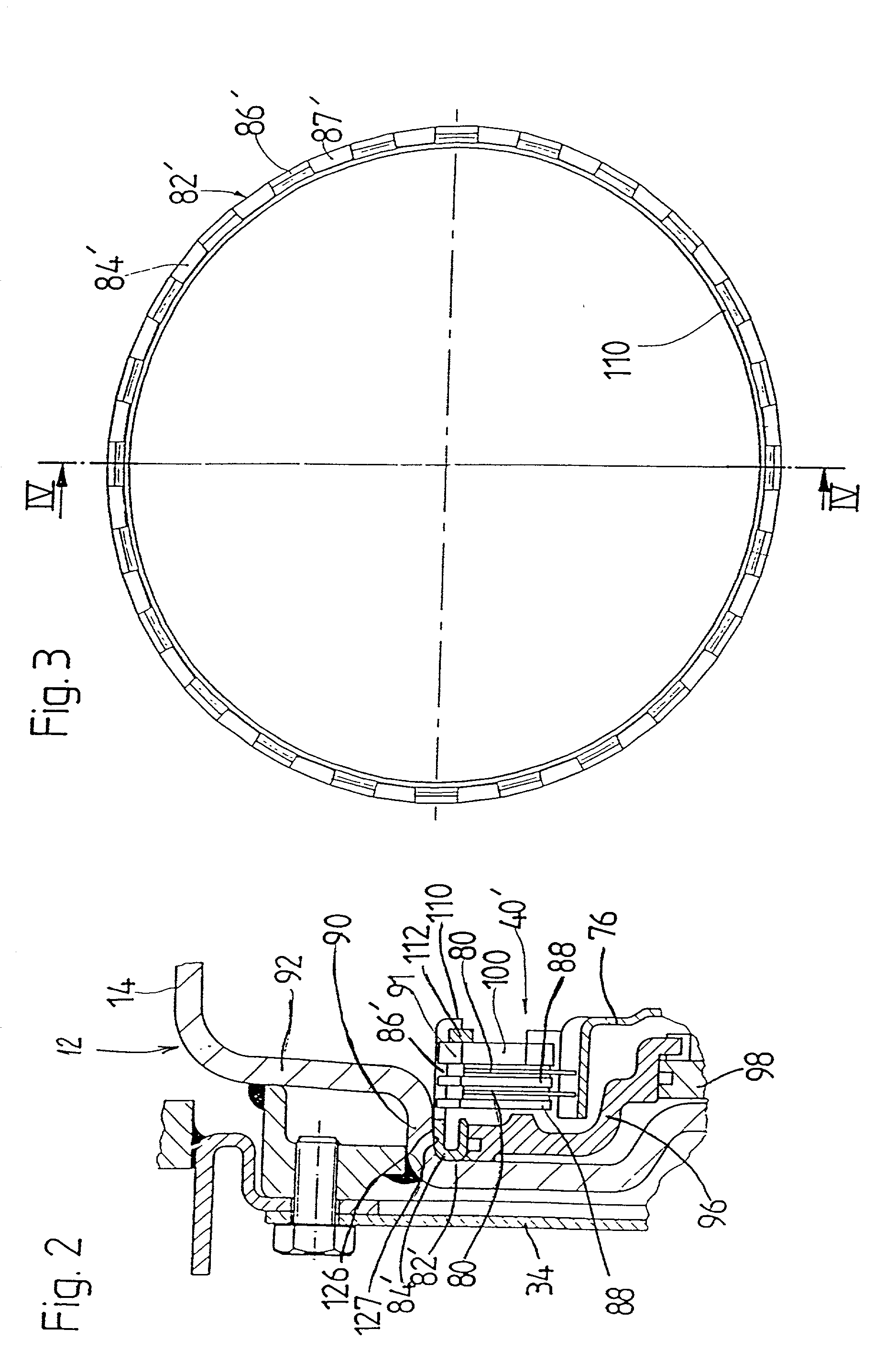

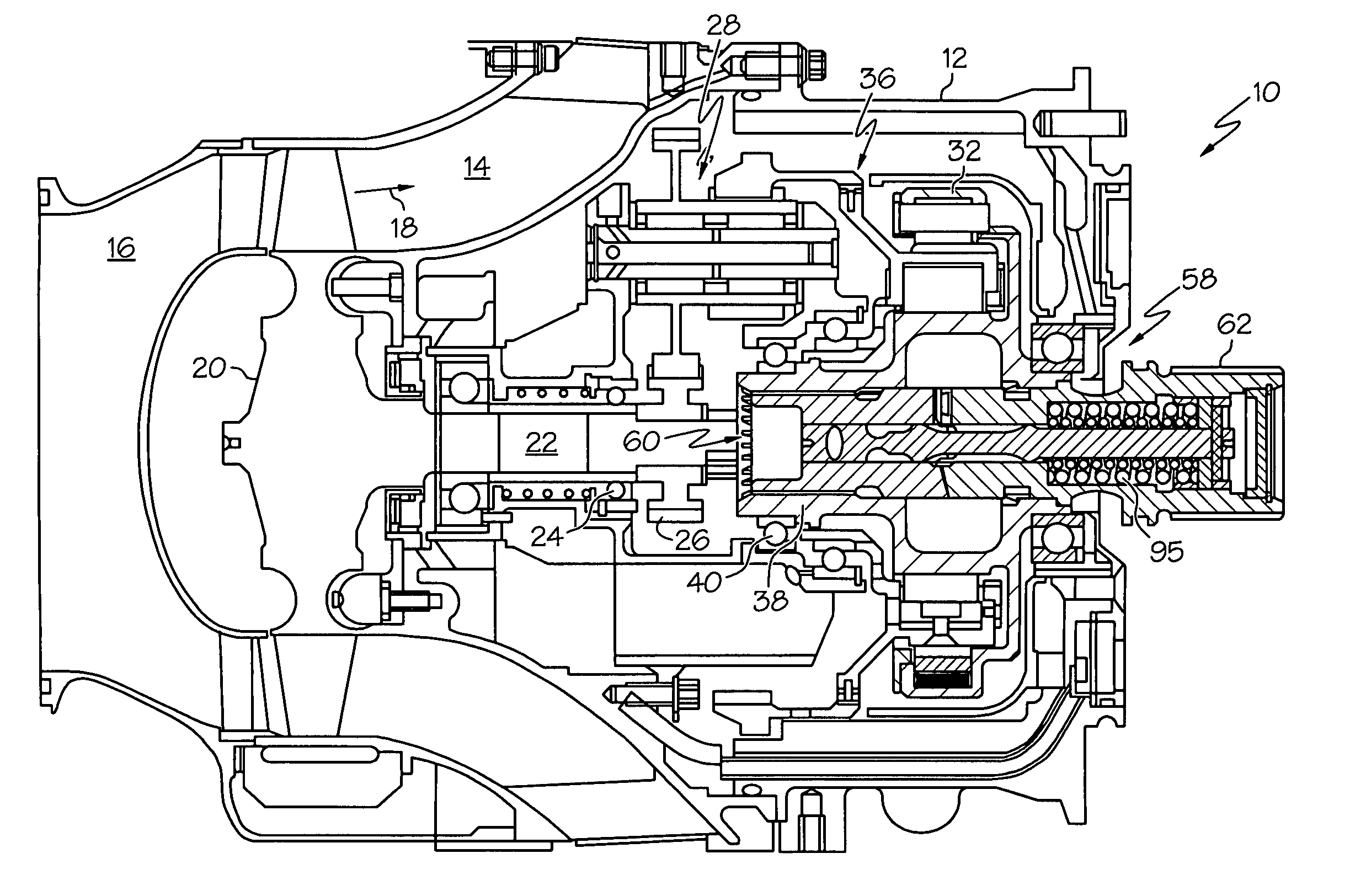

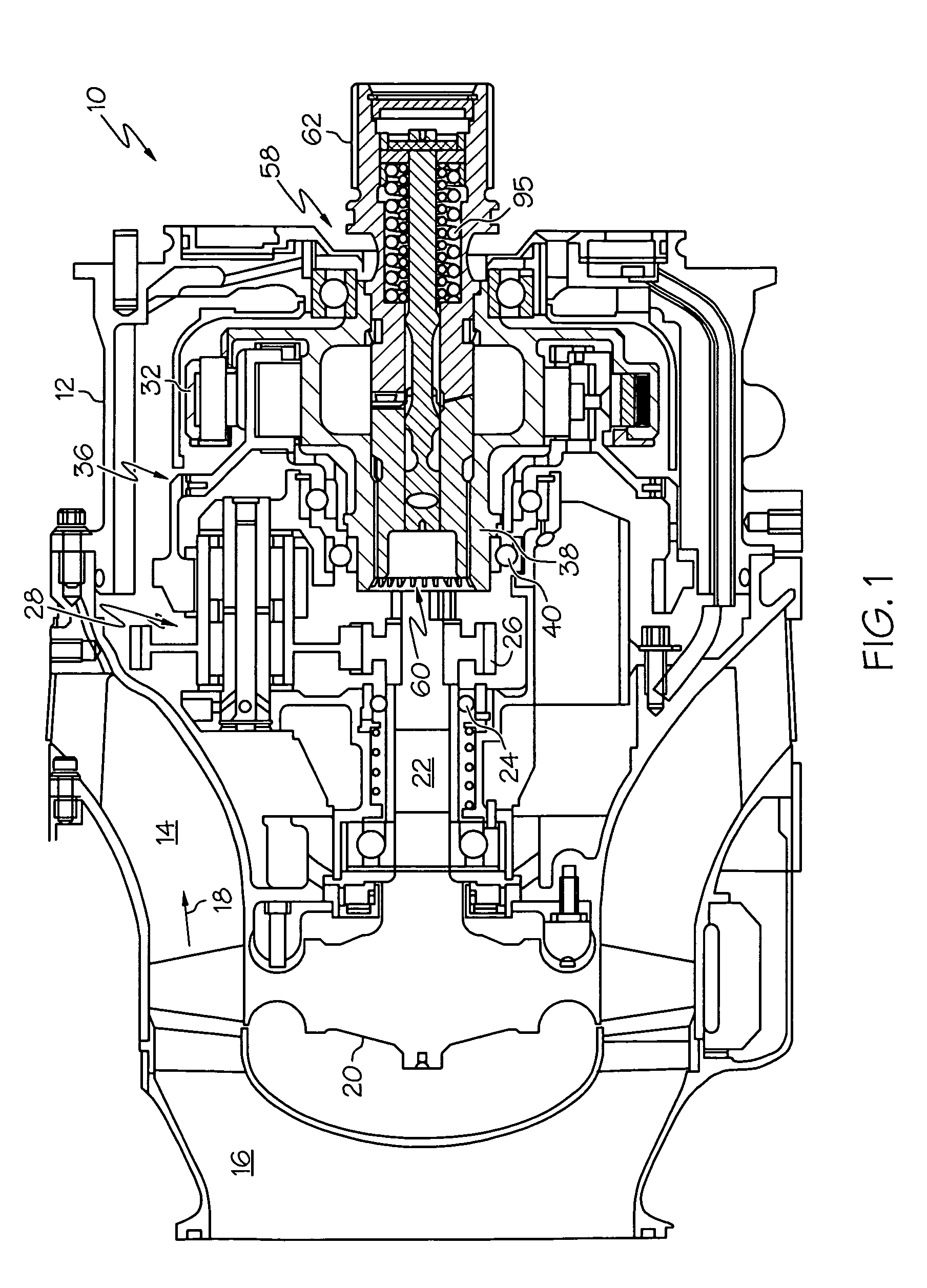

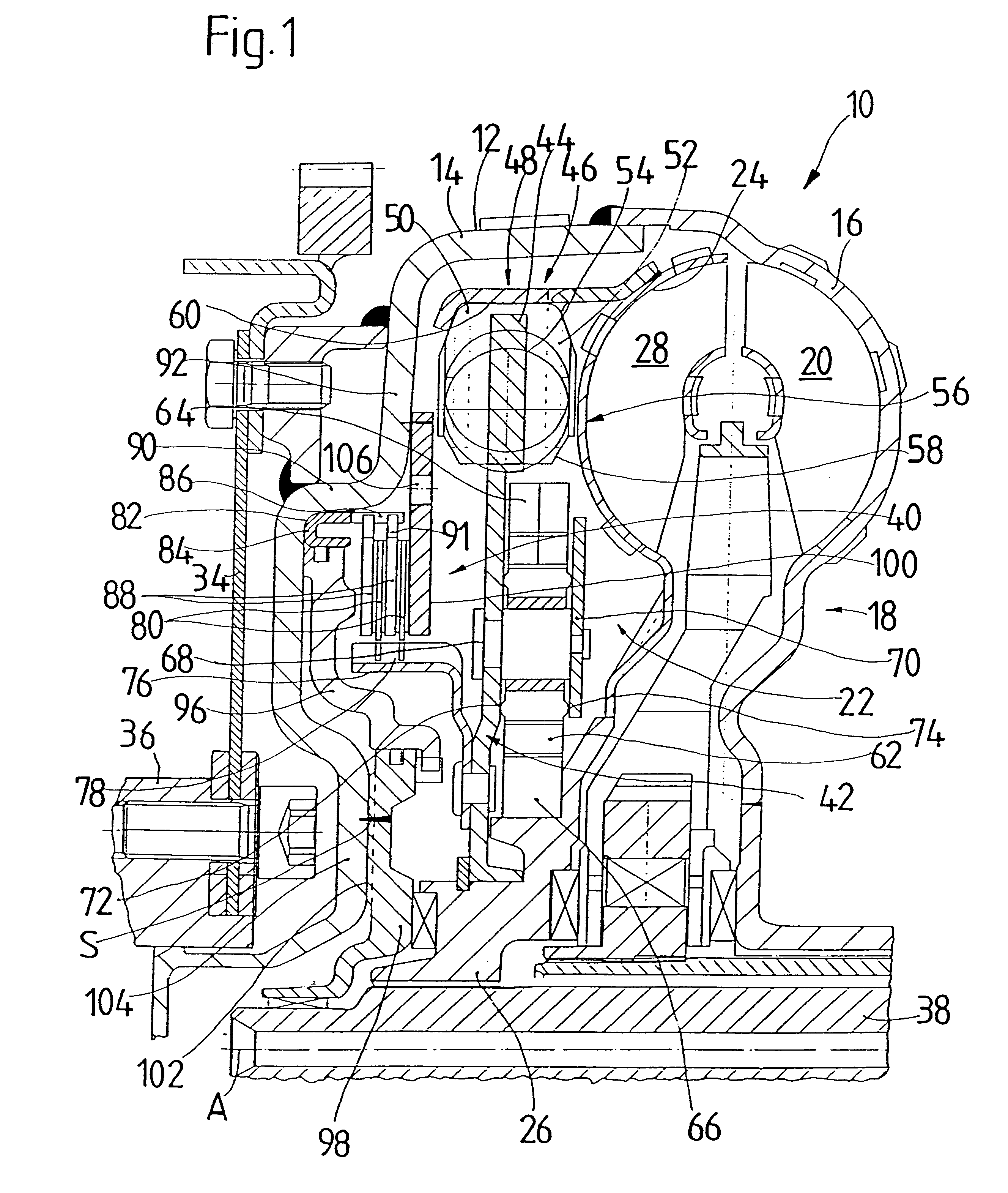

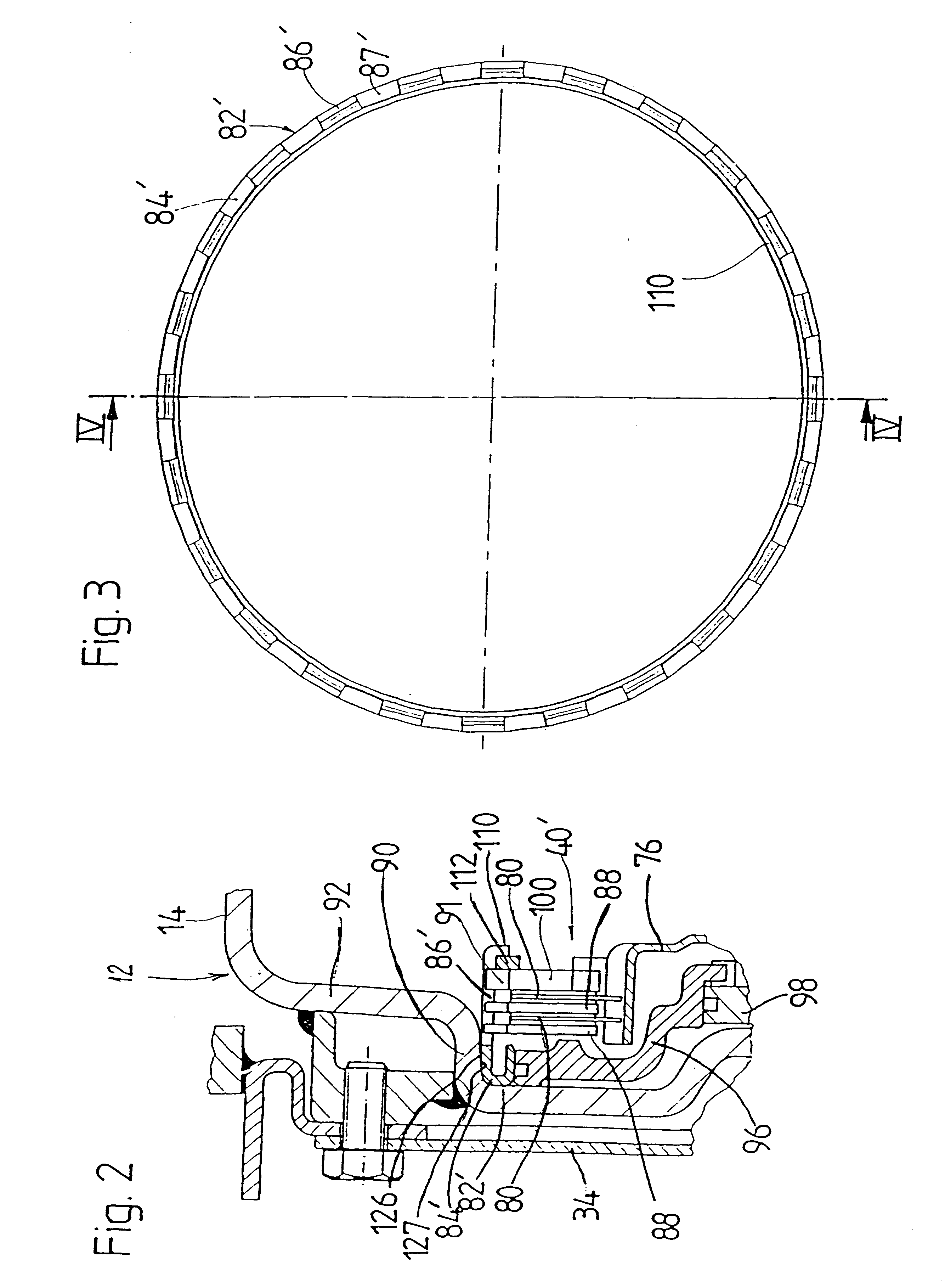

Hydrodynamic torque converter

InactiveUS20020033310A1Improve performanceSimple and accurate mannerRotary clutchesFluid actuated clutchesRotational axisImpeller

A hydrodynamic torque converter includes a converter housing and a turbine wheel which is arranged in the converter housing and is rotatable with respect to the converter housing about a rotational axis of the converter. The torque converter further includes a lockup clutch for producing a torque transmission connection between the converter housing and the turbine wheel. The lockup clutch has a first friction surface arrangement held by a first friction surface carrier arrangement substantially fixed with respect to rotation relative to the converter housing, a second friction surface arrangement is held by a second friction surface carrier arrangement substantially fixed with respect to rotation relative to the turbine wheel, a contact pressing arrangement for pressing the first and the second friction surface arrangement against one another in frictional contact, and an abutment arrangement at which the first and second friction surface arrangement can be supported substantially in the direction of the axis of rotation when pressed by the contact pressure arrangement. The first friction surface carrier arrangement has a substantially annular body region connected either directly or indirectly with the converter housing and driver projections which are arranged at a distance from one another in the circumferential direction proceeding from the body region. Respective counter-driver projections at the first friction surface arrangement engage between these driver projections.

Owner:ZF FRIEDRICHSHAFEN AG

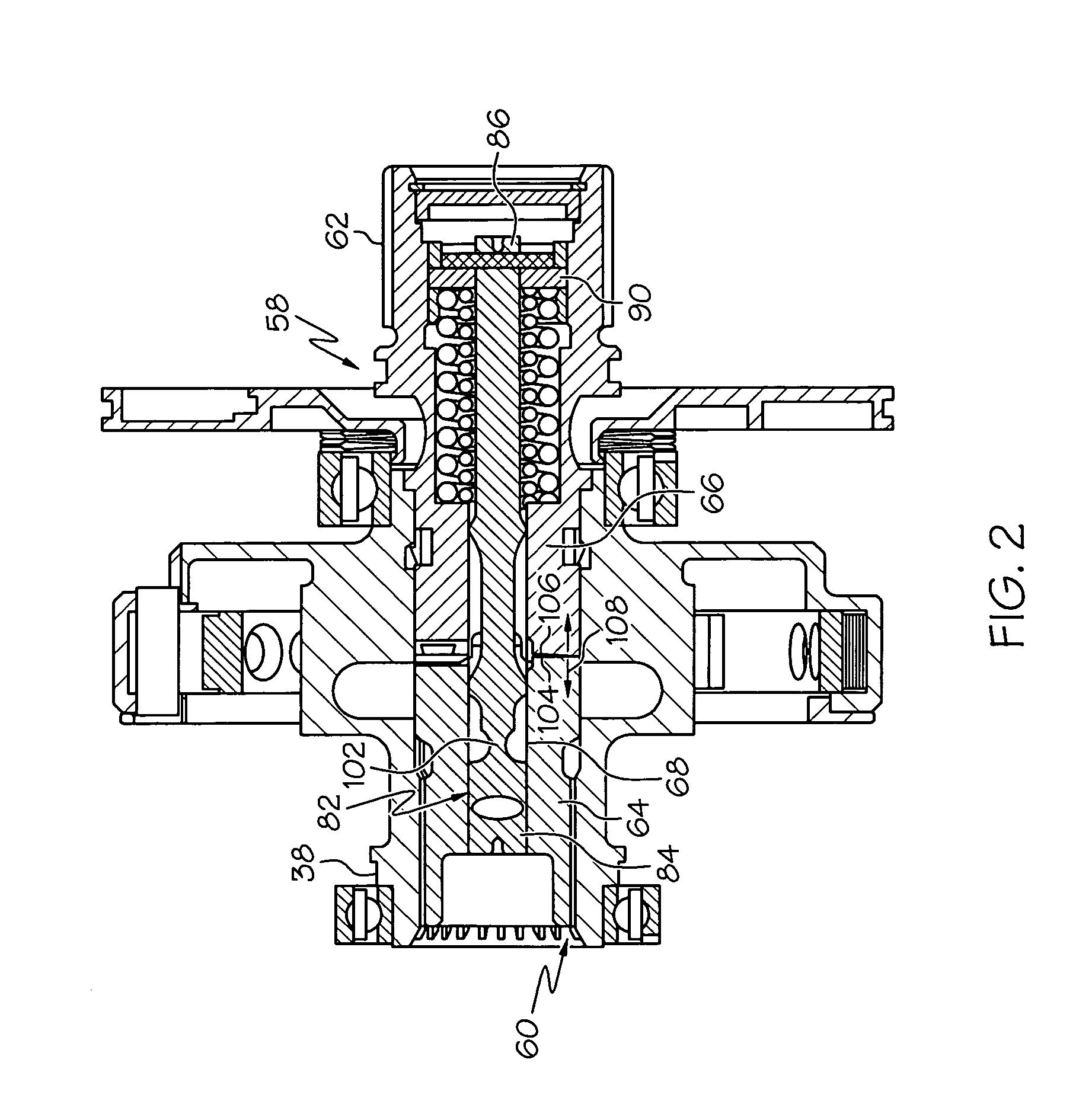

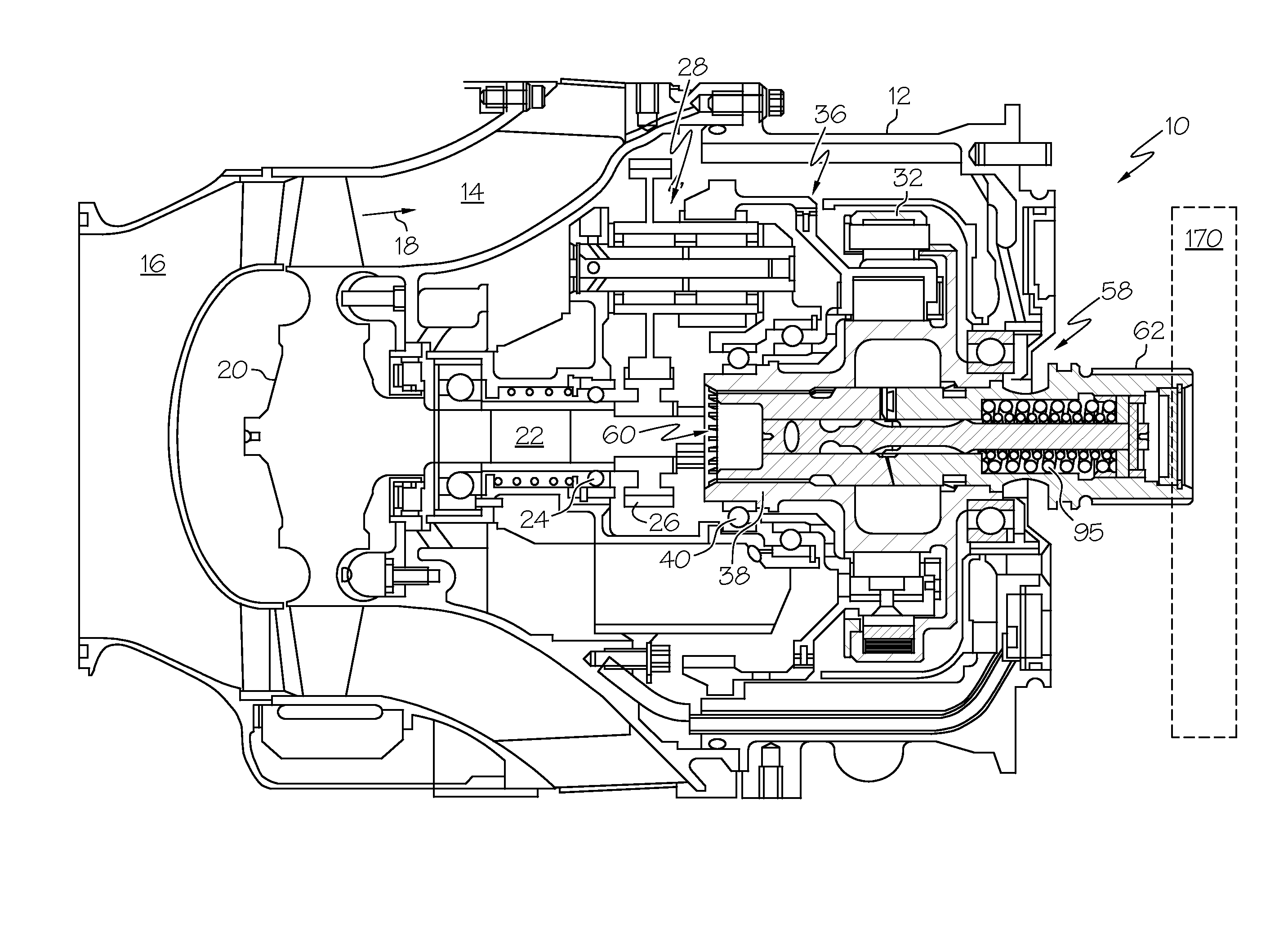

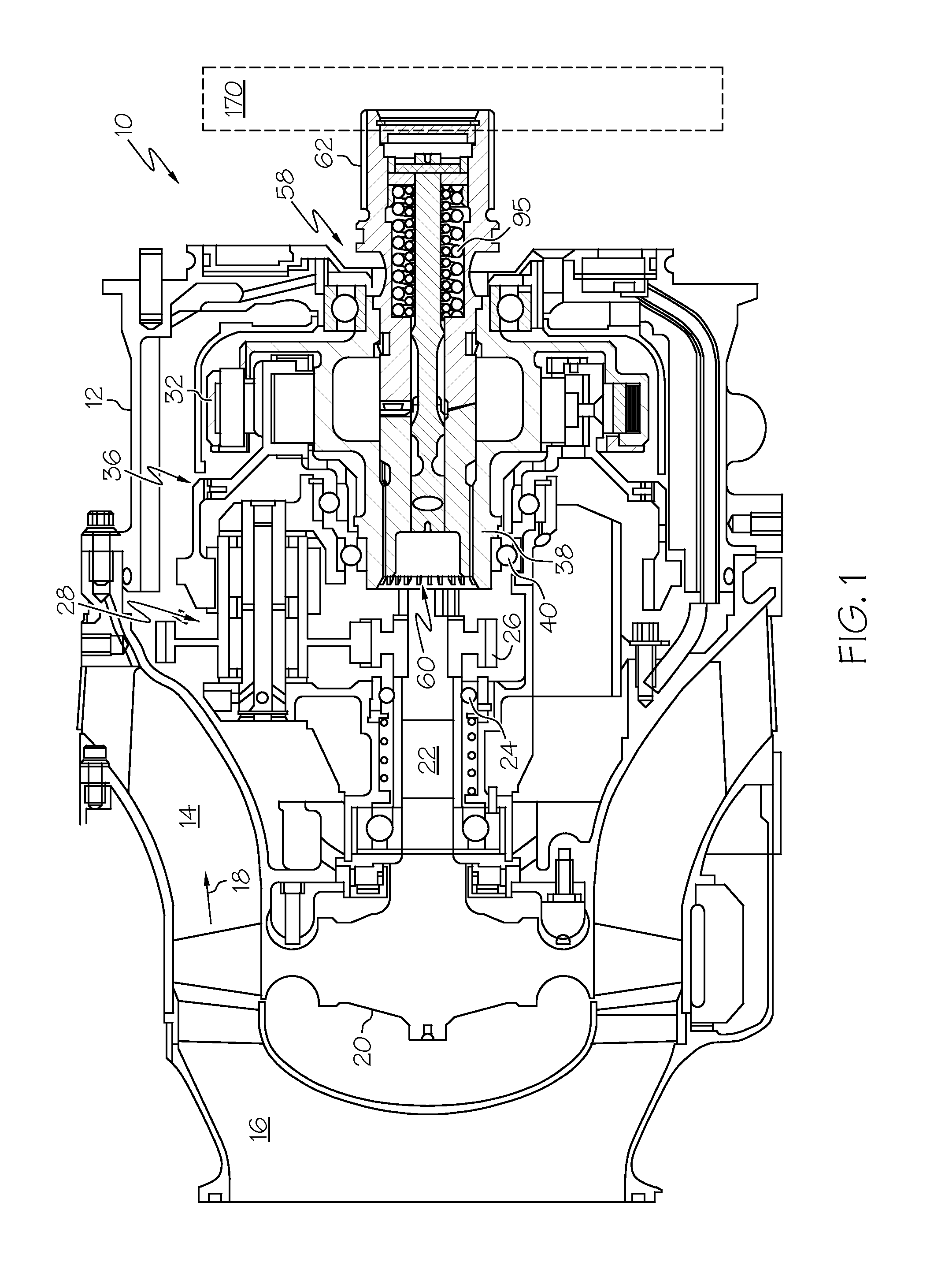

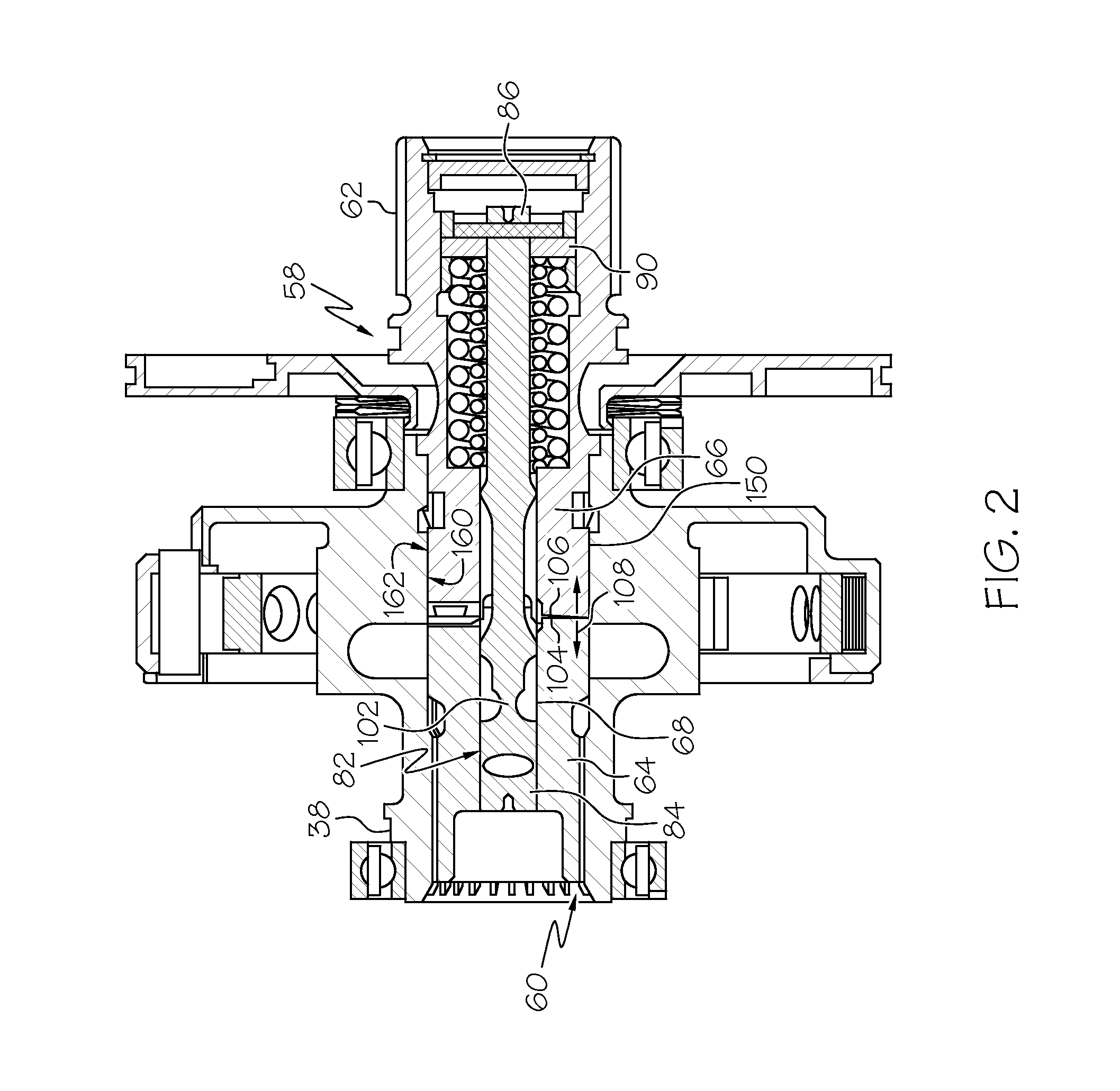

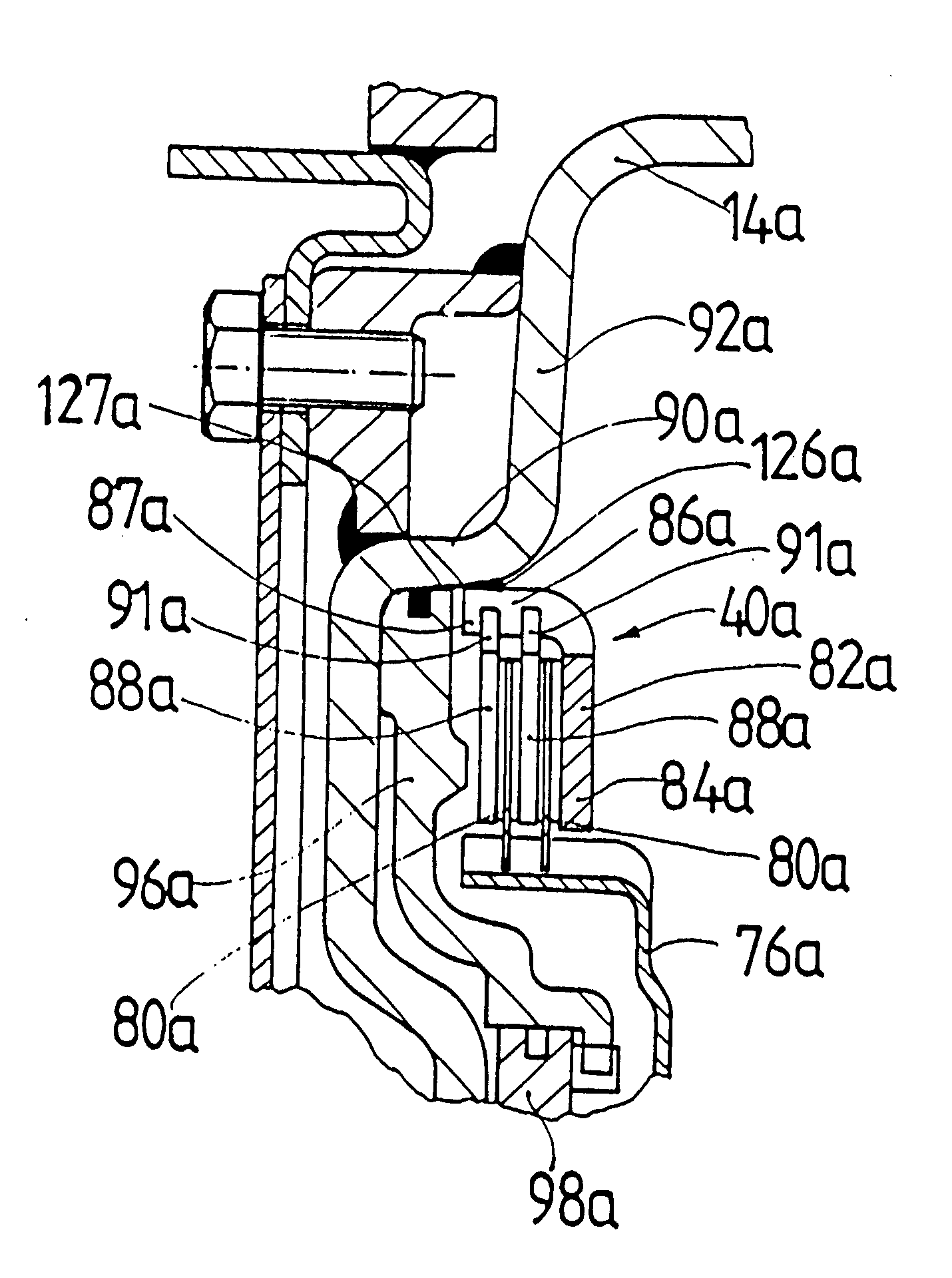

Decoupler devices to prevent backdrive in air turbine starters

ActiveUS20090199567A1Reduce frictionLimit dynamic movementYielding couplingEngine fuctionsEngineeringTurbine

An air turbine starter for starting an engine includes a housing, and a flow path communicating a flow of gas therethrough; a turbine member; a clutch; and a decoupler device at least partially housed within the output member of the clutch. The decoupler device includes a first shaft portion coupled to and rotating with the output member and a second shaft portion coupled to and rotating with the engine. The first and second shaft portions are axially aligned and configured to engage each another for rotation in a first direction and to separate from each other in a second direction to decouple the output member of the clutch from the engine. The starter further includes a bearing between the inner surface of the output member and the second shaft portion for reducing friction between the second shaft portion and the inner surface of the output member when the first and second shaft portions are decoupled.

Owner:HONEYWELL INT INC

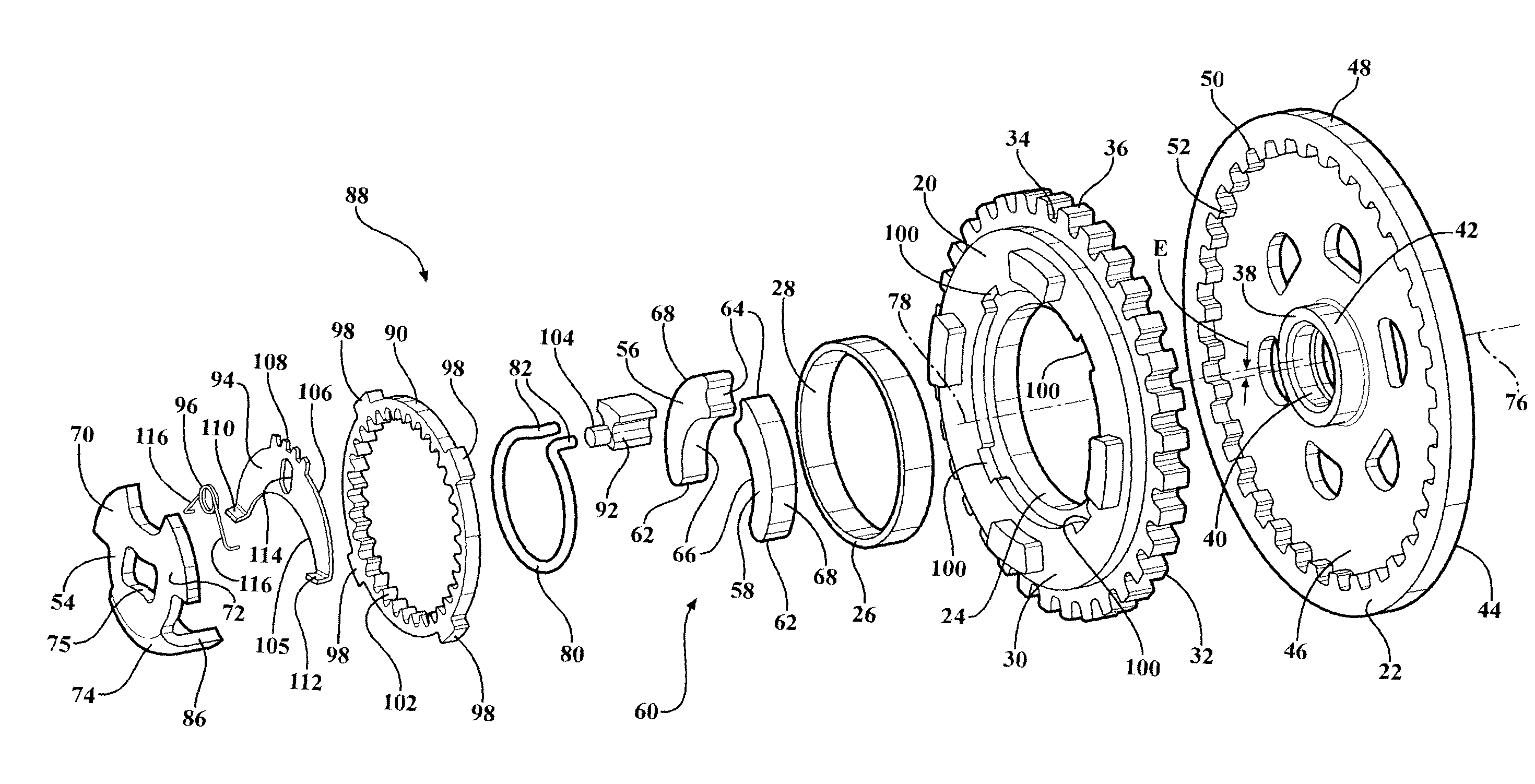

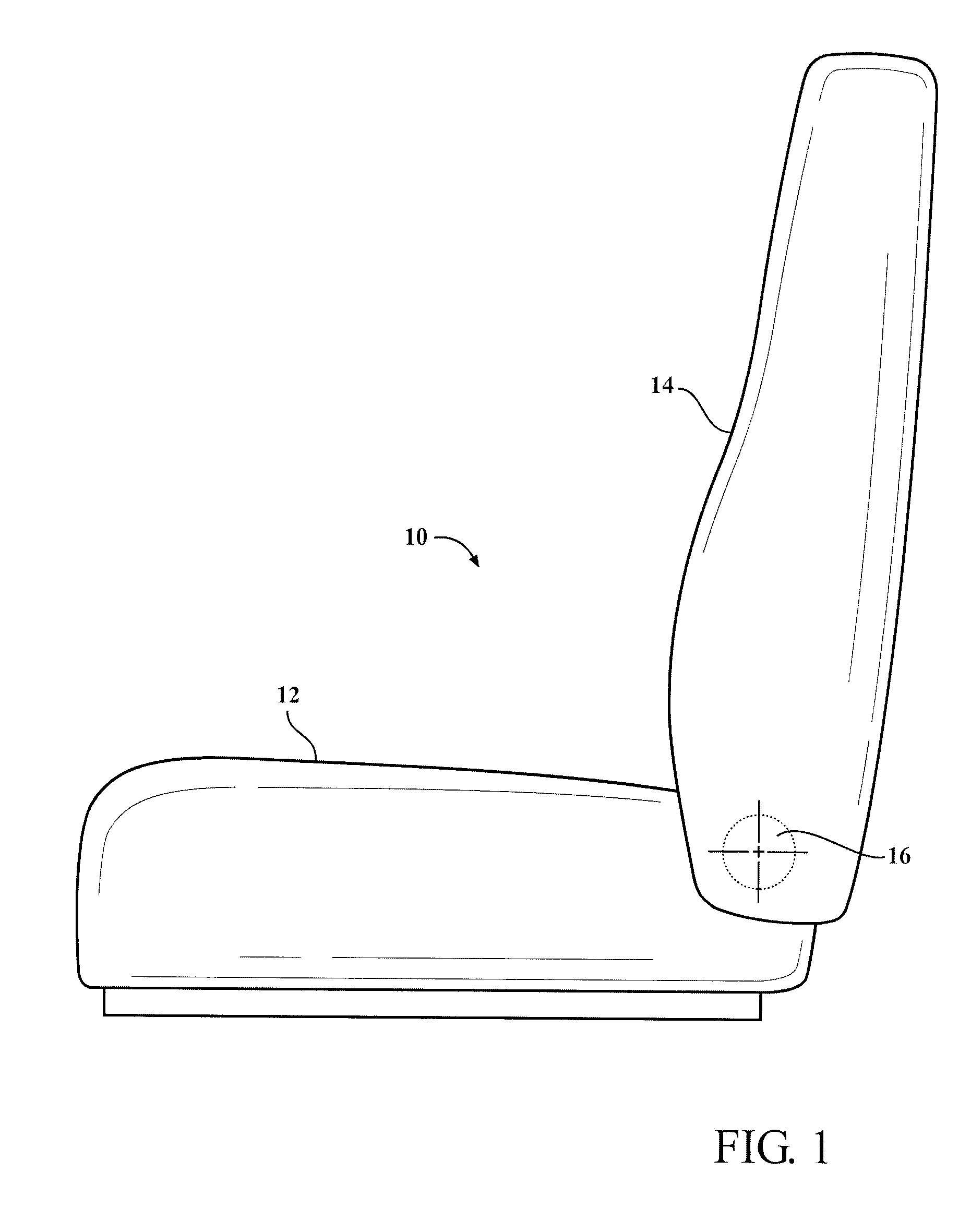

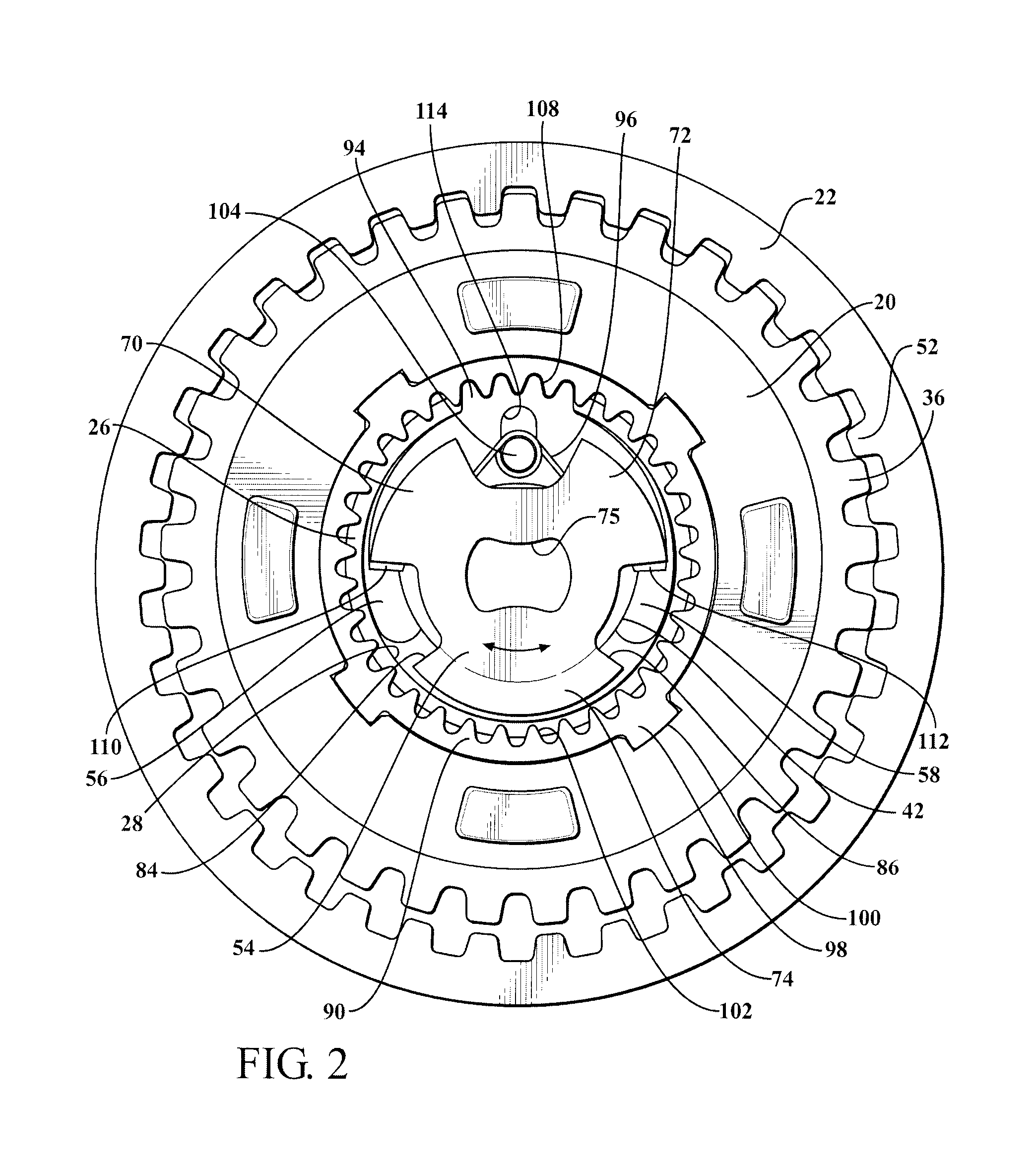

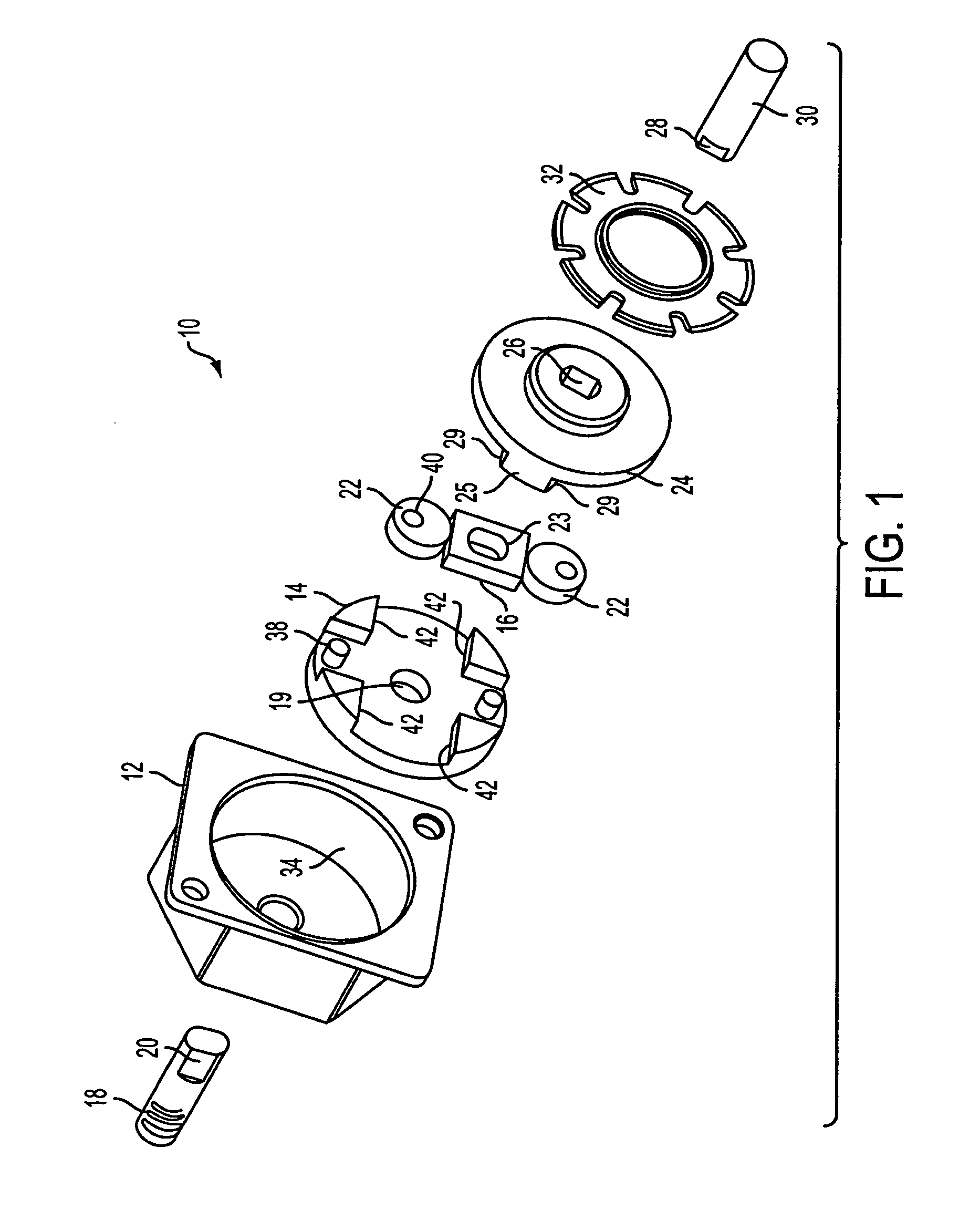

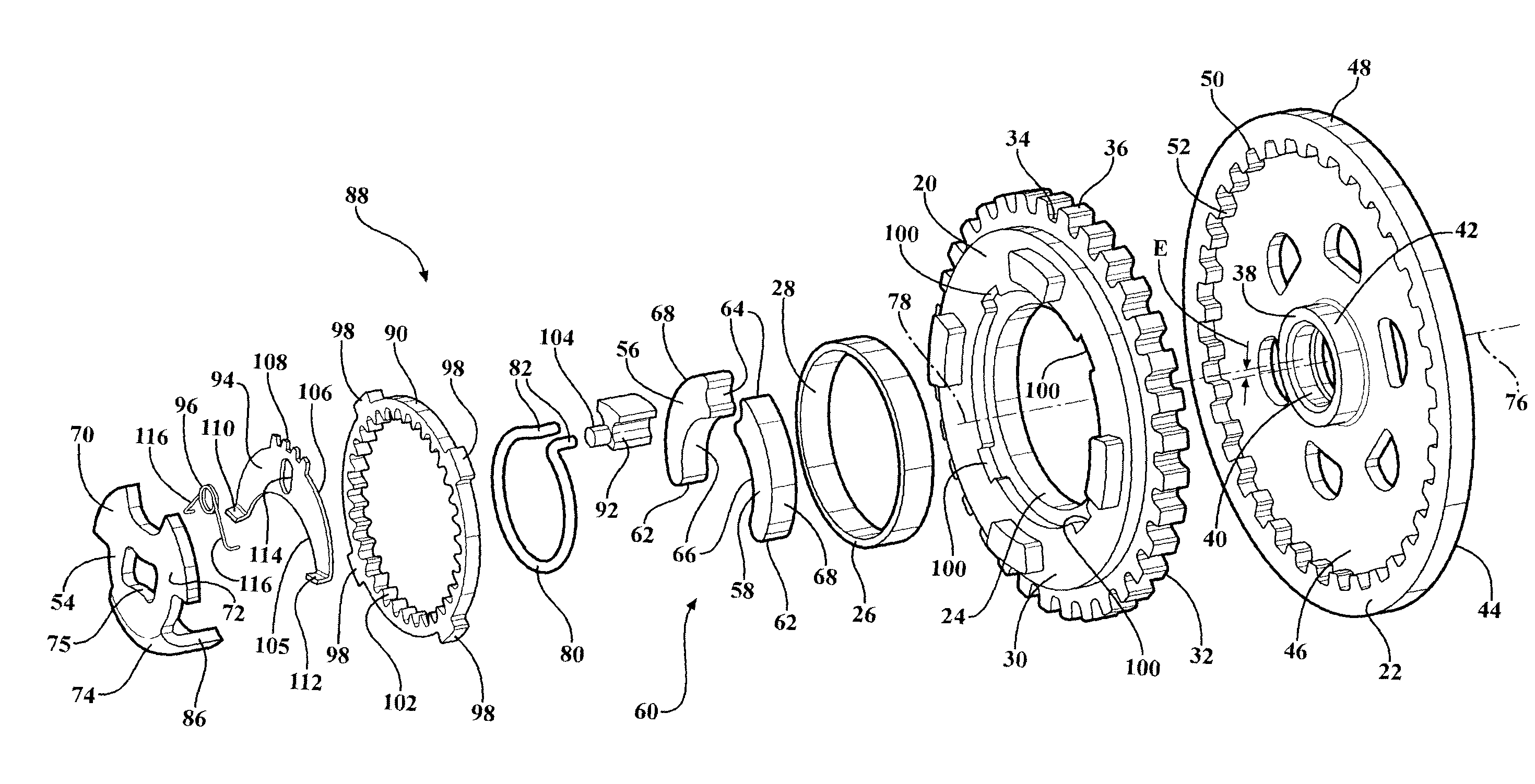

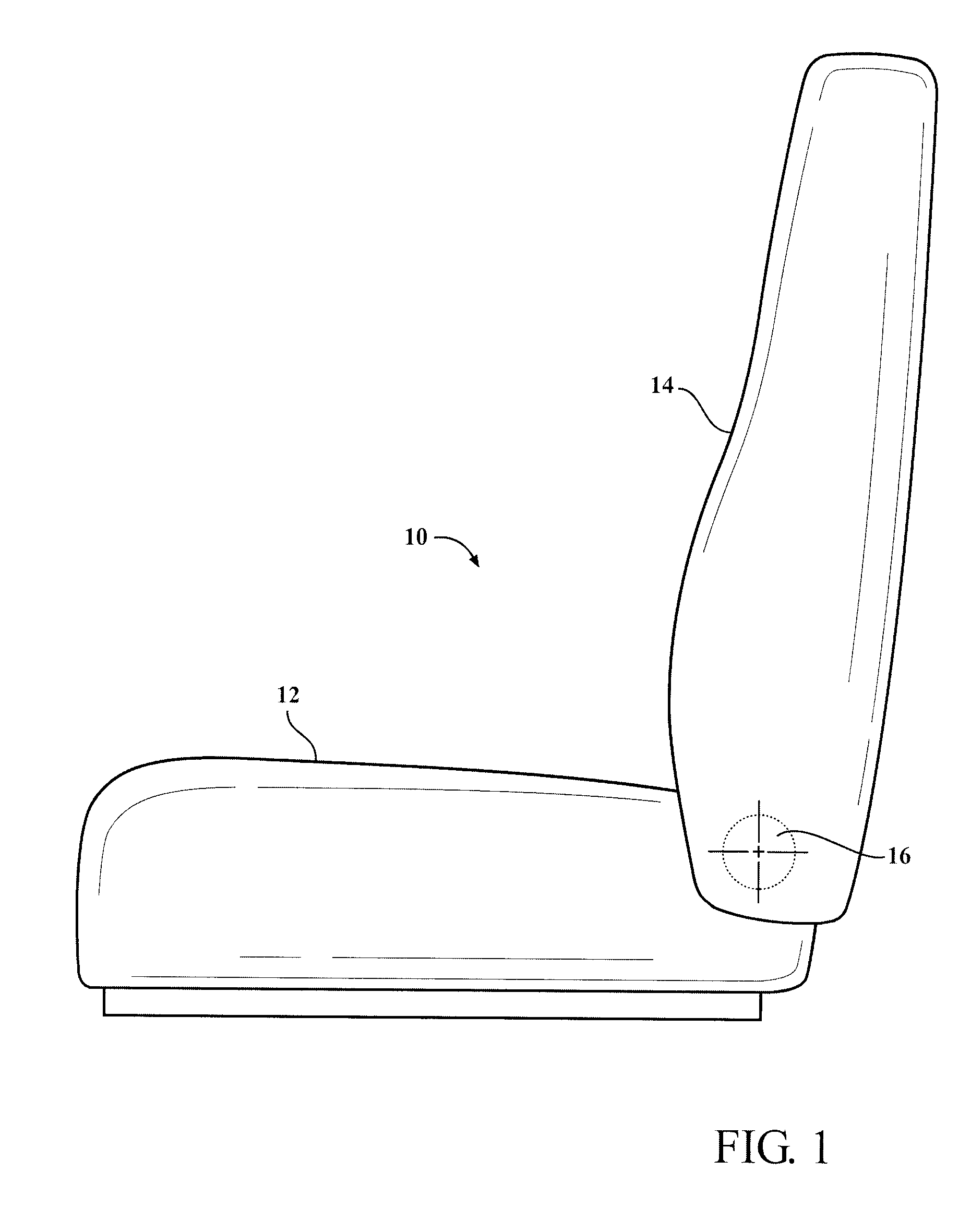

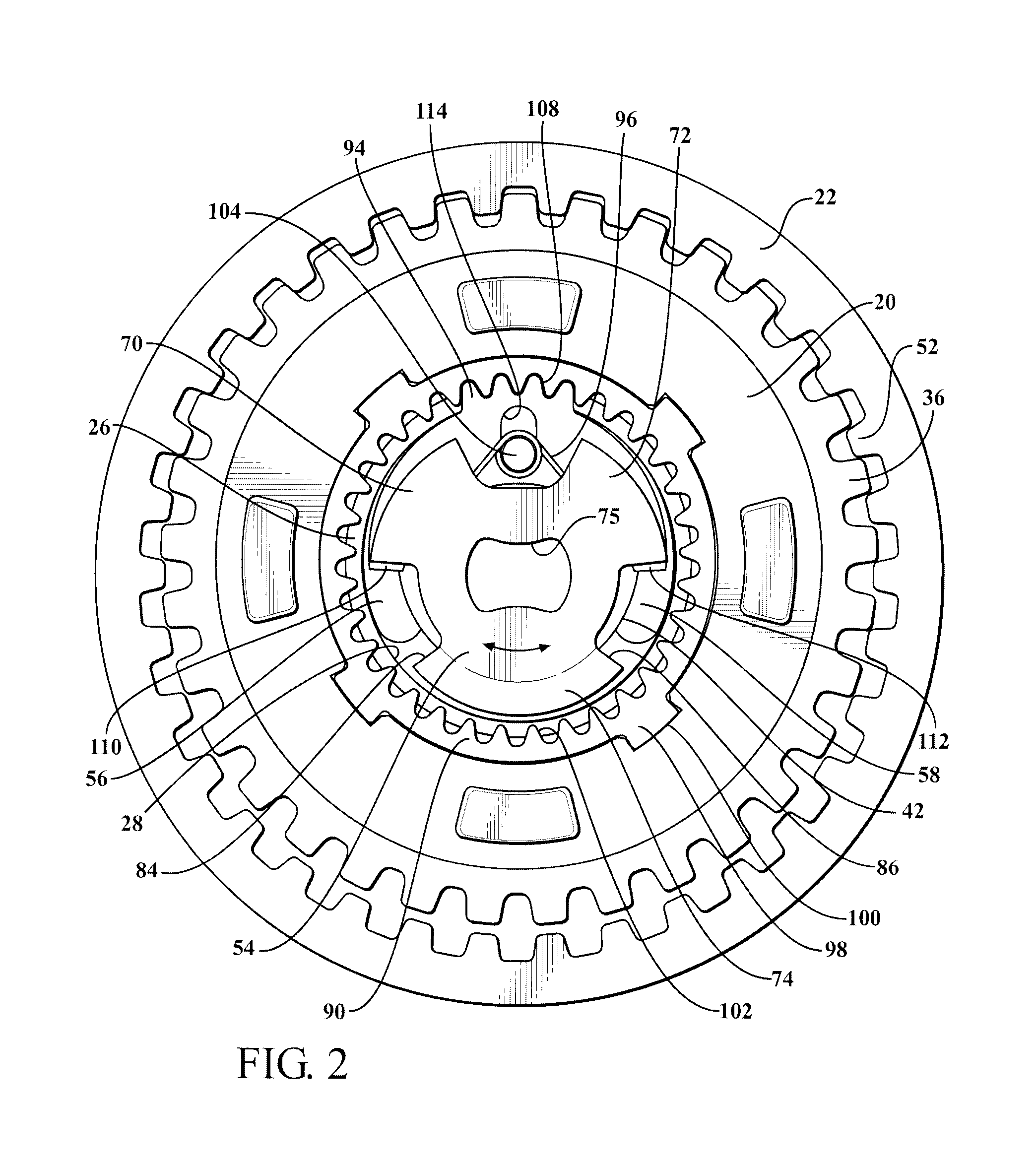

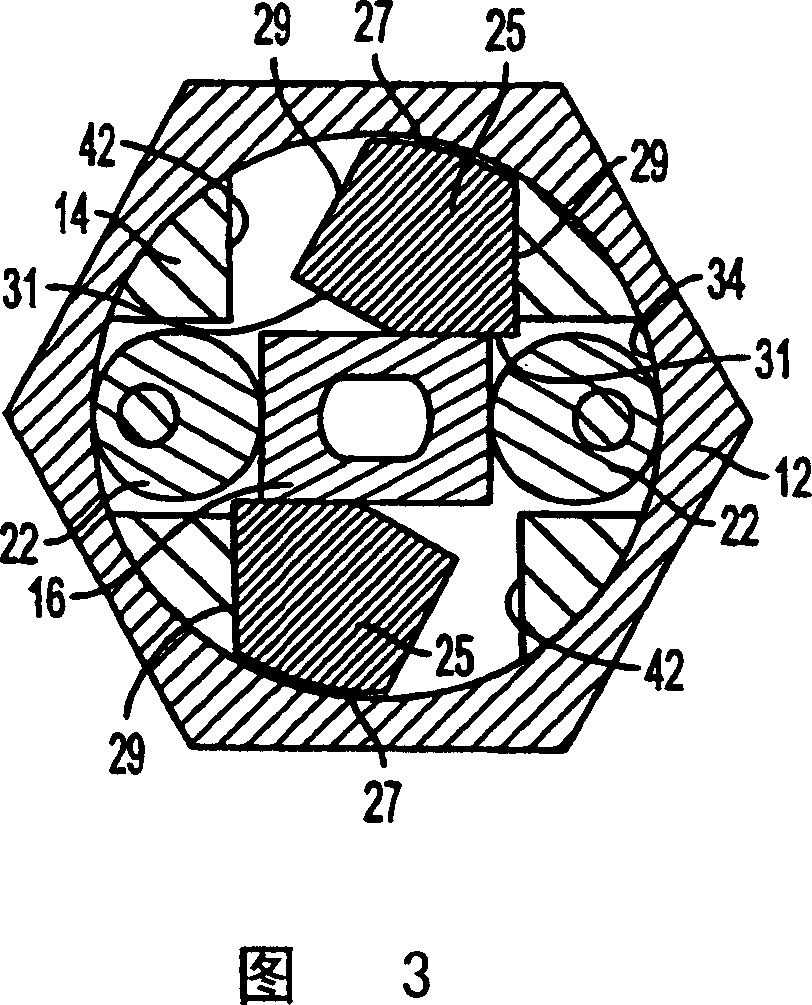

Anti-Backdrive For Continuous Disc Recliner

A disc recliner includes a fixed plate having a plurality of outer teeth and a movable plate having a plurality of inner teeth meshingly engageable with the outer teeth to allow rolling movement of the movable plate relative to the fixed plate. A pair of wedges defining an eccentric is rotatably mounted between the fixed and movable plates and rotation of the wedges causes the rolling movement of the movable plate. An anchor is disposed between the wedges for rotation therewith. A lock plate is coupled to the anchor and is movable between a locked position engaged with the fixed plate to prevent rotation of the wedges and an unlocked position disengaged with the fixed plate to permit rotation of the wedges. A cam actuates the lock plate from the locked position to the unlocked position and rotates the wedges thereby causing the rolling movement of the movable plate.

Owner:MAGNA SEATING

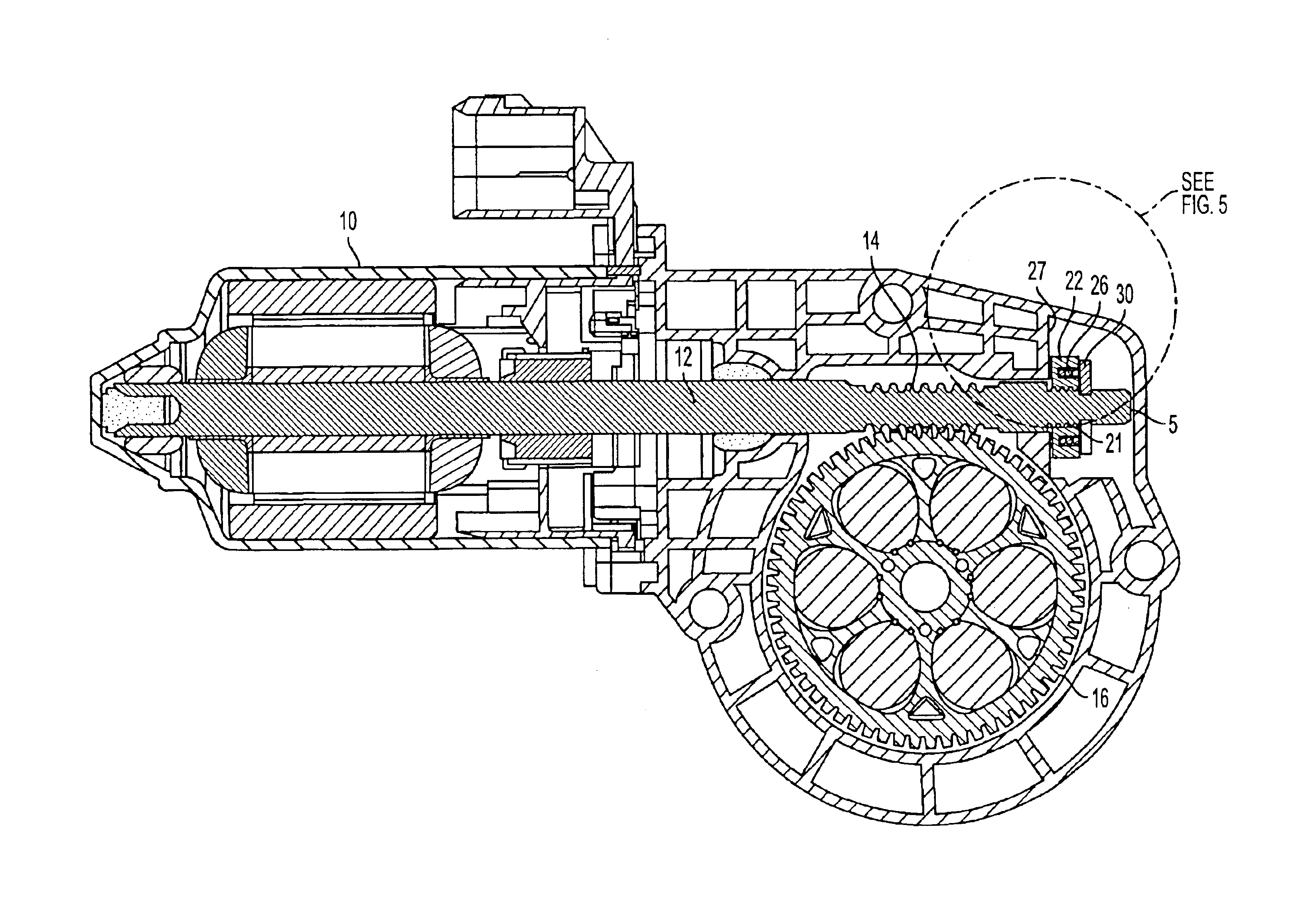

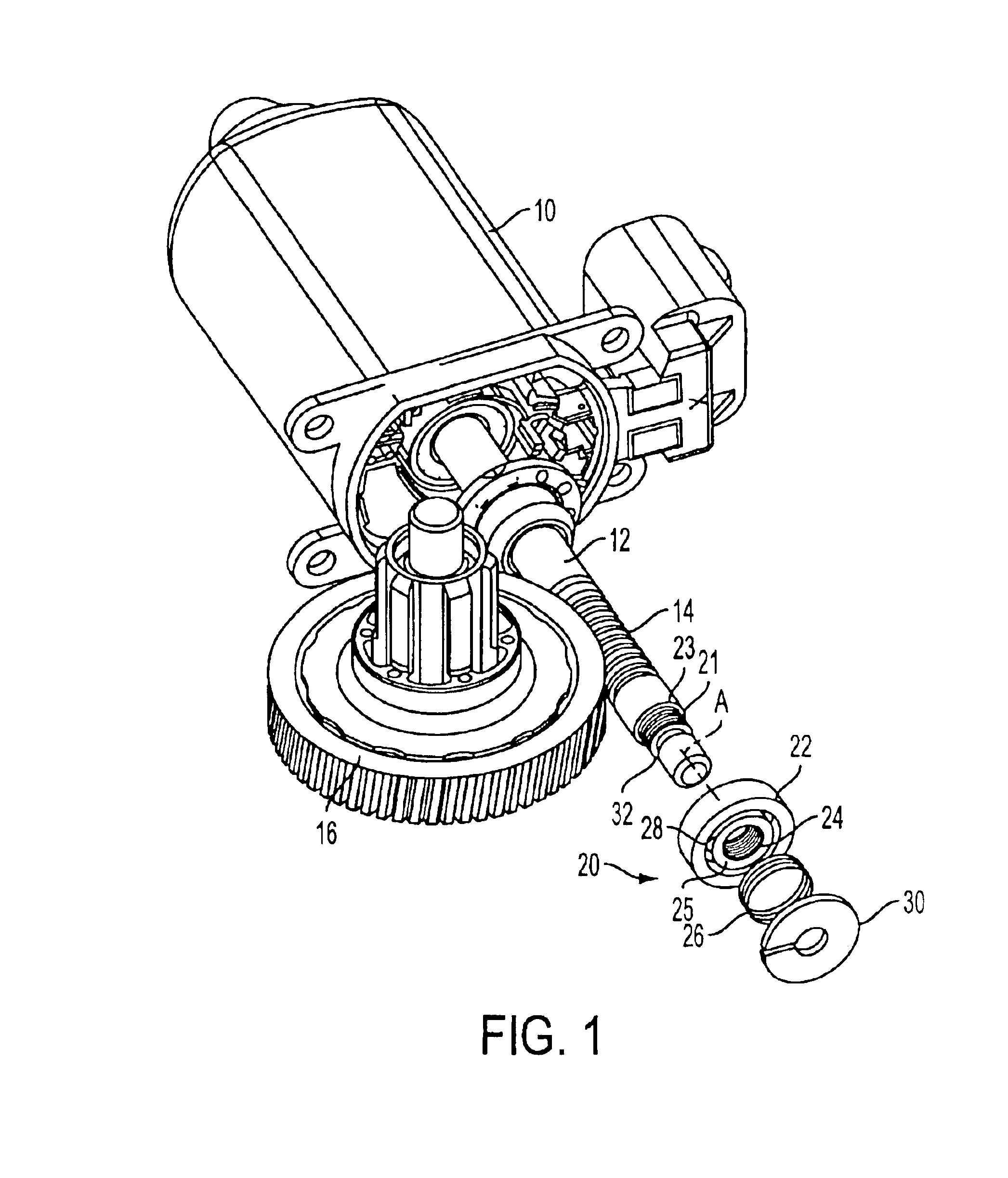

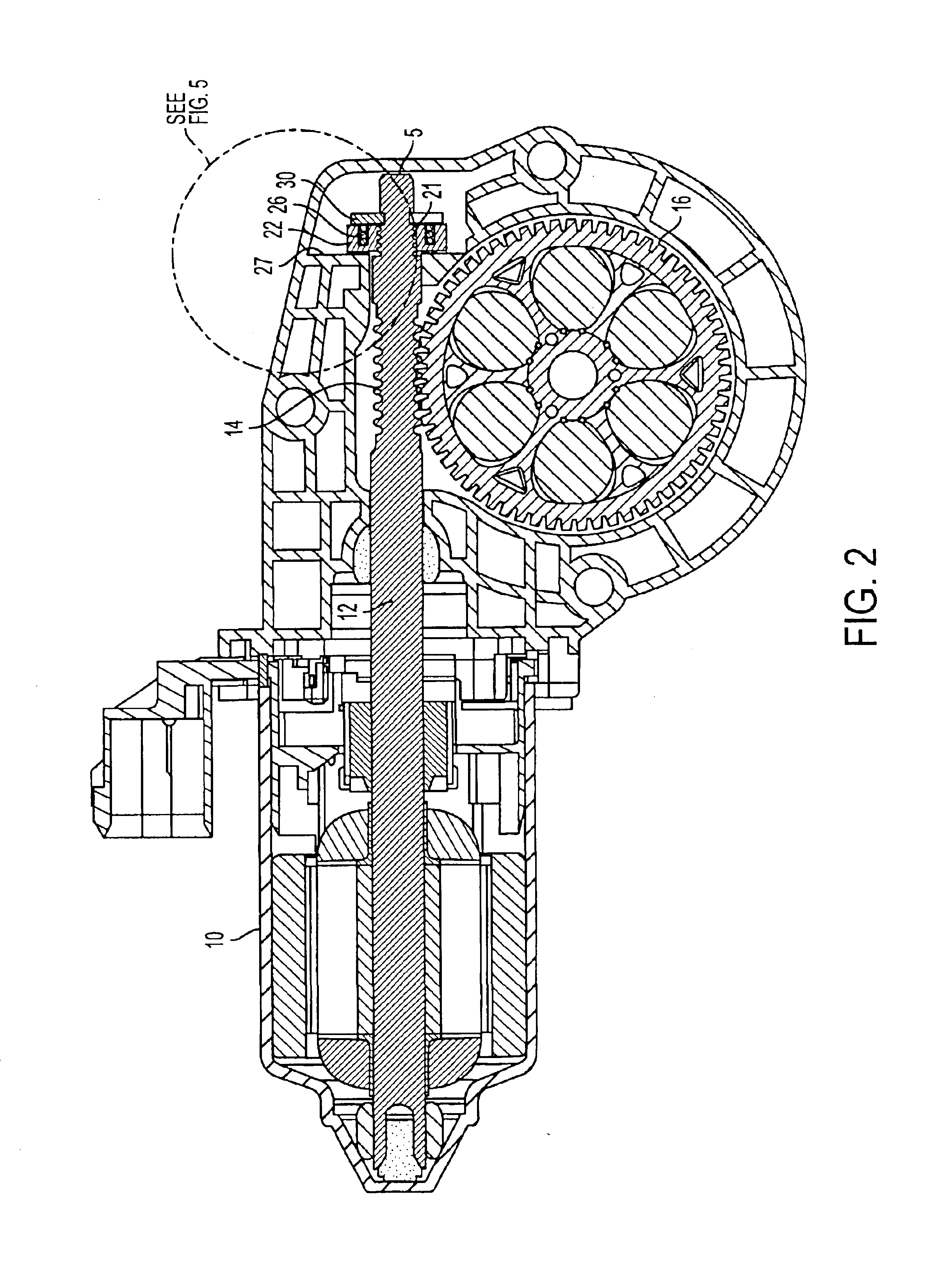

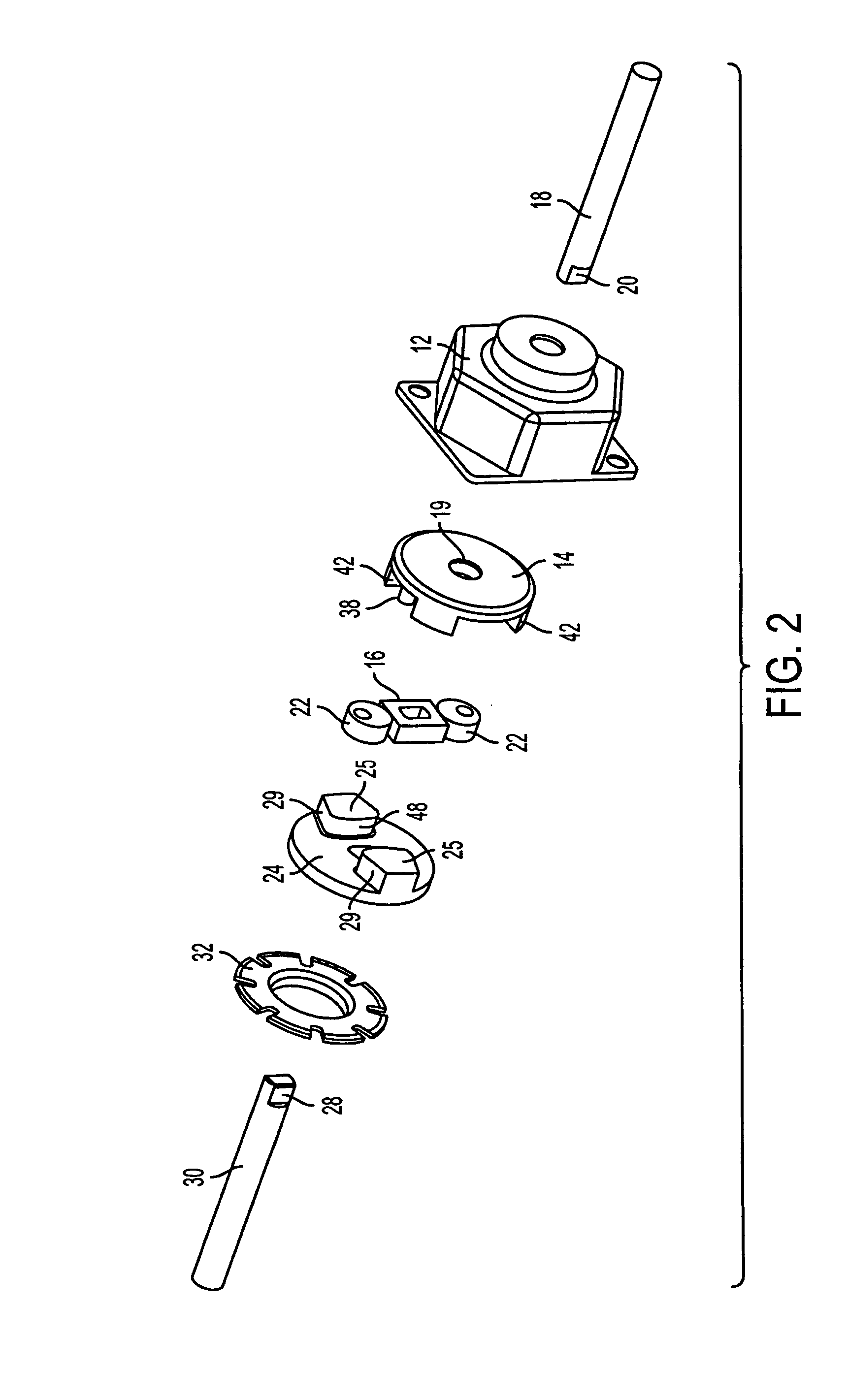

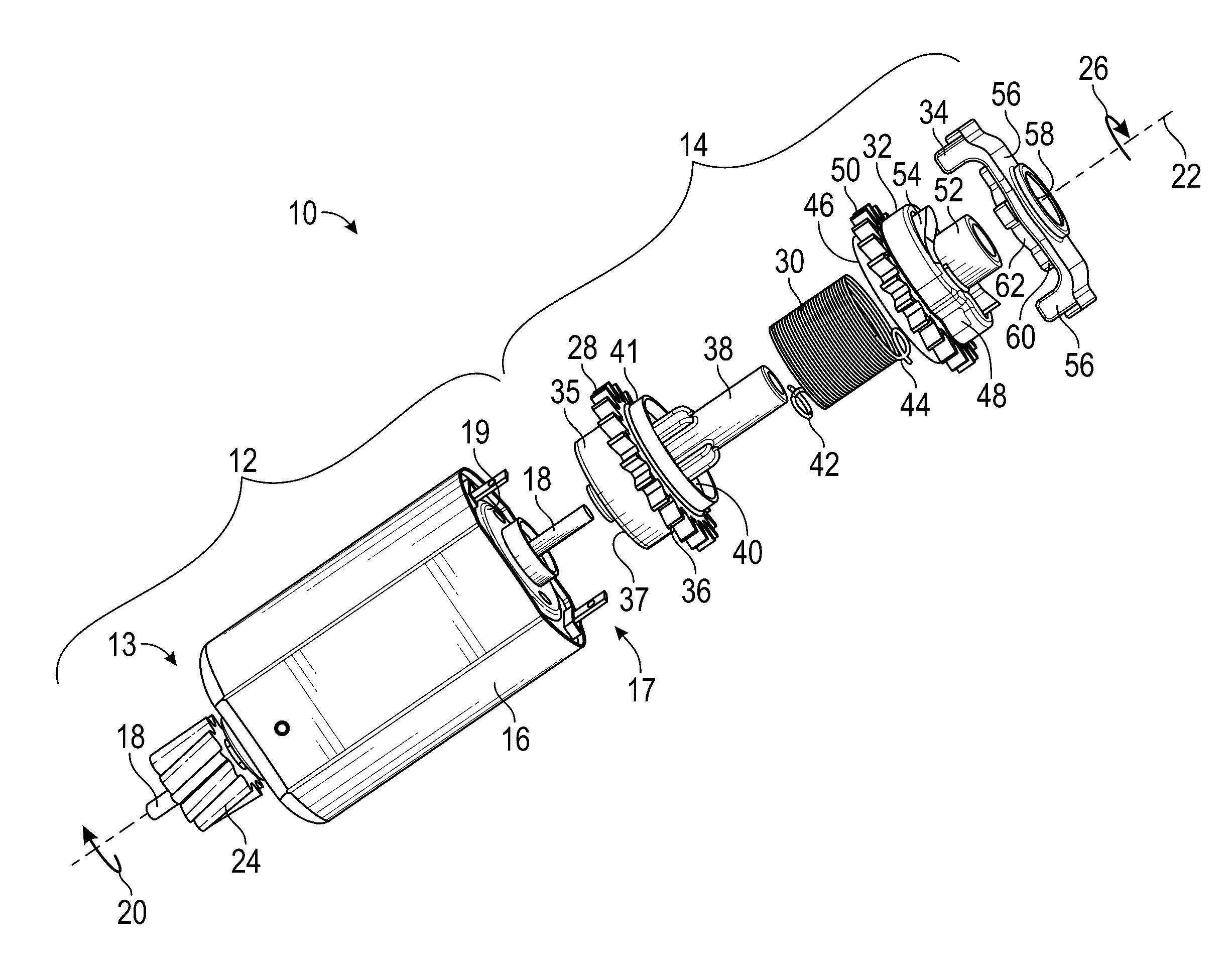

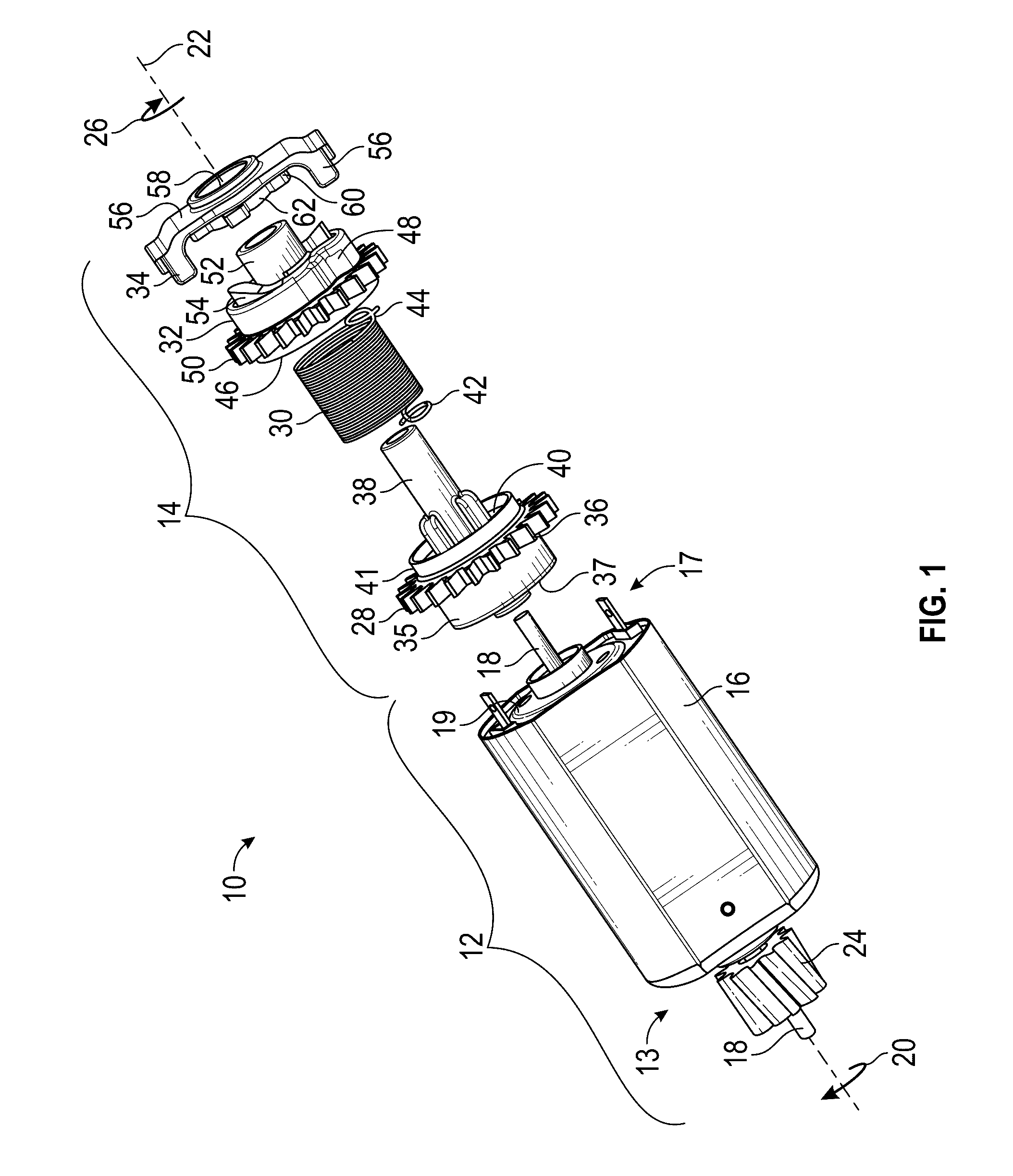

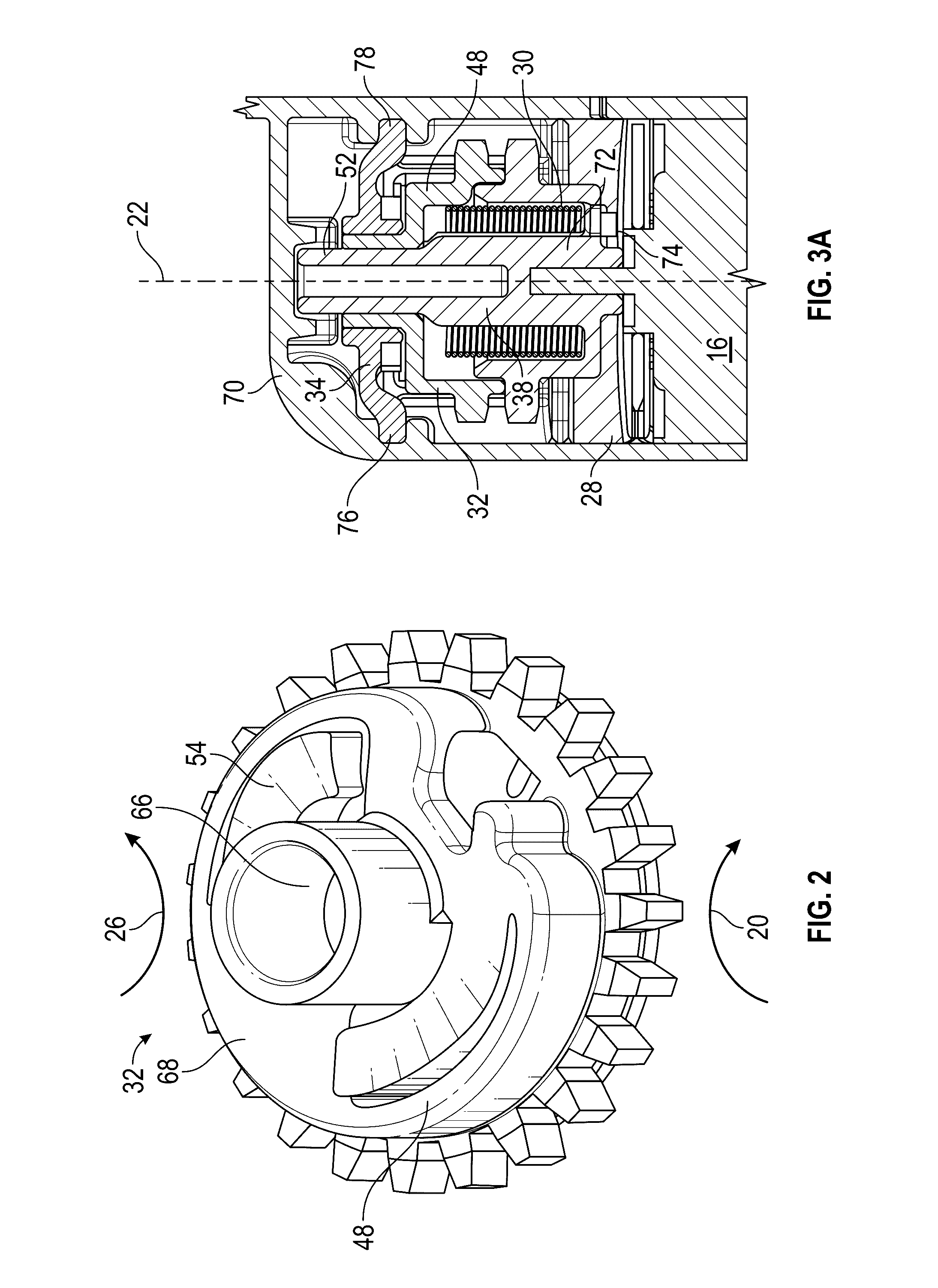

Inertia clutch mechanism in motors to prevent backdrive

A clutch mechanism 20 is provided for a motor 10. The motor has a shaft 12, a worm 14 associated with the shaft, a gear 16 engaged by the worm, and a friction surface 27. The clutch mechanism 20 includes a pressure plate 22 mounted for movement with respect to the shaft toward and away from the friction surface 27. A spring 26 is constructed and arranged to bias the pressure plate towards the friction surface. A stop 30 is constructed and arranged to limit movement of the pressure plate in a direction away from the friction surface. Whereby, under a back drive condition of the motor when the motor is not energized and the gear is moved by an externally applied torque causing an axial force to be exerted on the worm inducing an axial and an angular movement to the shaft, the pressure plate is constructed and arranged to move towards and engage the friction surface thereby impeding rotation of the shaft.

Owner:RPX CORP +1

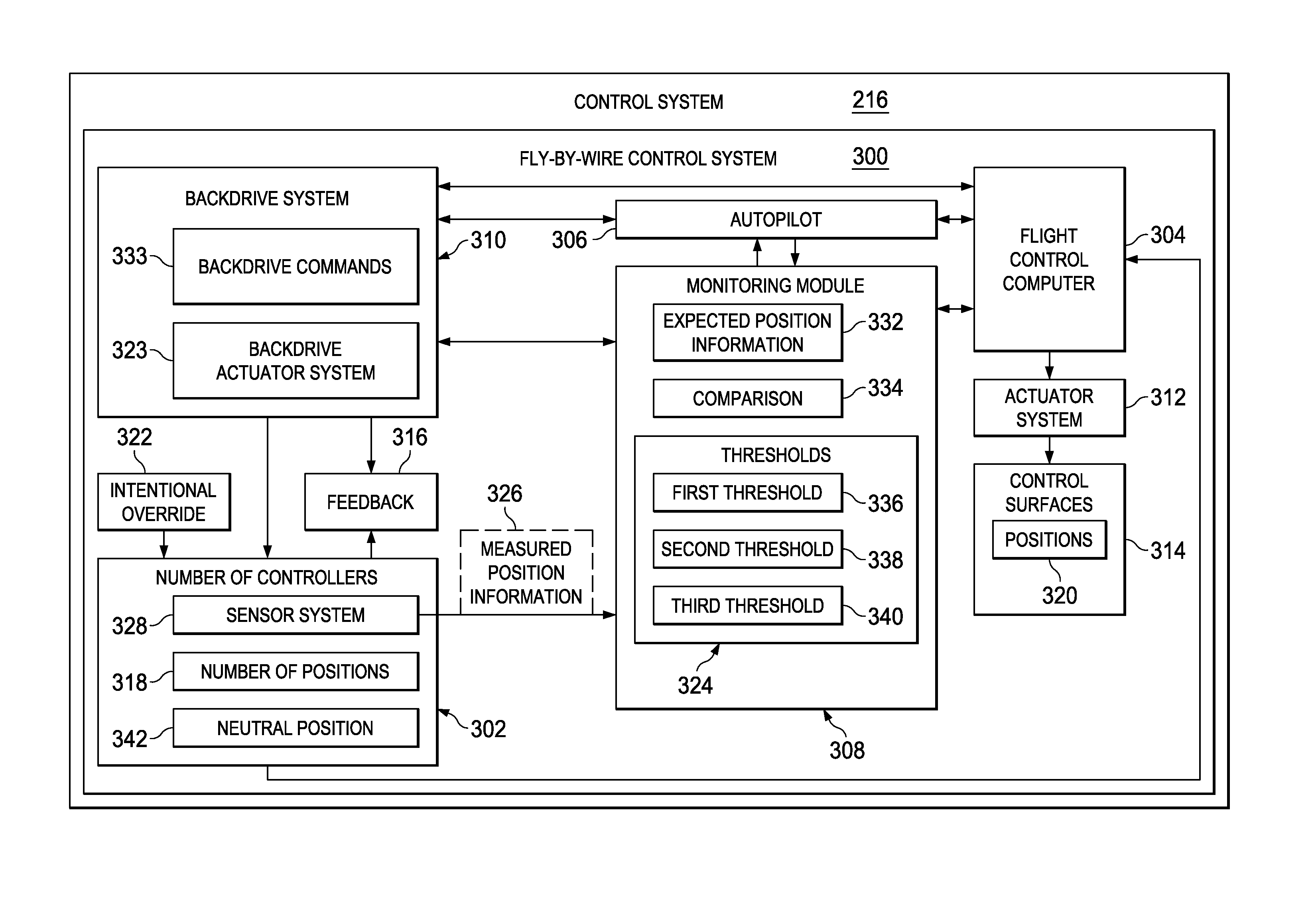

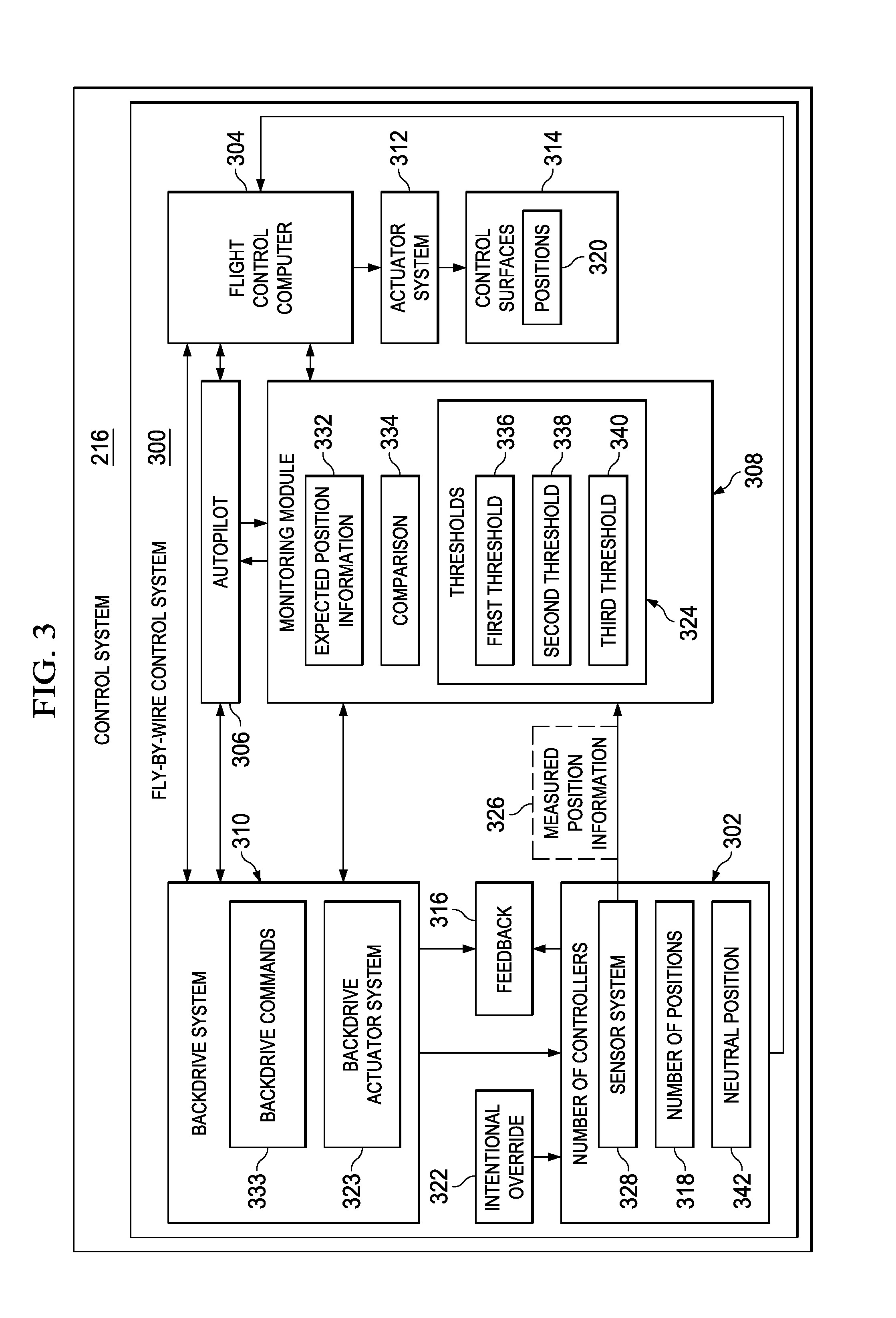

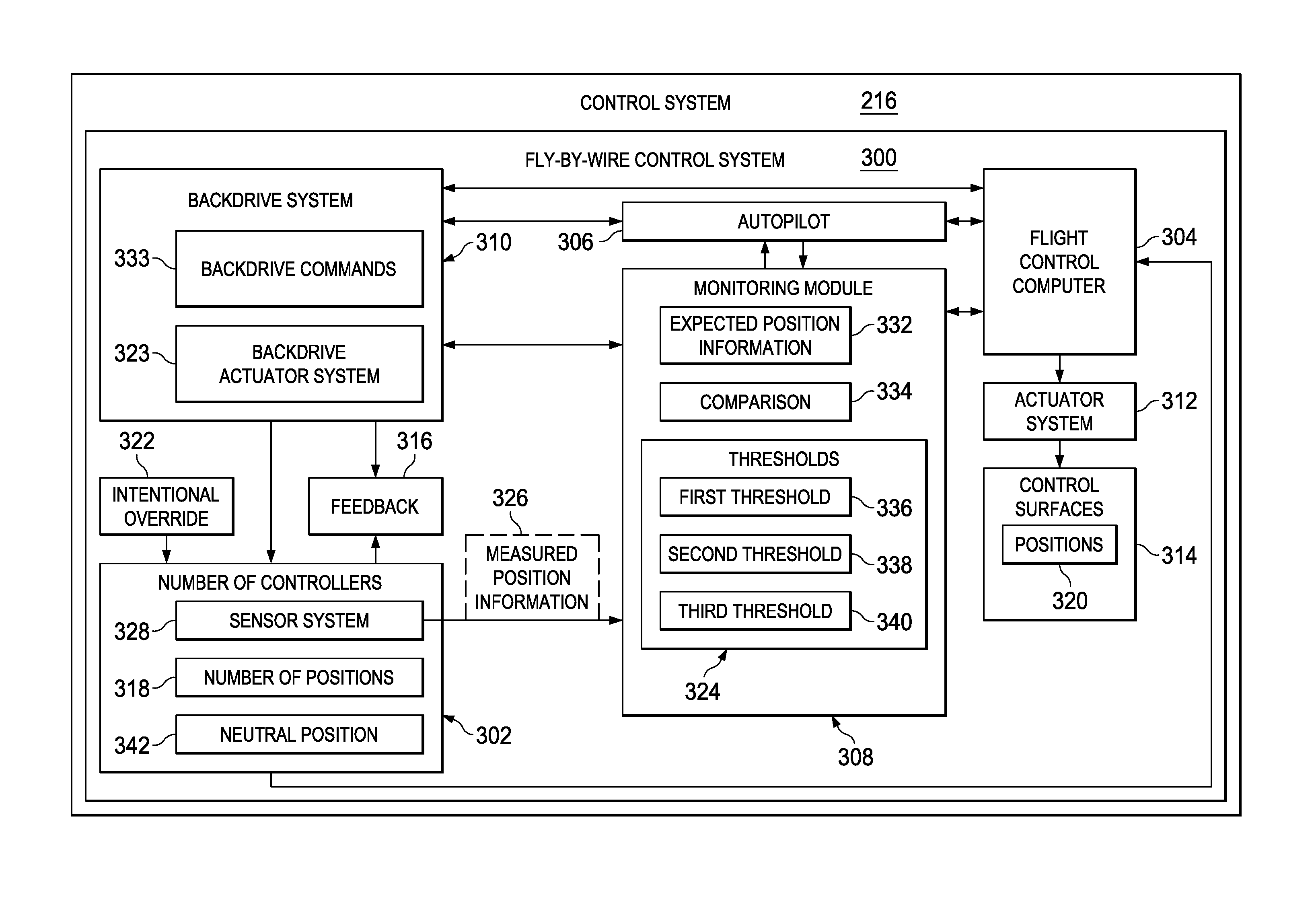

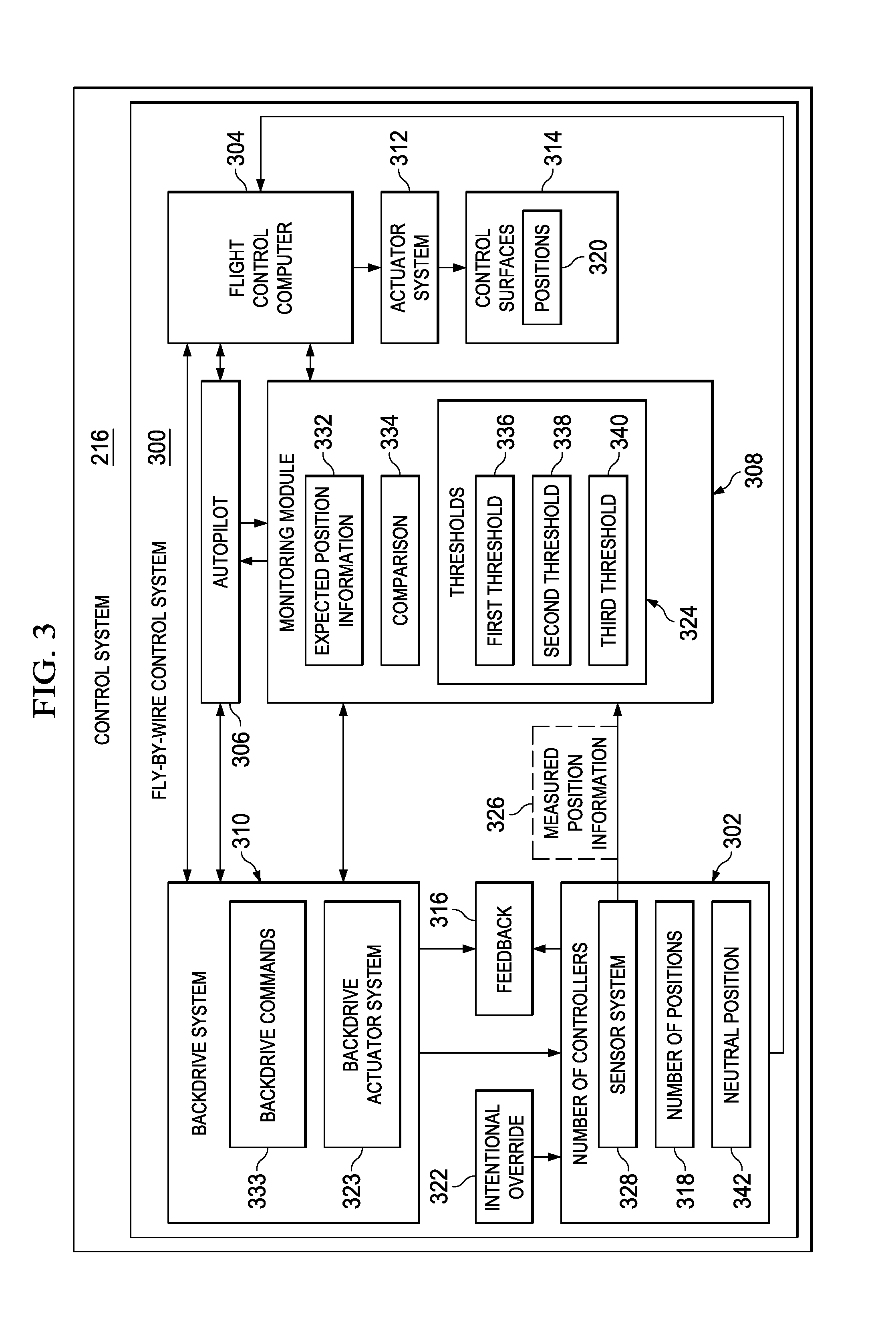

Flight Controller Management System with a Backdrive Monitor

ActiveUS20120277933A1Steering initiationsDigital data processing detailsControl systemComputer module

A method and apparatus for a monitoring module. The monitoring module is configured to identify a difference between measured position information for a controller and expected position information for the controller. The monitoring module is configured to compare the difference with thresholds for managing an autopilot in a control system of a vehicle to form a comparison. The monitoring module is configured to manage an operation of the autopilot based on the comparison such that the autopilot remains operating when a backdrive system is inoperative and an intentional override of the autopilot is absent.

Owner:THE BOEING CO

Decoupler devices to prevent backdrive in air turbine starters

ActiveUS8105018B2Reduce frictionLimit dynamic movementYielding couplingEngine fuctionsTurbineBackdrive

An air turbine starter for starting an engine includes a housing, and a flow path communicating a flow of gas therethrough; a turbine member; a clutch; and a decoupler device at least partially housed within the output member of the clutch. The decoupler device includes a first shaft portion coupled to and rotating with the output member and a second shaft portion coupled to and rotating with the engine. The first and second shaft portions are axially aligned and configured to engage each another for rotation in a first direction and to separate from each other in a second direction to decouple the output member of the clutch from the engine. The starter further includes a bearing between the inner surface of the output member and the second shaft portion for reducing friction between the second shaft portion and the inner surface of the output member when the first and second shaft portions are decoupled.

Owner:HONEYWELL INT INC

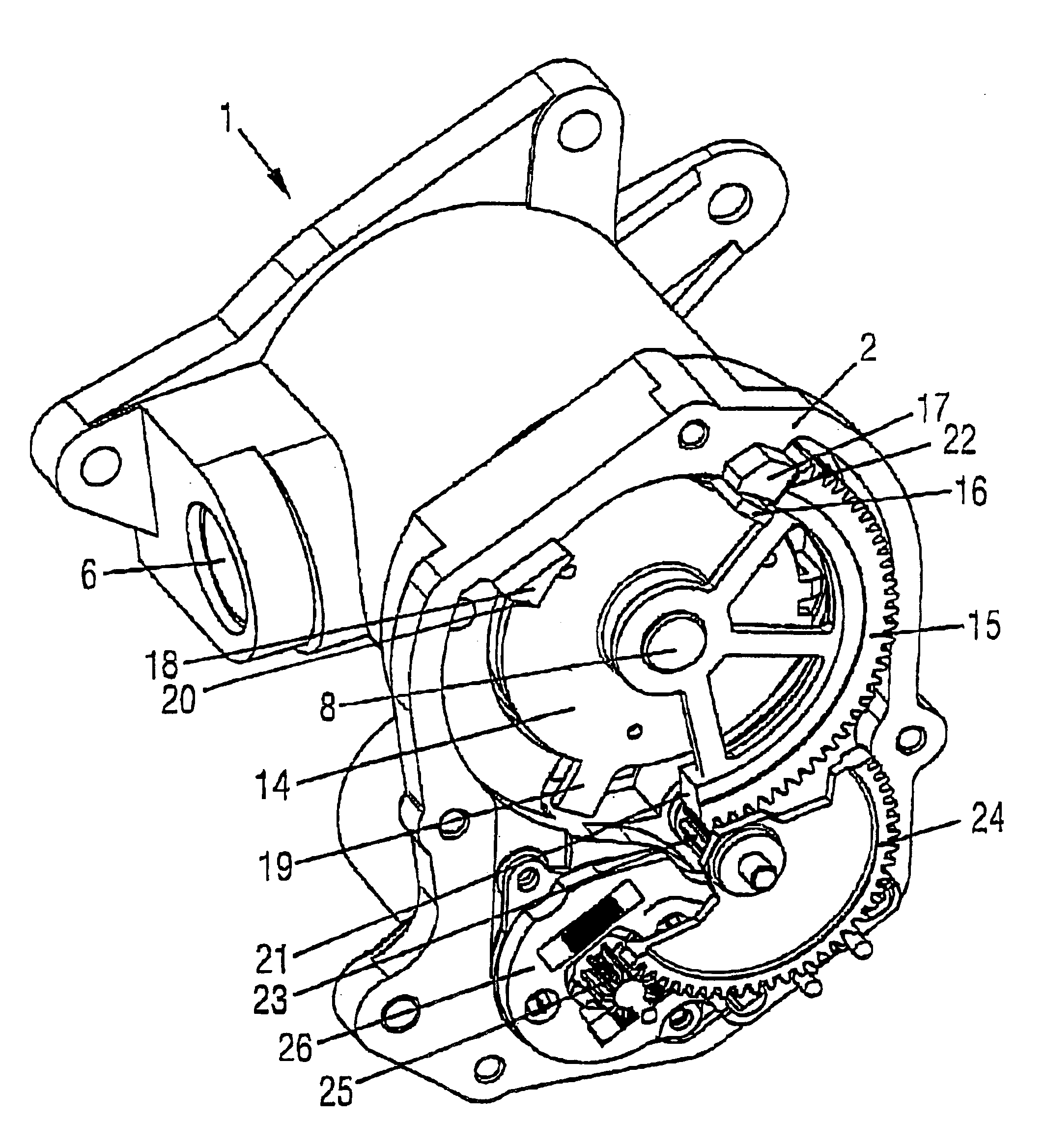

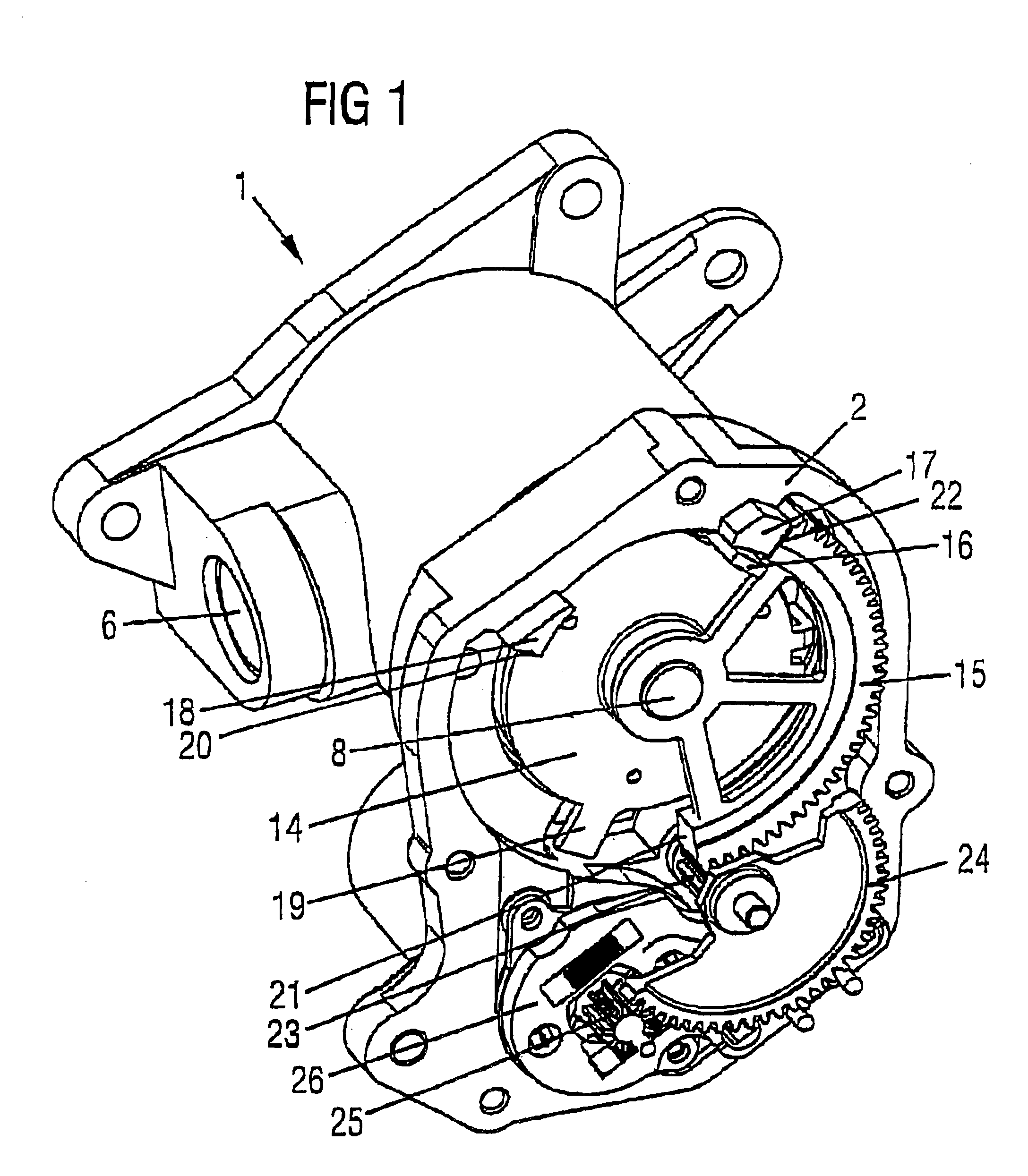

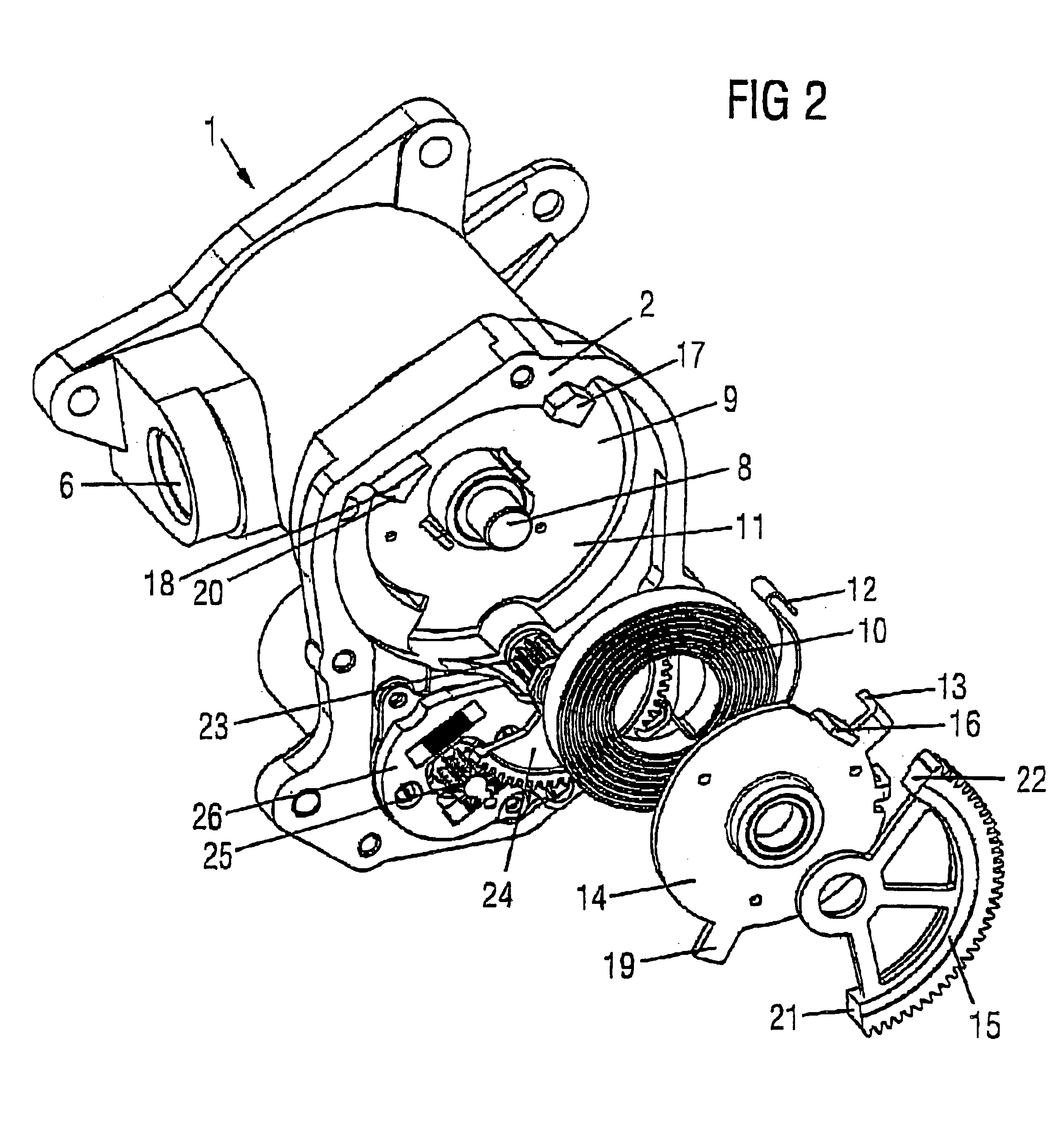

Actuating device

ActiveUS6913241B2Save energySimple and cost-effective constructionOperating means/releasing devices for valvesCoolant flow controlEngineeringMechanical engineering

Owner:CONTINENTAL AUTOMOTIVE GMBH

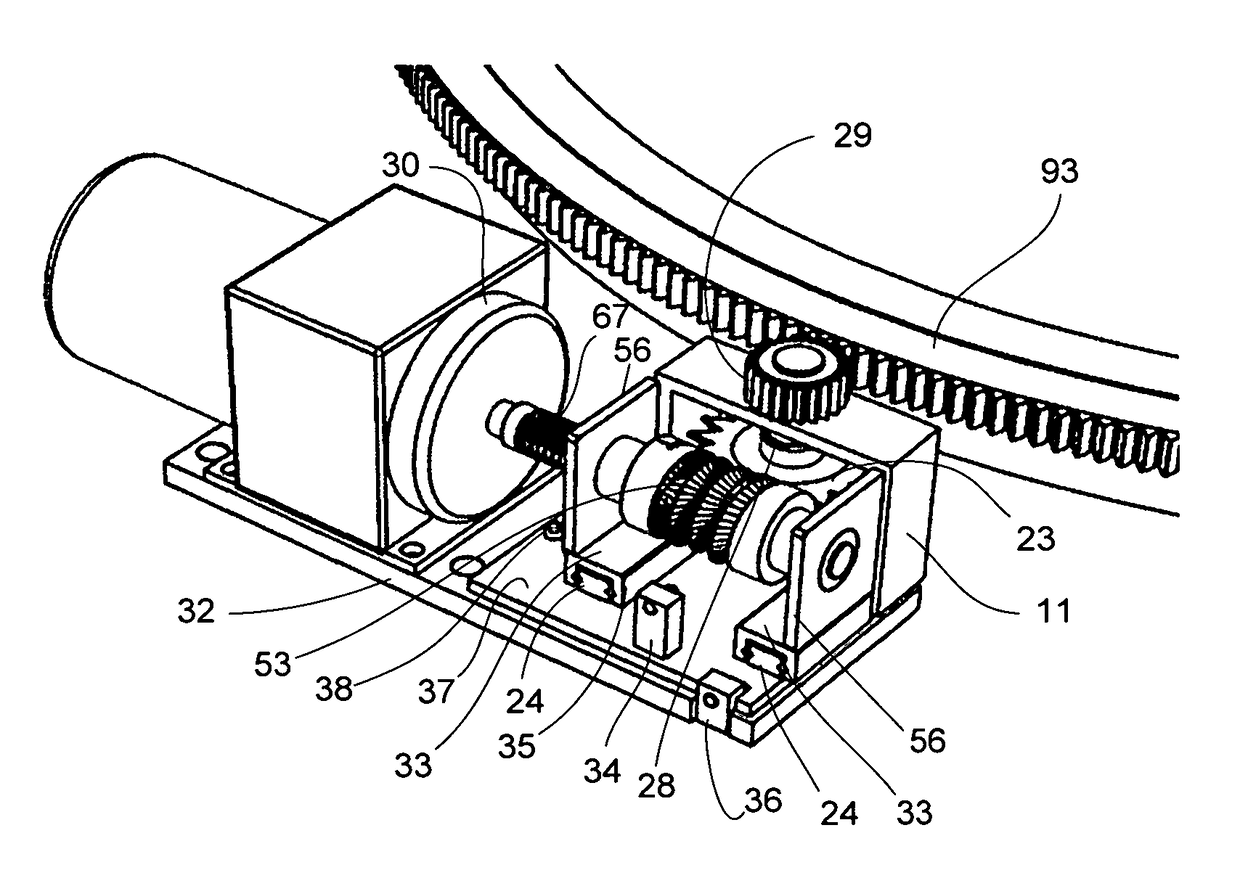

Precision positioning device and stage incorporating a globoid worm and its manufacture

The device is a precision motion right angle drive for use with linear and rotary stages which employs a combination of globoid worm and small diameter star gear. Coaxial with the star gear, on the same shaft, is a spur gear which drives the rotary stage gear or a linear rack. The thin star gear achieves meshing accuracy with the globoid worm permitting a large tooth angle for direct preloading without jamming. This gear combination eliminates backlash, allows a low gear ratio for low globoid worm speed, and enables the use of an ordinary spur gear to engage the stage gear without backdrive or backlash. Further, it allows for gear contact area to compensate for the thinness of the star gear. An embodiment including an integrated bearing rotary stage permits flexibility of application and avoidance of need for custom bearing designs by achieving high motion precision at low cost.

Owner:MAURO COMML IND OF VERO BEACH LLC

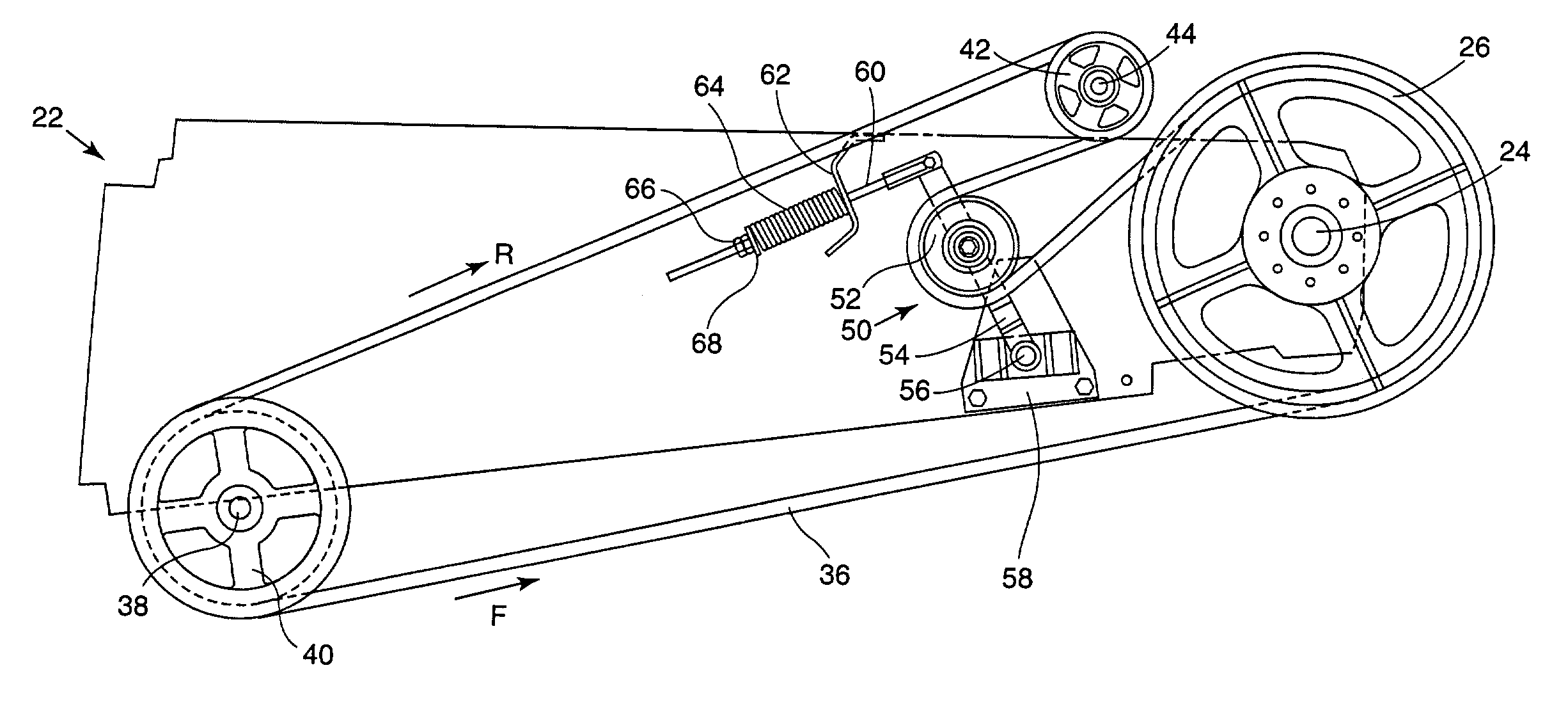

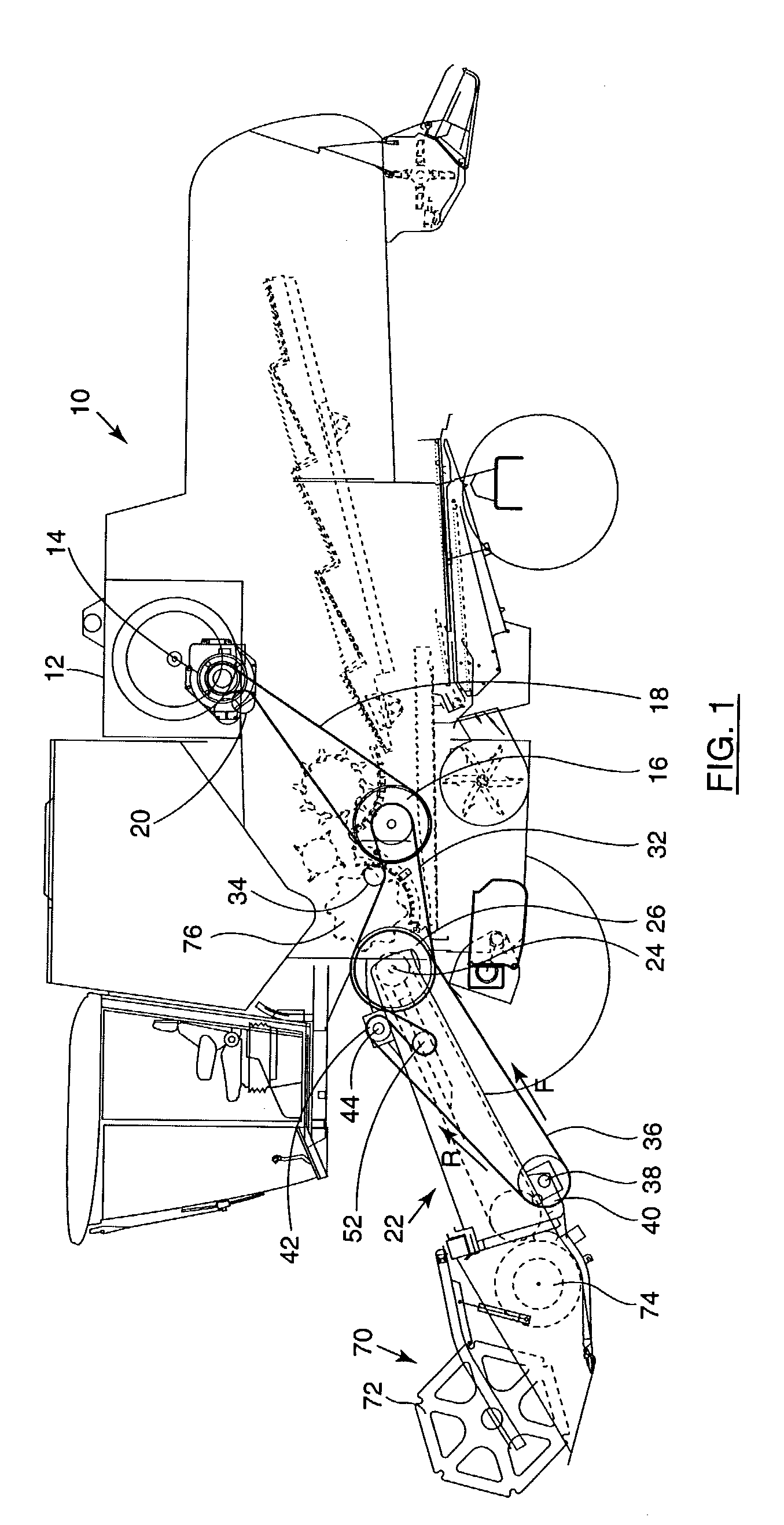

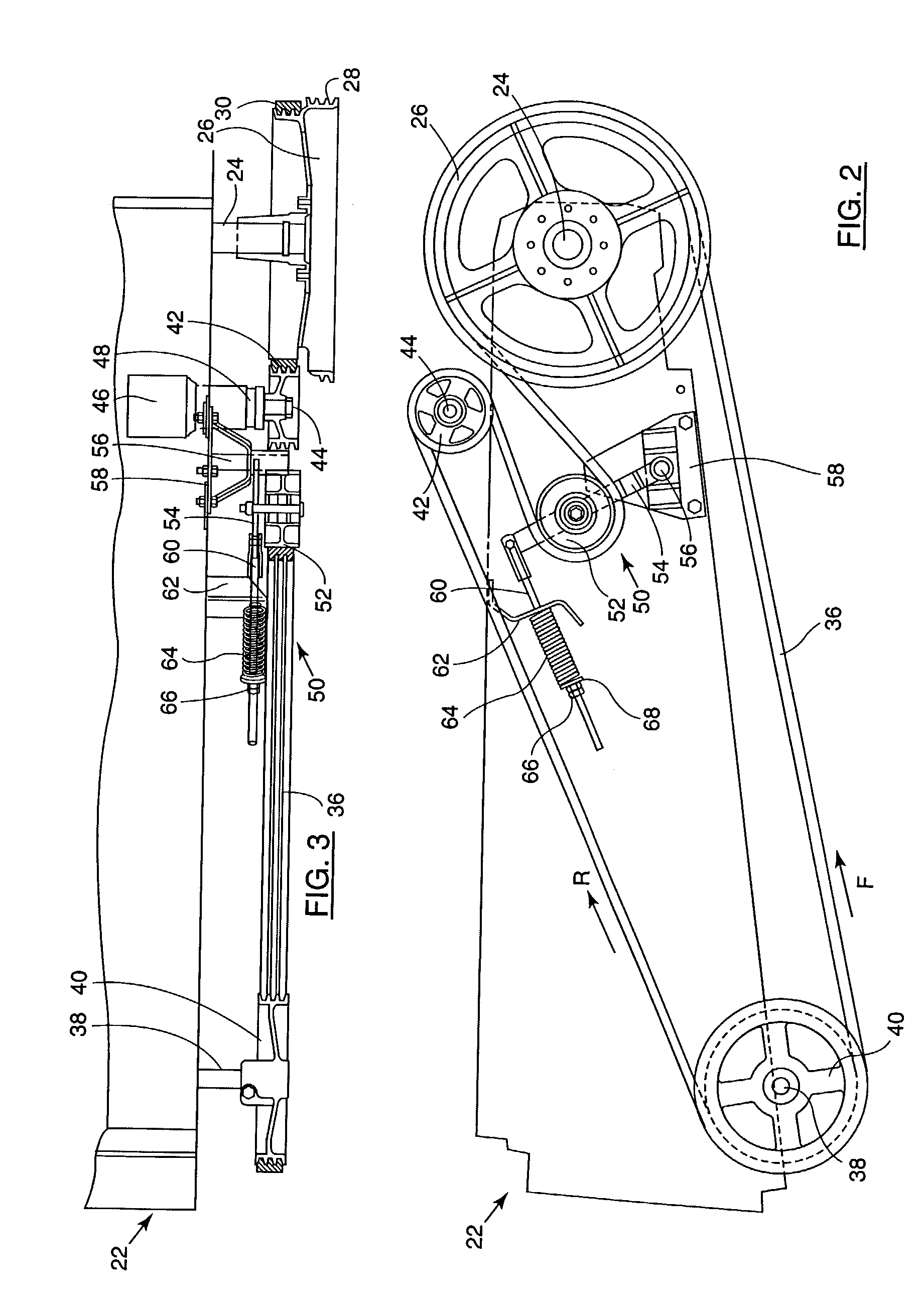

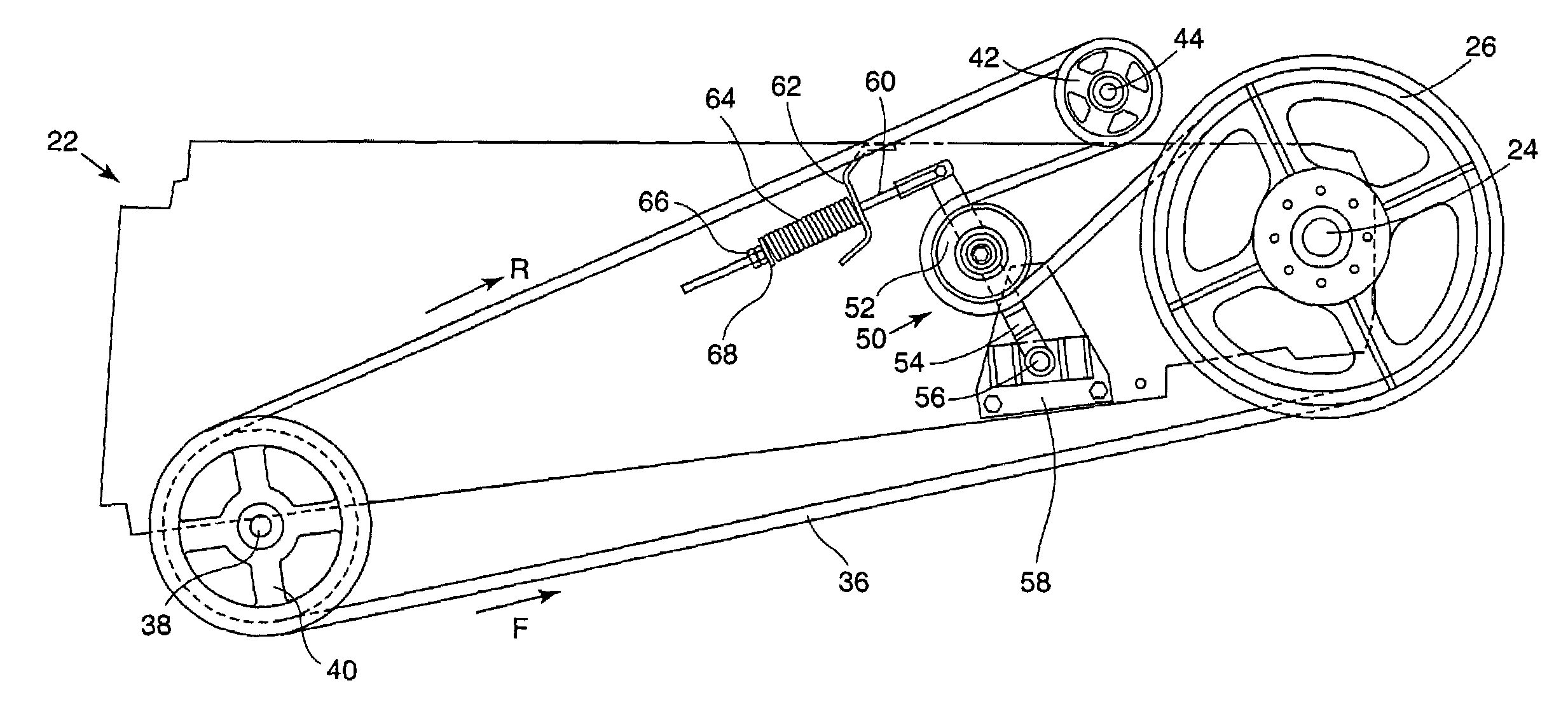

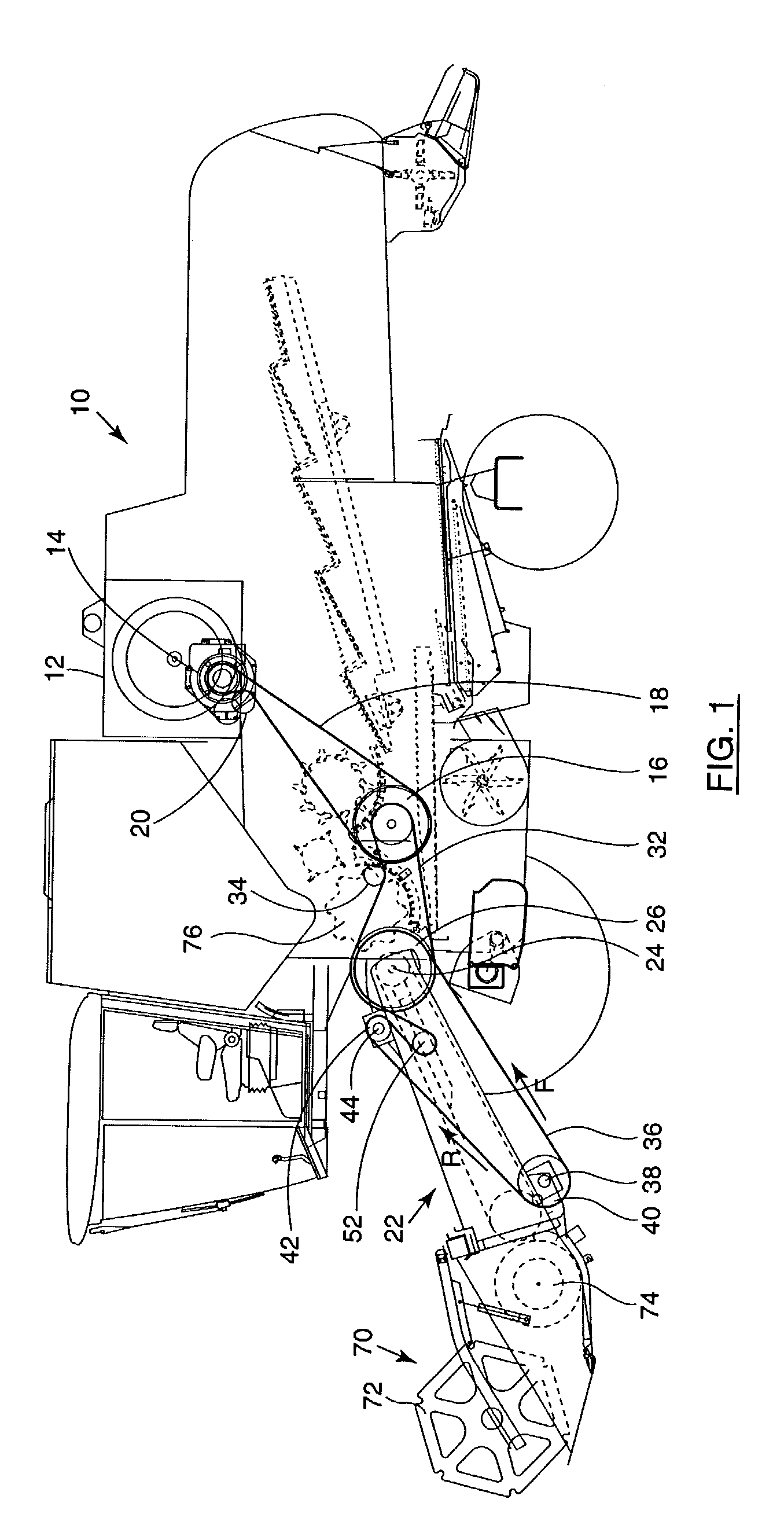

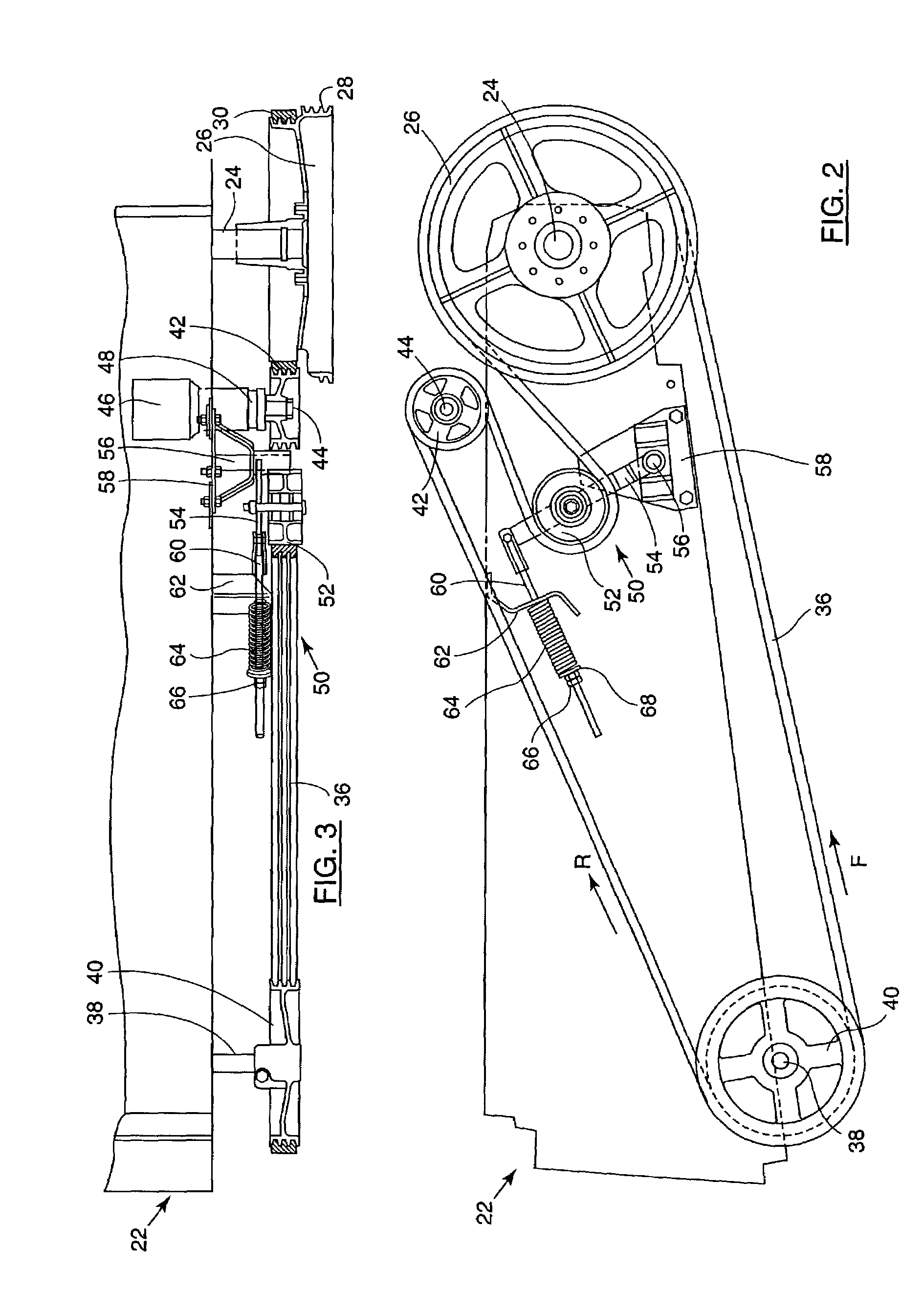

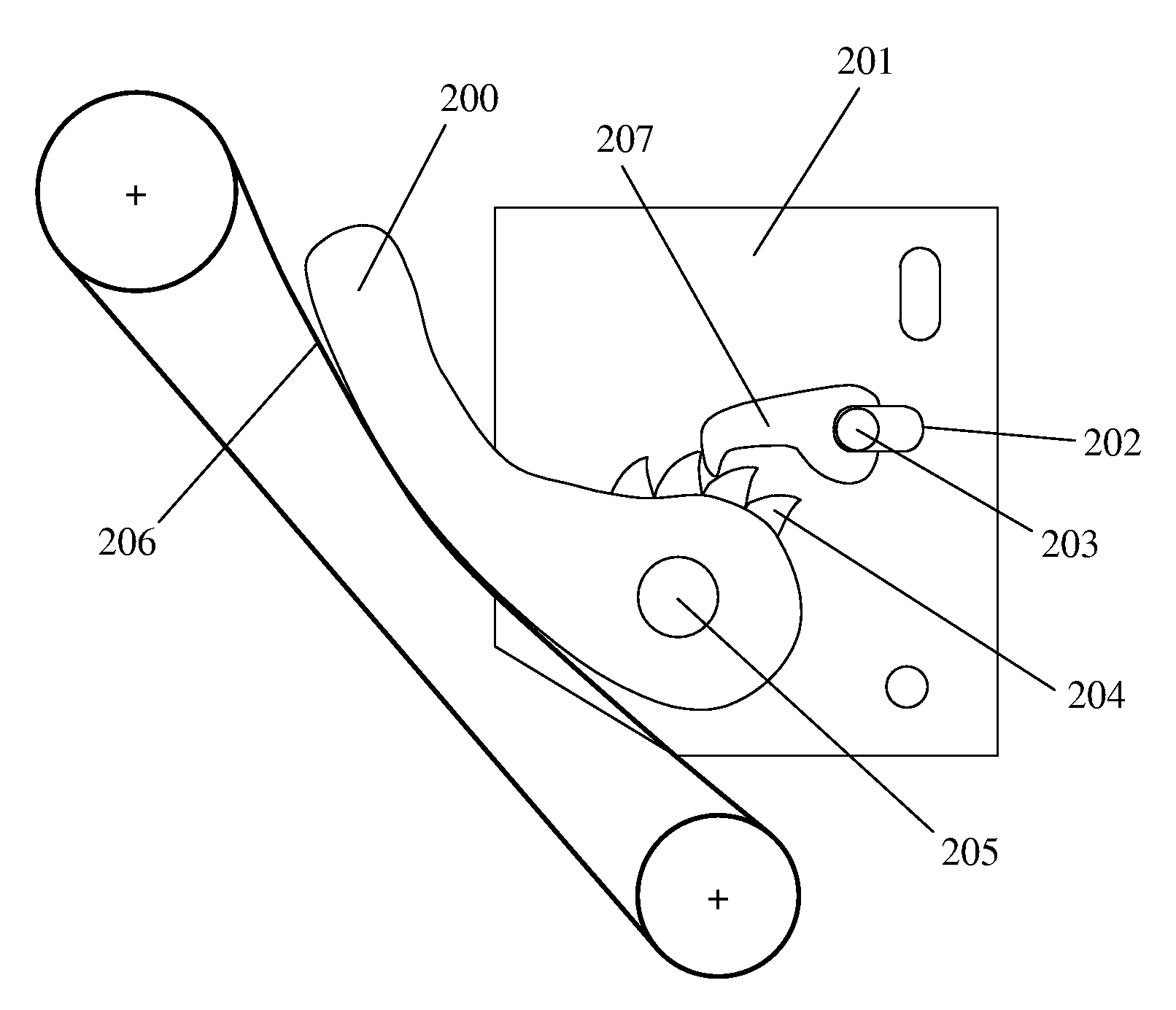

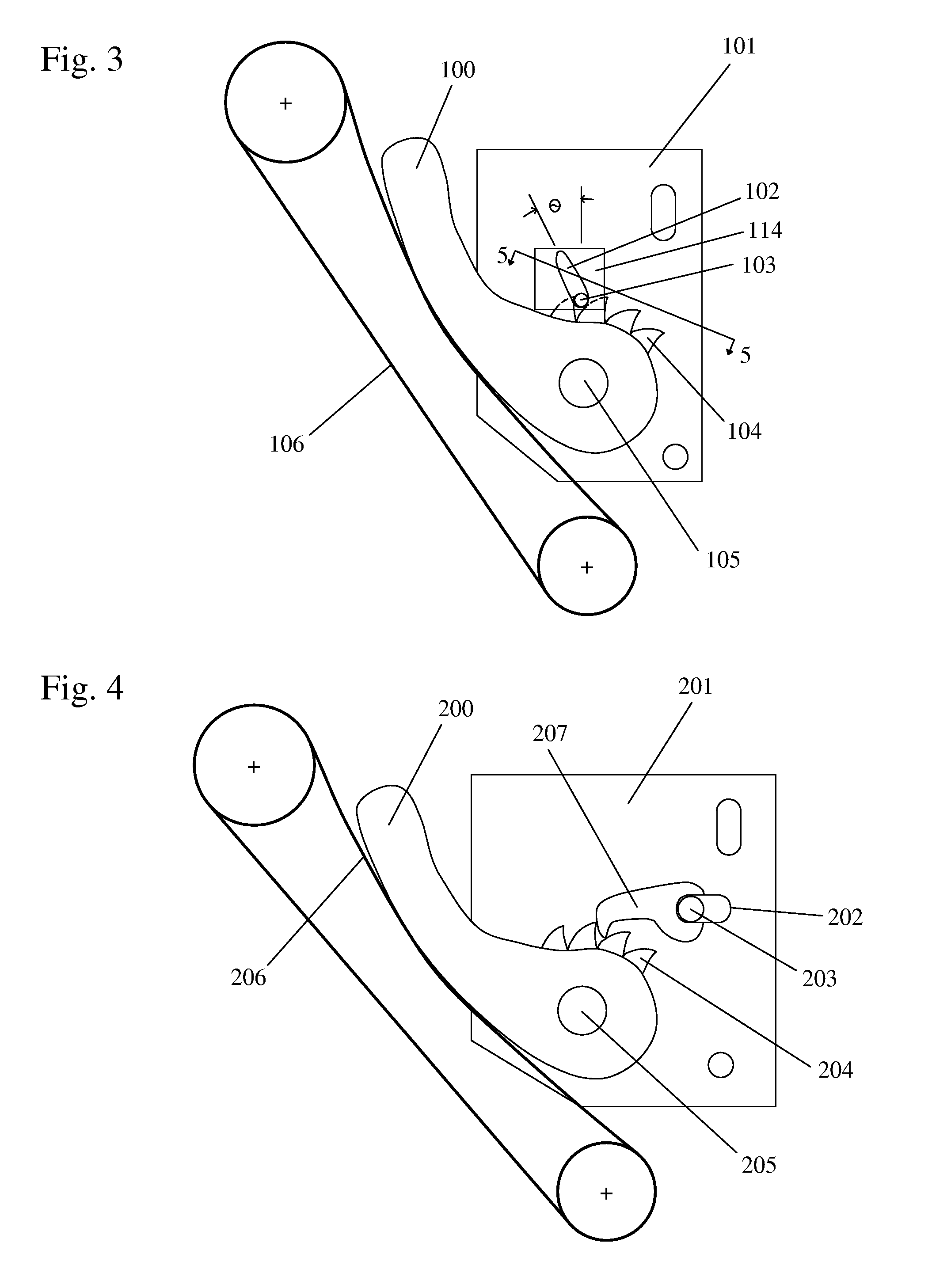

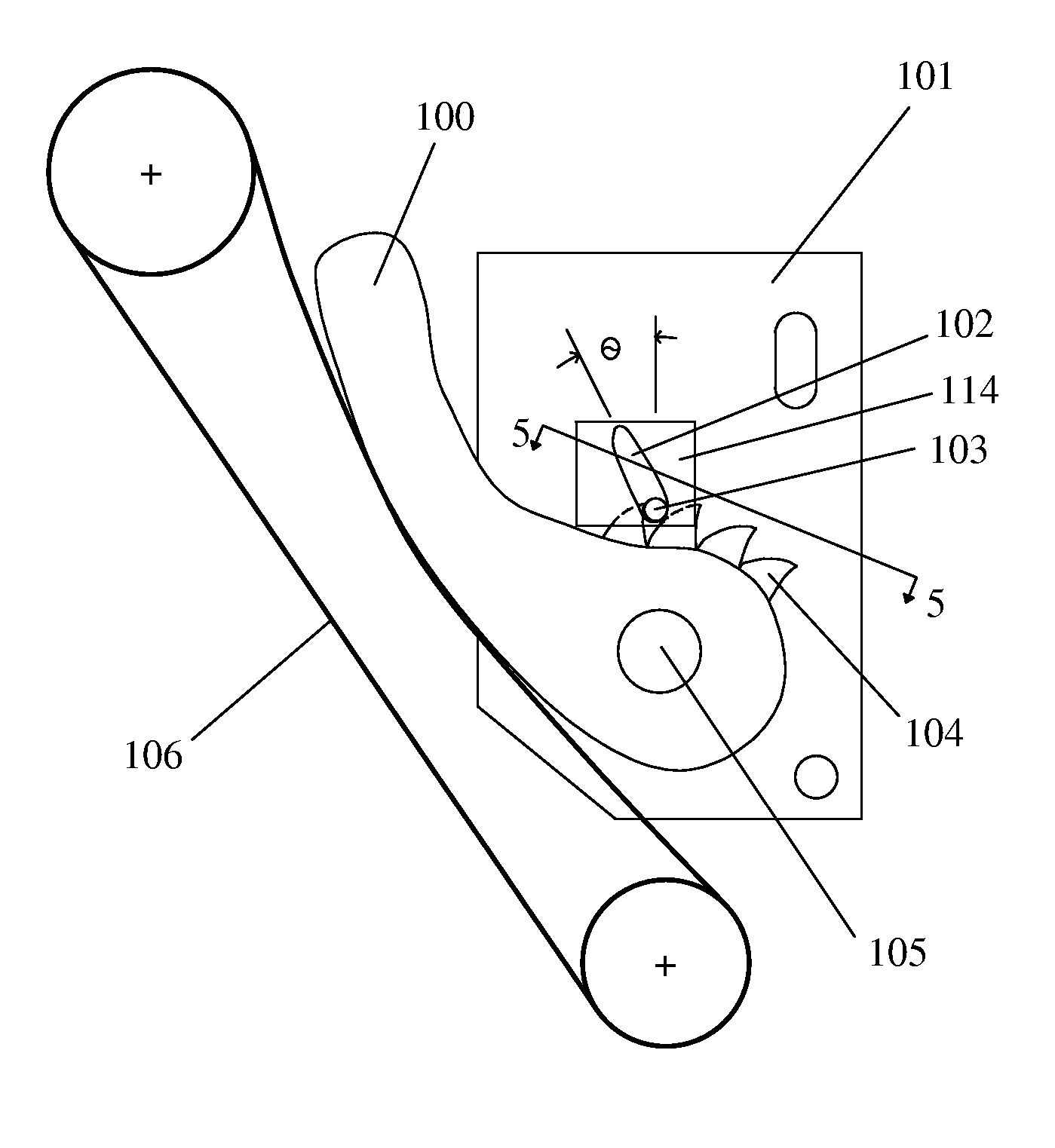

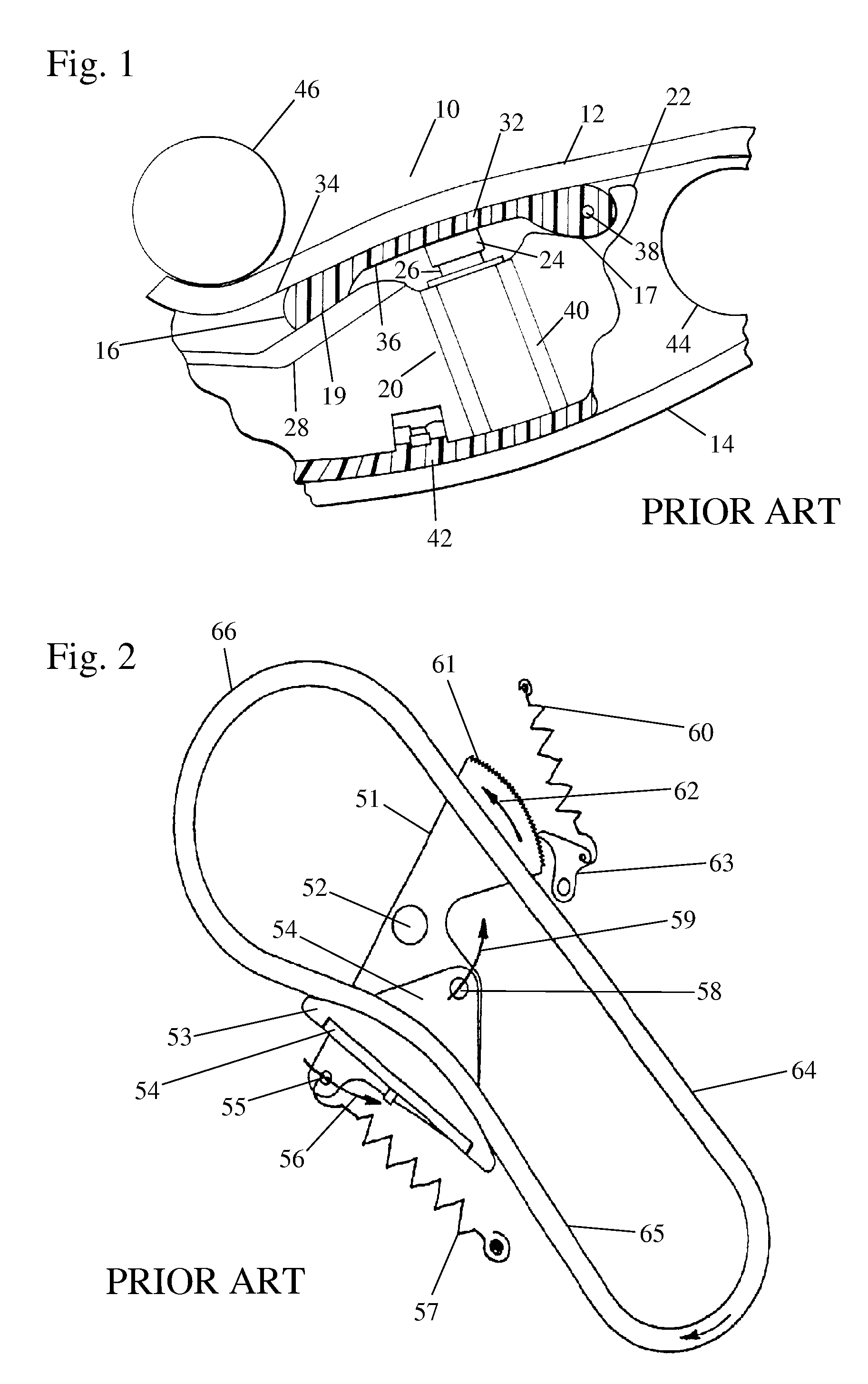

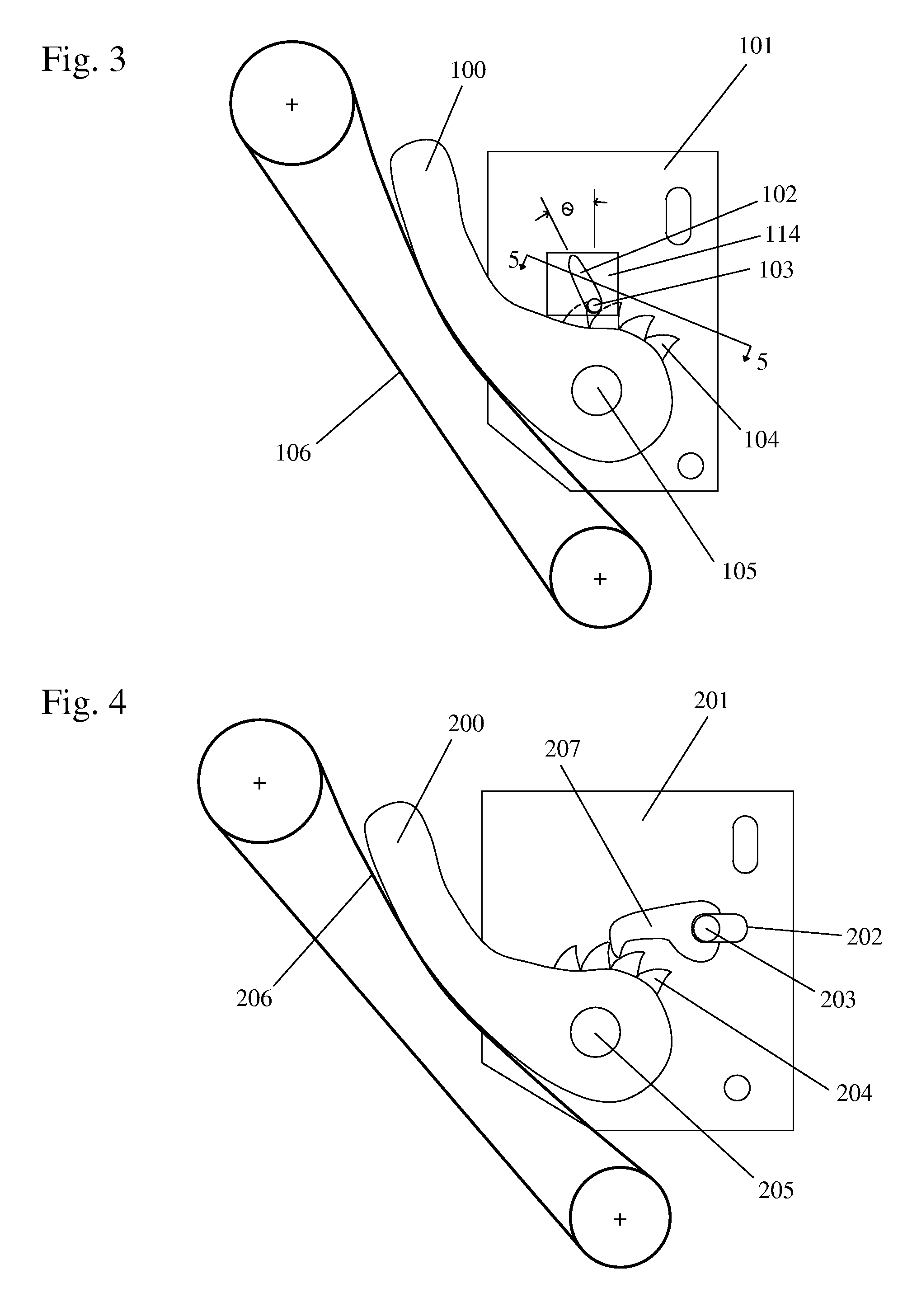

Utility machinery and associated reversible feeder mechanisms

ActiveUS20050181900A1Improved utility machineryOptimization mechanismMowersGearingDrive wheelIdler-wheel

A drive mechanism for utility machinery is disclosed. The mechanism includes a driver wheel and a driven wheel that are coupled by means of an endless flexible band trained around outer rims of the driver and driven wheels. The driver wheel is adapted to transmit drive to the driven wheel in a forward direction F along a loaded side of the band. The mechanism further comprises an idler wheel that runs on an outer side of the band and applies an inwardly directed tensioning force to the band on a run of the band that is unloaded when forward drive is being transmitted. A reverse driver is positioned between the idler wheel and the driven wheel on an inner portion of the side of the band that is unloaded during forward drive. The reverse driver is adapted to selectively provide a reverse drive to the band.

Owner:BLUE LEAF I P INC +1

Utility machinery and associated reversible feeder mechanisms

A drive mechanism for utility machinery is disclosed. The mechanism includes a driver wheel and a driven wheel that are coupled by means of an endless flexible band trained around outer rims of the driver and driven wheels. The driver wheel is adapted to transmit drive to the driven wheel in a forward direction F along a loaded side of the band. The mechanism further comprises an idler wheel that runs on an outer side of the band and applies an inwardly directed tensioning force to the band on a run of the band that is unloaded when forward drive is being transmitted. A reverse driver is positioned between the idler wheel and the driven wheel on an inner portion of the side of the band that is unloaded during forward drive. The reverse driver is adapted to selectively provide a reverse drive to the band.

Owner:BLUE LEAF I P INC +1

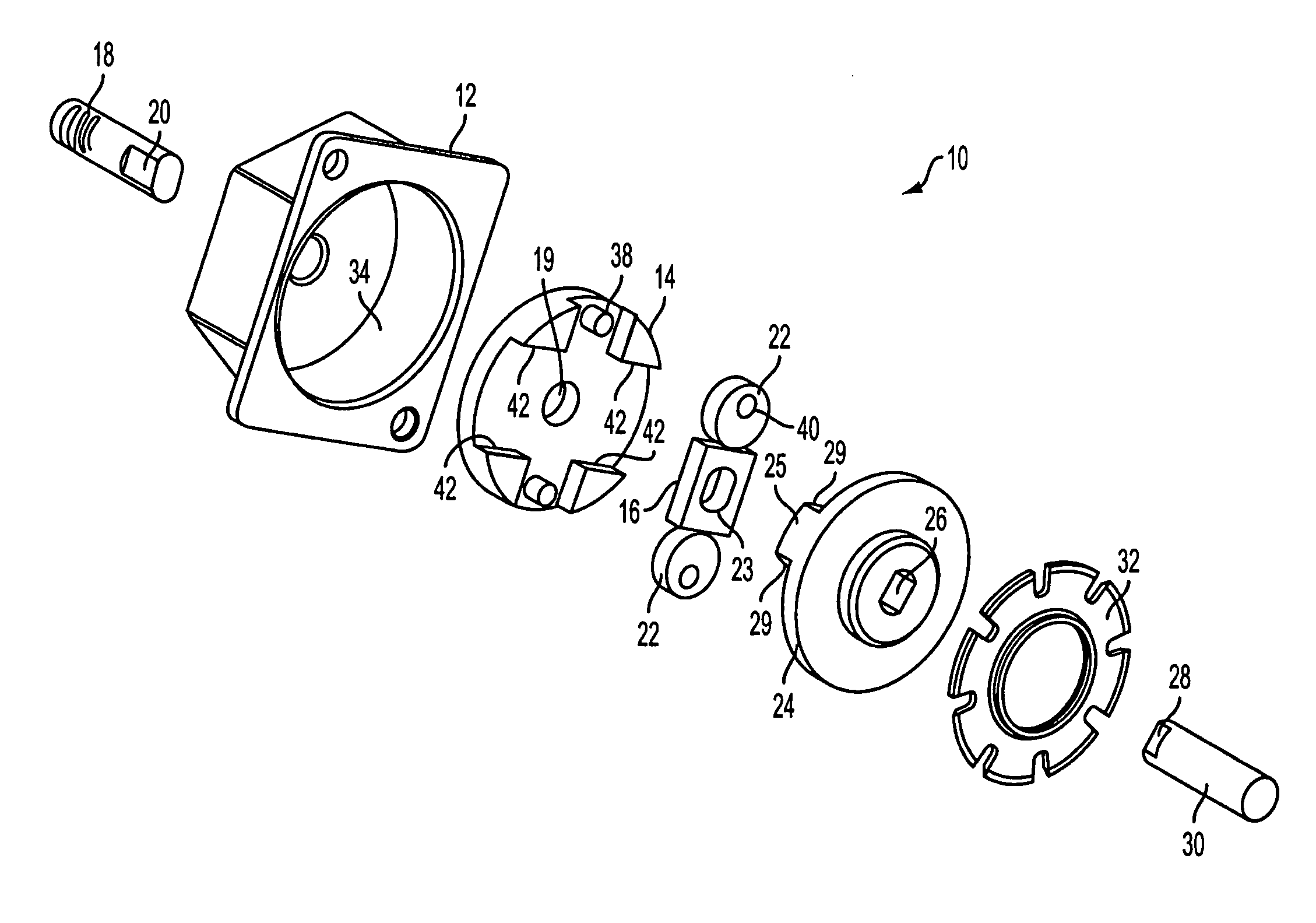

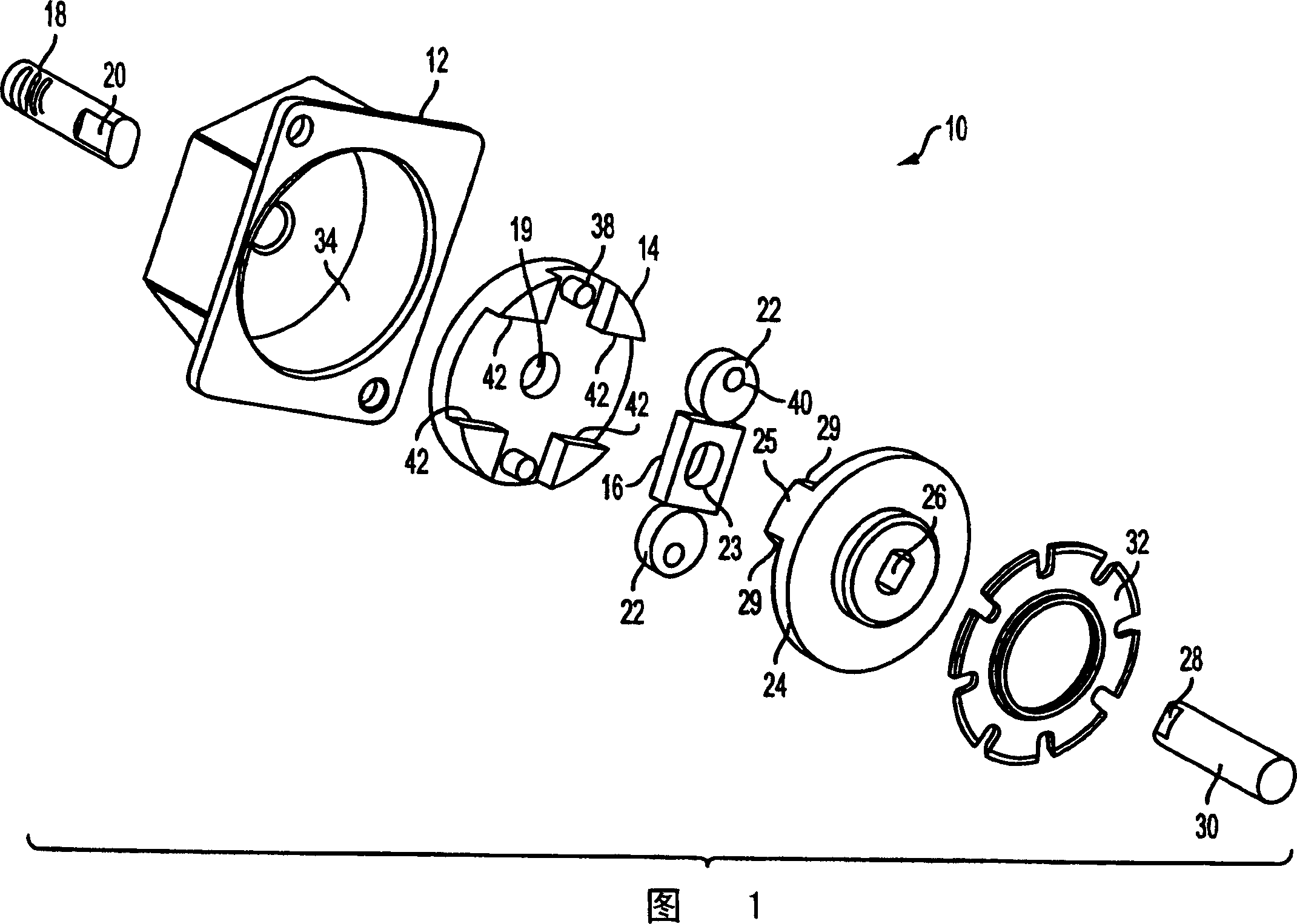

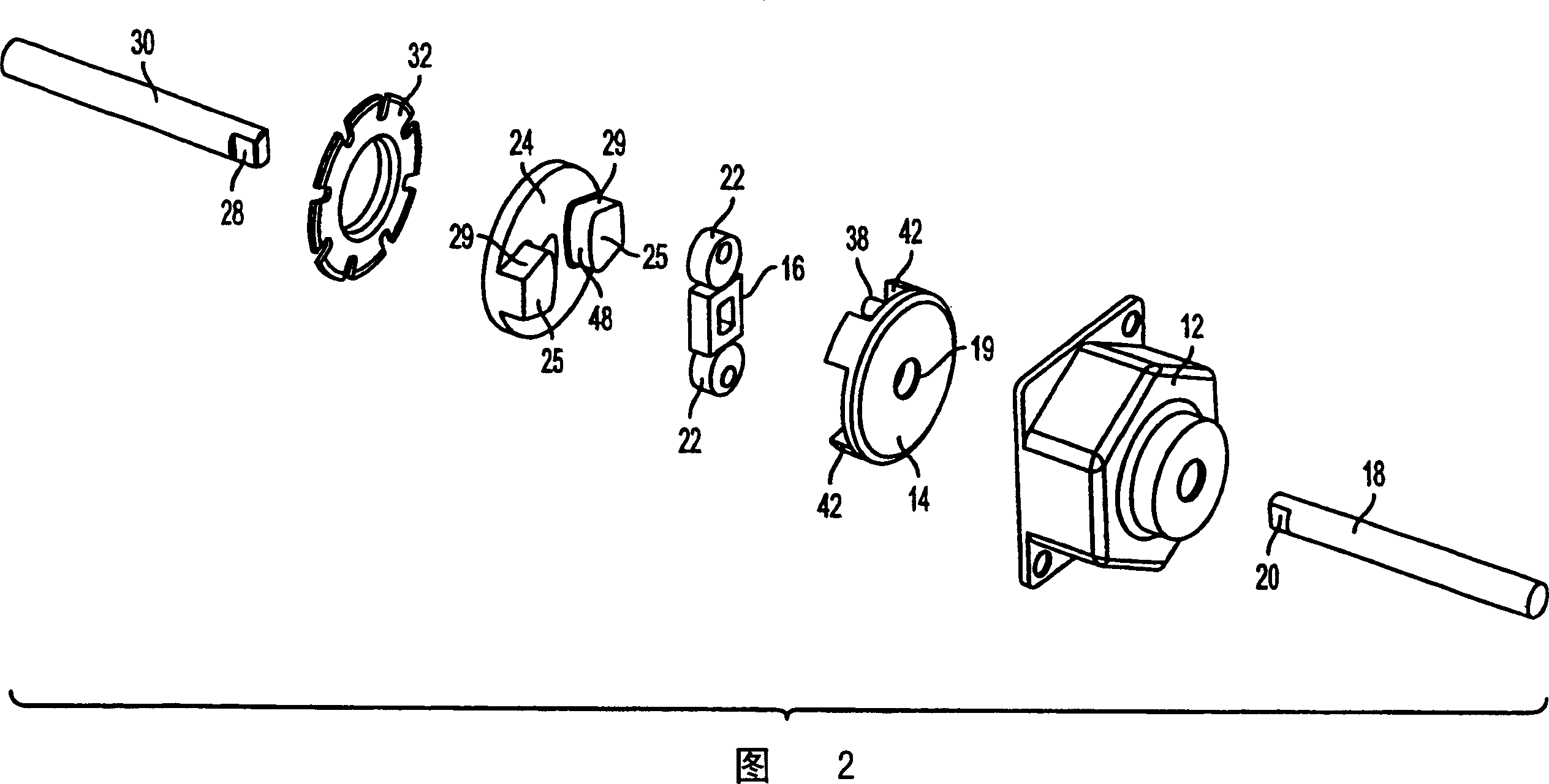

Bi-directional friction clutch assembly for electric motors to prevent backdrive

A clutch assembly 100 is provided for a motor having an armature shaft and a worm shaft having a worm constructed and arranged to engage a gear. The clutch assembly includes a clutch housing 112 including a race surface 132; a cam 117 coupled to the worm shaft; follower structure 122 operatively associated with the cam; a clutch plate 114, and a clutch coupler 118 associated with the clutch plate, the cam, and the follower structure. The coupler is coupled to the armature shaft for rotation therewith, such that rotation of the coupler rotates the clutch plate, the cam and follower structure, and thus the worm shaft. During a back drive condition of the motor, when torque is transmitted to the worm shaft and thus to the cam, the cam is constructed and arranged to causes the follower structure 122 to contact and exert pressure on the race surface 132 thereby preventing rotation of the worm shaft.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Hydrodynamic torque converter

InactiveUS6634474B2Improve performanceSimple and accurate mannerRotary clutchesFluid actuated clutchesRotational axisImpeller

A hydrodynamic torque converter includes a converter housing and a turbine wheel which is arranged in the converter housing and is rotatable with respect to the converter housing about a rotational axis of the converter. The torque converter further includes a lockup clutch for producing a torque transmission connection between the converter housing and the turbine wheel. The lockup clutch has a first friction surface arrangement held by a first friction surface carrier arrangement substantially fixed with respect to rotation relative to the converter housing, a second friction surface arrangement is held by a second friction surface carrier arrangement substantially fixed with respect to rotation relative to the turbine wheel, a contact pressing arrangement for pressing the first and the second friction surface arrangement against one another in frictional contact, and an abutment arrangement at which the first and second friction surface arrangement can be supported substantially in the direction of the axis of rotation when pressed by the contact pressure arrangement. The first friction surface carrier arrangement has a substantially annular body region connected either directly or indirectly with the converter housing and driver projections which are arranged at a distance from one another in the circumferential direction proceeding from the body region. Respective counter-driver projections at the first friction surface arrangement engage between these driver projections.

Owner:ZF FRIEDRICHSHAFEN AG

Anti-backdrive for continuous disc recliner

A disc recliner includes a fixed plate having a plurality of outer teeth and a movable plate having a plurality of inner teeth meshingly engageable with the outer teeth to allow rolling movement of the movable plate relative to the fixed plate. A pair of wedges defining an eccentric is rotatably mounted between the fixed and movable plates and rotation of the wedges causes the rolling movement of the movable plate. An anchor is disposed between the wedges for rotation therewith. A lock plate is coupled to the anchor and is movable between a locked position engaged with the fixed plate to prevent rotation of the wedges and an unlocked position disengaged with the fixed plate to permit rotation of the wedges. A cam actuates the lock plate from the locked position to the unlocked position and rotates the wedges thereby causing the rolling movement of the movable plate.

Owner:MAGNA SEATING

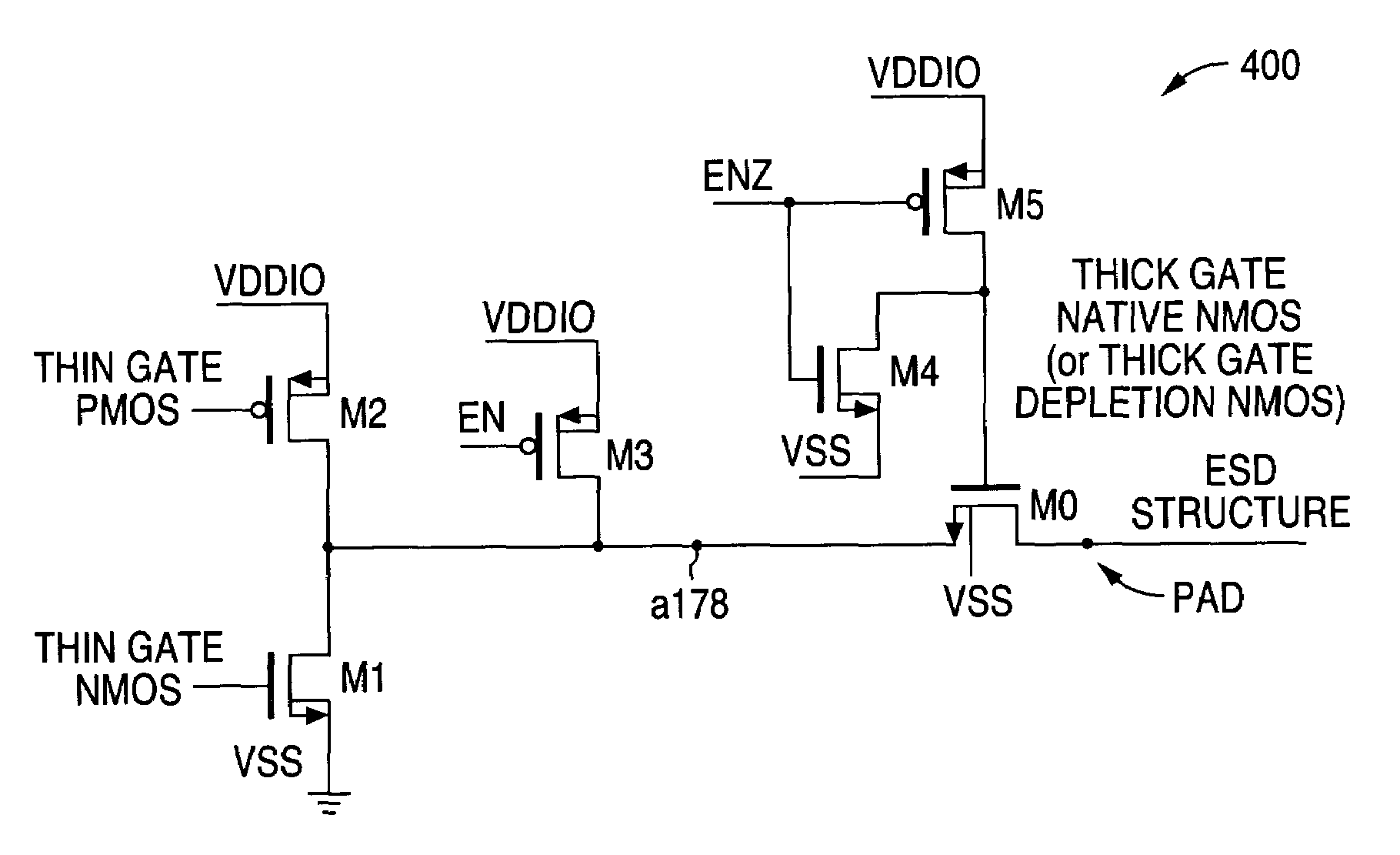

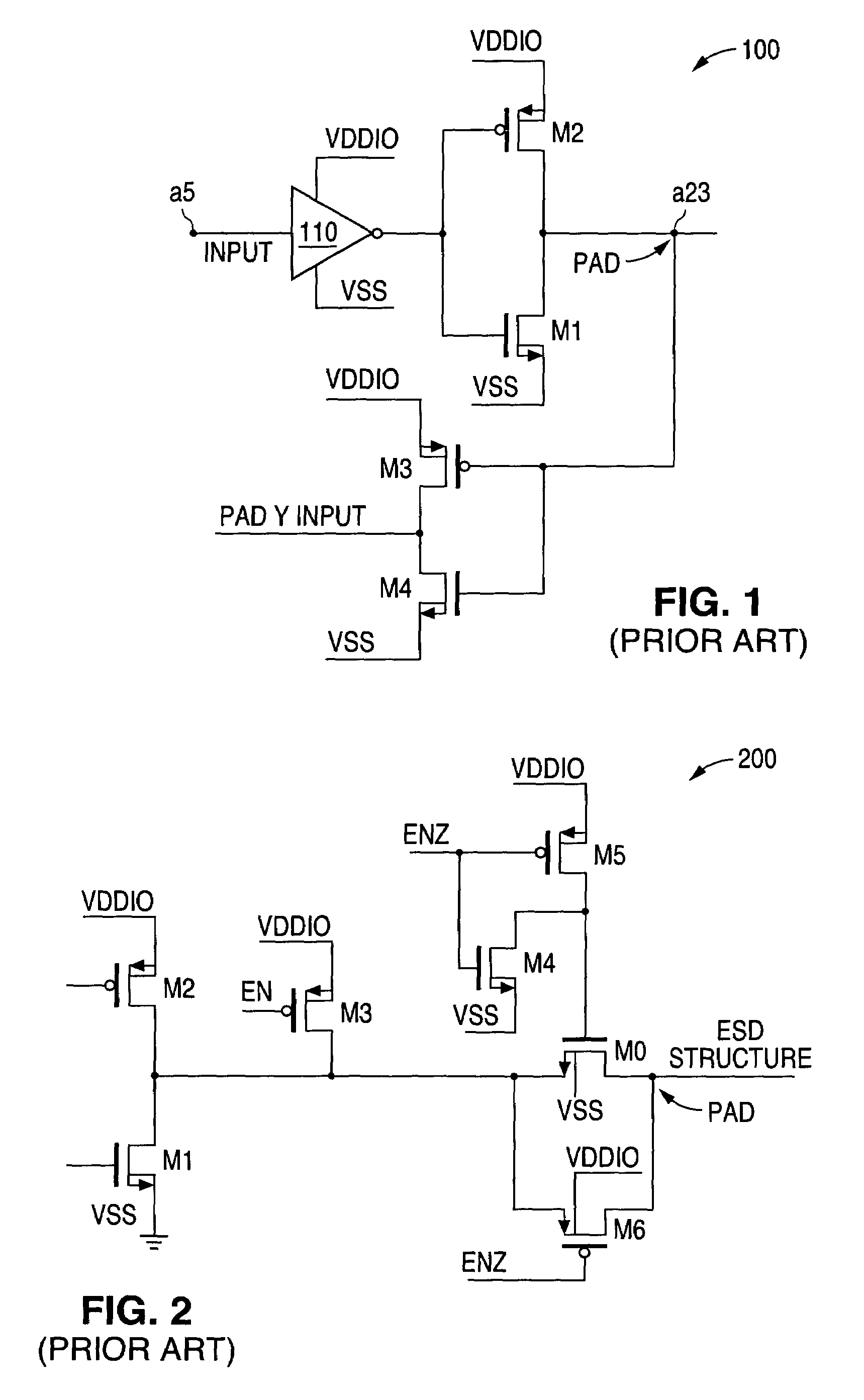

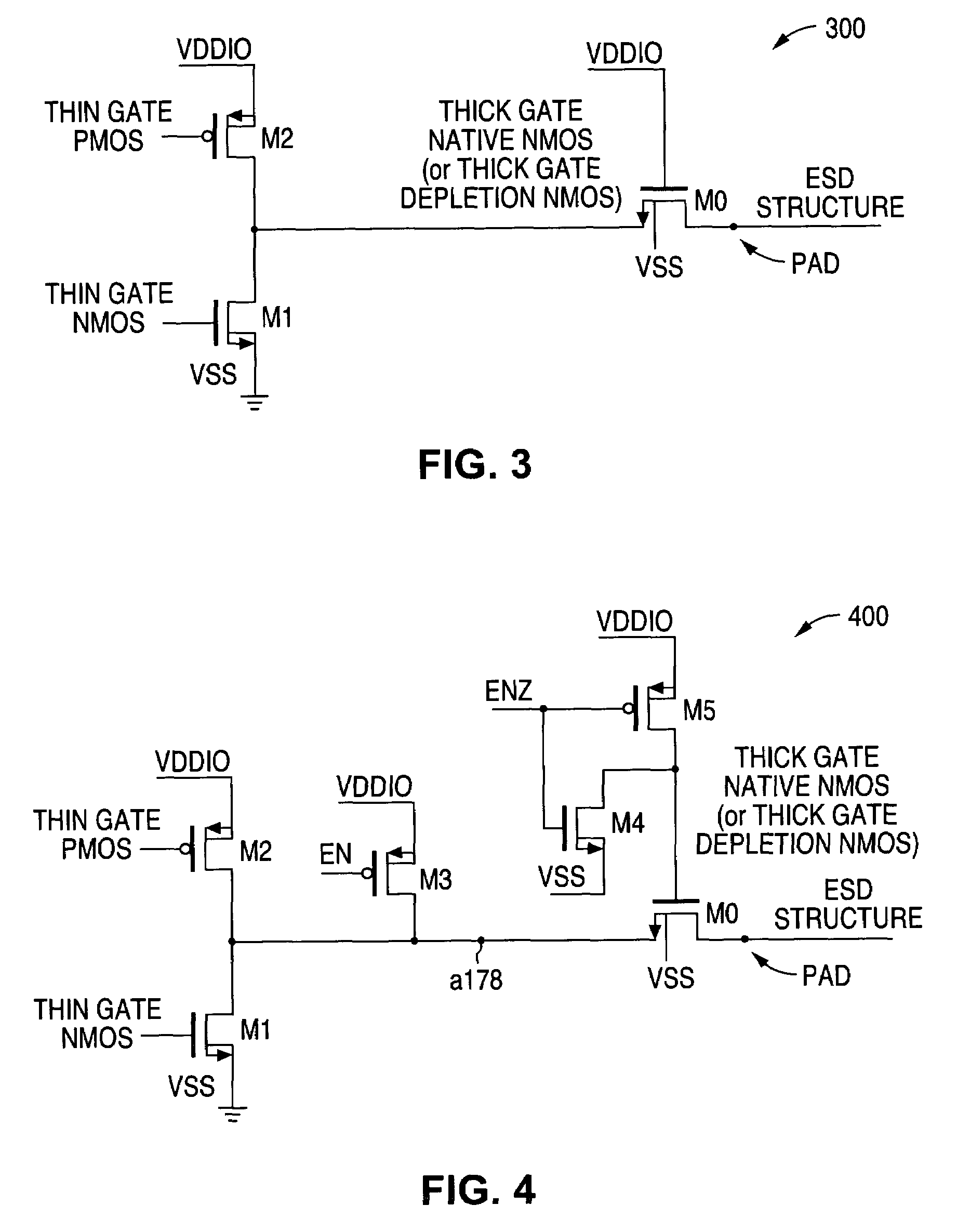

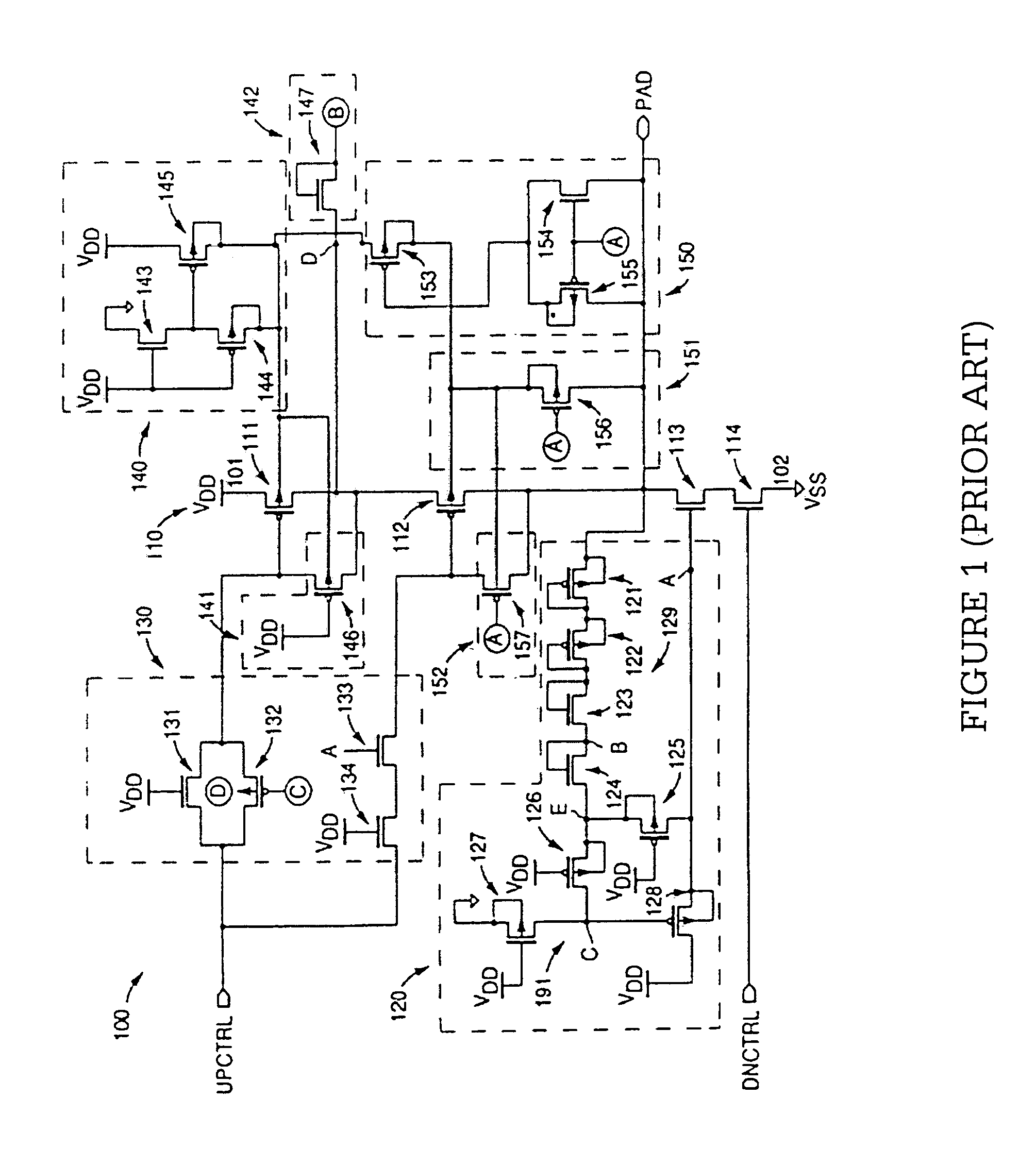

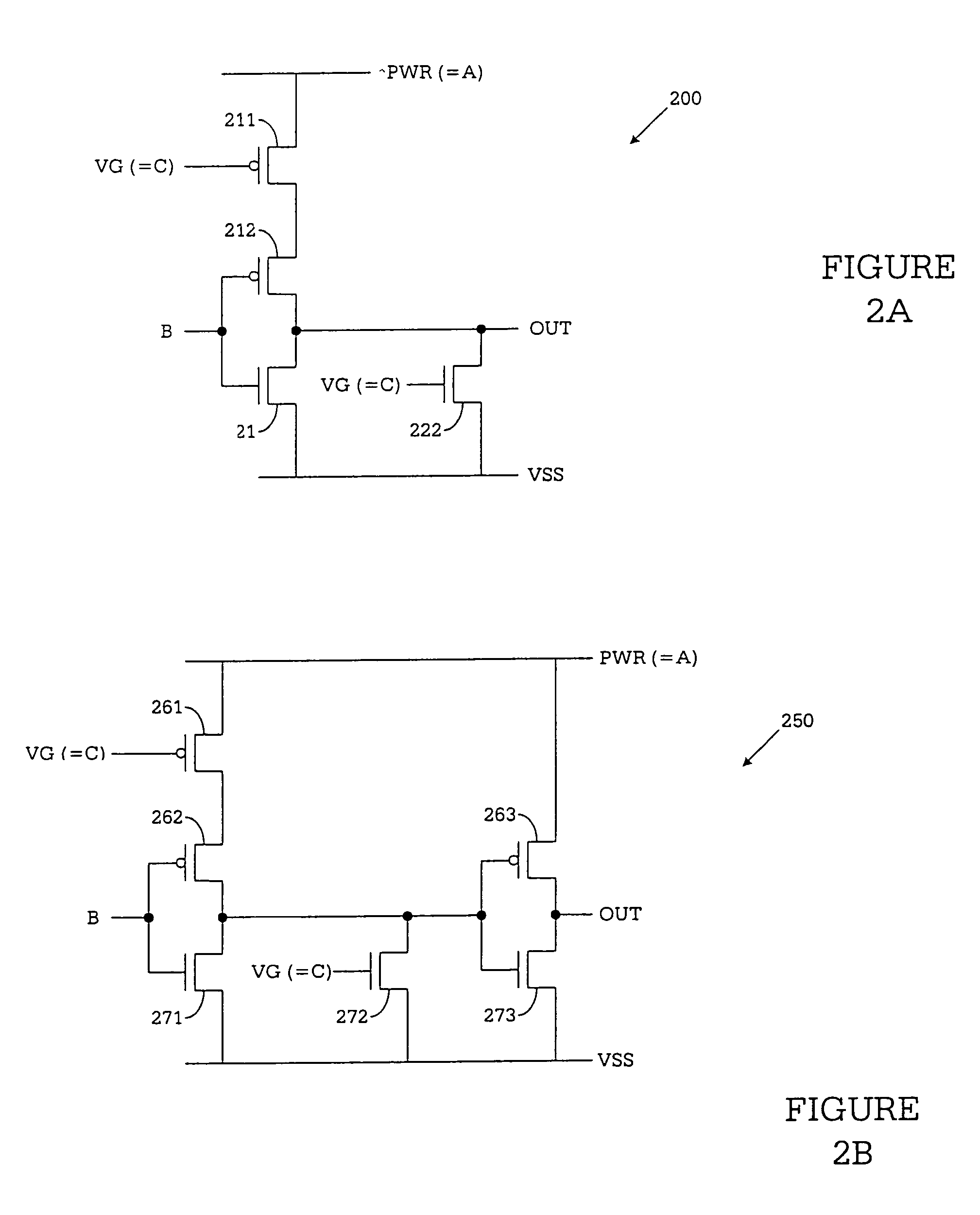

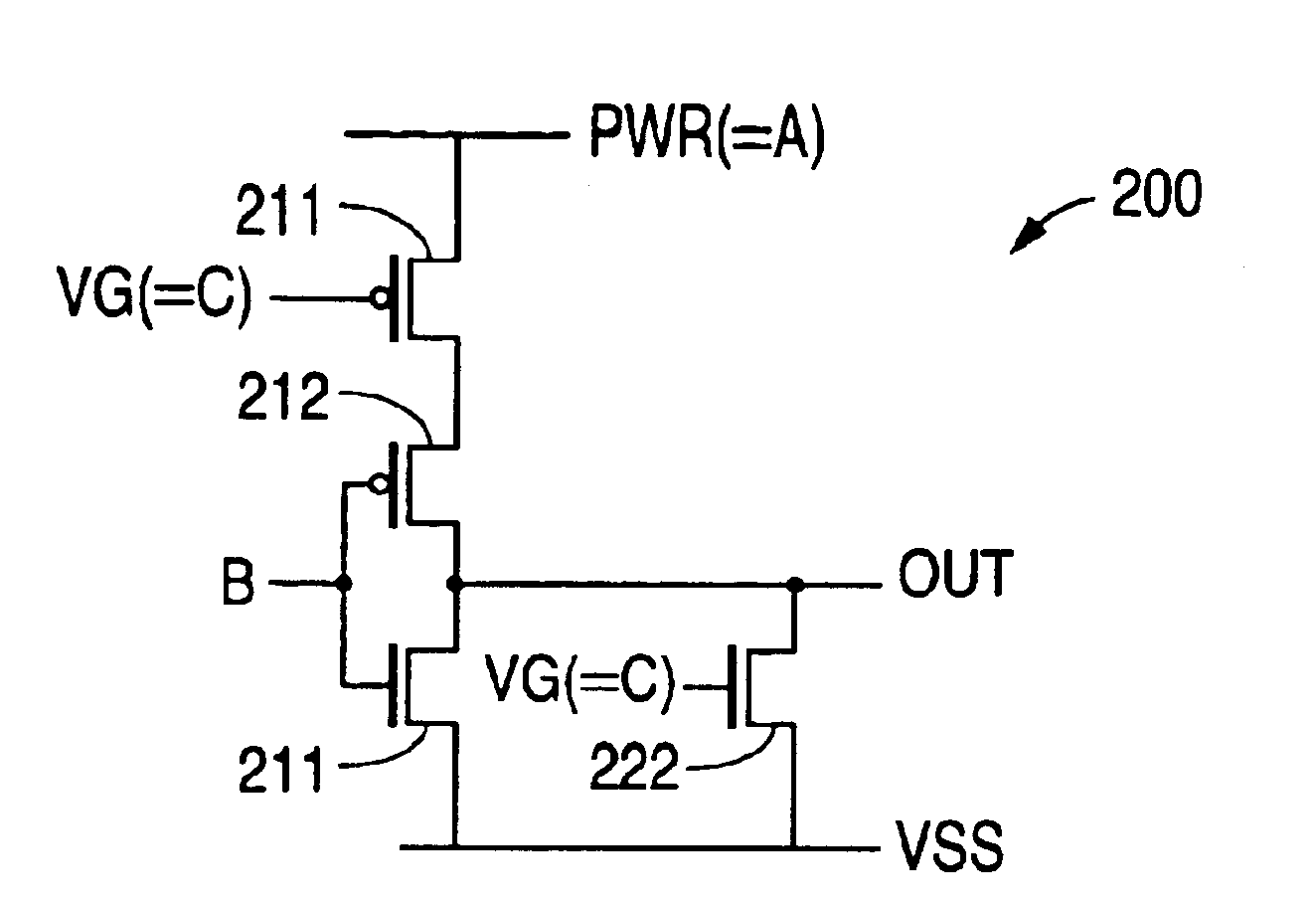

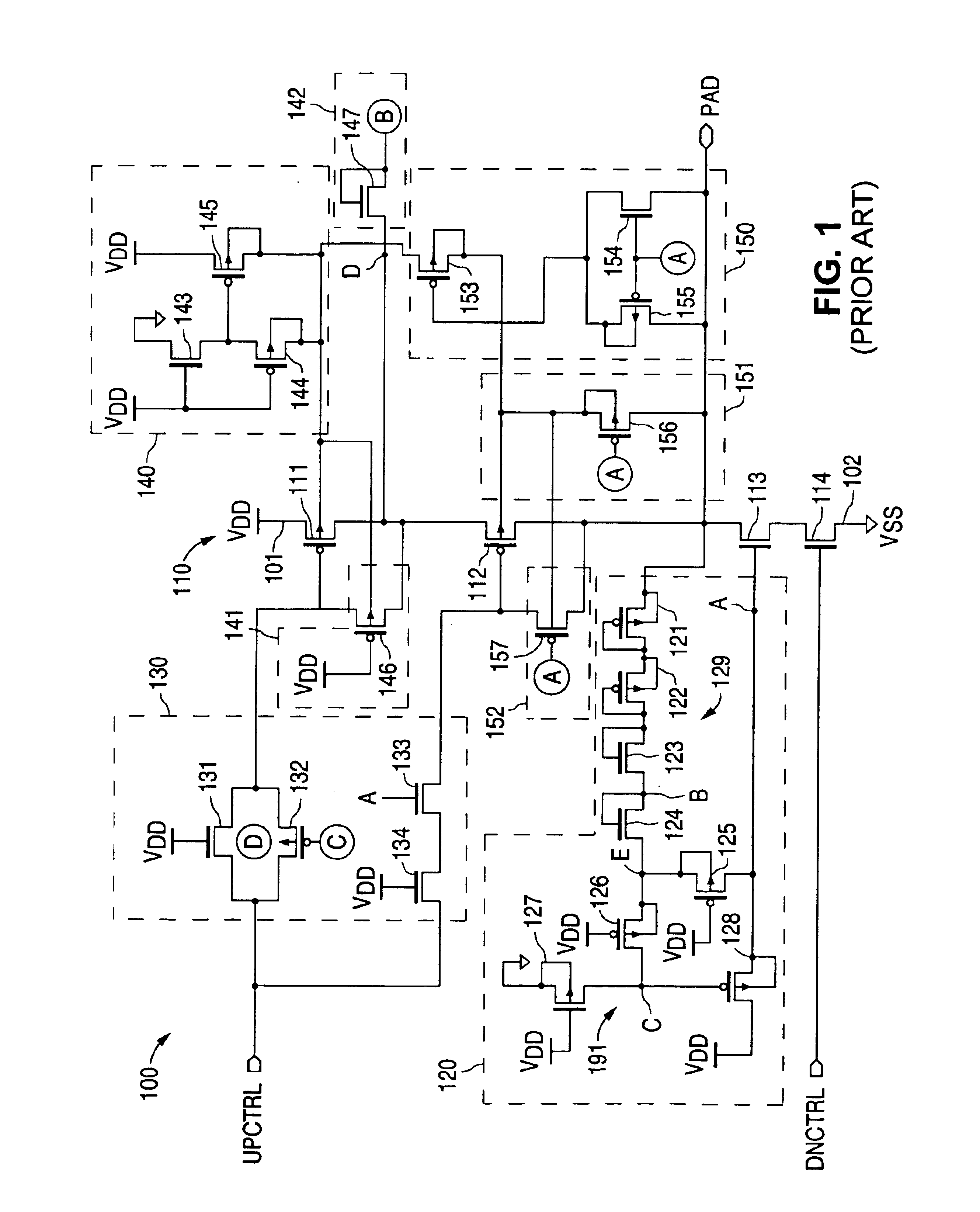

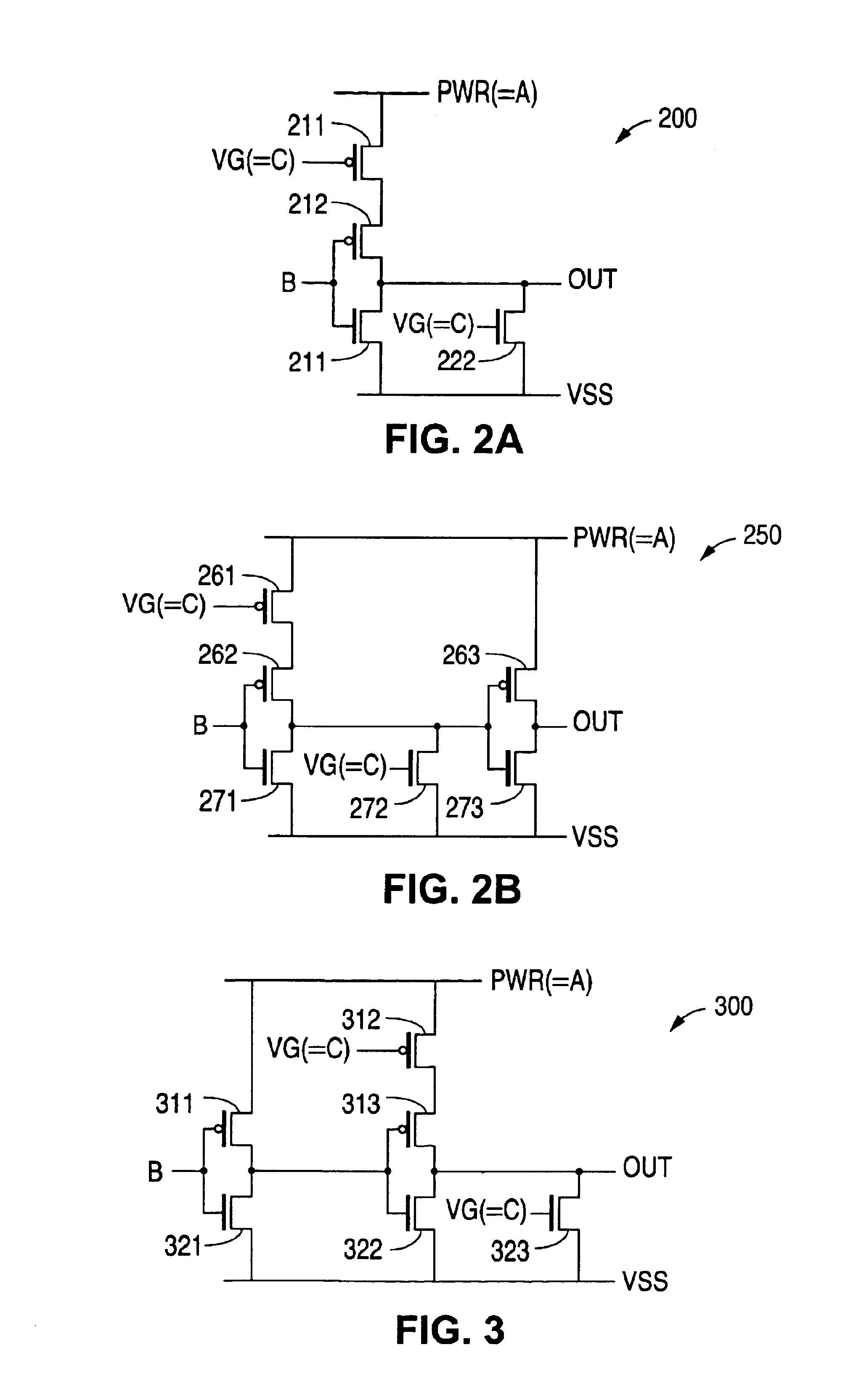

System and method for providing a low voltage thin gate input/output structure with thick gate overvoltage/backdrive protection

ActiveUS7642600B1Pulse automatic controlSemiconductor/solid-state device detailsOvervoltageLow voltage

A system and method are disclosed for providing an integrated circuit low voltage thin gate input / output structure with thick gate overvoltage / backdrive protection. In an advantageous embodiment of the present invention, a transfer gate of the input / output structure comprises at least one thick gate native (or depletion) n-channel metal oxide semiconductor (NMOS) transistor that is connected to an output pad node of the input / output structure. The thick gate native (or depletion) NMOS transistor prevents current from the output pad node from entering the input / output structure when a voltage level of the output pad node is high.

Owner:NAT SEMICON CORP

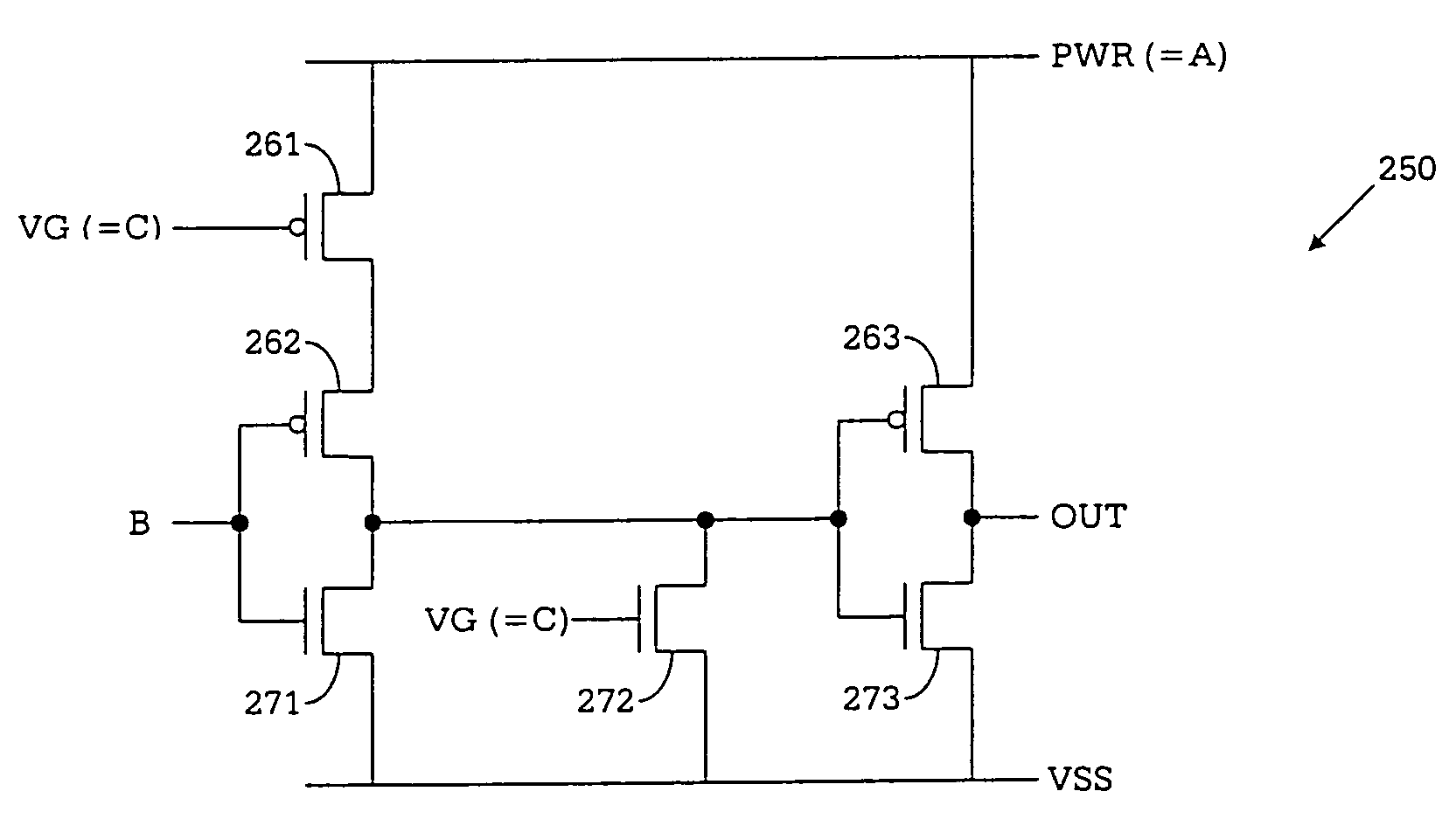

Circuitry for providing overvoltage backdrive protection

InactiveUS7123053B1Logic circuits coupling/interface using field-effect transistorsReliability increase in field effect transistorsElectronic systemsLow voltage

A logic gate for use in an electronic system comprising: i) a first component operating from a low voltage power supply rail; ii) a second component operating from a high voltage power supply rail; and iii) an over-voltage protection circuit that detects an over-voltage on an output pad of the first component and, in response to the detection generates from the over-voltage a generated power supply voltage and a generated reference signal. According to an advantageous embodiment of the present invention, the logic gate comprises a plurality of transistors, wherein the plurality of transistors are powered by the generated power-supply voltage and at least one of the plurality of transistors is turned ON and OFF by the generated reference signal.

Owner:NAT SEMICON CORP

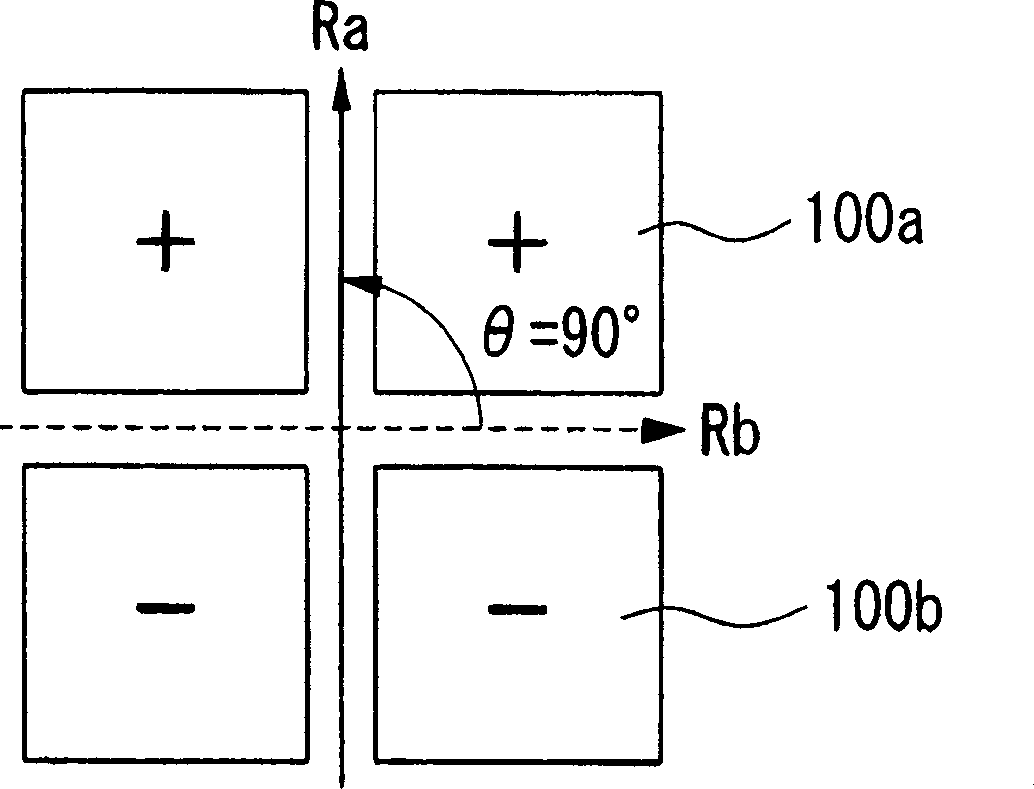

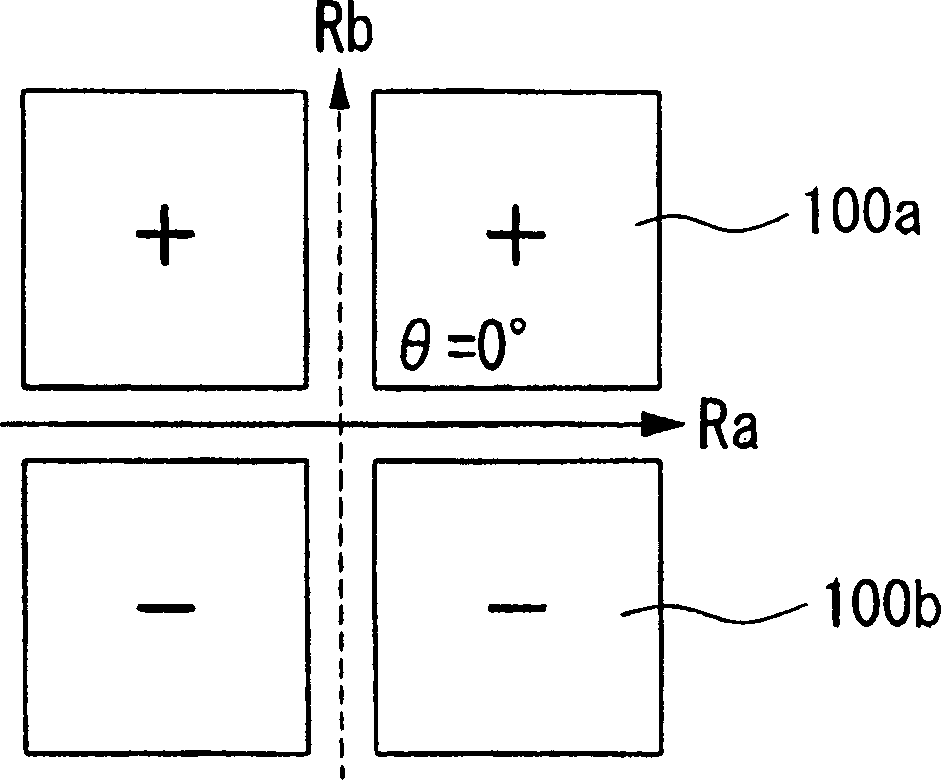

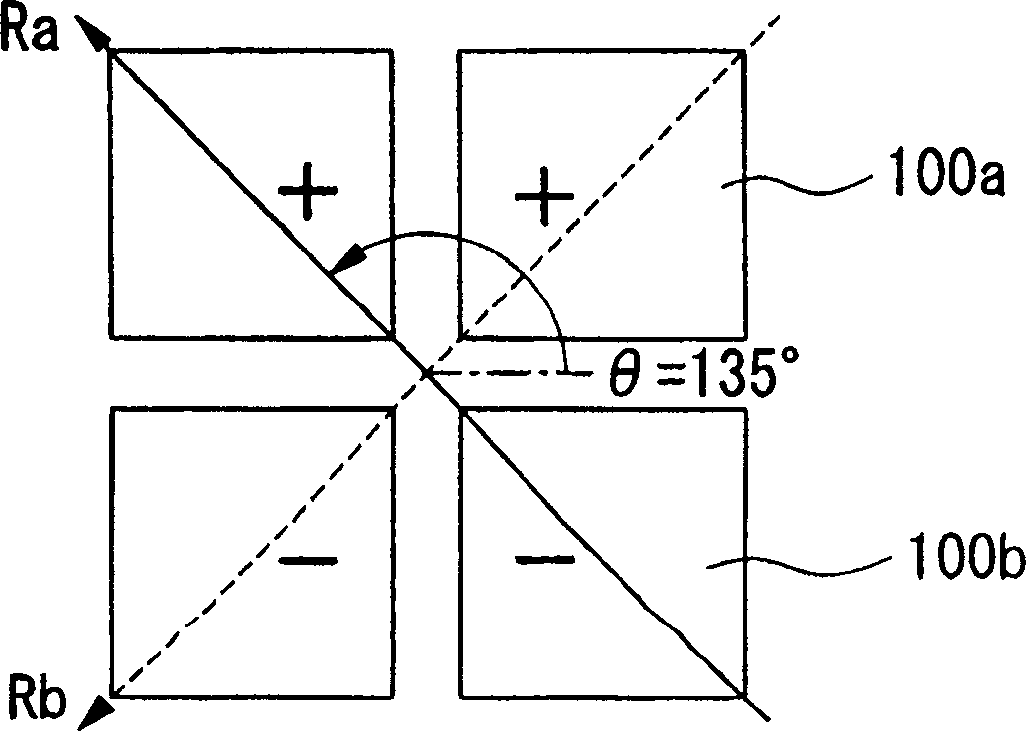

Active matrix liquid crystal display device with lin/row reverse driver and electronic device thereof

InactiveCN1532800AReduce disclinationReduce display failureStatic indicating devicesNon-linear opticsActive-matrix liquid-crystal displayLiquid-crystal display

An active-matrix liquid crystal display is composed of an active matrix substrate, a liquid crystal, and an opposite substrate having a common electrode. The active matrix substrate fabricates a first group of pixel electrodes that are aligned and supplied with picture signals of a first polarit, and a second group of pixel electrodes that are aligned to adjoin with the first group of pixel electrodes respectively and are supplied witb picture signals of a second polari. An inorganic orientation film is formed on the surfac of the active matrix substrate to provide a first orientation direction (Ra) to its proximal liquid crystal moleclges, while an organic orientation film is formed on the surface ofthe opposite substrate to provide a second orientation direction Rb, rectangularly crossing the first oneenation direction, to its proximal liquid-crstal molecules.

Owner:SEIKO EPSON CORP

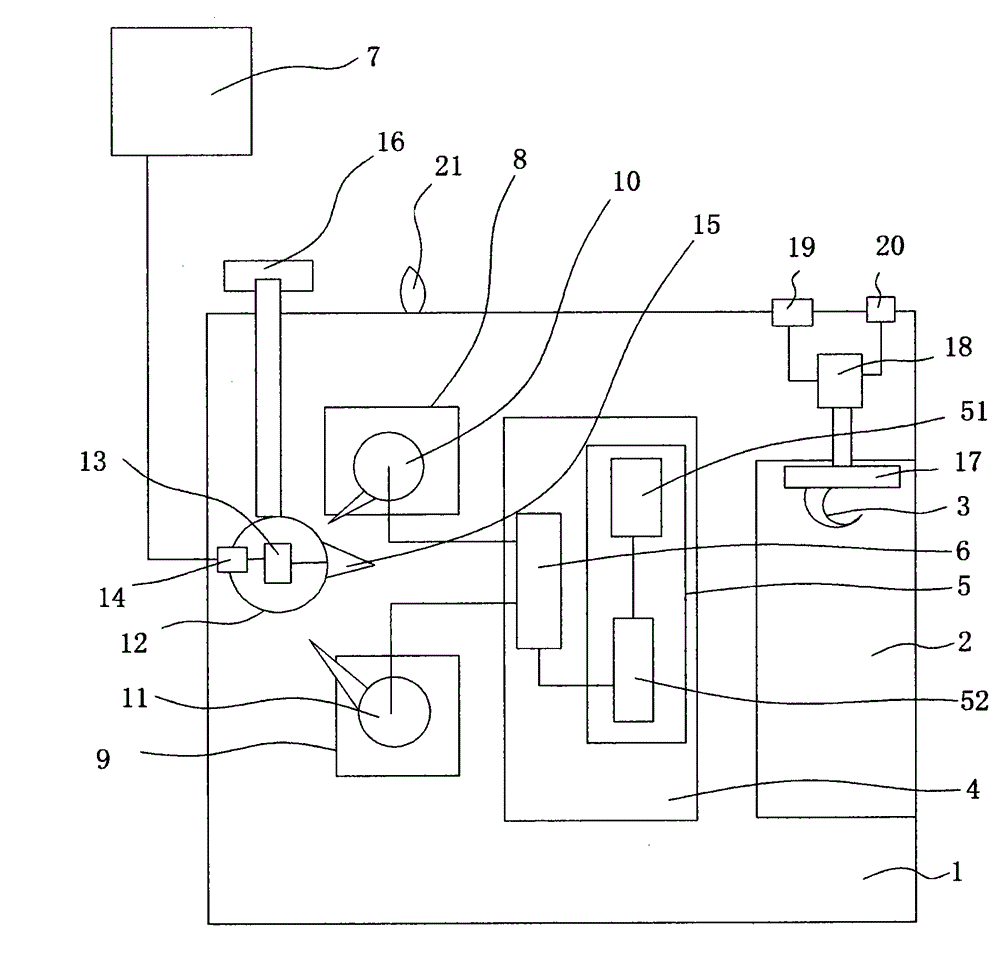

Power plant dust removal device

The invention discloses a power plant dust removal device comprising a dust removal housing. A plurality of recessed cavities are arranged in the dust removal housing. Dust removal cloth bag hooks are arranged on the recessed cavities. A control cavity is arranged in the dust removal housing. A pulse device and a pulse controller are arranged in the control cavity. A host computer connected with the pulse controller is arranged on the outer side of the dust removal housing. A forward adjustment cavity and a reverse adjustment cavity are arranged in the dust removal housing. A forward adjustment drive is arranged in the forward adjustment cavity, and a reverse adjustment drive is arranged in the reverse adjustment cavity. A forward-reverse adjustment disc is arranged in the dust removal housing. A microprocessor is arranged in the forward-reverse adjustment disc. An input terminal and an output terminal are arranged on the side of the forward-reverse adjustment disc. An adjustment knob connected with the forward-reverse adjustment disc is arranged on the top of the dust removal tank. The device provided by the invention has the advantages of simple structure, convenient and fast application, high applicability, good practicality, good application stability and high feasibility.

Owner:NANTONG CHUNGUANG AUTOMATIC CONTROL EQUIP ENG

Pivot arm tensioner with sliding ratchet mechanism

An engine chain or belt tensioning system includes a tensioner pivot arm with a ratcheting means that includes backlash in an engine timing system. The tensioner system includes a tensioner pivot arm having a fixed pin, radially projecting ratchet teeth, a tensioner pivot arm biasing device, and a ratchet mechanism that engages the radially projecting ratchet teeth. The ratchet mechanism is oriented such that the tensioner pivot arm freely rotates in one direction, but backdrive is limited in the opposite direction.

Owner:BORGWARNER INC

Circuitry for providing overvoltage backdrive protection

InactiveUS6906553B1Logic circuits coupling/interface using field-effect transistorsReliability increase in field effect transistorsOvervoltageElectronic systems

A logic gate for use in an electronic system comprising: i) a first component operating from a low voltage power supply rail; ii) a second component operating from a high voltage power supply rail; and iii) an over-voltage protection circuit that detects an over-voltage on an output pad of the first component and, in response to the detection generates from the over-voltage a generated power supply voltage and a generated reference signal. According to an advantageous embodiment of the present invention, the logic gate comprises a plurality of transistors, wherein the plurality of transistors are powered by the generated power supply voltage and at least one of the plurality of transistors is turned ON and OFF by the generated reference signal.

Owner:NAT SEMICON CORP

Backdrive assembly with a variable preload

A system is disclosed herein. The system having a backdrive assembly that includes a spring body retainer having a first body portion, the spring body retainer configured for rotational movement about an axis. A biasing member is provided that is configured to exert a backdriving force on the spring body retainer. A spring leg retainer is provided having a second body portion and a plurality of projections, the spring leg retainer being configured to incrementally apply a preload torque to the biasing member. A spring locking plate is operably connected to the spring leg retainer, the spring locking plate being configured to engage at least one of the plurality of projections.

Owner:INTEVA PRODUCTS LLC

Flight controller management system with a backdrive monitor

A method and apparatus for a monitoring module. The monitoring module is configured to identify a difference between measured position information for a controller and expected position information for the controller. The monitoring module is configured to compare the difference with thresholds for managing an autopilot in a control system of a vehicle to form a comparison. The monitoring module is configured to manage an operation of the autopilot based on the comparison such that the autopilot remains operating when a backdrive system is inoperative and an intentional override of the autopilot is absent.

Owner:THE BOEING CO

Bi-directional friction clutch assembly for electric motors to prevent backdrive

A clutch assembly (100) is provided for a motor having an armature shaft and a worm shaft having a worm constructed and arranged to engage a gear. The clutch assembly (100) includes a clutch housing (112) including a race surface (132); a cam (117) coupled to the worm shaft; follower structure (122) operatively associated with the cam; a clutch plate (114), and a clutch coupler (118) associated with the clutch plate, the cam, and the follower structure. The coupler is coupled to the armature shaft for rotation therewith, such that rotation of the coupler rotates the clutch plate, the cam and follower structure, and thus the worm shaft. During a back drive condition of the motor, when torque is transmitted to the worm shaft and thus to the cam, the cam is constructed and arranged to causes the follower structure (122) to contact and exert pressure on the race surface (132) thereby preventing rotation of the worm shaft.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Pivot arm tensioner with sliding ratchet mechanism

An engine chain or belt tensioning system includes a tensioner pivot arm with a ratcheting means that includes backlash in an engine timing system. The tensioner system includes a tensioner pivot arm having a fixed pin, radially projecting ratchet teeth, a tensioner pivot arm biasing device, and a ratchet mechanism that engages the radially projecting ratchet teeth. The ratchet mechanism is oriented such that the tensioner pivot arm freely rotates in one direction, but backdrive is limited in the opposite direction.

Owner:BORGWARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com