Power plant dust removal device

A dedusting device and a technology of a power plant, which are applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve problems such as inability to reverse control, affect the normal operation of the power plant, and affect the equipment of the power plant. Simple structure, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

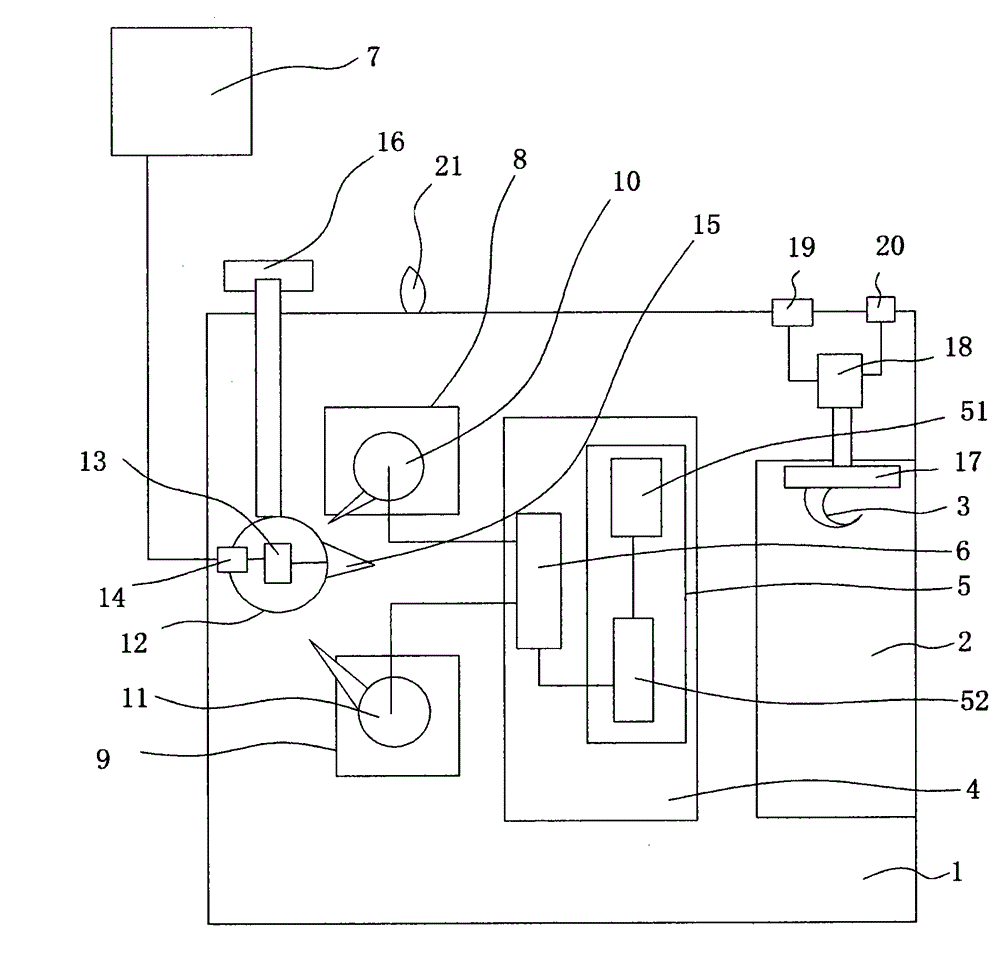

[0013] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0014] See figure 1 , a dust removal device for a power plant, including a dust removal housing 1, a plurality of concave cavities 2 are arranged in the dust removal housing 1, and a dust removal bag hook 3 is provided on the concave cavities 2, and a dust removal bag hook 3 is arranged in the dust removal housing 1 There is also a control cavity 4 inside, and a pulse device 5 and a pulse controller 6 are arranged in the control cavity 4, the pulse controller 6 is connected with the pulse device 5, and the pulse device 5 is connected with the concave The cavity 2 is connected, and a host computer 7 connected to the pulse controller 6 is provided outside the dust removal housing 1, and a forward adjustment chamber 8 and a reverse adjustment chamber are also provided in the dust removal housing 1. 9. A forward driver 10 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com