Vortex type small-sized pulverizer

A pulverizer and scroll technology, applied in the field of grinding, can solve problems such as general grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

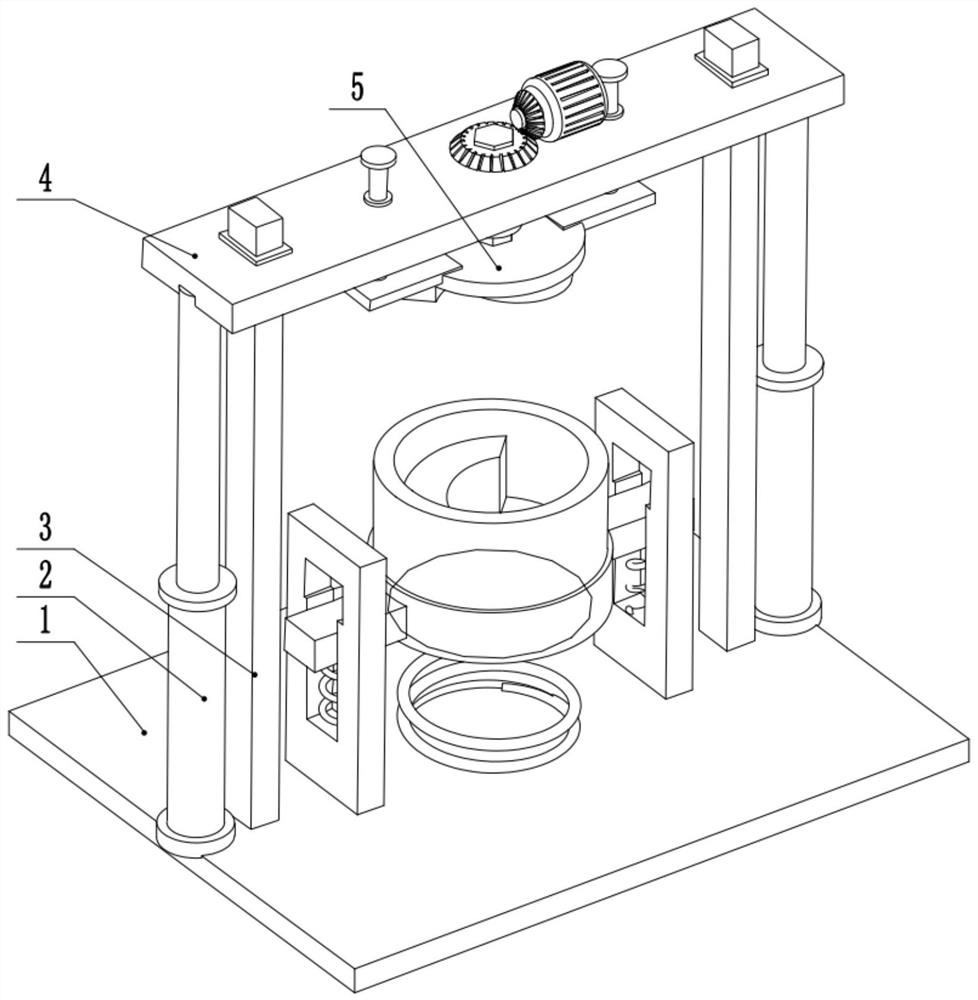

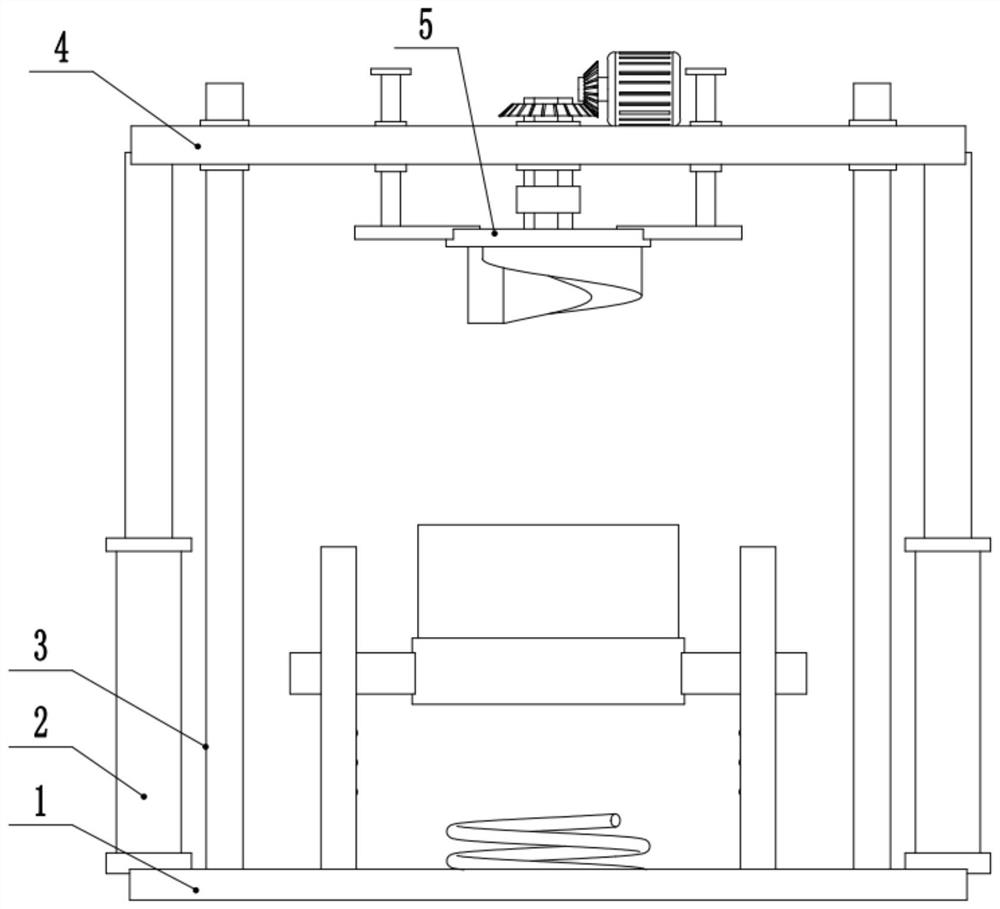

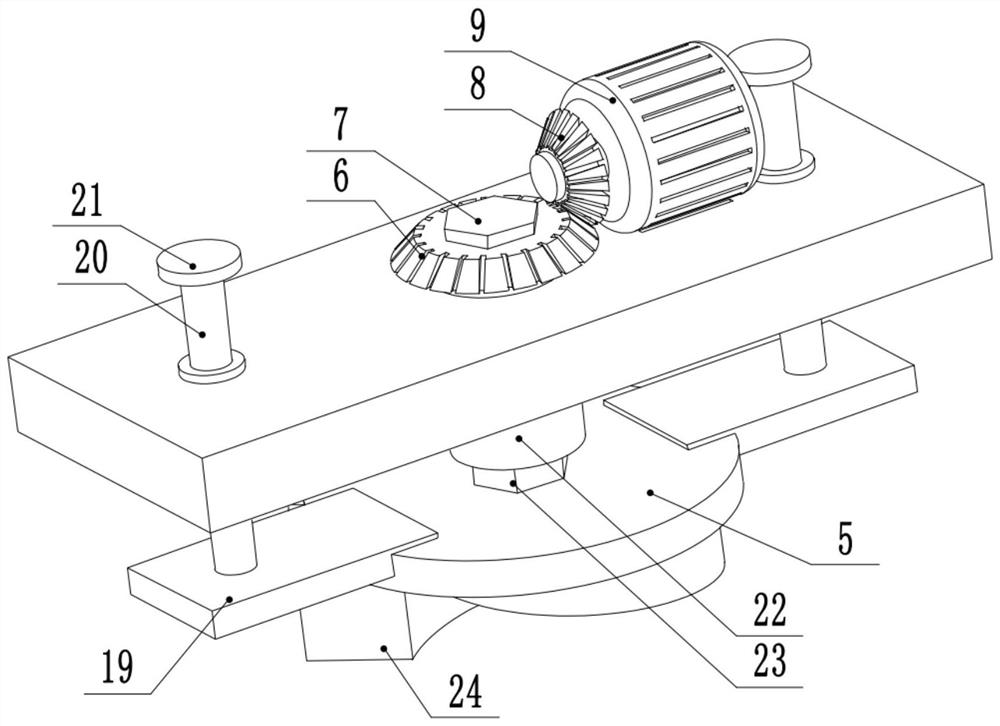

[0030] see Figure 1-8 , a small vortex mill, comprising a base plate 1, the left and right ends of the upper surface of the base plate 1 are provided with support columns 3, the upper part of the support column 3 is slidingly connected to the lifting plate 4, and the upper part of the base plate 1 is provided with a cylinder 2, the cylinder The piston rod of 2 is fixedly connected to the left and right ends of the lifting plate 4, the middle part of the lifting plate 4 is rotatably connected to the first rotating rod 7, the bottom of the first rotating rod 7 is provided with a grinding plate 5, and the bottom of the grinding plate 5 is provided with an upper Grinding head 24. The right side of the upper surface of the lifting plate 4 is provided with a drive motor 9, the output shaft of the drive motor 9 is fixedly connected to the first bevel gear 8, the first bevel gear 8 is meshed with the second bevel gear 6, and the second bevel gear 6 is fixedly connected The upper end...

Embodiment 2

[0033] see Figure 7 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the top of the first chute 12 is provided with a second chute 15, and the internal size of the second chute 15 is greater than the cross-sectional size of the sliding rod 14 . In order to facilitate the removal of the product from the grinding tube 17, a second chute 15 with a larger size is arranged on the upper part of the first chute 12. After the device finishes grinding, the whole device can be raised so that the sliding rod 14 slides into the In the second chute 15, the slide bar 14 can rotate in the second chute 15 at this time, so that the grinding tube 17 is tilted forward, so that the material inside the grinding tube 17 falls to realize the effect of unloading.

[0034] During the implementation of the present invention, the cylinder 2 is started, and the piston rod of the cylinder 2 is stretched out, so that the grinding plate 5 moves upwards. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com