Patents

Literature

53results about How to "Drip evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

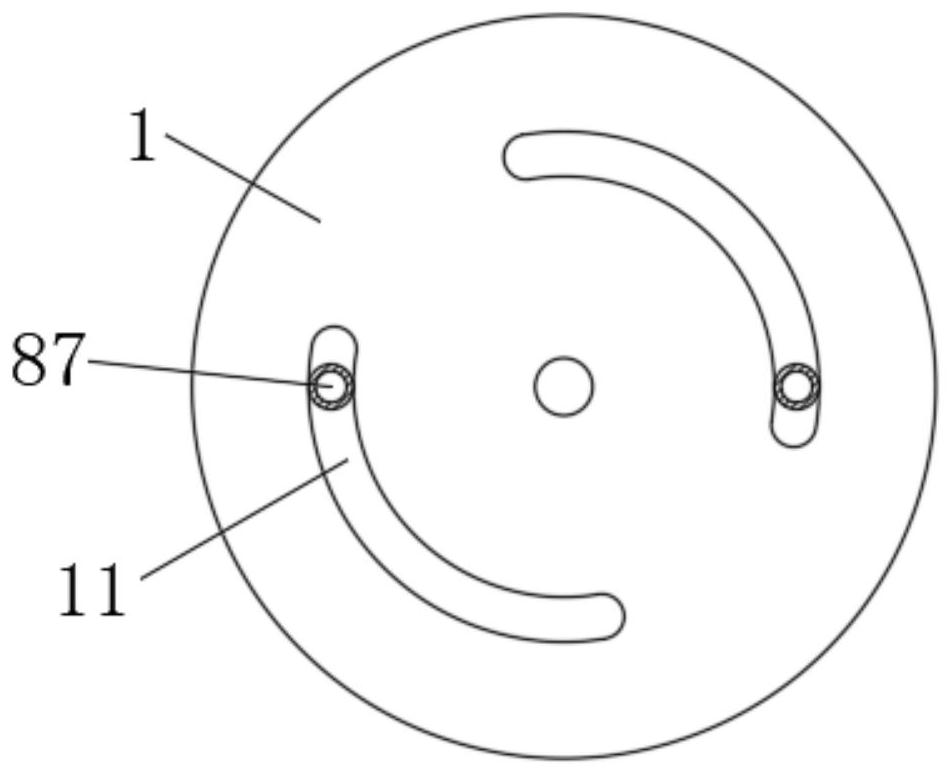

Distributor in falling film evaporator

ActiveCN106482400AAvoid taking awayEven and effective dischargeEvaporators/condensersFluid circulation arrangementEngineeringRefrigerant

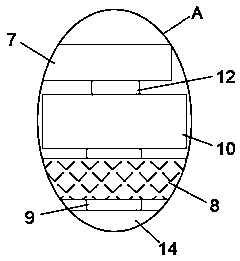

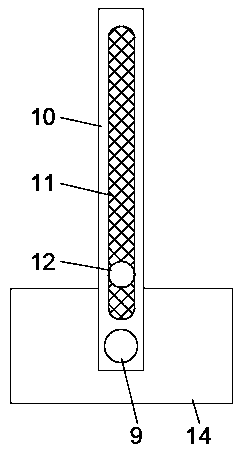

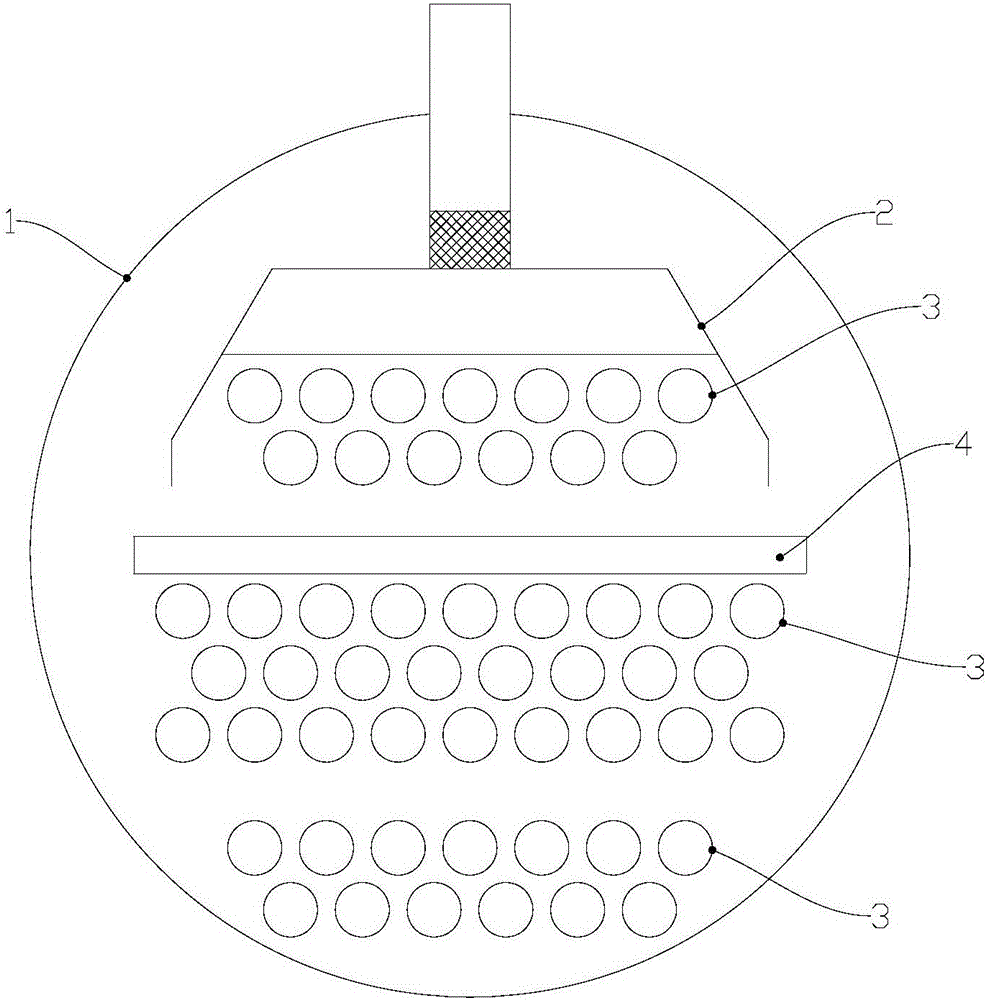

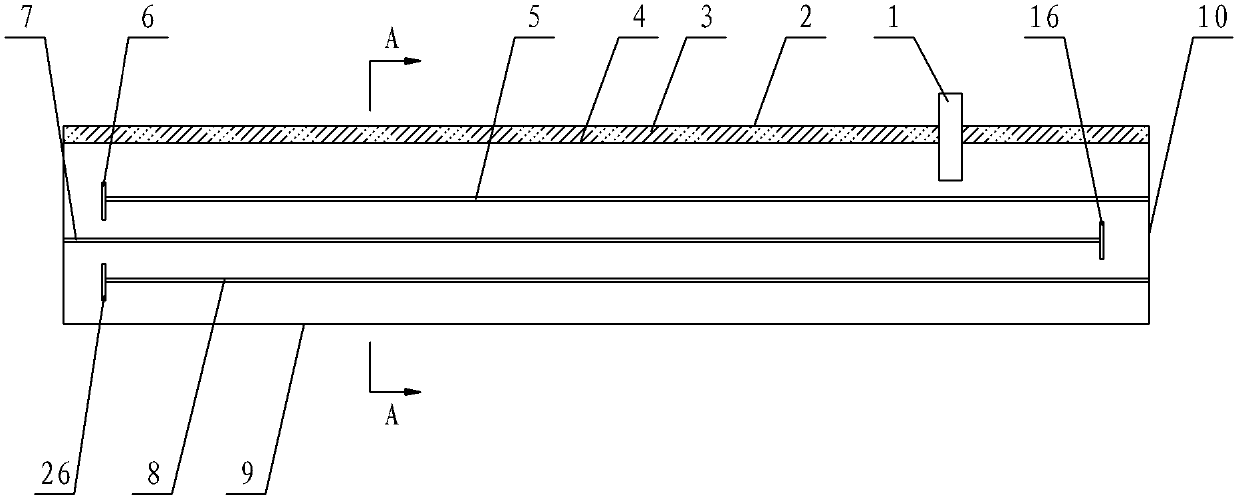

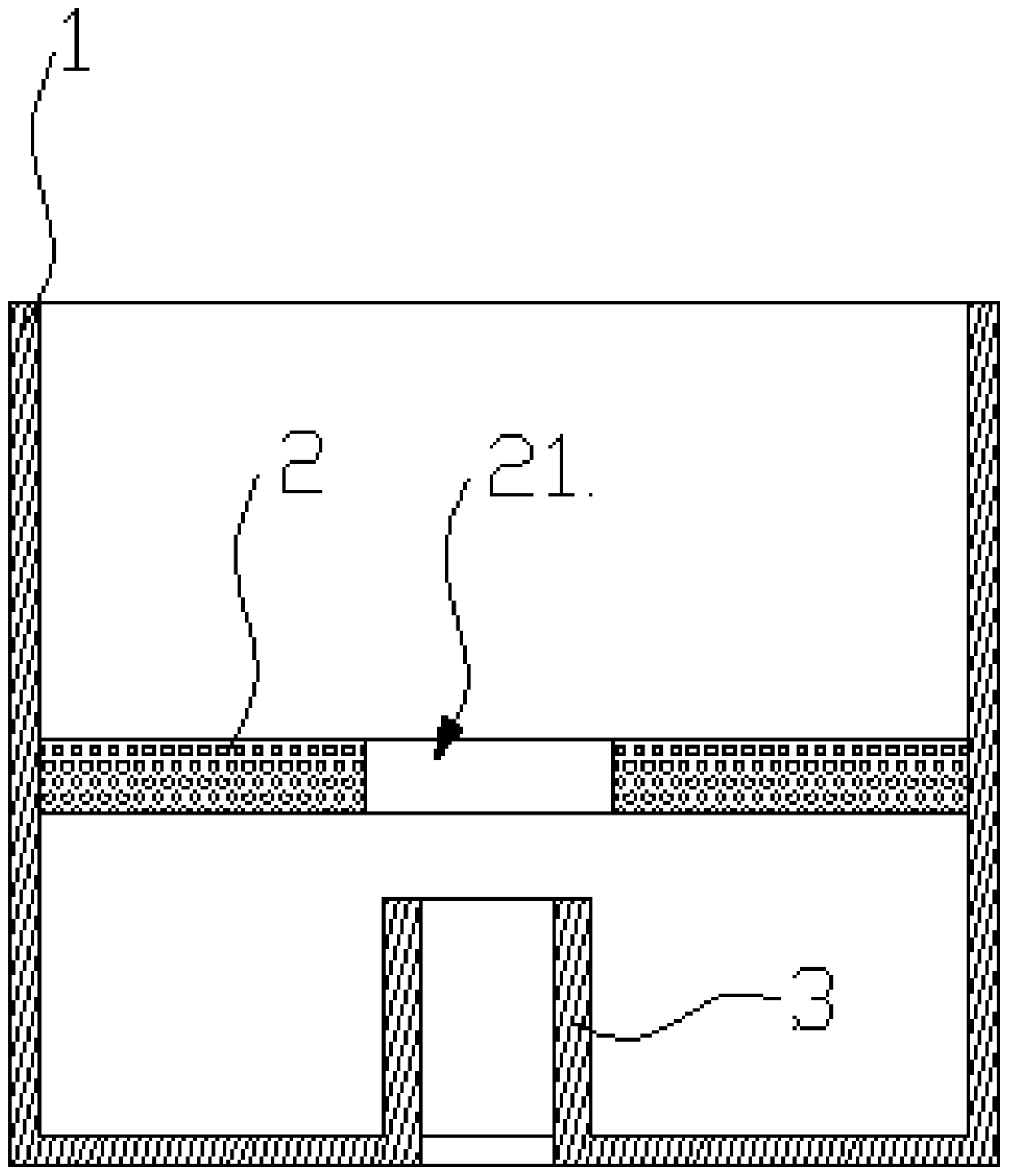

The invention relates to evaporator accessories in refrigerating equipment, in particular to a distributor in a falling film evaporator. The distributor comprises a cover plate, a gas-liquid separation disc and a gravity drop-leaching disc, wherein water holes are uniformly and densely distributed and a plurality of partition plates are arranged at the bottom of the gravity drop-leaching disc; the gas-liquid separation disc is connected with the top end of the gravity drop-leaching disc; pressure holes are uniformly distributed on a baseplate at the bottom of the gas-liquid separation disc; the cover plate is fixedly connected onto the gas-liquid separation disc; the gas-liquid separation disc and the cover plate are combined to form an enclosed gas-liquid separation cavity; and a liquid inlet and a demister are arranged on the cover plate. The distributor provided by the invention has the following beneficial effects: a gaseous refrigerant in a gas-liquid two-phase refrigerant can be separated out, and liquid drops can be prevented from being entrained by the gaseous refrigerant, thereby achieving uniform and effective gas exhaust; and meanwhile, uniform dropping of a liquid can be guaranteed, thereby reducing the adverse impact of gas flow in an evaporation process.

Owner:顿汉布什(中国)工业有限公司

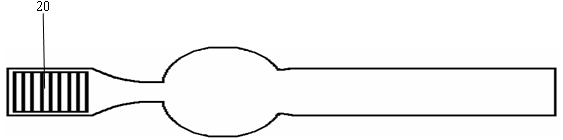

Oscillation pulsed drip irrigation emitter and drip irrigation device

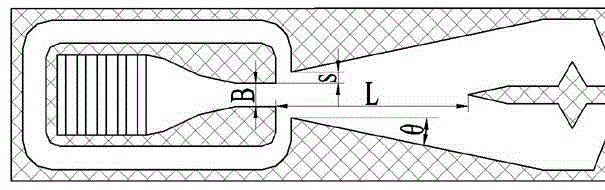

InactiveCN102599036AImprove transportation capacityImprove anti-clogging performanceWatering devicesCultivating equipmentsField cropWater flow

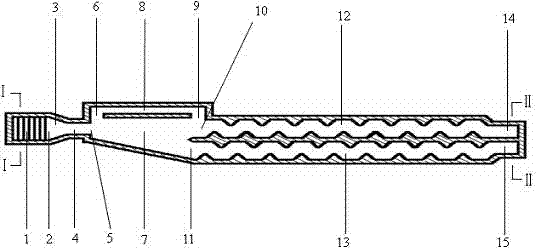

The invention belongs to the technical field of agricultural water-saving irrigation, and relates to a drip irrigation emitter, in particular to an oscillation pulsed drip irrigation emitter and a drip irrigation device. The emitter is composed of a water inlet trough, an oscillation pulsed generator, two runners and a water outlet trough, wherein the water inlet trough is provided with a filter window, and is communicated with the oscillation pulsed generator which is communicated with the runner; and the water outlet trough is positioned at the end of the runner. A fluidic feedback oscillation technique is applied to drive the water flow to flow in the two runners intermittently, thus continuous pulse process is realized; strong turbulent fluctuation and impact water flow is formed in the runner; the anti-blocking capacity and the irrigation uniformity of the emitter are enhanced; and elastic body structures, such as rubber, plastic films and springs and the like of the drip irrigation emitter are omitted. The drip irrigation emitter provided by the invention has the characteristics of being simple in structure and strong in reliability and durability, and can be widely applied to the demands of irrigation in field crops, vegetables, fruit industry and the like.

Owner:JIANGSU UNIV

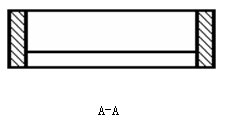

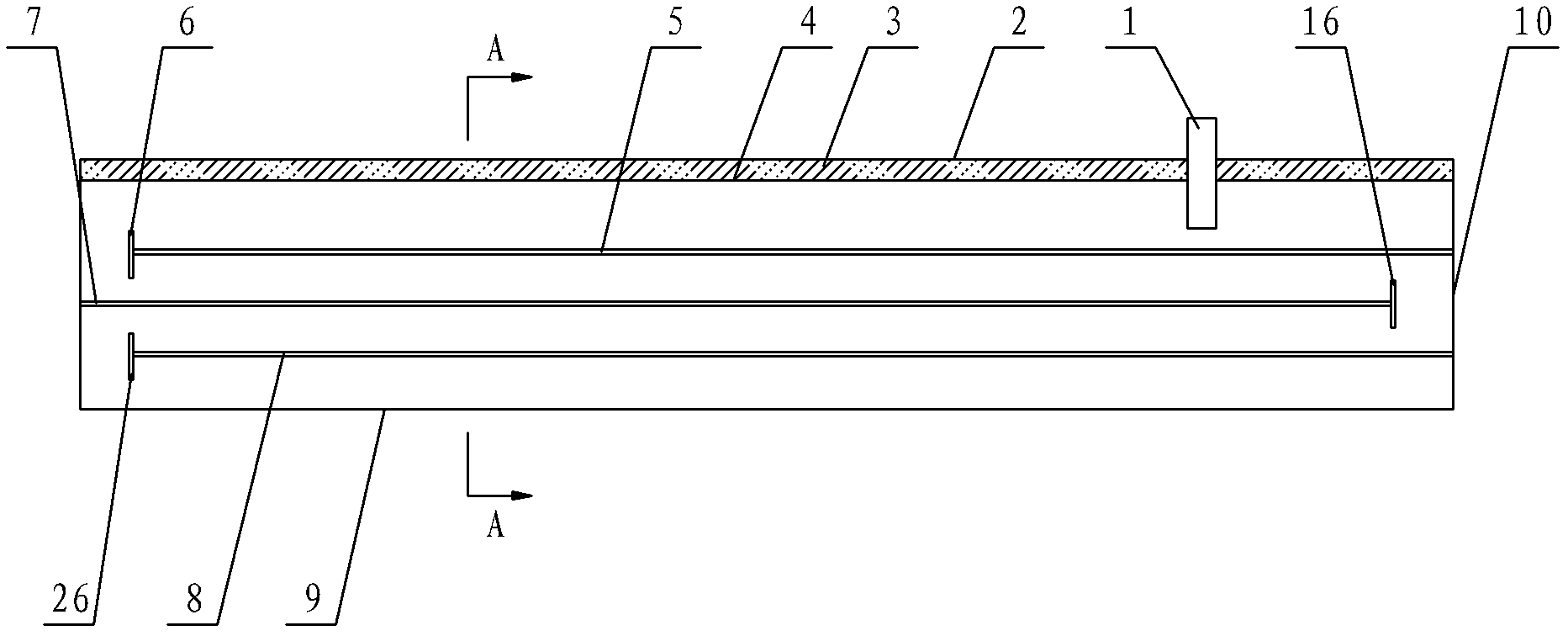

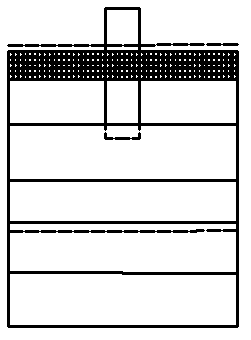

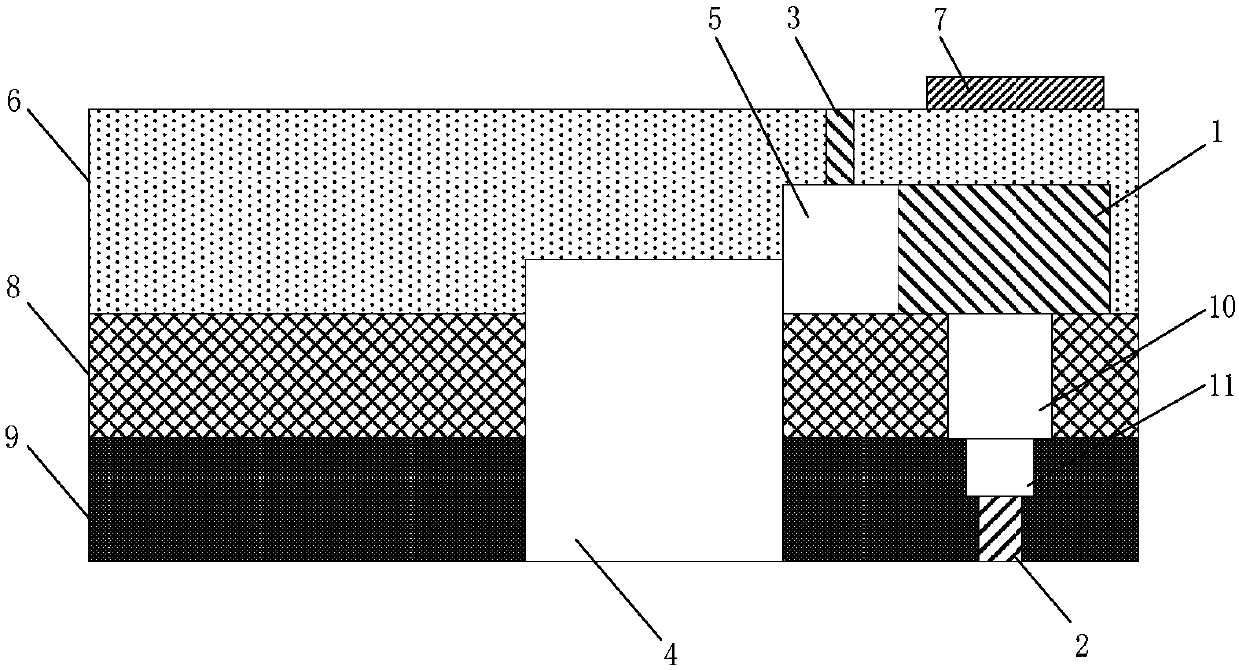

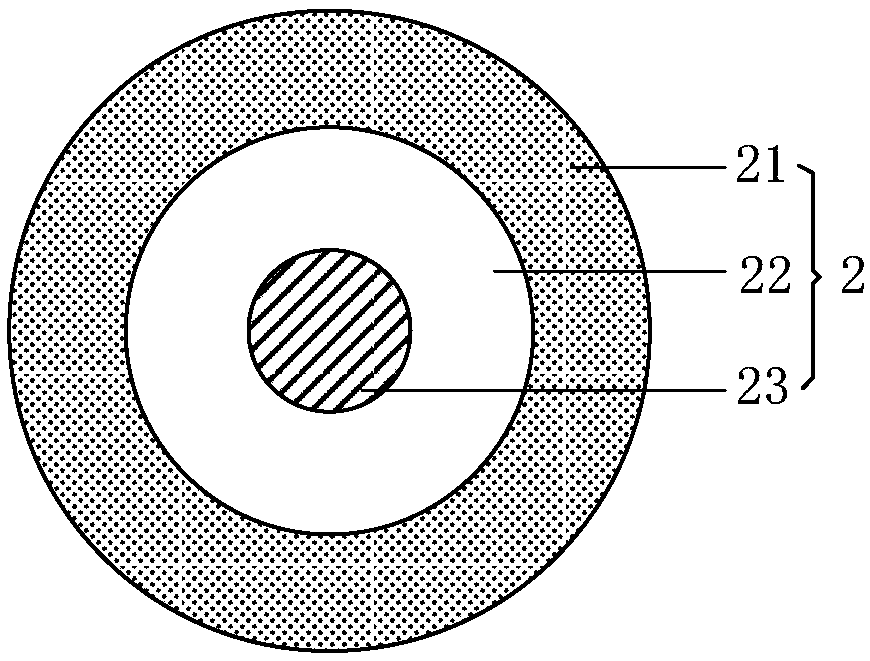

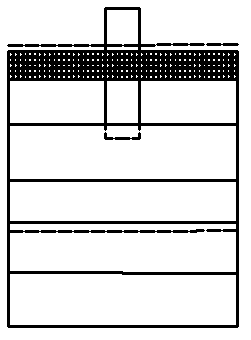

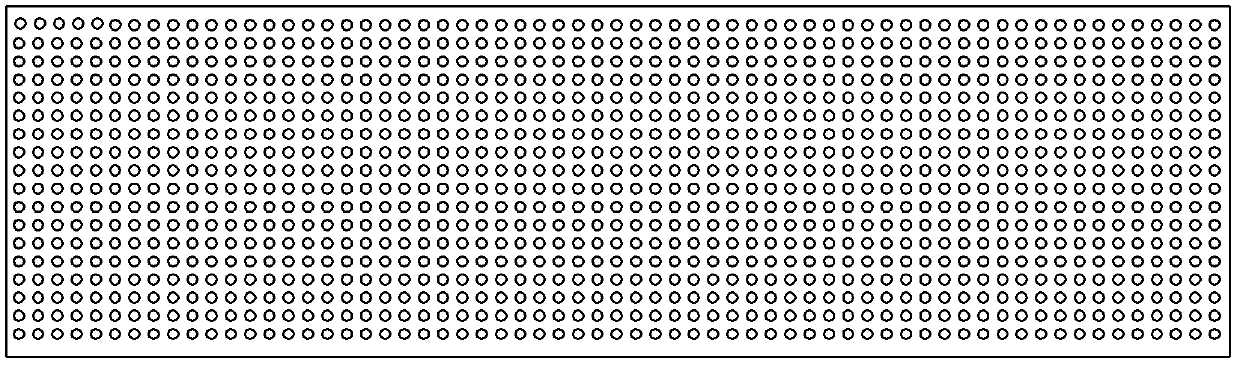

Refrigerant distributor of falling film evaporator for water chilling unit

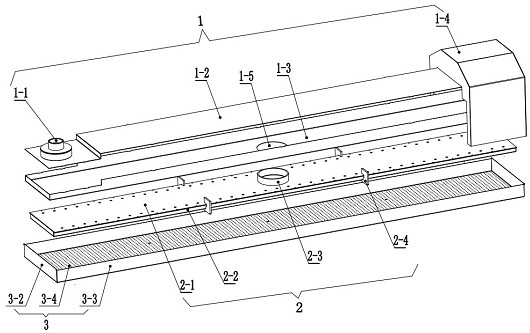

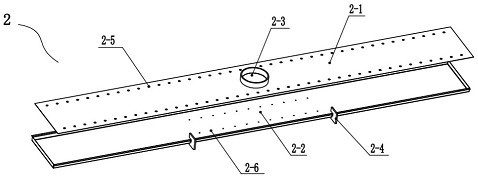

ActiveCN102661638ADrip evenlyHigh purityEvaporators/condensersFluid circulation arrangementRefrigerant distributionEngineering

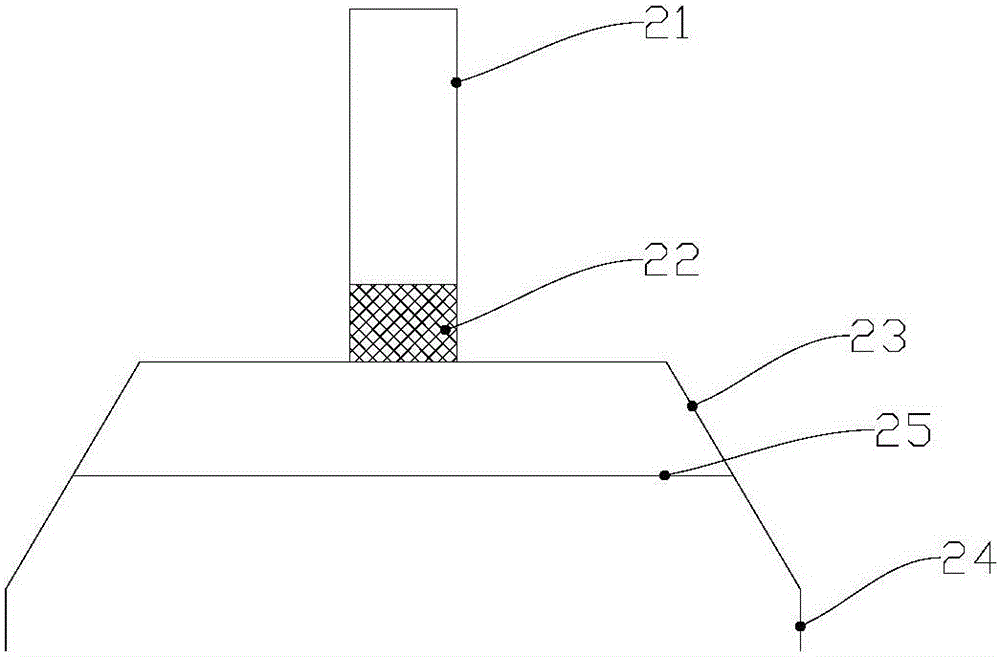

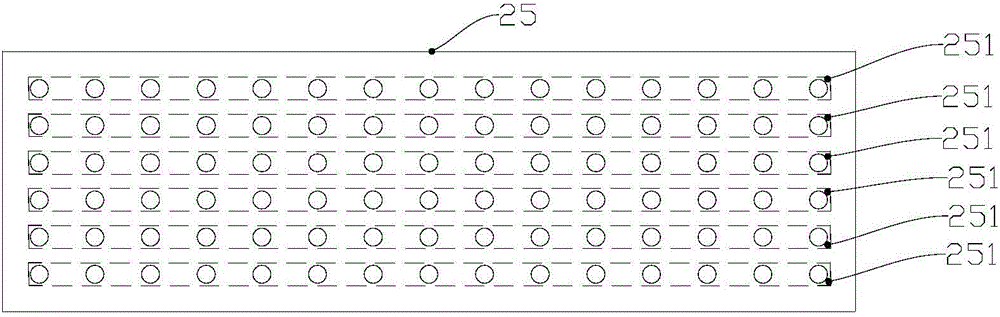

A refrigerant distributor of a falling film evaporator for a water chilling unit comprises a refrigerant inlet, an upper porous top plate, a filter screen, a lower porous top plate, a porous bottom plate and side plates, wherein the filter screen is sandwiched between the upper porous top plate and the lower porous top plate, the upper porous bottom plate is positioned below the lower porous top plate, the upper porous top plate, the filter screen, the lower porous top plate, the porous bottom plate and the side plates jointly encircle to form a cavity, more than one distributing pore plate is arranged in the cavity, one end of the refrigerant inlet is provided with an opening after sequentially penetrating through the upper porous top plate, the filter screen and the lower porous top plate, and the opening is arranged above the distributing pore plates. The distributing pore plates include a primary distributing pore plate, the primary distributing pore plate is connected with the side plates and sequentially divides the cavity into two portions from top to bottom, and a first opening is formed between at least one lateral edge of the primary distributing pore plate and the corresponding side plate. The refrigerant distributor is simple and reasonable in structure, flexible in operation, low in manufacturing cost, fine in refrigerant gas and liquid separation effect and uniform in flow distribution.

Owner:谛卓(北京)咨询顾问有限公司

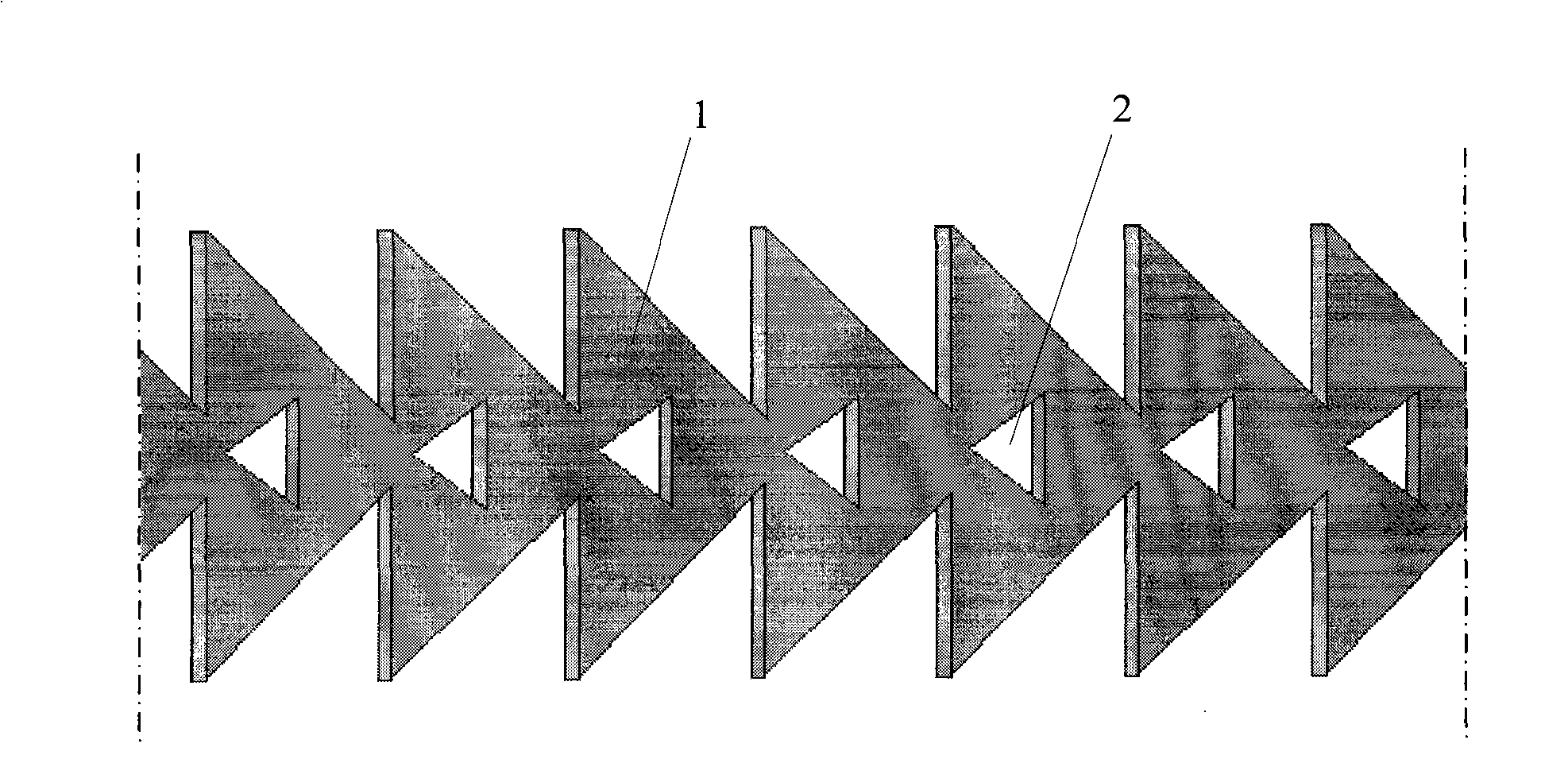

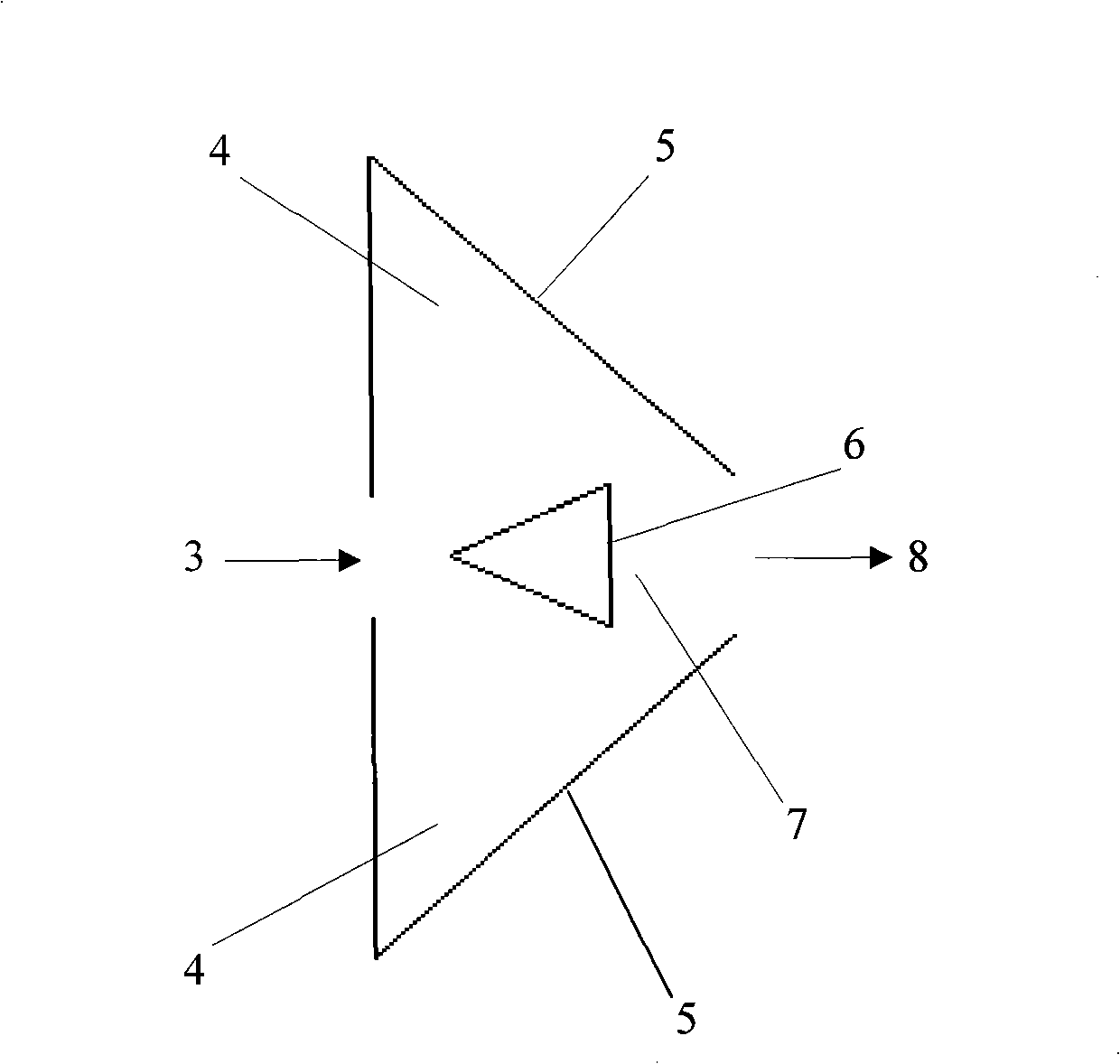

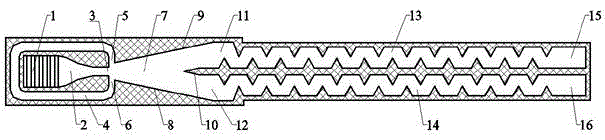

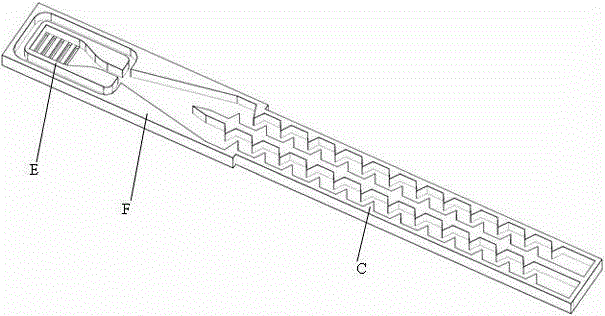

Triangular circumferential motion drip irrigation douche irrigation device flow passage

InactiveCN101402075AImprove anti-clogging performanceEfficient energy dissipation effectWatering devicesSpray nozzlesWater flowDrip irrigation

The invention discloses a flow passage of a triangular circumferential flow drip irrigation douche. The flow passage is provided based on the flowing mechanism of a triangular circumferential flow, a sudden expansion tube, and a sudden contraction tube in hydraulics; a sudden expansion triangular flat cylinder, a sudden contraction triangular flat cylinder and a circumferential triangular flat cylinder which is inbuilt between the sudden expansion triangular flat cylinder and the sudden contraction triangular flat cylinder form a flow passage unit; and a plurality of flow passage units are sequentially connected into a whole so as to form the flow passage of the triangular circumferential flow drip irrigation douche. The flow passage of the drip irrigation douche has large overflow cross section and has hydraulic characteristic of the sudden expansion tube, the sudden contraction tube and the triangular circumferential flow; and flow in a main flow region has strong turbulent motion, high-efficiency energy dissipation effect and condensate conveying capacity, thereby strengthening the anti-blocking performance and water irrigating evenness of the drip irrigation douche. The flow passage can construct drip irrigation douches with various structural forms and can be widely suitable for the requirements of irrigating crops and vegetables in large fields and in the forest and fruit industry and the like.

Owner:JIANGSU UNIV

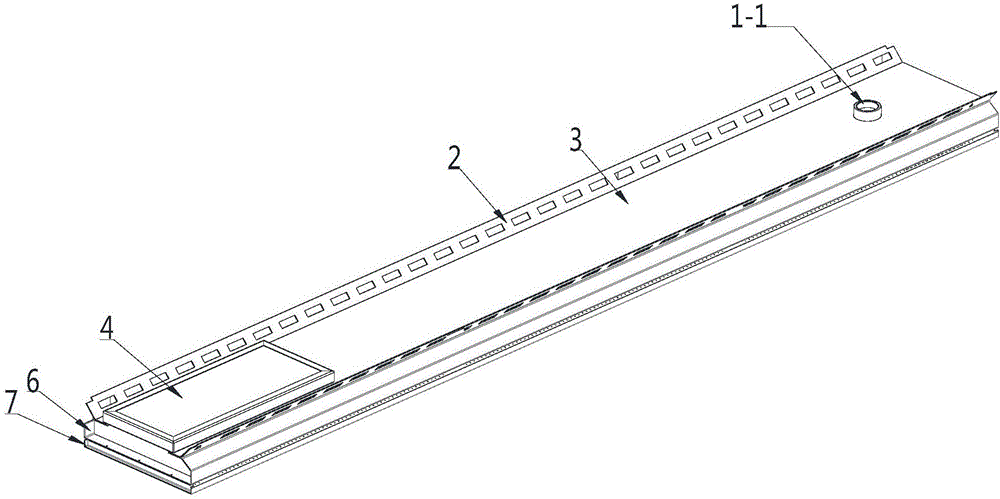

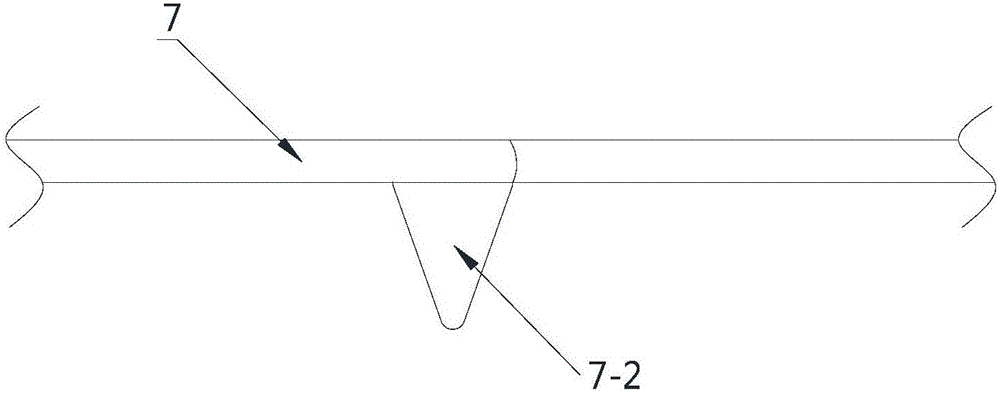

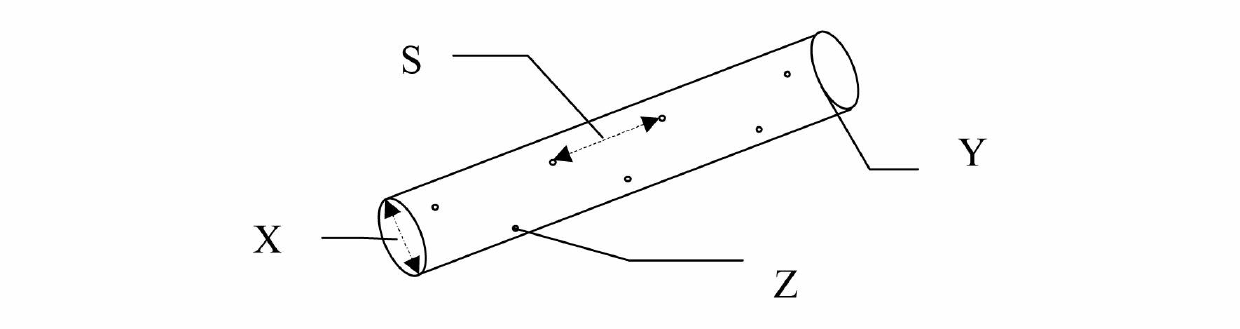

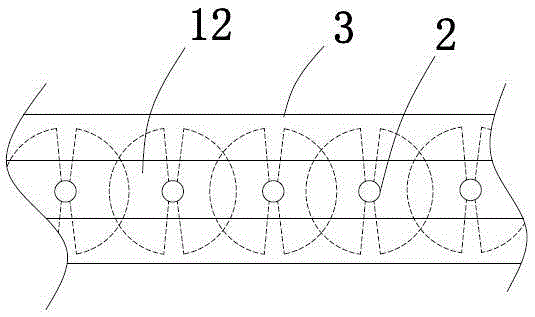

Novel micro-irrigation belt and preparation method and application thereof

InactiveCN102553740AReasonable formulaSimple production processWatering devicesSpray nozzlesAgricultural irrigationAgricultural engineering

The invention discloses a novel micro-irrigation belt and a preparation method and an application thereof. The entire novel micro-irrigation belt is a belt-shaped pipe body; the outer surface of the belt-shaped pipe body has a convex-concave structure; and the side wall of the belt-shaped pipe body is provided with a plurality of micro holes. The micro-irrigation belt comprises the following raw material components in percentage by weight: 75-90 percent of polyethylene particles, 5-10 percent of an antioxidant, 5-7 percent of EVA (Ethylene Vinylacetate) particles, 1-3 percent of a toner, 4-9 percent of an antifoaming agent and 2-6 percent of a toughening agent. In application to agricultural irrigation, the micro-irrigation belts are paved in a field at the intervals of 0.5-1 meter, are connected with a water pump through a filter, and are connected with the filter through a pipeline. The micro-irrigation belt disclosed by the invention has the advantages of reasonable formula, wide raw material source, simple production process, good anti-ageing effect and high anti-blocking performance. The surface of the micro-irrigation belt is uneven, micro holes of the micro-irrigation belt are distributed uniformly, and the micro-irrigation belt is elastic, so that high anti-ageing performance, high anti-bonding performance, uniform water dripping and high anti-blocking performance are realized, and the micro-irrigation belt is suitable for an irrigation system in which a modern cultivating way is adopted.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI +1

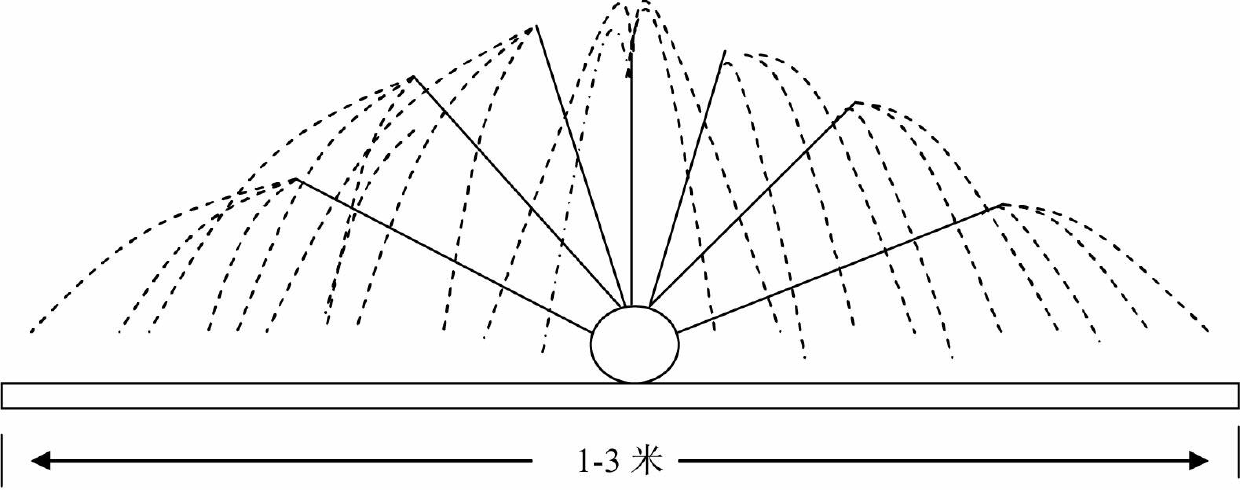

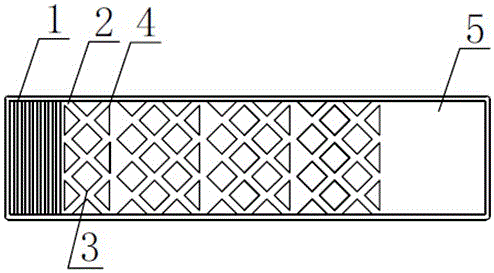

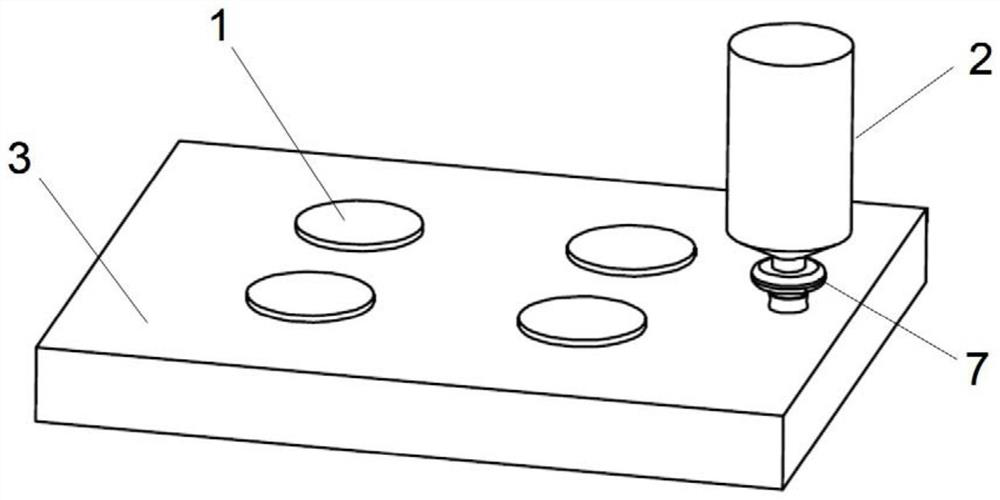

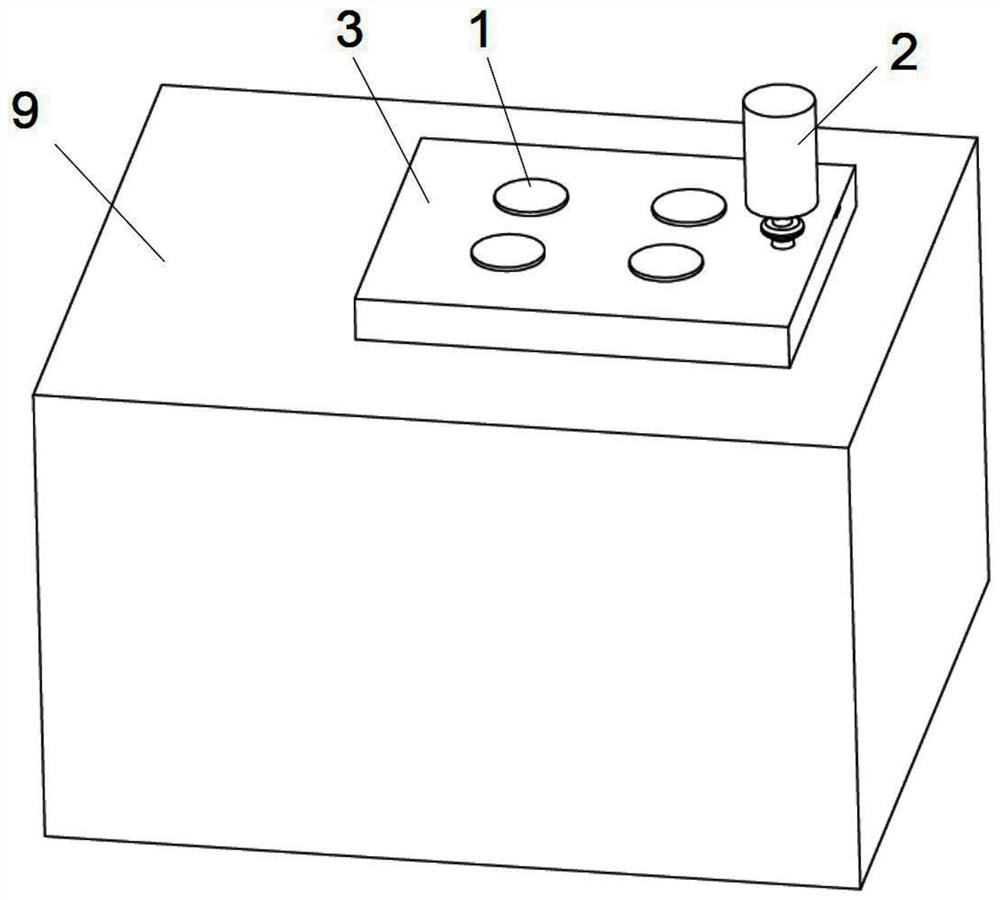

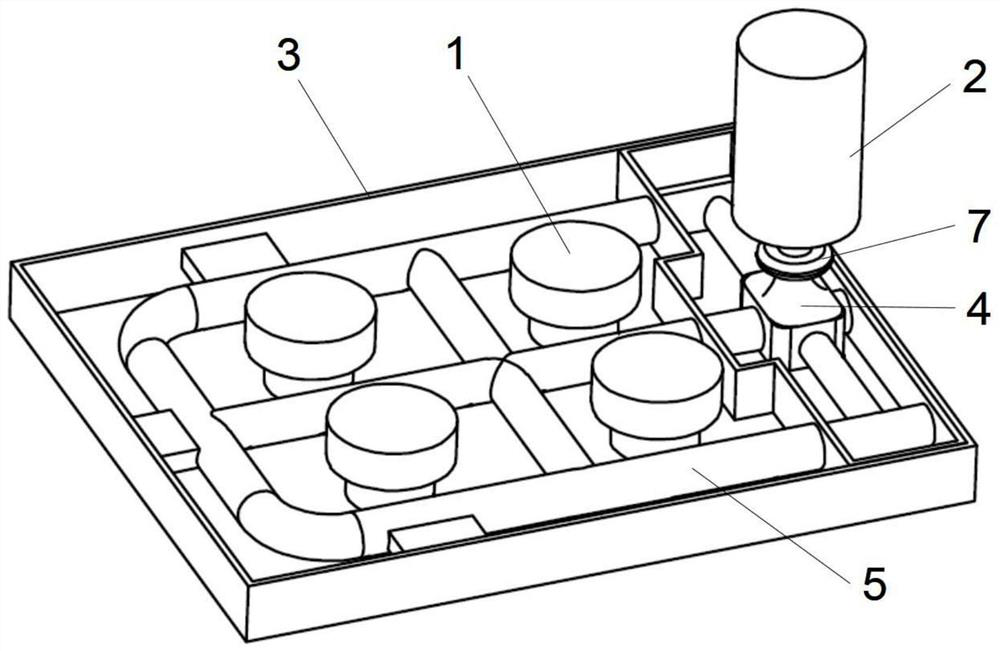

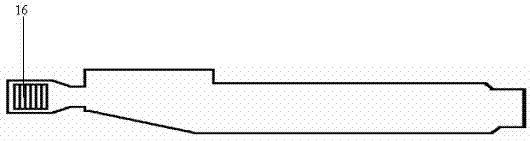

Inner inlay patch-type drip emitter

ActiveCN105123431ASimple structureEasy to processWatering devicesCultivating equipmentsDrip irrigationEngineering

The invention relates to the technical field of water-saving irrigation, and provides an inner inlay patch-type drip emitter. The drip emitter comprises a narrow slit comb-shaped filter window structure water inlet (1), communicated with a flowing channel (2). The other end of the flowing channel is communicated with a water outlet (5). The flowing channel is a net flowing channel. The net flowing channel is divided into two parts of a front part and a rear part. The front part of the net flowing channel is communicated with the water inlet (1). The rear part of the net flowing channel, formed by a plurality of same units, is communicated with the water outlet (5). The drip emitter is different from a previous drip emitter. The flowing channel of the drip irrigation emitter is a net flowing channel, formed by communicating a plurality of flowing channels. The flowing channel can effectively solve a blocking problem. The drip emitter has efficient energy dissipation effect, and is beneficial for reducing flow stance index of the drip emitter, so drip is more even. The drip emitter can be widely applied in the field of agriculture and gardening and other water-saving irrigation fields.

Owner:北京大禹智慧农业科技有限公司

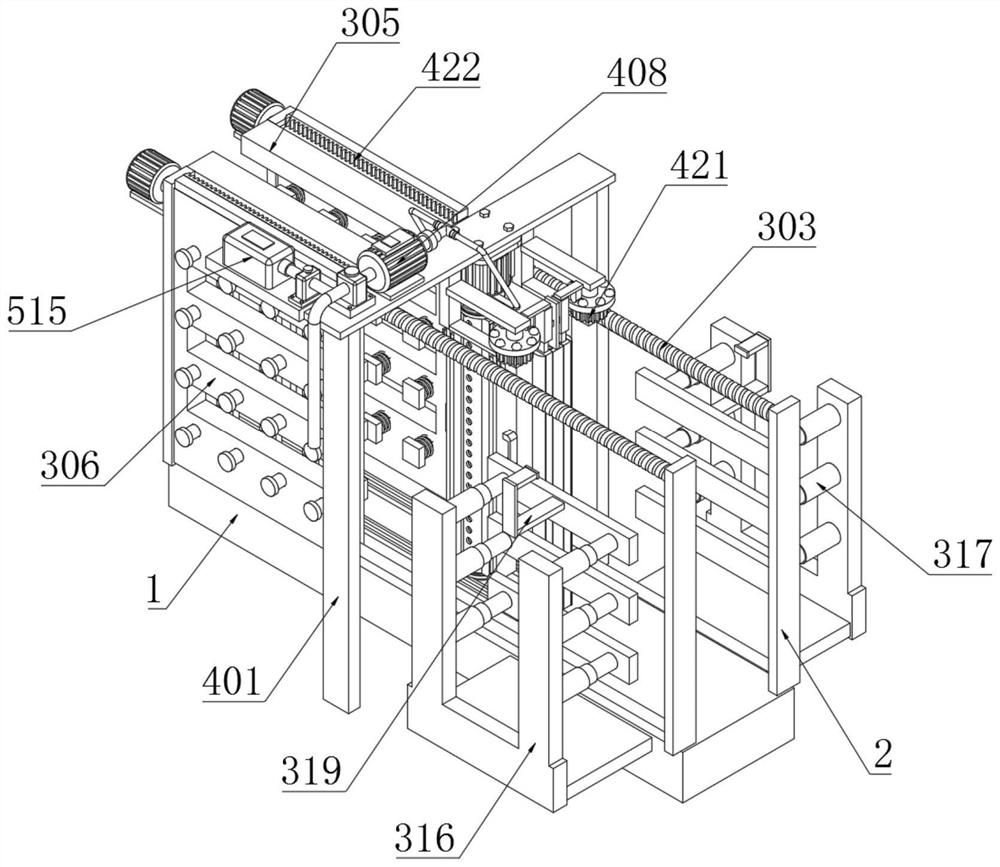

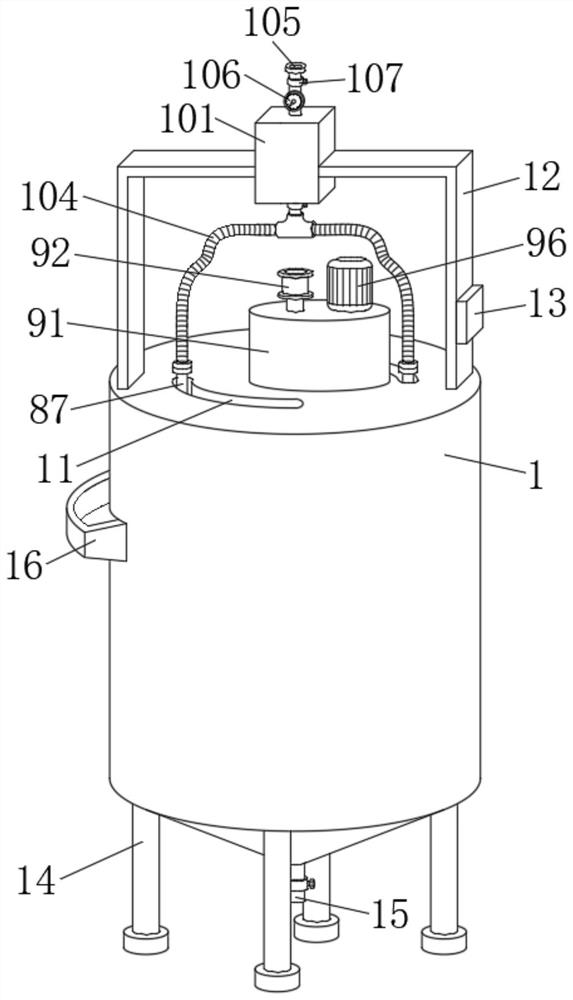

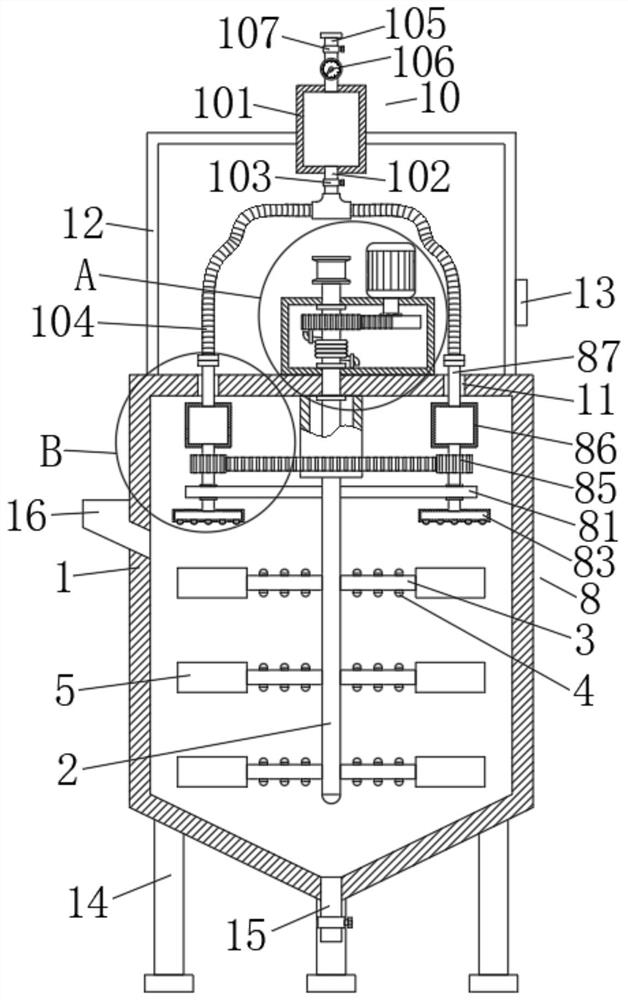

Composting equipment for laboratories

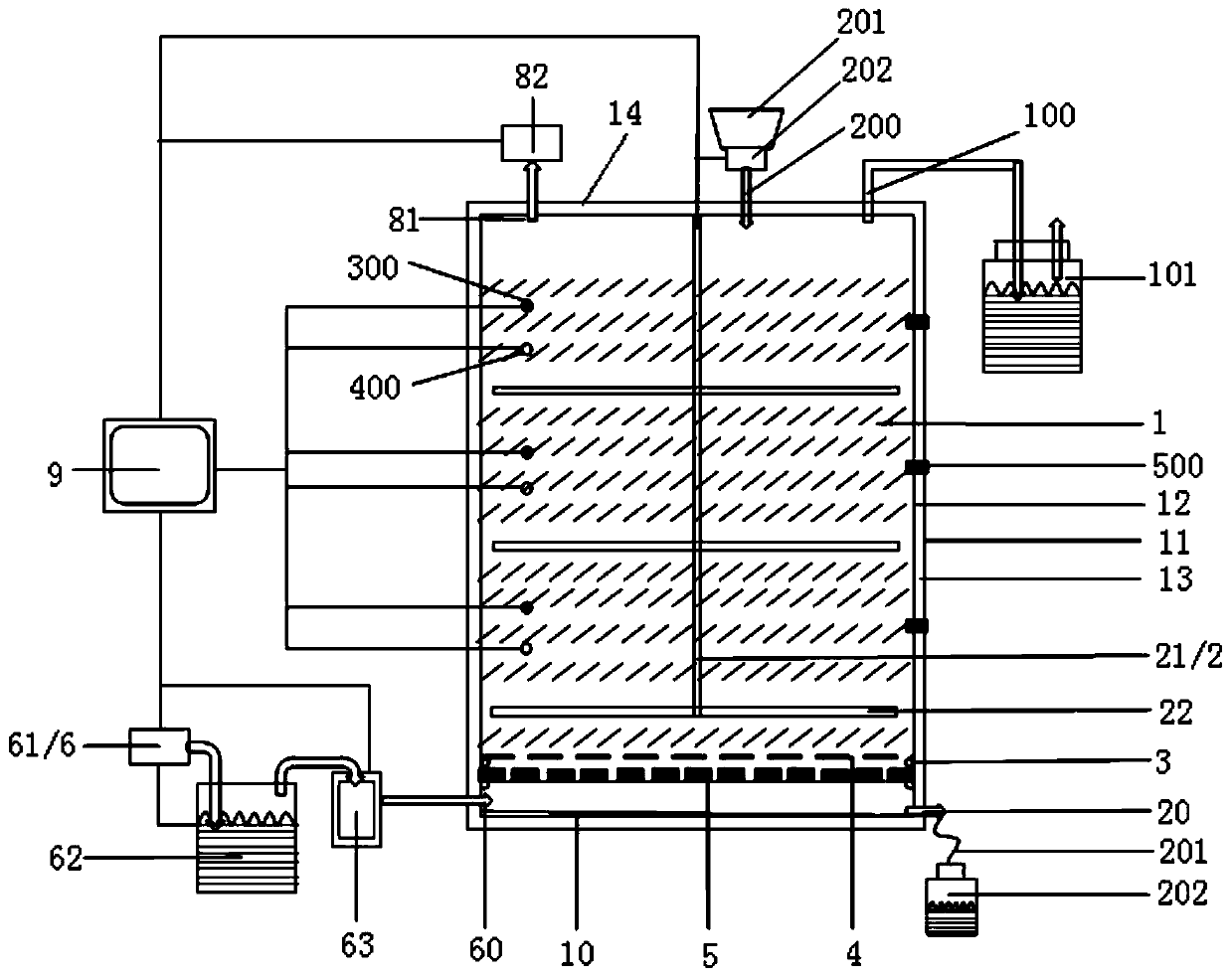

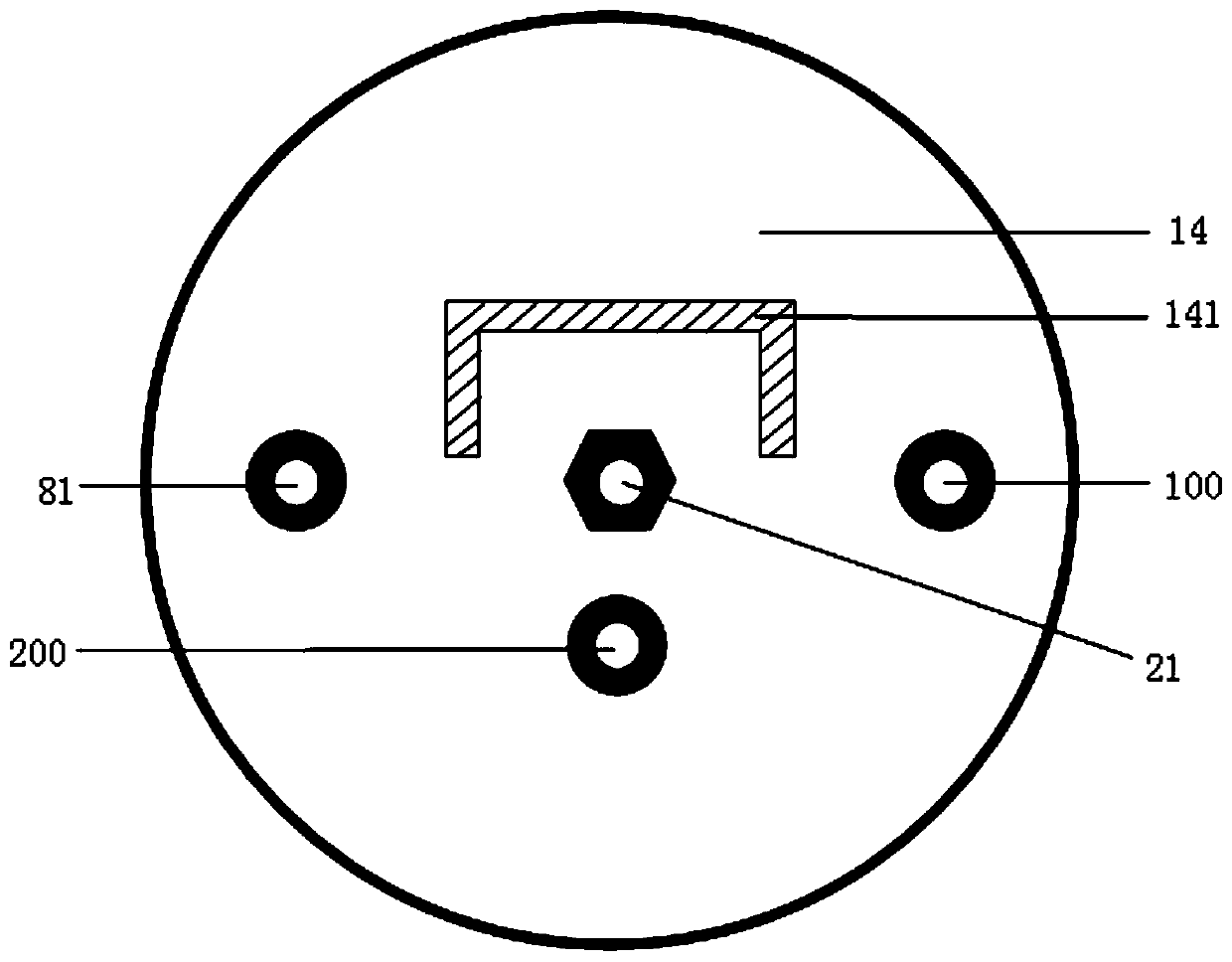

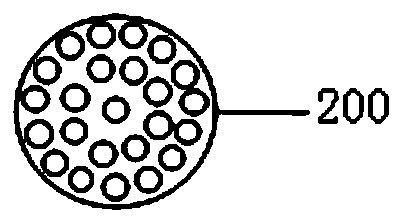

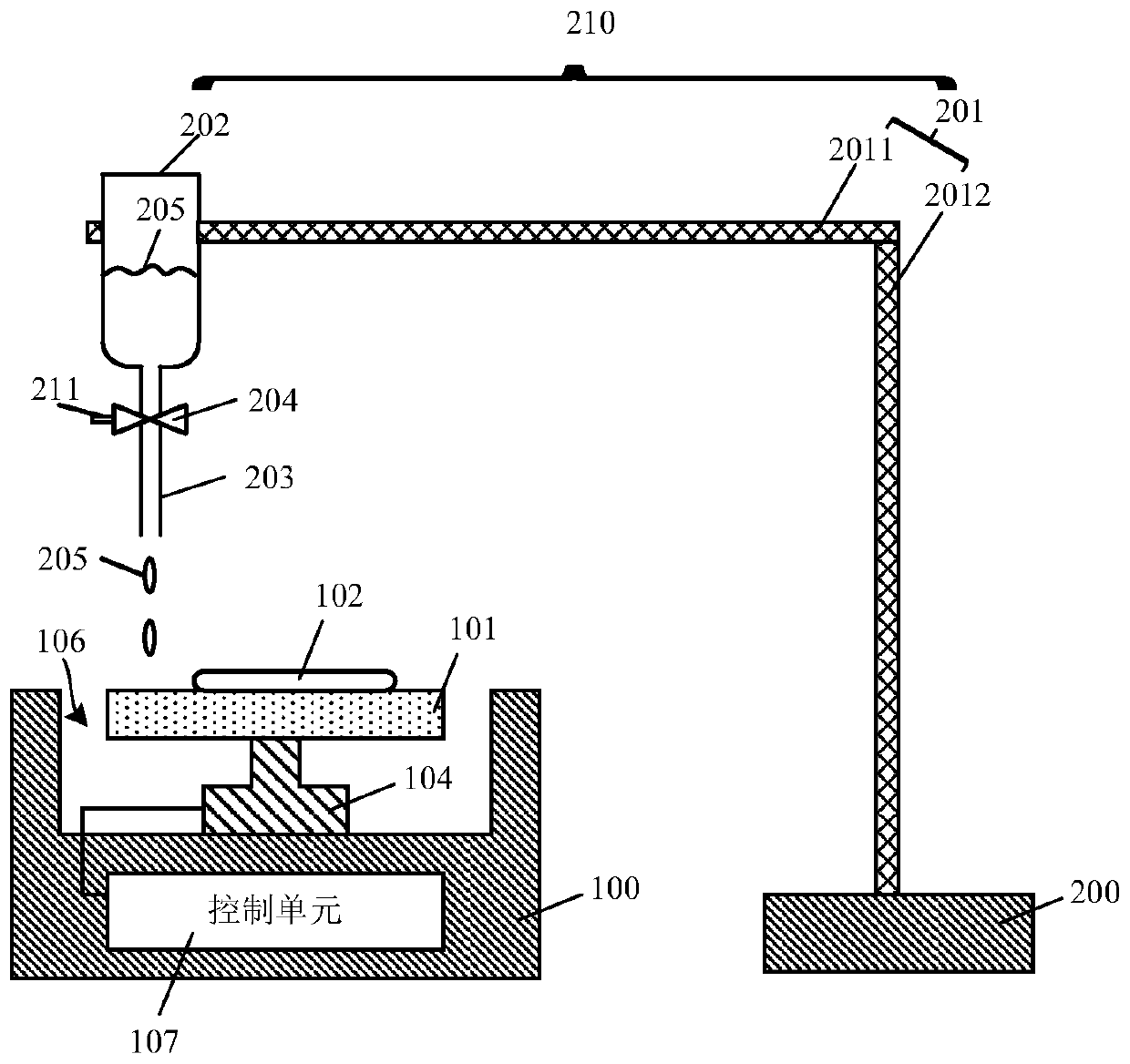

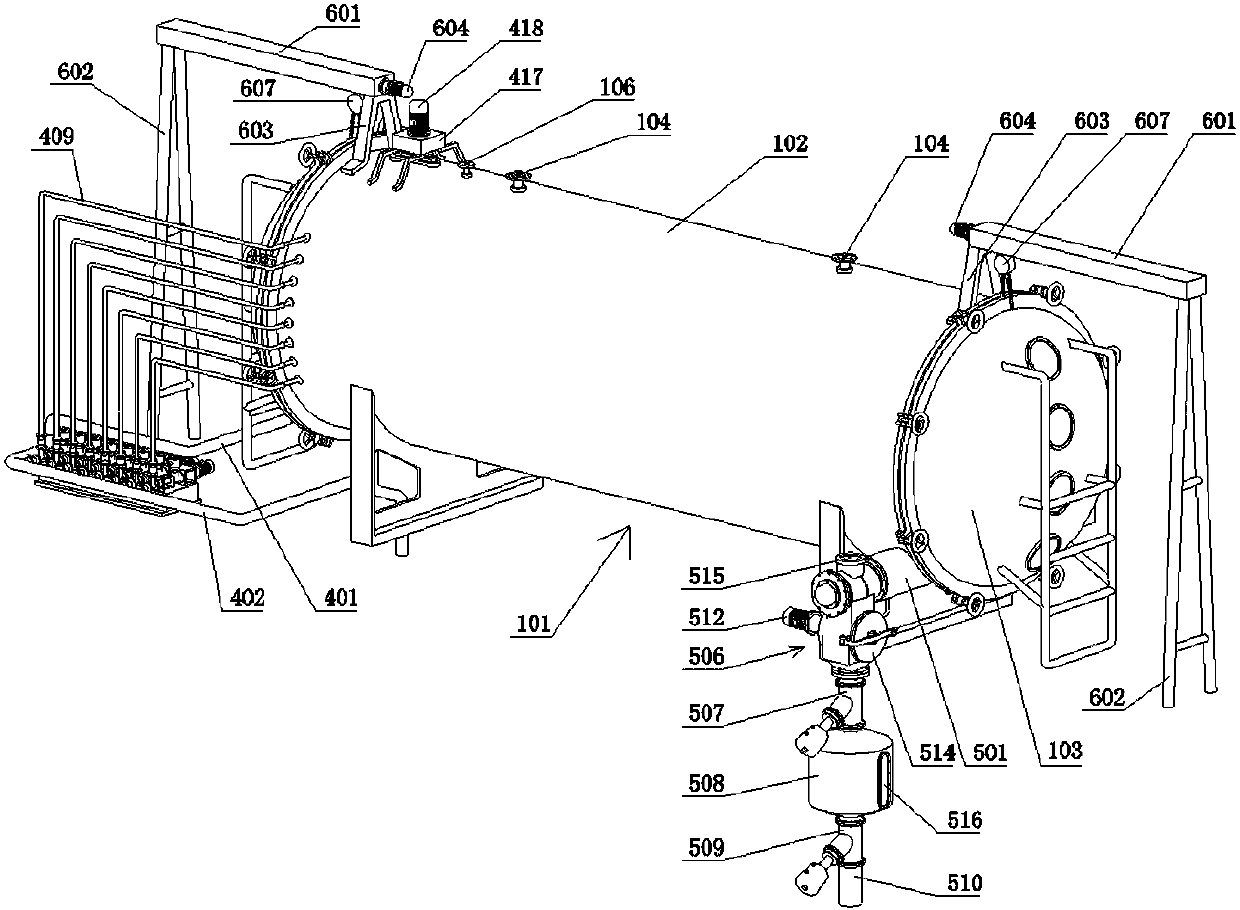

PendingCN111499442ASimple and fast operationEasy to useBio-organic fraction processingMeasurement devicesAutomatic controlProcess engineering

The invention relates to composting equipment for laboratories, wherein the composting equipment comprises a material bin with an accommodating space, a stirring mechanism, object carrying tables, object bearing plates, a ventilation plates, an aeration device, a water supplementing mechanism, an exhaust mechanism and an integrated automatic control system; the material bin is provided with an airinlet and a leachate outlet; at least part of the stirring mechanism is arranged in the material bin; the object carrying tables, the object bearing plates and the ventilation plates are arranged inthe material bin, the plurality of object carrying tables are arranged in the material bin, and the object bearing plates and the ventilation plates are arranged on the object carrying tables; the aeration device, the water supplementing mechanism and the exhaust mechanism are connected with the material bin, the heating mechanism is connected to the bottom of the material bin, and the exhaust mechanism and the water supplementing mechanism are connected to the top of the material bin; the integrated automatic control system is electrically connected with the stirring mechanism, the heating mechanism, the water supplementing mechanism and the exhaust mechanism. The composting equipment for the laboratories can accurately determine various parameters required by composting, can automatically measure the temperature and the humidity, can automatically supply water to a compost body, and can collect gas and leachate at the same time.

Owner:ZHONGNONGXINKE SUZHOU ORGANIC RECYCLING RES INST CO LTD

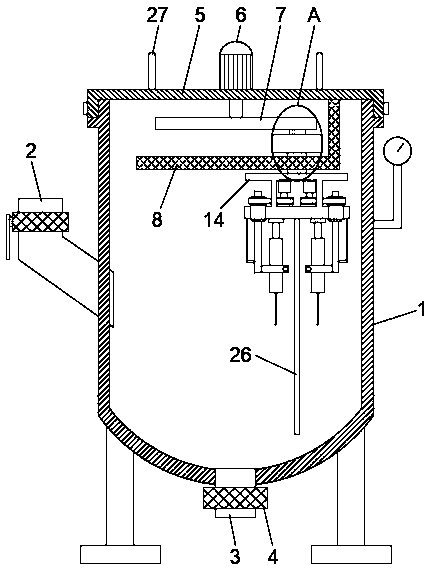

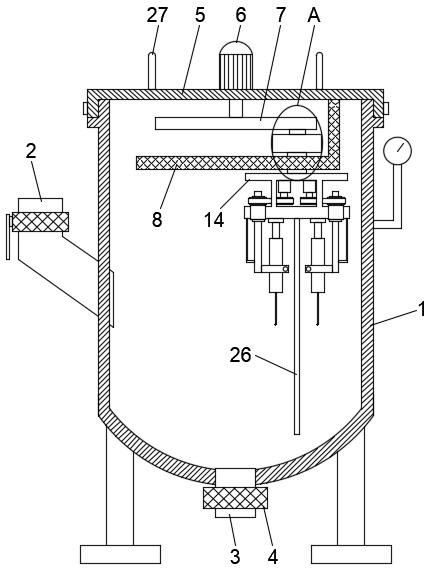

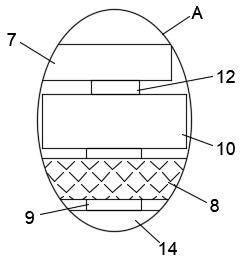

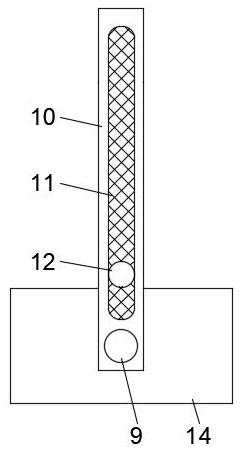

Device for preparing solvent-free graphene modified electrostatic-conductive acrylic resin

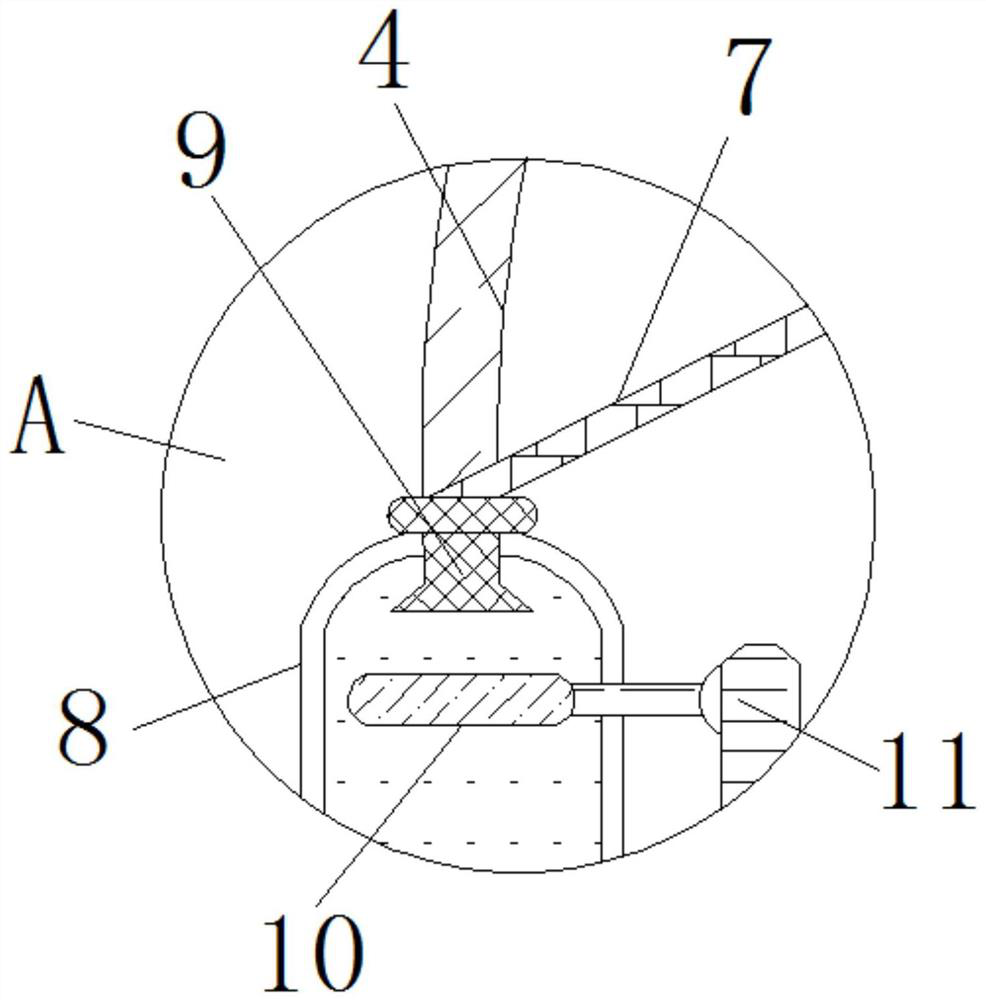

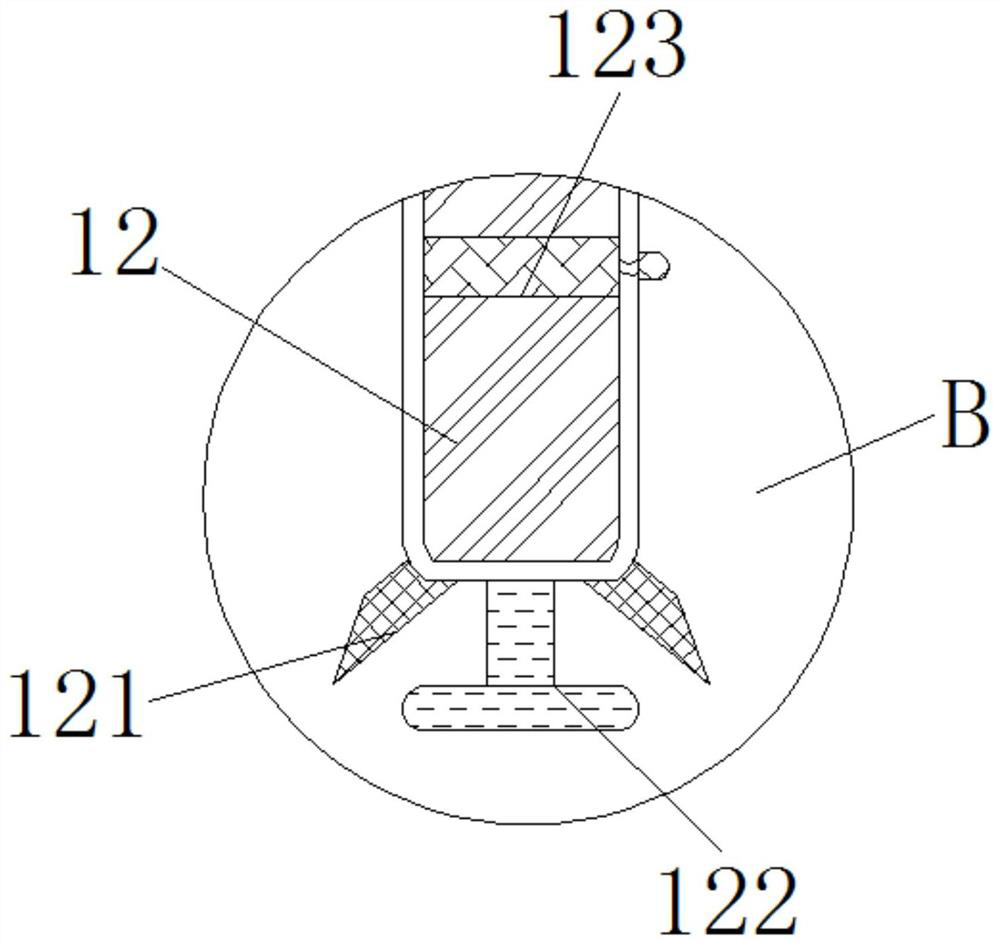

ActiveCN109499510ADrip evenlyGuarantee the catalytic effect of the reactionChemical/physical/physico-chemical stationary reactorsFeed devicesTemperature controlAcrylic resin

The invention discloses a device for preparing solvent-free graphene modified electrostatic-conductive acrylic resin. The device comprises a reactor, wherein a temperature controller is arranged inside the reactor, a charging pipe is arranged on the sidewall of the reactor in a penetrating manner, a discharging pipe is mounted at the bottom of the reactor, a cover body is arranged at the upper endof the reactor, a plurality of locking screws are arranged between the cover body and the reactor, a first motor is fixedly mounted at the upper end of the cover body, an output rod of the first motor penetrates through the cover body, a turntable fixedly sleeves the lower end of the output rod, a frame body is further welded to the bottom of the cover body, a connecting shaft is arranged on theframe body in a penetrating manner, and a transmission seat which is horizontally arranged is welded to the upper end of the connecting shaft. According to the device, occurrence and transition of a reaction can be catalyzed through uniformly and dropwise adding a catalyst during the preparation of the solvent-free graphene modified electrostatic-conductive acrylic resin, so that the effect of preparation of the product can be guaranteed; reactants can be uniformly stirred, so that the rate of reaction is accelerated.

Owner:林浩

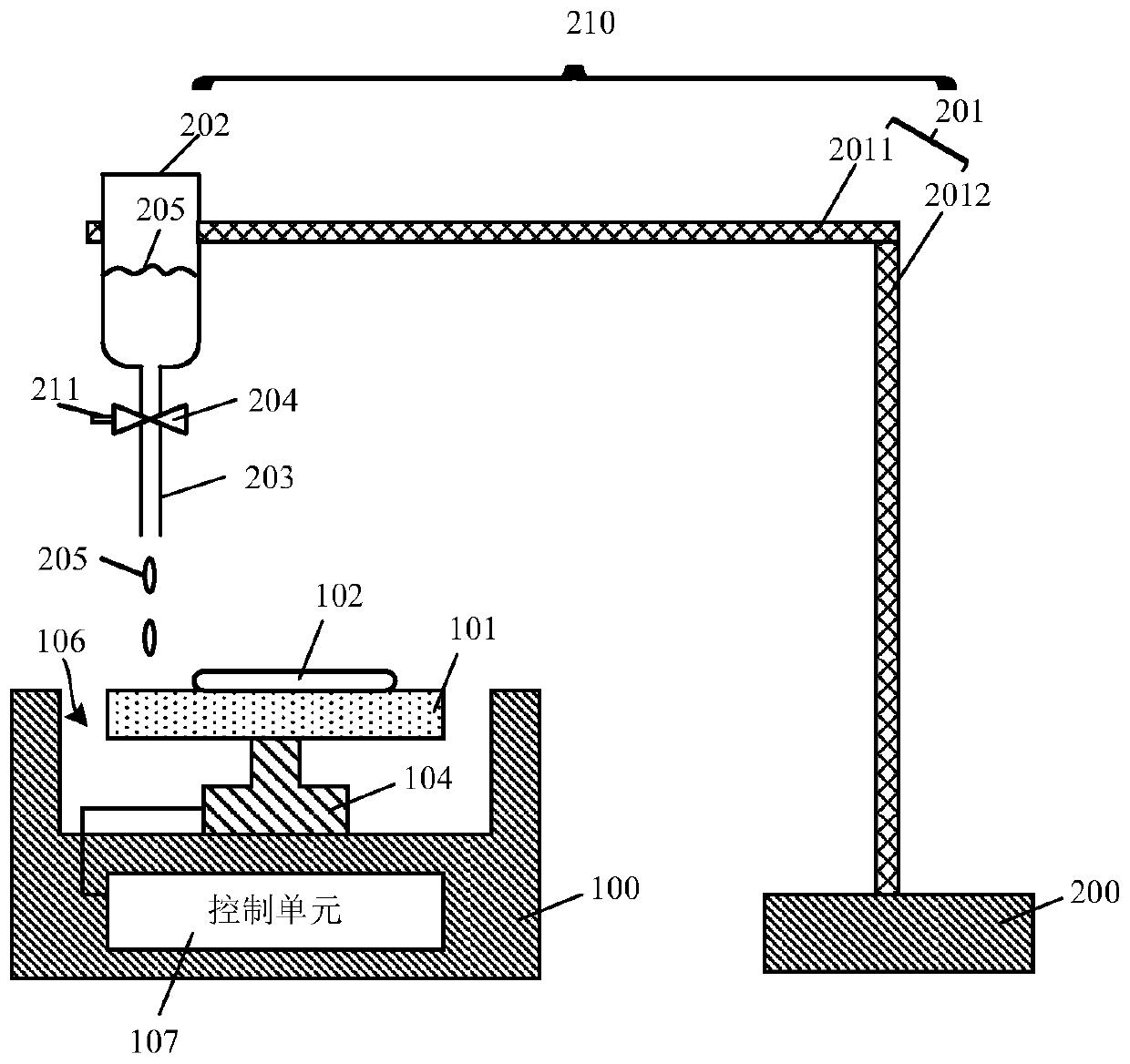

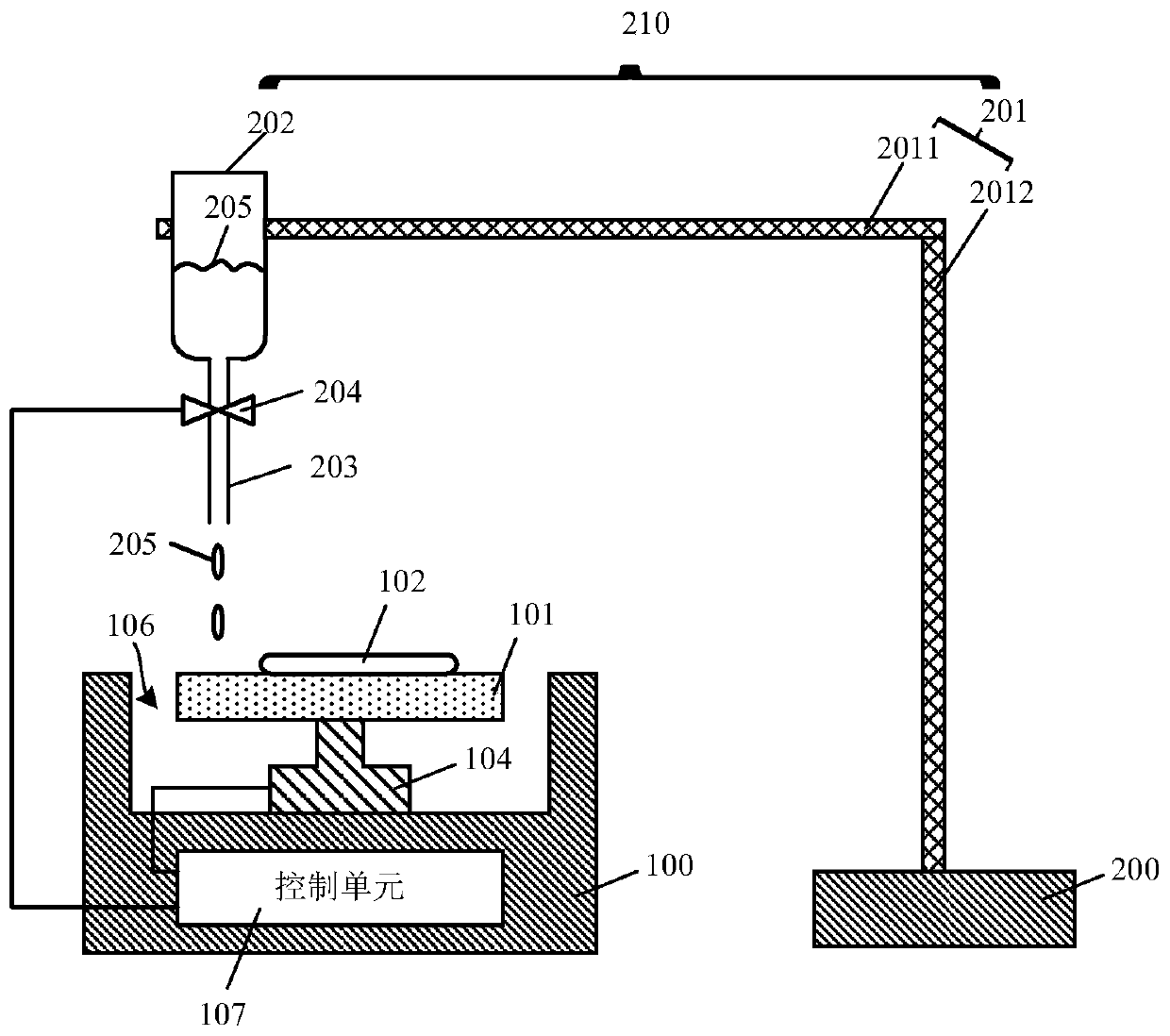

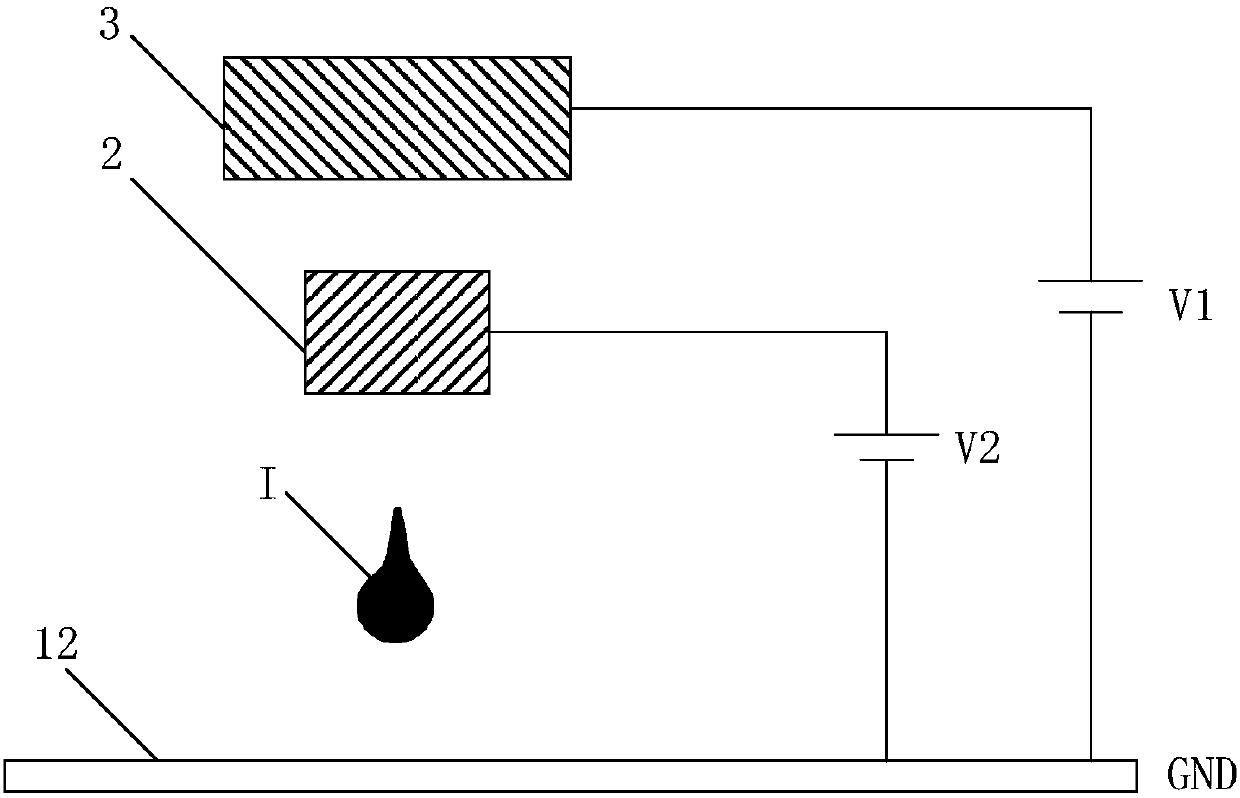

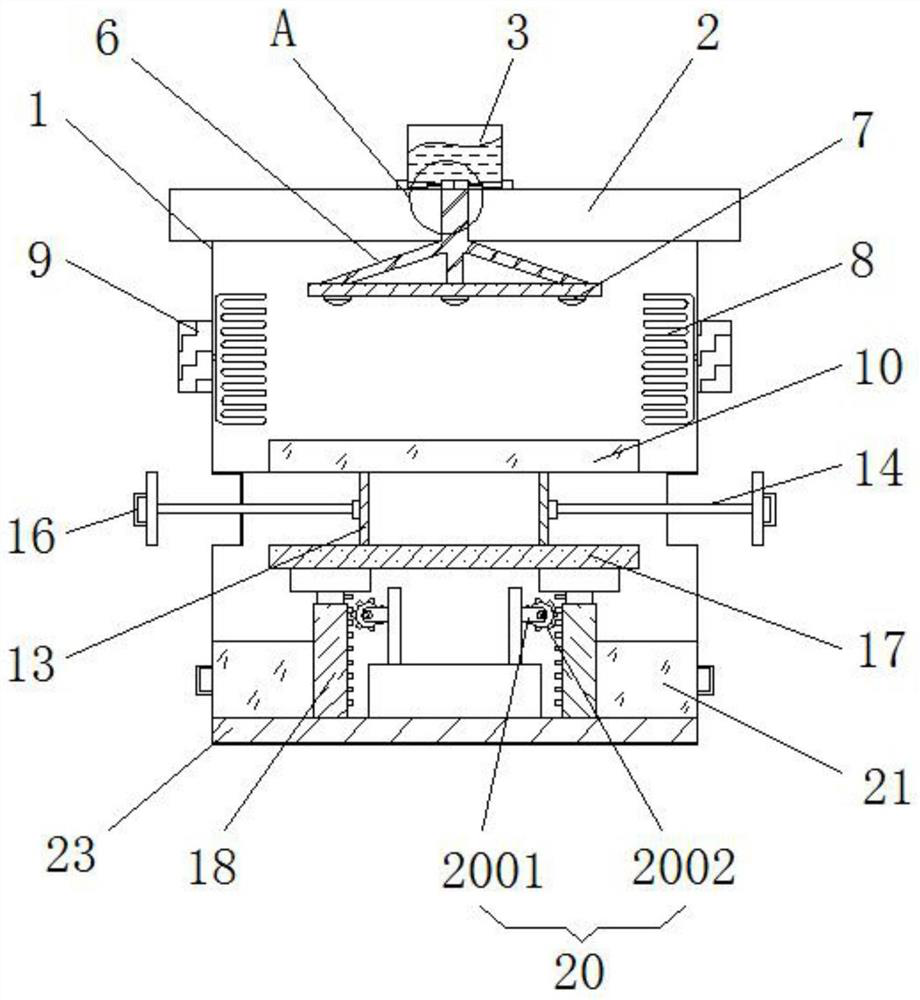

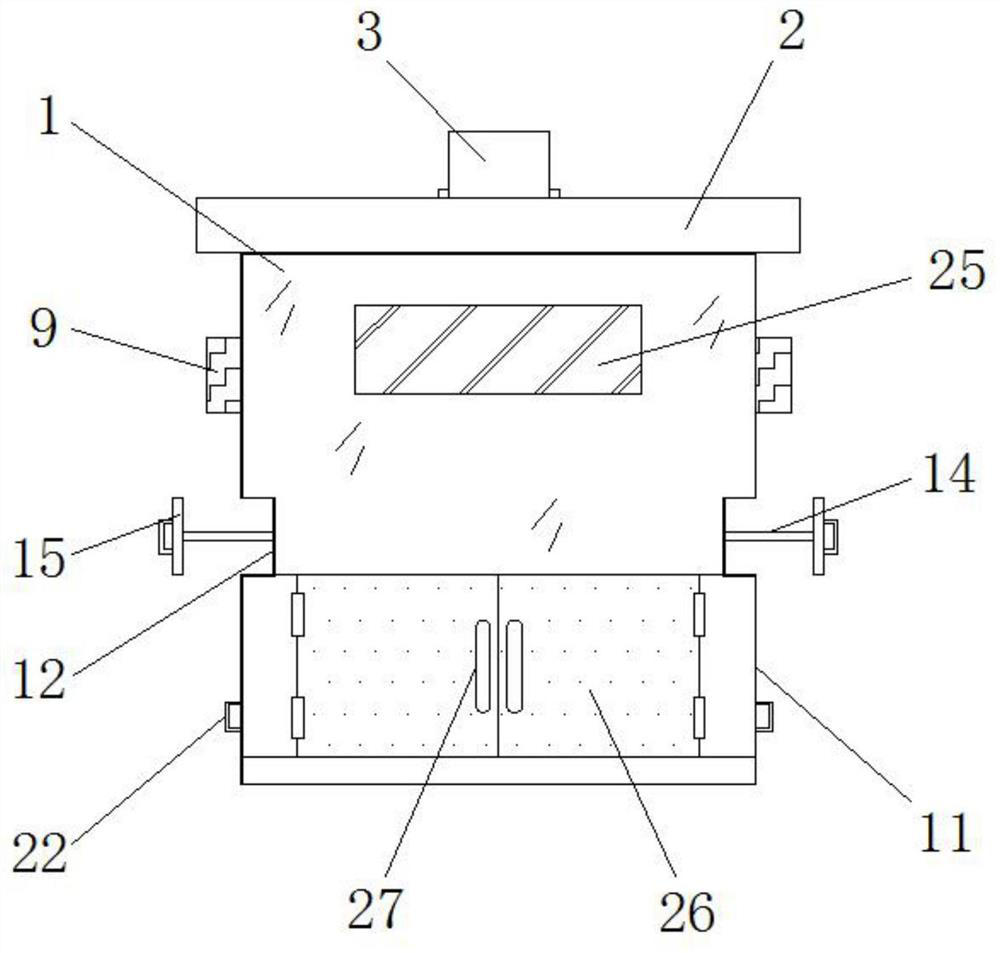

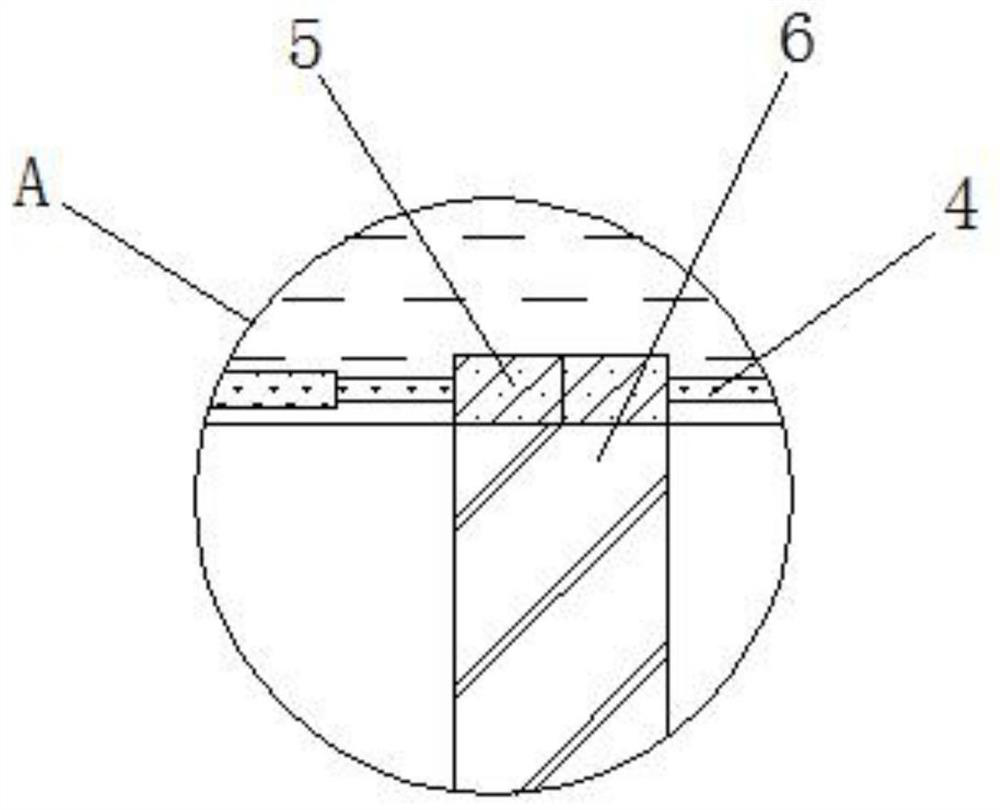

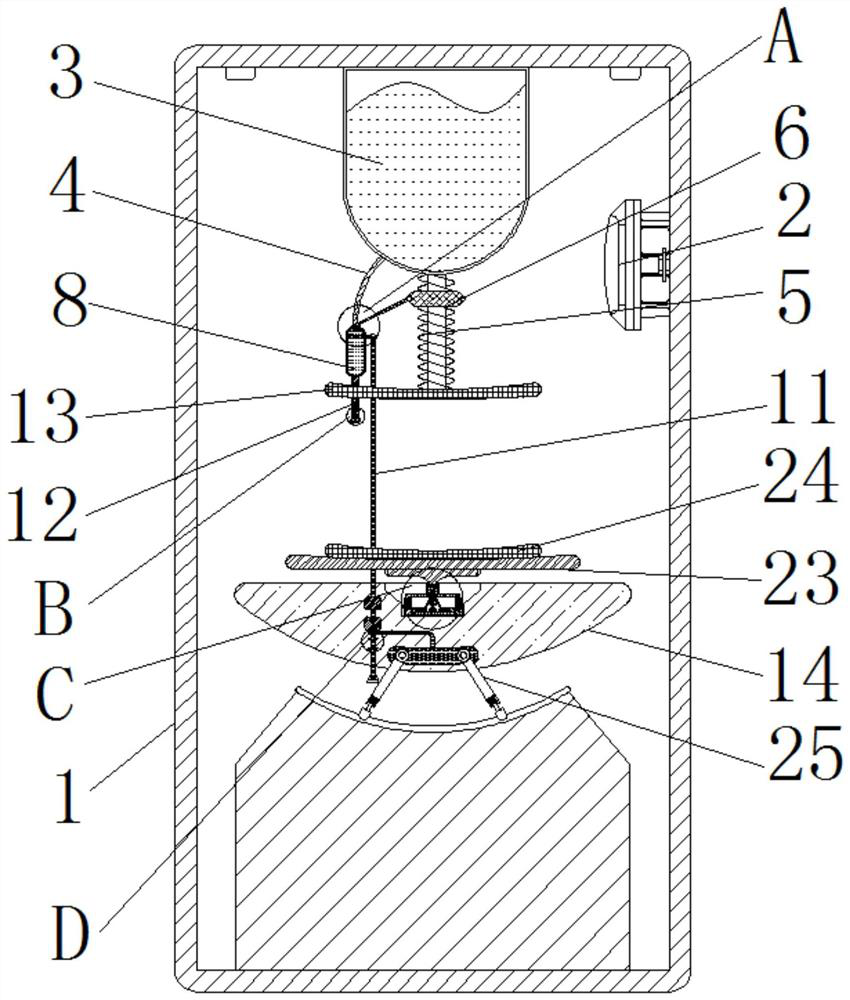

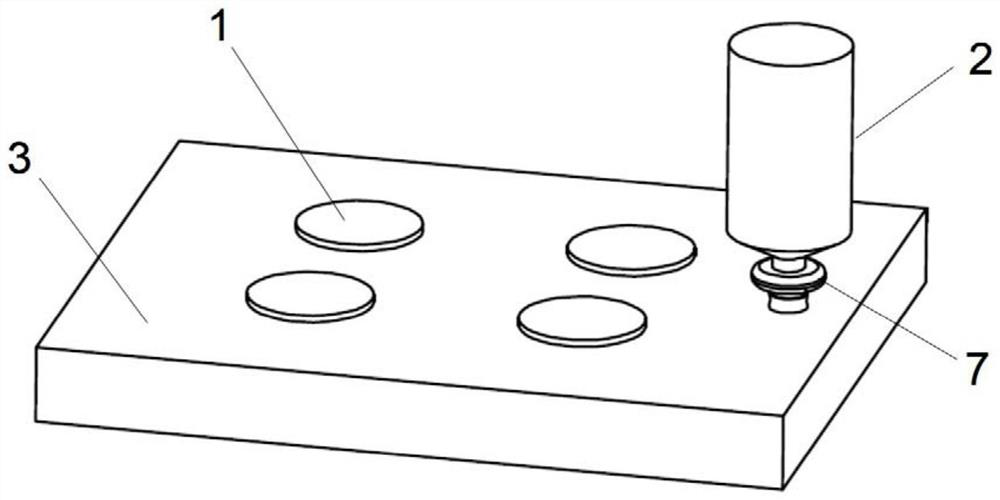

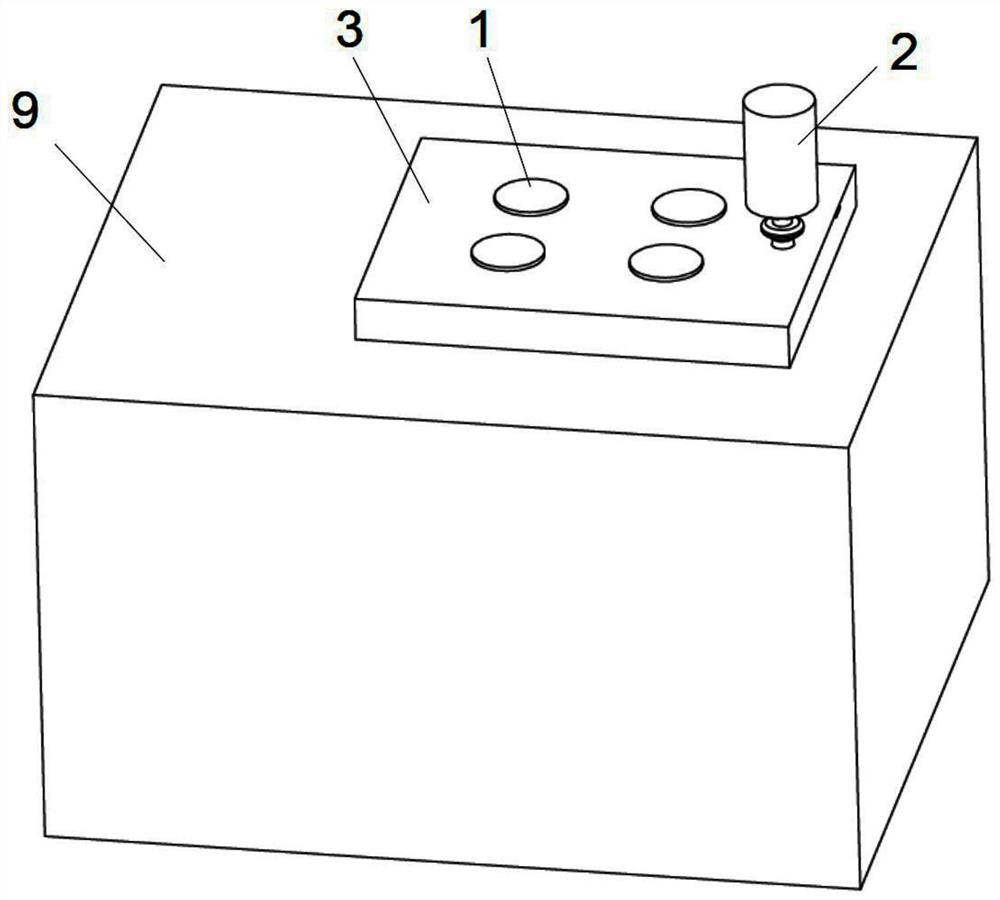

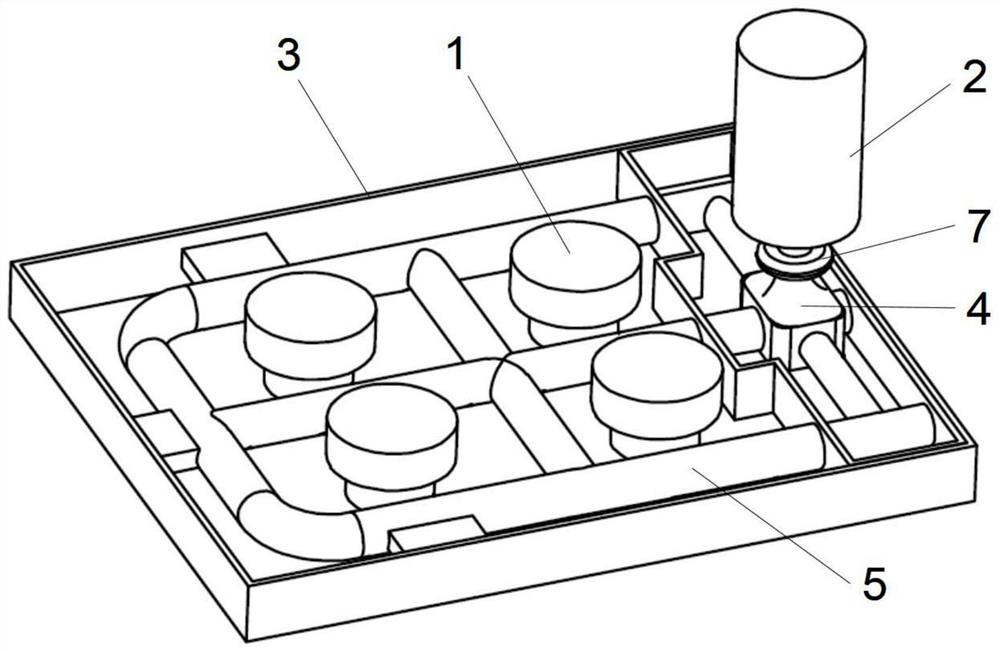

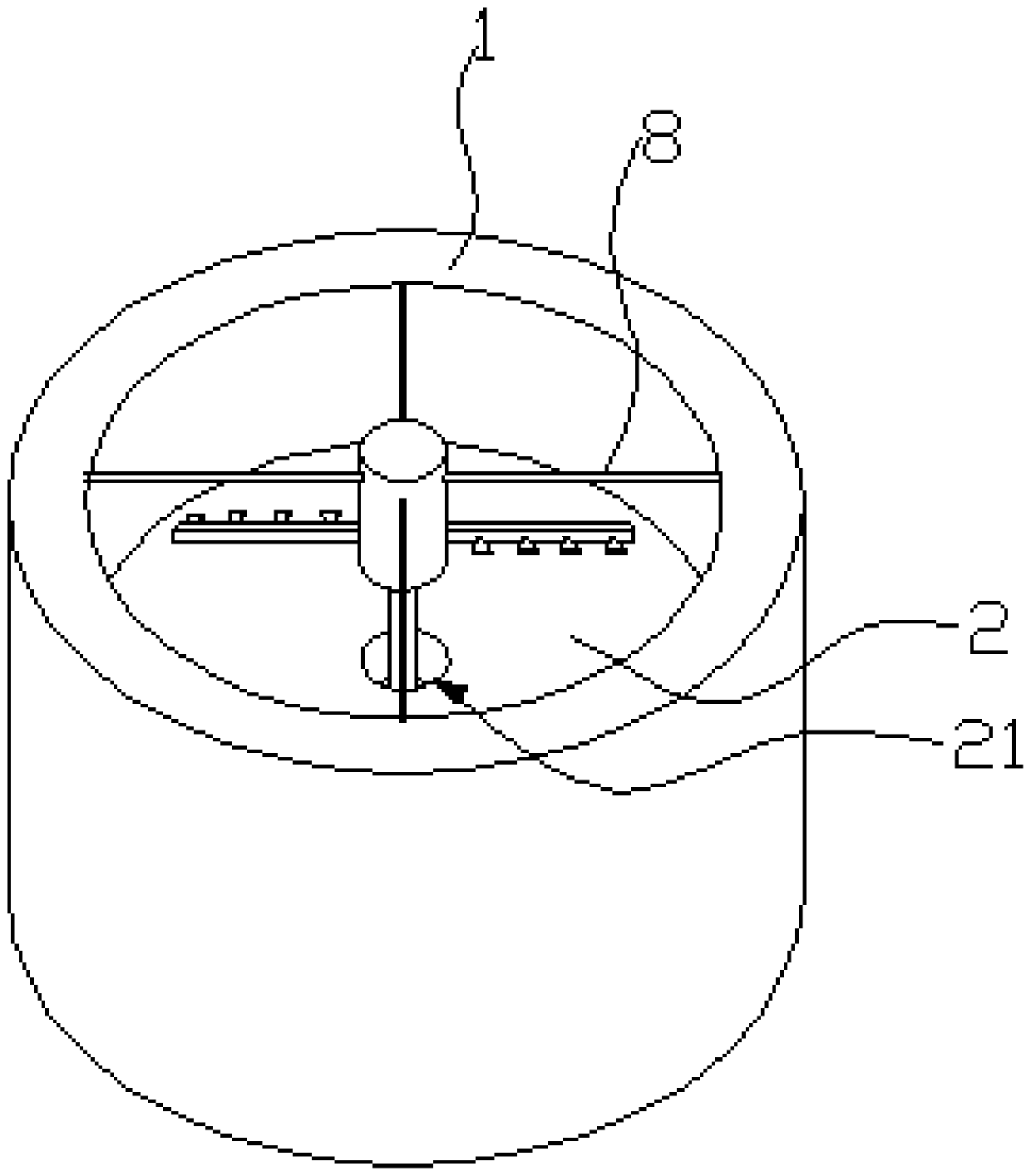

Invalid wafer grinding device

PendingCN111152128AImprove grinding uniformityImprove uniformityLapping machinesGrinding/polishing apparatusWaferEngineering

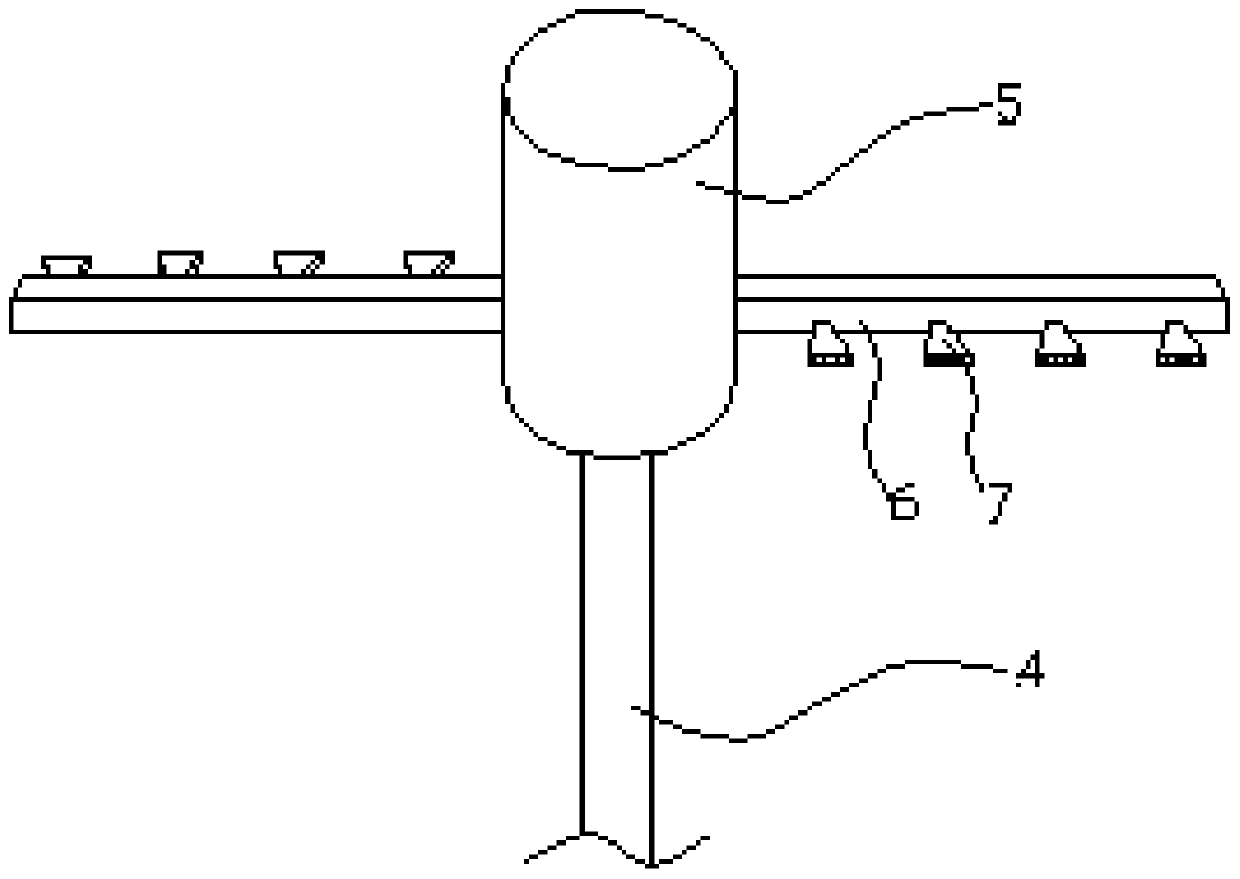

The invention provides an invalid wafer grinding device. The invalid wafer grinding device comprises a grinding table provided with a grinding surface and used for grinding the to-be-ground surface ofan invalid wafer, and a grinding fluid automatic dripping unit used for evenly dripping grinding fluid onto the grinding surface of the grinding table when the grinding table carries out grinding onthe to-be-ground surface of the invalid wafer. The grinding fluid automatic dripping unit can evenly drip the grinding fluid onto the grinding surface of the grinding table when the grinding table carries out grinding on the to-be-ground surface of the invalid wafer. Thus, the invalid wafer grinding device can accurately control the dripping rate and dripping quantity of the grinding fluid to prevent waste of the grinding fluid through manual dripping and can improve the grinding evenness of the invalid wafer. When the reverse side of the invalid wafer needs to be pressed during grinding, an operator or an inspector can press the reverse side of the invalid wafer with the two hands so as to improve the grinding evenness of the invalid wafer.

Owner:YANGTZE MEMORY TECH CO LTD

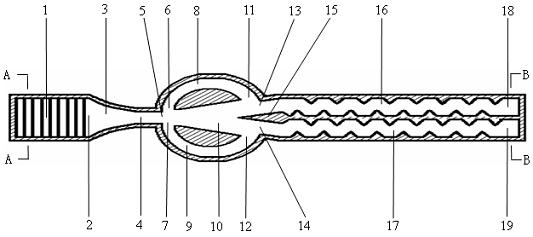

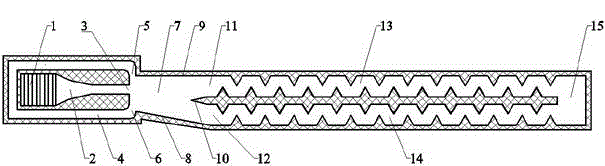

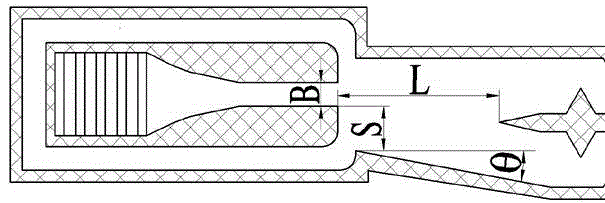

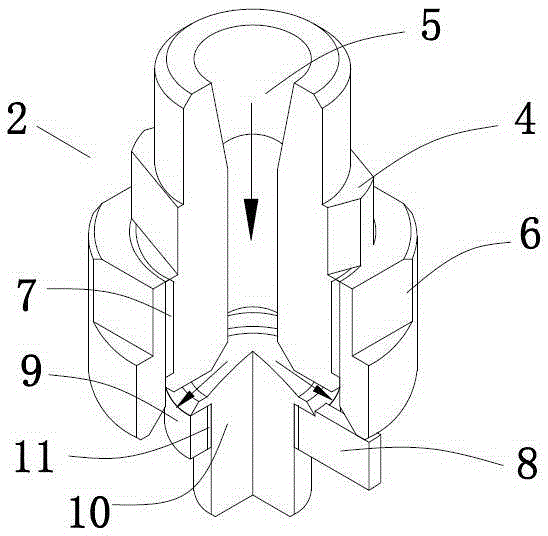

Oscillating drip irrigation emitter

InactiveCN102870650AImprove transportation capacityImprove anti-clogging performanceClimate change adaptationWatering devicesField cropInlet channel

The invention discloses an oscillating drip irrigation emitter which consists of a water inlet channel, an oscillation element and a runner body, wherein the water inlet channel is provided with a filter window and communicated with an inlet of the oscillation element; the oscillation element is of an asymmetric structure; an outlet of the oscillation element is communicated with an inlet of the runner body; and a water outlet channel is arranged at the tail end of the runner body. According to the Coanda and negative-pressure control oscillation technology and the characteristic of the asymmetric structure, the water flow is driven to flow intermittently in two runners to realize a continuous oscillation and pulse process and form a strong turbulence and impact water flow in the runners as well as enhance the anti-blocking ability and irrigation uniformity of the irrigation emitter. According to the invention, elastic structures such as rubber, plastic films, springs and the like of the existing drip irrigation pulse generator are saved, and the oscillating drip irrigation emitter has the characteristics of simple structure and high reliability and durability. The material and processing equipment and method of the existing drip irrigation emitter can be adopted, the oscillating drip irrigation emitter is subjected to once injection molding, the processing technology is simple, the manufacturing cost is low, and the oscillating drip irrigation emitter is convenient to mount and use. The oscillating drip irrigation emitter disclosed by the invention can be widely applied to the irrigation of the field crops, vegetables, forestry and fruit growing and the like.

Owner:JIANGSU UNIV

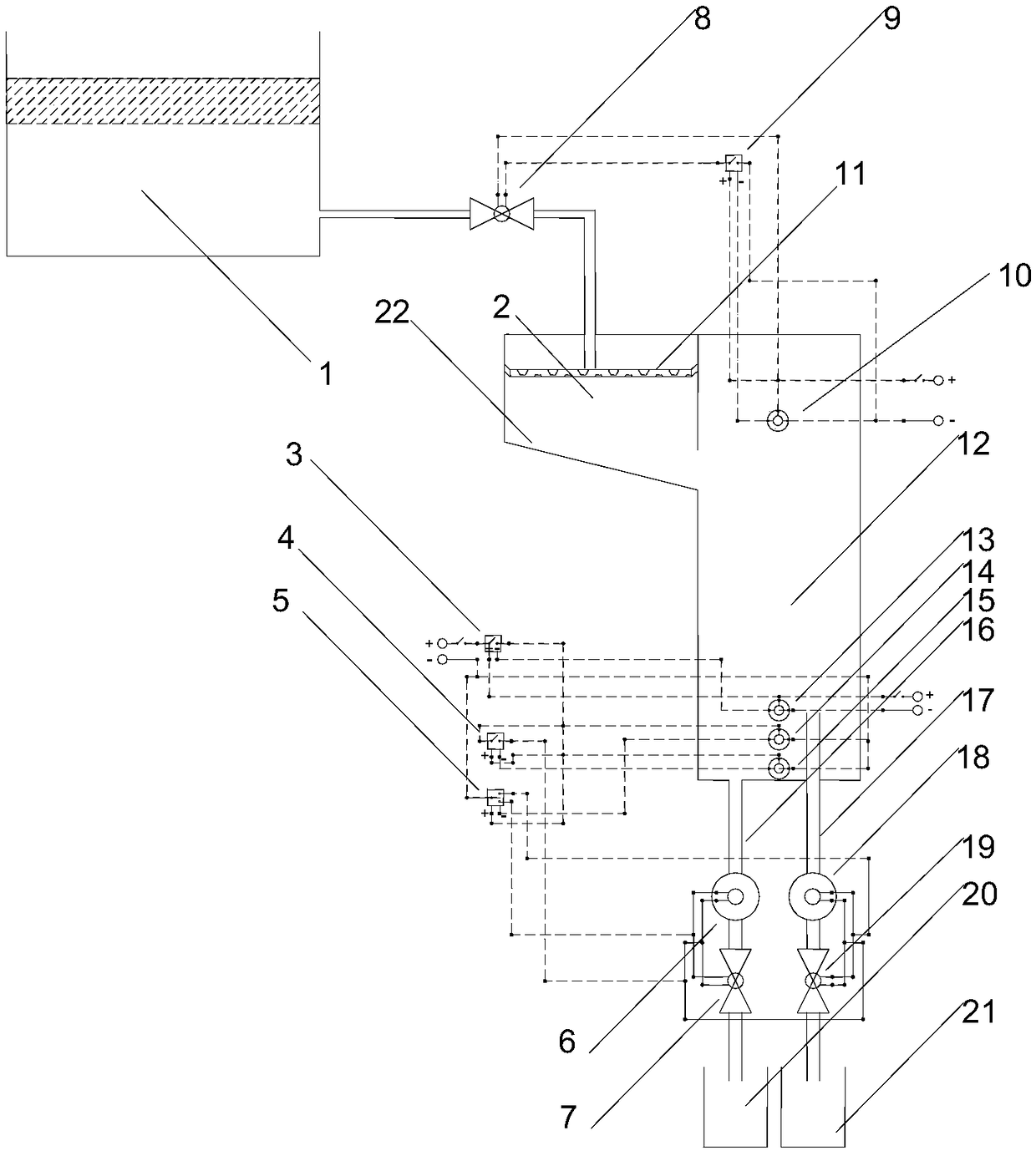

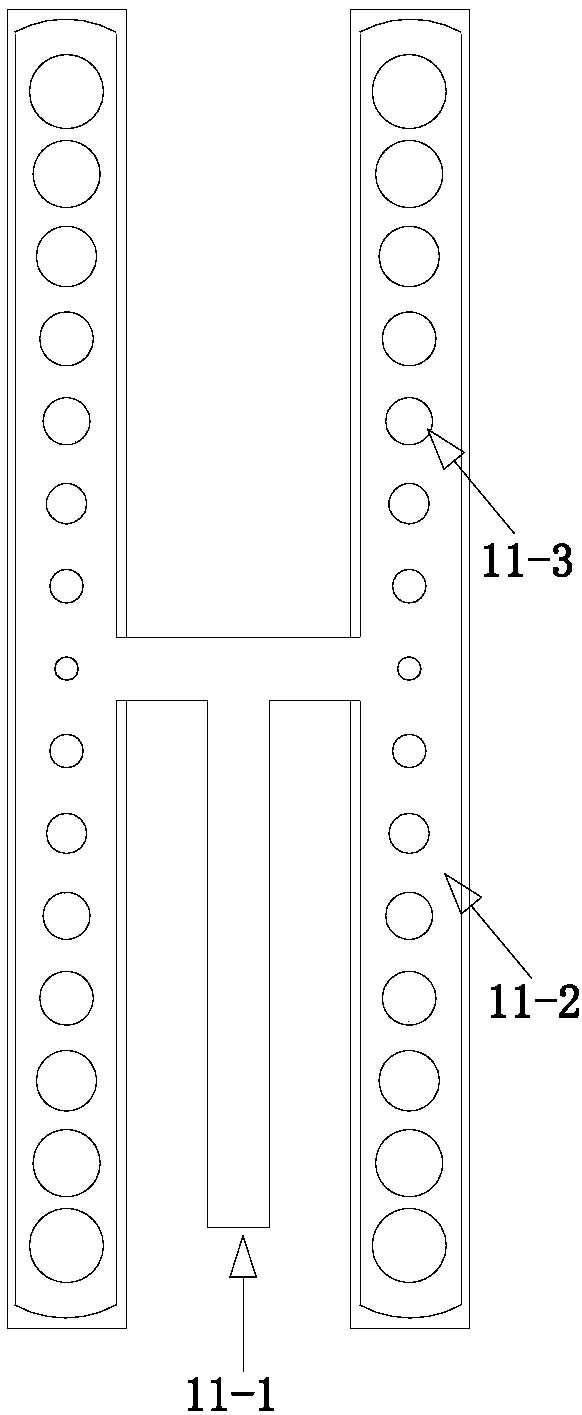

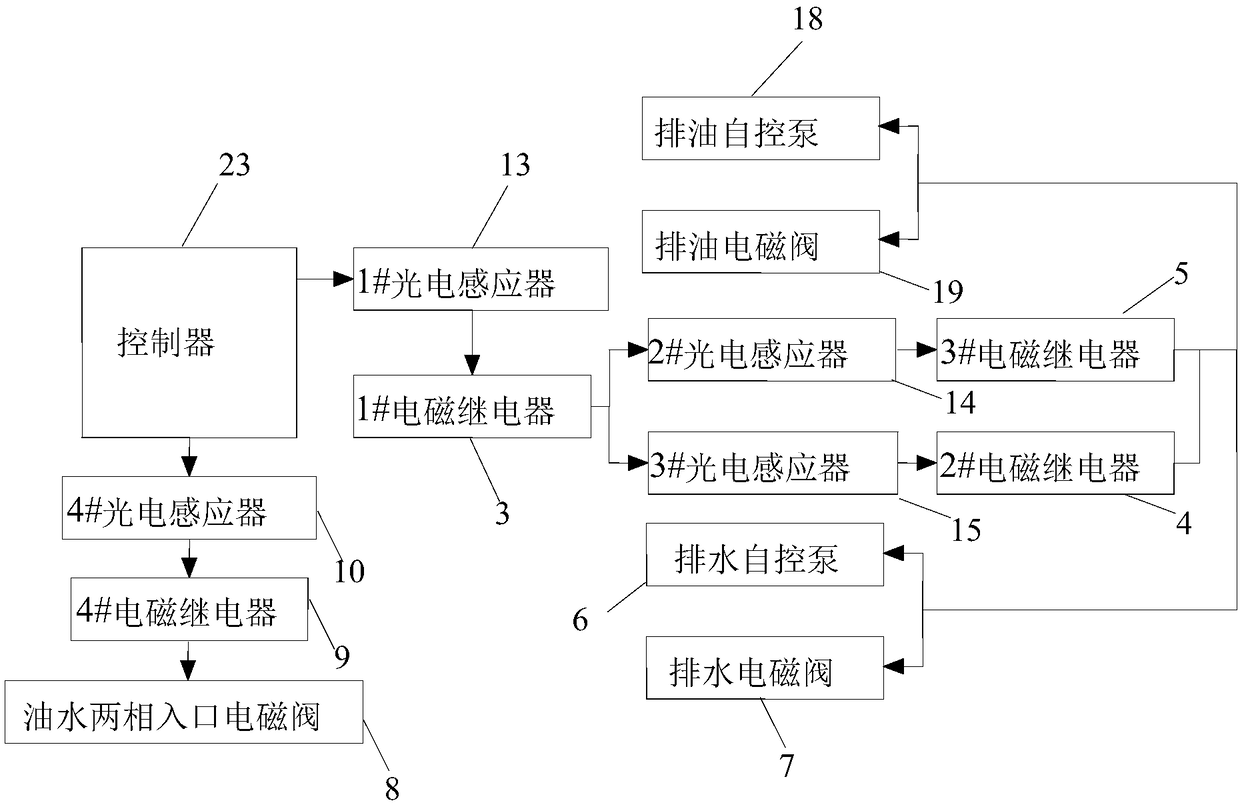

Photoelectric induction type oil-water two-phase automatic separating device

InactiveCN108392898ARealize automatic switchingRealize fully automatic controlLiquid separation auxillary apparatusFiltration circuitsAutomatic controlProcess engineering

The invention relates to the technical field of oil-water separation and discloses a photoelectric induction type oil-water two-phase automatic separating device. The photoelectric induction type oil-water two-phase automatic separating device comprises a filter, an oil-water two-phase dropping zone, a first electromagnetic relay, a second electromagnetic relay, a third electromagnetic relay, a draining automatic control pump, a draining electromagnetic valve, an oil-water two-phase inlet electromagnetic valve, a fourth electromagnetic relay, a fourth photoelectric sensor, an oil-water two-phase distributor, an oil-water two-phase settlement separating zone, a first photoelectric sensor, a second photoelectric sensor, a third photoelectric sensor, a draining pipe, an oil draining pipe, anoil drain automatic control pump, an oil drain electromagnetic valve, a water collector, an oil collector, a hydrophobic and oleophylic coating and a controller. According to the photoelectric induction type oil-water two-phase automatic separating device, intelligent detection and automatic efficient control over the process are realized; by automatic efficient control of the device, manual efficiency is greatly improved.

Owner:SHENYANG AGRI UNIV

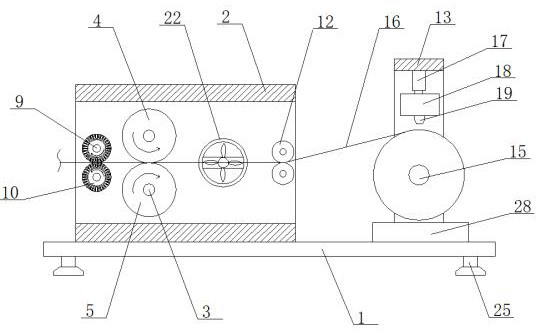

T8 carbon steel cold rolling production device

PendingCN113926855AReduce power consumptionEvenly distributedWork cleaning devicesMetal rolling arrangementsCarbon steelEngineering

The invention relates to the technical field of T8 carbon steel cold rolling, and discloses a T8 carbon steel cold rolling production device which comprises a base, a box body is fixedly connected to the upper end of the base, roll shafts are symmetrically and rotationally connected to the box body through two first bearings, the shaft walls of the two roll shafts located in the box body are fixedly sleeved with an upper cold roll and a lower cold roll correspondingly, the shaft walls of the two roll shafts located outside the box body are fixedly sleeved with large gears, the two large gears are meshed with each other, one side of the base is fixedly connected with a mounting plate, and the two roll shafts are rotationally connected with the mounting plate through two bearings. According to the T8 carbon steel cold rolling production device, before a T8 carbon steel strip is subjected to cold rolling machining, impurities attached to the T8 carbon steel strip can be removed, so that the flatness of the T8 carbon steel strip rolled by a cold rolling roller is prevented from being affected, and the T8 carbon steel strip can be evenly coated with anti-rust oil, so that the anti-rust effect on the T8 carbon steel strip is better.

Owner:浙江豪环新材料有限公司

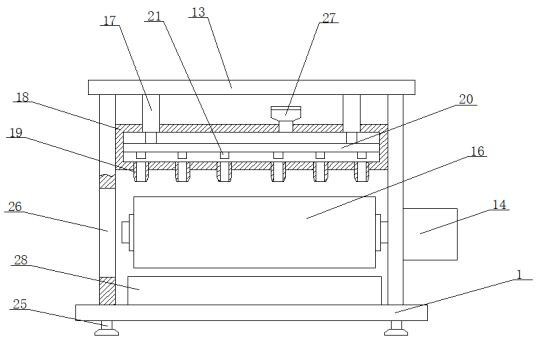

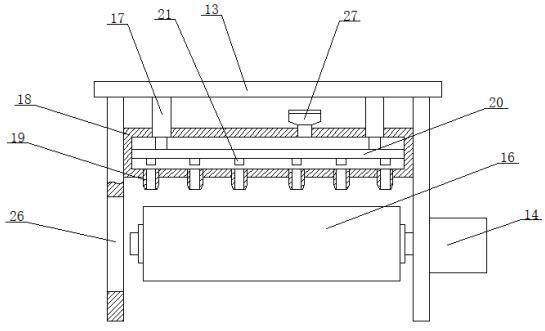

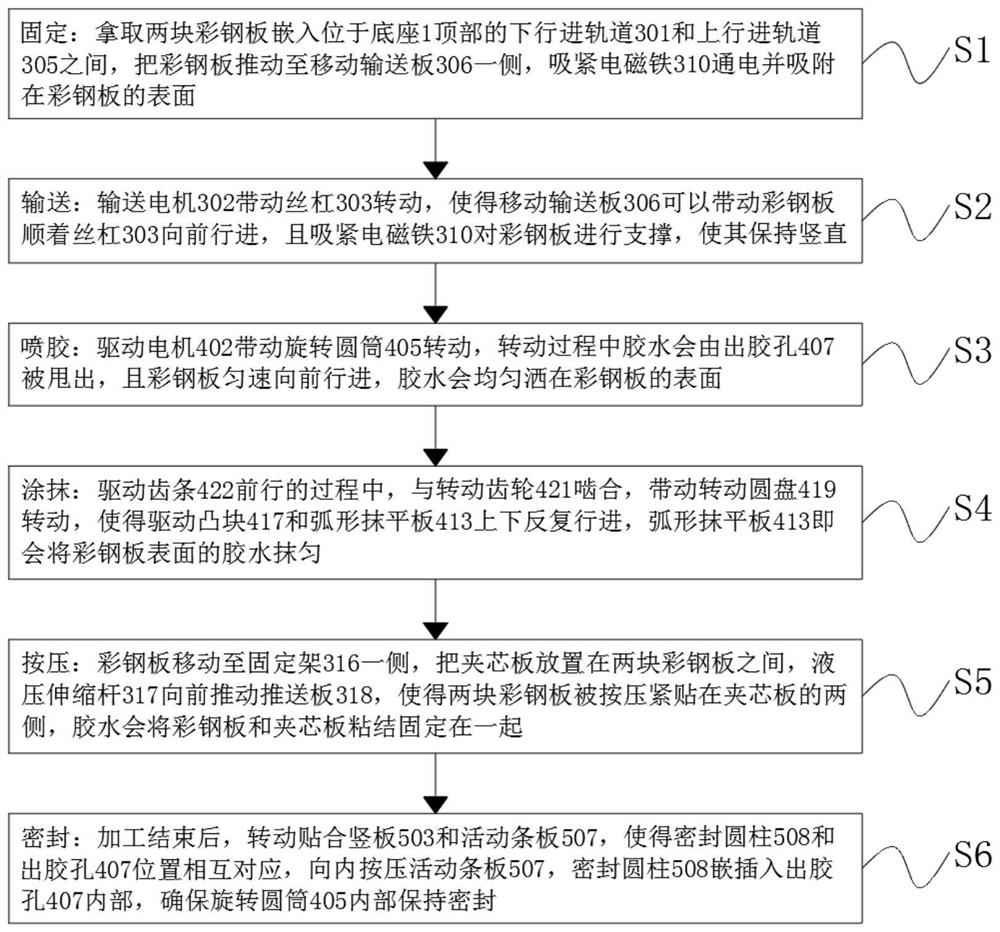

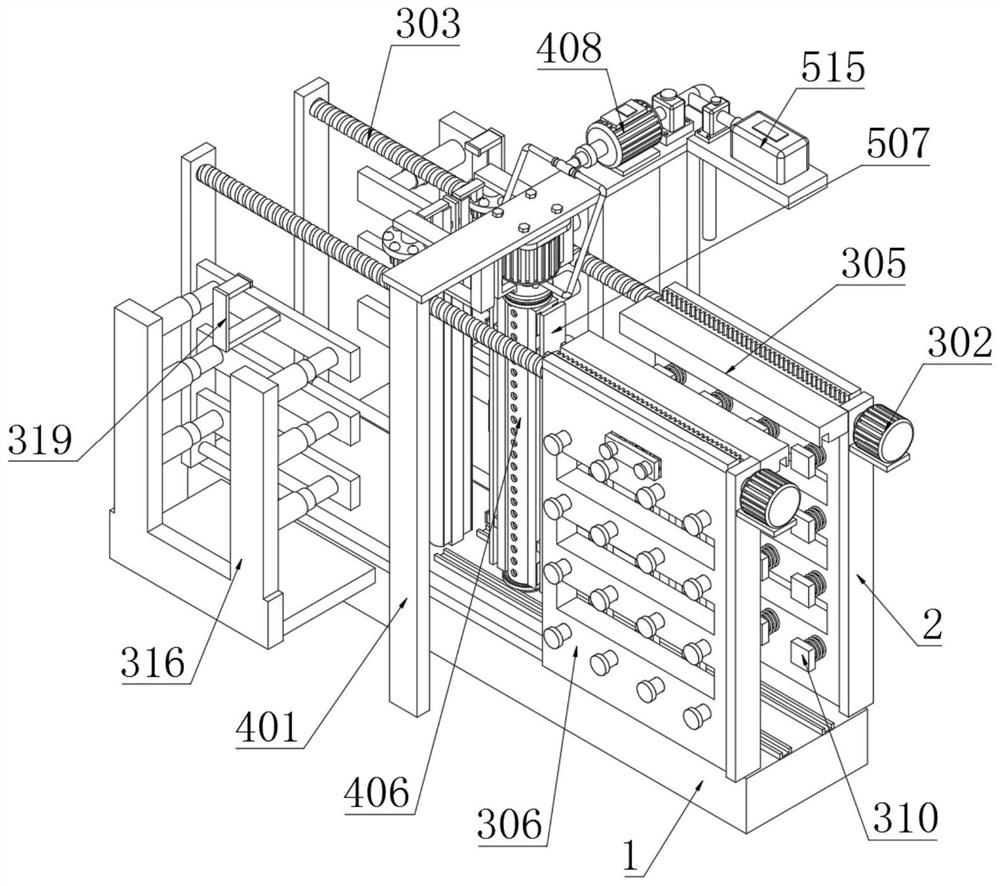

Preparation method of high-strength composite color steel plate

PendingCN114161785AScientific and reasonable structureEasy to useLamination ancillary operationsLaminationSuction forceAdhesive glue

The invention discloses a preparation method of a high-strength composite color steel plate, which comprises the following steps of: fixing: taking two color steel plates, embedding the color steel plates between a lower advancing track and an upper advancing track which are positioned at the top of a base 1, pushing the color steel plates to one side of a movable conveying plate, and electrifying an attraction electromagnet and adsorbing the attraction electromagnet on the surfaces of the color steel plates. Meanwhile, the two color steel plates are vertically and forwards conveyed, the two color steel plates can be directly attached to the two sides of the sandwich plate in the follow-up process conveniently, when the color steel plates move forwards to one side of the movable conveying plate along the lower advancing track and the upper advancing track, the suction electromagnets generate certain suction force, and the color steel plates are made of metal and attract the suction electromagnets; and the limited positions of the color steel plates cannot be changed, the suction force pulls the suction electromagnets to move forwards, the reset springs are lengthened, the suction electromagnets located on the two sides adsorb and fix the color steel plates, the two color steel plates can be conveyed and coated with glue at the same time, and the working efficiency is improved.

Owner:朱爱民

Rubber extruding and spraying device

The invention relates to a rubber extruding and spraying device and solves the problems that water flow impact easily impacts shallow pits on a rubber strip and the water flow difficultly covers the whole width of the rubber strip of the rubber strip spraying device in the prior art. The device comprises a conveying trough for conveying rubber strips, wherein a water supply pipe is arranged at the upper part of the conveying trough; a plurality of nozzles are uniformly arranged on the water supply pipe along the rubber strip conveying direction; the device is characterized in that each nozzle comprises a nozzle body; a vertical water channel is formed in each nozzle body; the upper end of each water channel is connected with the water supply pipe; a lower end opening of each water channel is a horn-shaped opening extended upwards; an umbrella-shaped adjusting block capable of adjusting up and down is arranged on the lower side of the lower end opening of each water channel; the top surface of each umbrella-shaped adjusting block is a conical surface; axes of the conical surfaces are in flush with the axes of the water channels. The rubber extruding and spraying device is large in water curtain coverage range; the water uniformly drops; the impact on the rubber strips is reduced; the shallow pits are avoided; with cooperation of coarse adjusting threads and fine adjusting threads, the positions of the umbrella-shaped adjusting blocks can be adjusted, so that the water yield and the water curtain shape can be adjusted.

Owner:浙江百纳橡塑设备有限公司

Shell-tube type dripping heat exchanger

InactiveCN105973035ASimple structureLess man-hours are required for productionStationary conduit assembliesEngineeringPlate heat exchanger

The invention provides a shell-and-tube dripping heat exchanger, which includes a heat exchanger cylinder, a distributor, a heat exchange tube and a liquid collector, and the distributor, heat exchange tube and liquid collector are arranged in the cylinder , the liquid collector is arranged between the tube groups of the heat exchange tubes. The distributor includes a liquid inlet, a filter screen, a cover plate, a liquid baffle, and a distribution plate, the liquid inlet is arranged outside the heat exchanger cylinder, and the filter mesh is arranged below the liquid inlet , the cover plate is set under the filter screen, the liquid baffle plate is set on both sides of the cover plate, the distribution plate is set under the cover plate and the two ends are against the cover plate Next, the distribution plate has a plurality of flow ports equally spaced along its width direction. In the shell-and-tube dripping heat exchanger of the present invention, a distributor with a very simple structure is arranged above the heat exchange tube group. The distributor has only one layer of distribution plates, and the structure is very simple, so less man-hours are required for manufacture.

Owner:胡建英

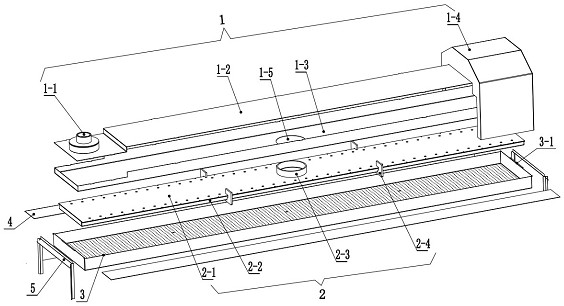

Vacuum belt dryer

PendingCN109966765AImprove continuitySolve the problem of long time and easy sex changeEvaporator accessoriesEvaporation by sprayingEngineeringSlurry

A vacuum belt dryer is disclosed which includes a cylinder body, multiple conveyor belt layers arranged inside the cylinder body, a feeding system and a discharging system. Conveying motors of conveyor belts convey a slurry raw material from feeding ends to discharging ends synchronously. The feeding system achieves material supplying through screw pumps and feeding branch pipelines, with the number of the screw pumps being same as the number of the conveyor belt layers. Swing arms on a vertical shaft and extending to feeding ends of the conveyor belt layers are driven to swing back and forthby a material paving motor through a crank. Material nozzles on the swing arms and communicating with the feeding branch pipelines uniformly arrange the slurry raw material onto the conveyor belts. The discharging system includes a discharging pipe in which a screw rod is arranged. A crusher, a first discharging valve, a middle storage tank, a second discharging valve and a powder outlet are arranged in order below the discharging end of the discharging pipe. The vacuum belt dryer can achieve automatic continuous drying, a high drying efficiency, uniform distribution of the slurry raw material, smooth discharging of a finished dried product, convenient maintenance, and good product quality after drying.

Owner:内蒙古恒光大药业股份有限公司

Inkjet head and driving method thereof, and ink-jet device

The present invention provides an inkjet head and a driving method thereof, and an ink-jet device. The inkjet head comprises a conductive layer, a piezoelectric material layer and an inkjet nozzle. The piezoelectric material layer is located between the conductive layer and the inkjet nozzle, and the inkjet nozzle is communicated with a pressure chamber; a first voltage is located in the pressurechamber to allow ink in the pressure chamber to be loaded with the first voltage; and a second voltage is loaded on the conductive layer to form a voltage difference between ink flowing through the inkjet nozzle and the conductive layer, and the piezoelectric material layer is deformed under the action of the voltage difference. The inkjet head and the driving method thereof, and the ink-jet device reduce a phenomenon of an inkjet nozzle being obstructed by ink and can allow ink to be uniformly dropped out from the inkjet nozzle.

Owner:BOE TECH GRP CO LTD

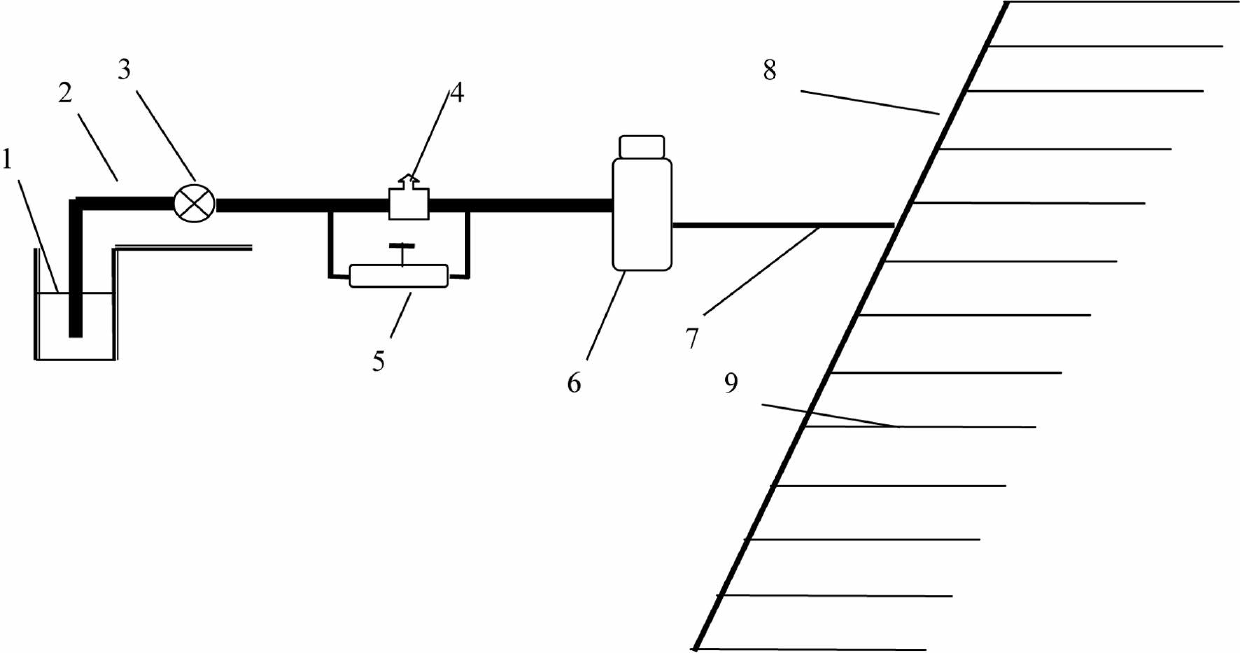

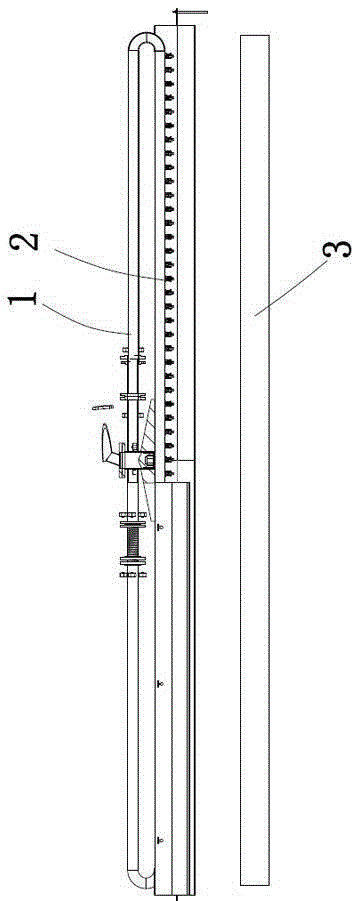

Soil sediment DGT sampling device and method

ActiveCN113447297ARealize field samplingEasy to replaceWithdrawing sample devicesSoil scienceSoil sediment

The invention relates to a soil sediment DGT sampling device and method, belongs to the technical field of soil sampling, and solves the problem that an existing DGT sampler cannot realize field sampling. The soil sediment DGT sampling device comprises a DGT sampler and a water dripping mechanism, the water dripping mechanism comprises a water dripping pipeline and a container, the container is connected with the water dripping pipeline, and purified water in the container continuously drips water to the surface layer of soil at a sampling point through the water dripping pipeline, so that the surface layer of the soil is kept in a wet state; the DGT sampler is arranged on the surface layer of wet soil and is used for adsorbing and sampling from the wet soil. The device is simple in structure and convenient to operate, continuous water dripping is achieved through the water dripping mechanism, soil at a sampling point is kept in a wet state, field sampling is achieved, and the application prospect is wide.

Owner:NAT RESERACH CENT OF GEOANALYSIS

Refrigerant distributor of falling film evaporator for water chilling unit

ActiveCN102661638BDrip evenlyHigh purityEvaporators/condensersFluid circulation arrangementRefrigerant distributionEngineering

A refrigerant distributor of a falling film evaporator for a water chilling unit comprises a refrigerant inlet, an upper porous top plate, a filter screen, a lower porous top plate, a porous bottom plate and side plates, wherein the filter screen is sandwiched between the upper porous top plate and the lower porous top plate, the upper porous bottom plate is positioned below the lower porous top plate, the upper porous top plate, the filter screen, the lower porous top plate, the porous bottom plate and the side plates jointly encircle to form a cavity, more than one distributing pore plate is arranged in the cavity, one end of the refrigerant inlet is provided with an opening after sequentially penetrating through the upper porous top plate, the filter screen and the lower porous top plate, and the opening is arranged above the distributing pore plates. The distributing pore plates include a primary distributing pore plate, the primary distributing pore plate is connected with the side plates and sequentially divides the cavity into two portions from top to bottom, and a first opening is formed between at least one lateral edge of the primary distributing pore plate and the corresponding side plate. The refrigerant distributor is simple and reasonable in structure, flexible in operation, low in manufacturing cost, fine in refrigerant gas and liquid separation effect and uniform in flow distribution.

Owner:谛卓(北京)咨询顾问有限公司

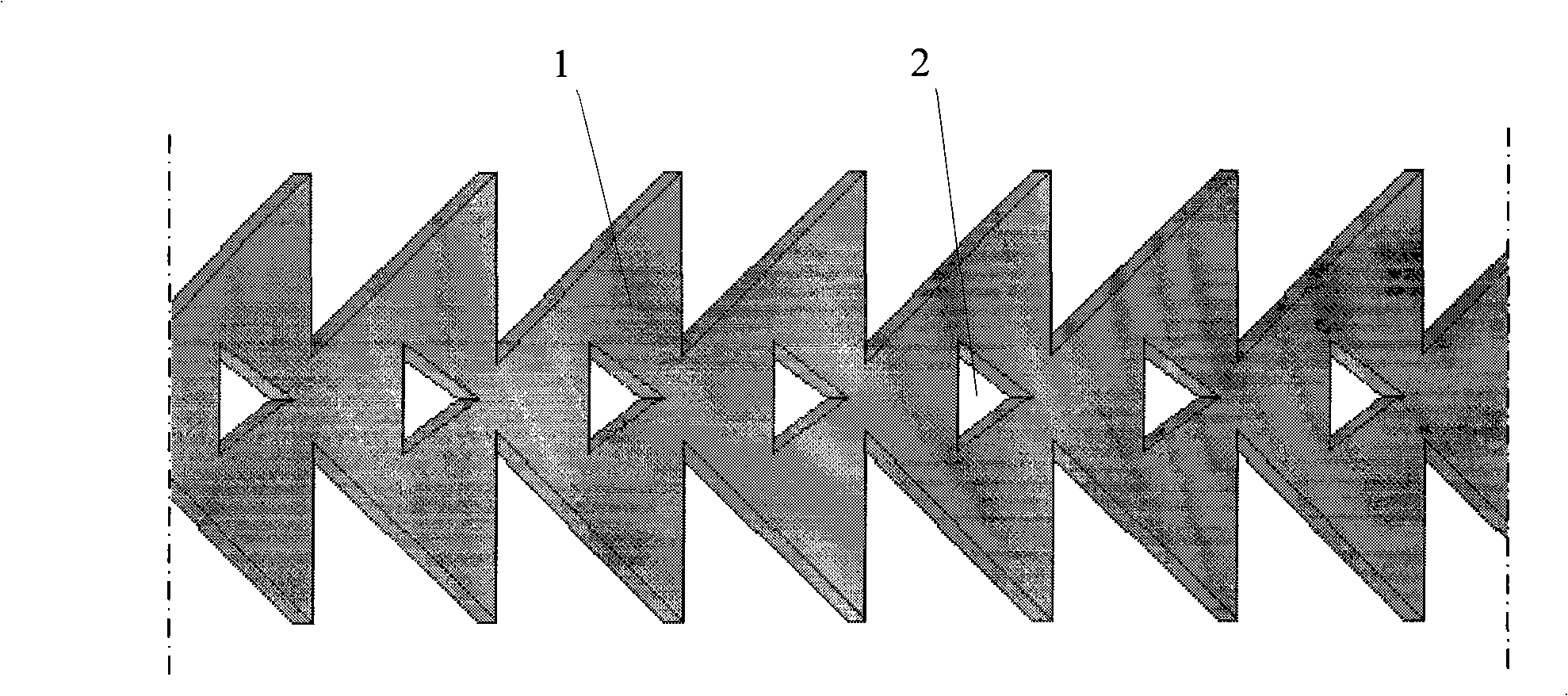

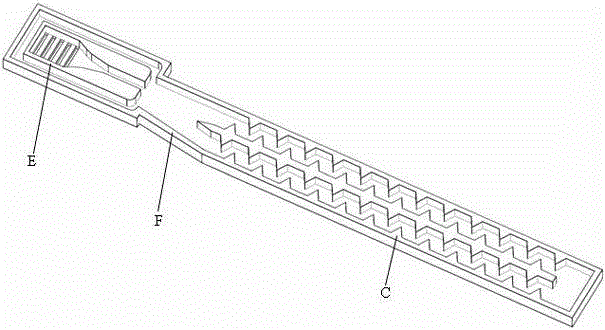

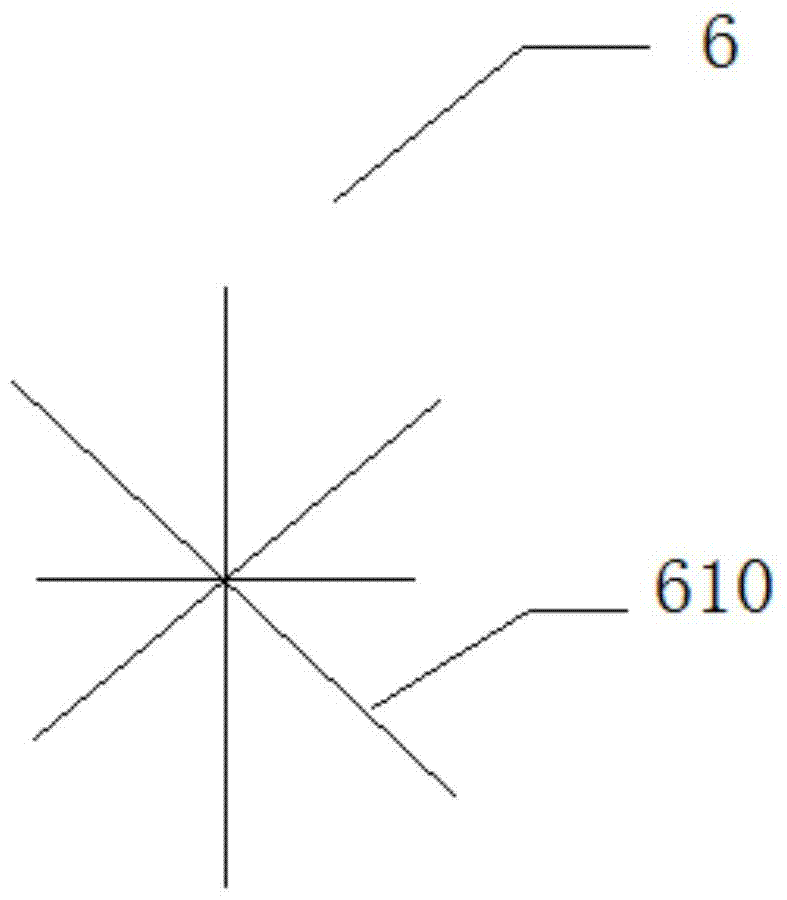

Jet oscillation drop irrigation emitter

InactiveCN102860246BImprove transportation capacityImprove anti-clogging performanceClimate change adaptationWatering devicesField cropElastomer

The invention discloses a jet oscillation drop irrigation emitter which is composed of a water inlet channel, a jet element and a runner body, wherein the water inlet channel is provided with a filter window and is connected with an inlet of the jet element, an outlet of the jet element is connected with an inlet of the runner body, and a water outlet channel is arranged at the tail end of the runner body. Water flow is driven to flow intermittently in two runners by using the Coanda technology and the negative pressure control oscillation technology to achieve the continuous oscillation and pulse process, strong turbulence and impact water flow form in the runners, and blocking resistance and irrigation uniformity of the emitter are improved. Elastic body structures such as rubber, plastic films and springs of the existing drop irrigation pulse generator are omitted, and the jet oscillation drop irrigation emitter has the advantages of being simple in structure and strong in reliability and durability. Materials, processing devices and processing methods of the existing drop irrigation emitter can be adopted, once injection forming is used, and the jet oscillation drop irrigation emitter is simple in processing technique, low in manufacture cost and convenient to install and use. The oscillation pulse drop irrigation emitter in various structural modes can be manufactured, and the jet oscillation drop irrigation emitter can be widely applied to irrigation of field crops, vegetables, forestry, the fruit industry and the like.

Owner:JIANGSU UNIV

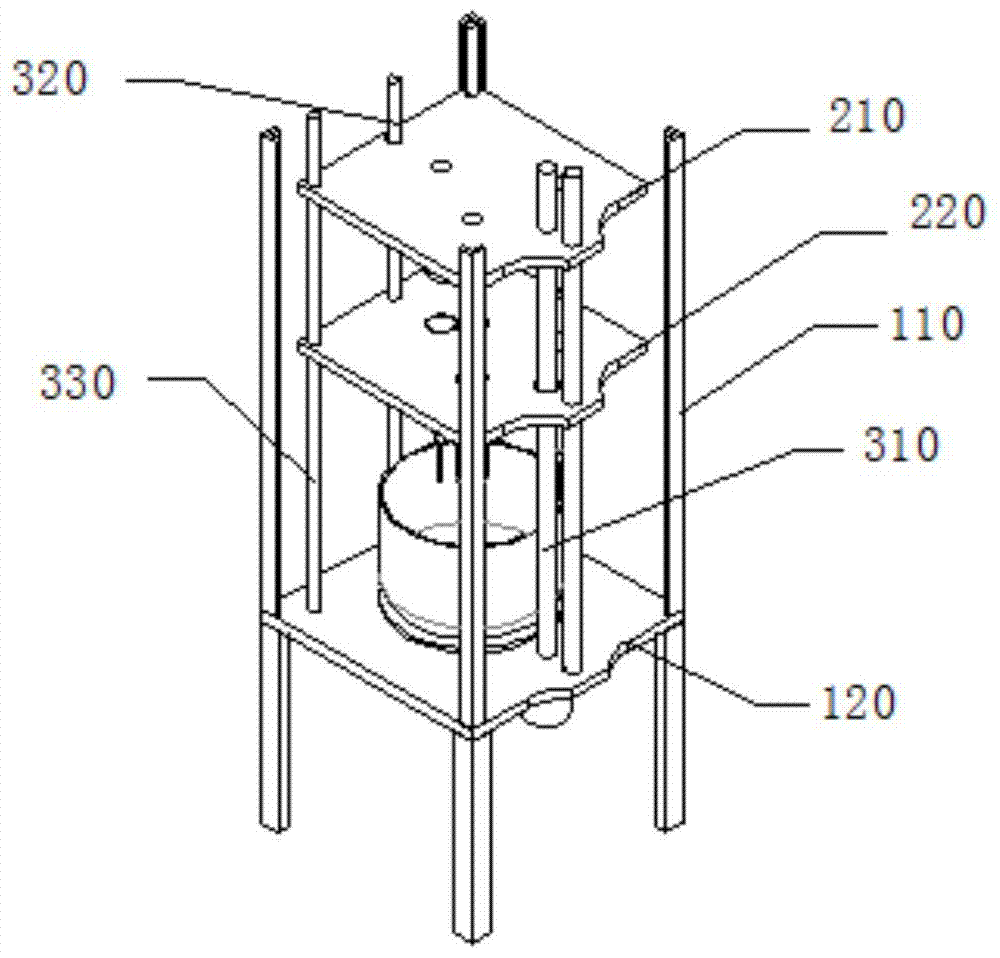

Deamination tower wastewater treatment device and use method thereof

InactiveCN113636613AAdd evenlyDrip evenlyRotary stirring mixersWater contaminantsProcess engineeringMechanical engineering

The invention discloses a deamination tower wastewater treatment device and a use method thereof. The deamination tower wastewater treatment device comprises a treatment tank; the top of the inner wall of the treatment tank is rotationally connected with a first rotating pipe; stirring pipes are fixedly connected to the outer side of the first rotating pipe at equal intervals; the interiors of the stirring pipes are communicated with the interior of the first rotating pipe; and spray heads are fixedly connected to the outer sides of the stirring pipes at equal intervals. The device is compact in structure, simple and convenient to operate and high in practicability. The adding amount of chemicals is metered through a metering mechanism, meanwhile, a driving mechanism is arranged to drive a chemical dripping mechanism to revolve and rotate, so that the chemicals can uniformly drip into waste water, and the chemicals are added more uniformly. Meanwhile, as the first rotating pipe and the stirring pipes with the spray heads are arranged, the inner wall of the equipment can be quickly cleaned after wastewater treatment is completed, manual cleaning operation is not needed, the labor amount of operators is greatly reduced, and actual use is facilitated.

Owner:四川省兴欣钒科技有限公司

Preparation device of solvent-free graphene modified static conductive acrylic resin

ActiveCN109499510BDrip evenlyGuarantee the catalytic effect of the reactionChemical/physical/physico-chemical stationary reactorsFeed devicesTemperature controlPtru catalyst

Owner:林浩

Biological reaction experiment device capable of preventing external bacteria from entering reaction cavity

InactiveCN112337412AAvoid enteringAvoid the problem of introducing bacteriaChemical/physical/physico-chemical processesFeed devicesBiotechnologyEngineering

The invention discloses a biological reaction experiment device capable of preventing external bacteria from entering a reaction cavity, the biological reaction experiment device comprises the reaction cavity, the top end of the reaction cavity is provided with a top cover, the upper surface of the top cover is connected with a liquid storage box, and the bottom ends of a sleeve and a collection box are both connected with a base located at the bottom end of the interior of a containing box; grooves are symmetrically formed in the upper surface of the base, a display screen is installed at thefront end of the reaction cavity, a box door is installed at the front end of the containing box, and a handle is fixedly connected to the outer surface of the box door. According to the biological reaction experiment device capable of preventing external bacteria from entering the reaction cavity, reaction raw materials are put into the containing box firstly and then conveyed into the reactioncavity through a carrier plate, the problem that the bacteria are brought into the reaction cavity when the hands stretch into the reaction cavity to place the raw materials can be avoided, and it isguaranteed that a reaction experiment is not disturbed by the outside; and raw materials left on the carrier plate after reaction are scraped by a scraping plate, so that the raw materials are convenient to clean and take out.

Owner:诸暨市福生源农业开发有限公司

An automatic gluing device for shoemaking machines for intelligent manufacturing

The invention provides an automatic gluing device for shoe-making machines for intelligent manufacturing, which includes a casing, a controller is fixedly installed on the right side of the inner cavity of the casing, and a glue bucket is fixedly installed on the top of the inner cavity of the casing. A connecting pipe is fixedly installed on the left side at the bottom of the glue bucket. The automatic gluing device of the shoemaking machine for intelligent manufacturing, by setting the switch and the vertical bar, the sole that needs to be glued is placed on the top of the lower mold, and the lower mold moves down under the action of the gravity of the sole, thereby pressing the start switch, and at the same time The controller controls the dispensing tube to drip glue. At the same time, when the lower mold moves down, the vertical bar drives the horizontal plate to press down the glue inside the dispensing column, so that the glue inside the dispensing column drips evenly to the soles. The two are combined with each other. Compared with other similar devices, this device automatically controls the start and stop of the dispensing column through the gravity of the sole, and at the same time uses the cross bar to make the dispensing column drip glue evenly, preventing the sole from affecting the bonding effect due to the difference in the amount of glue.

Owner:温岭市凯达鞋业有限公司

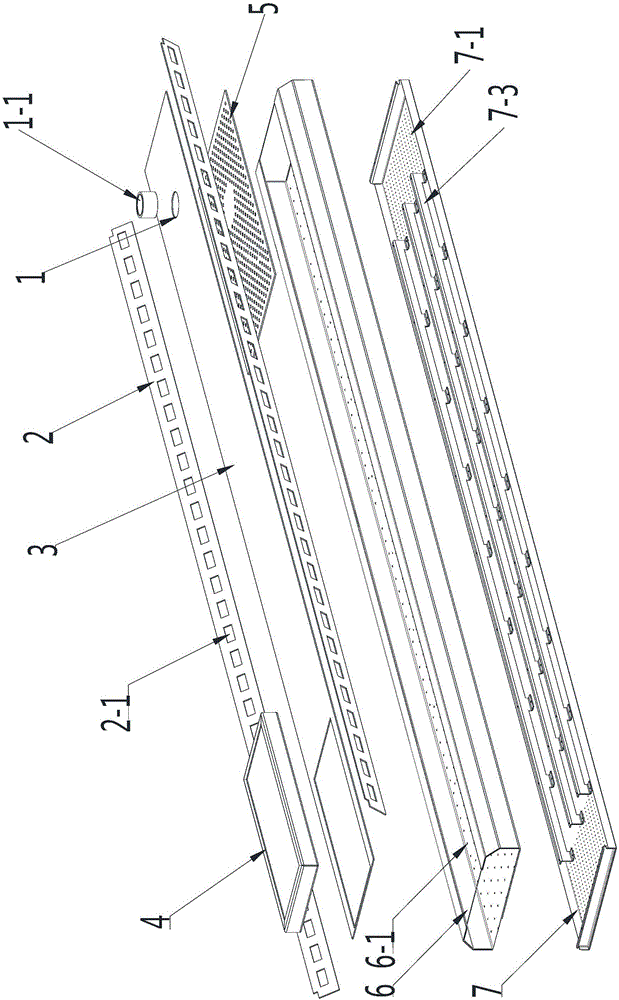

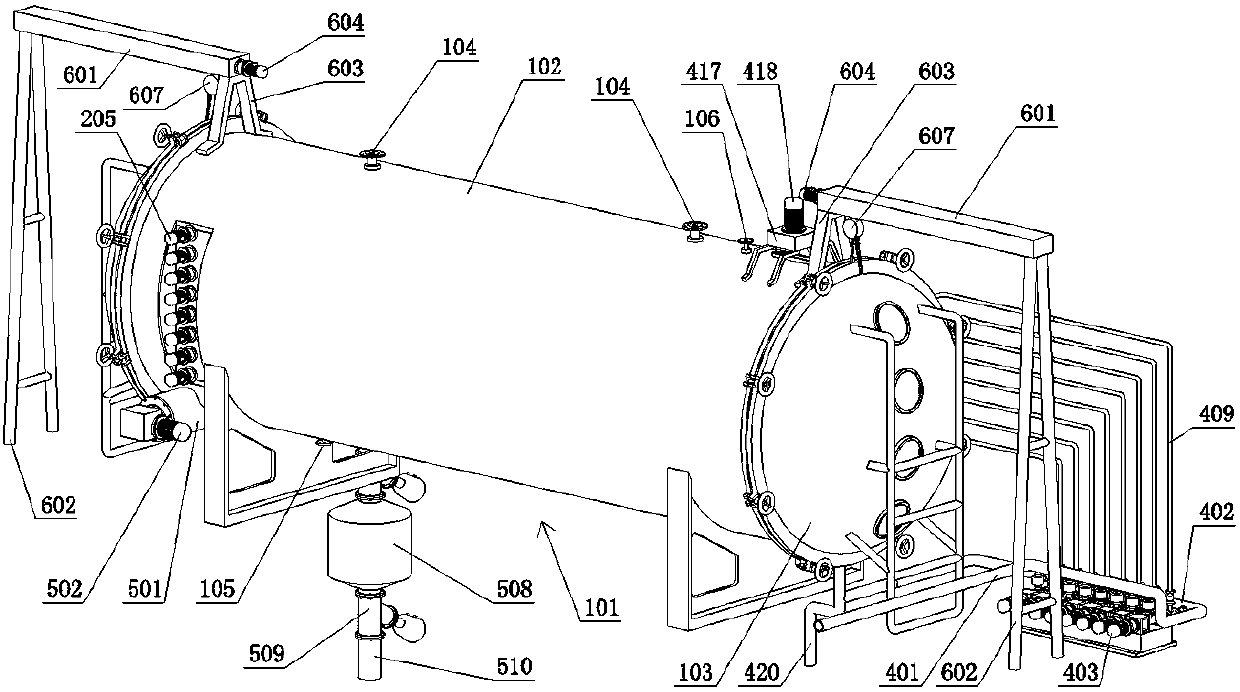

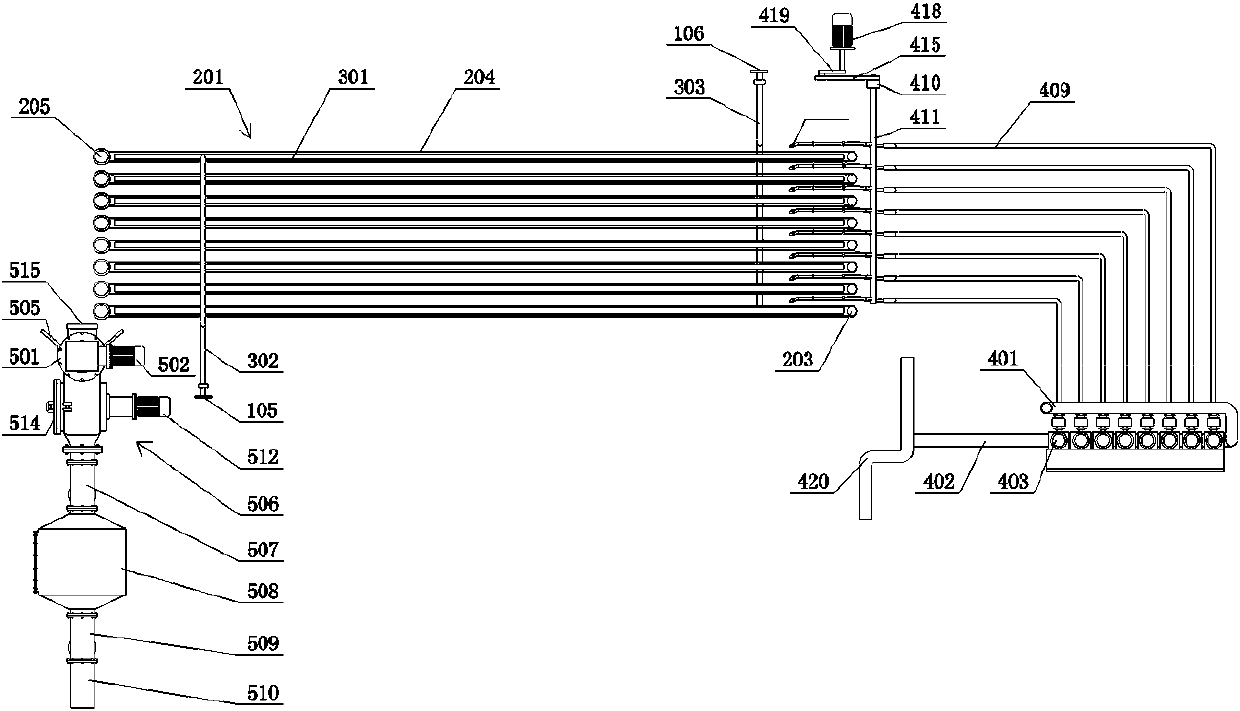

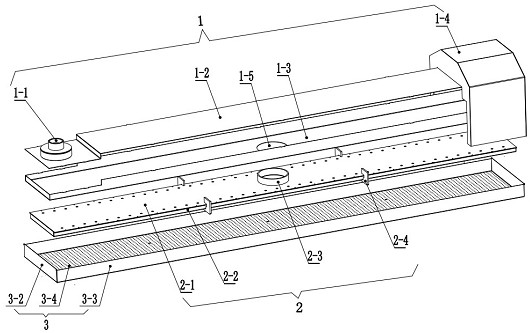

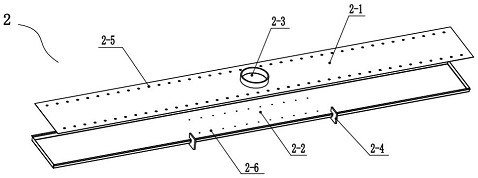

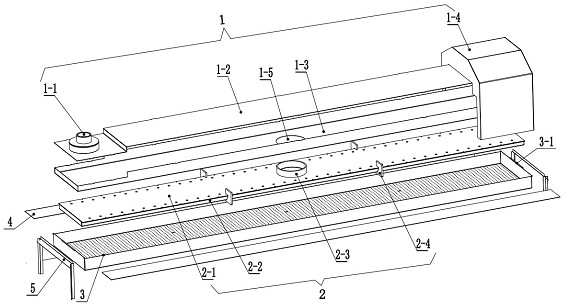

Distributor for falling-film evaporator of low-pressure refrigerating system

ActiveCN113970198ATackle splashEvenly distributedEvaporators/condensersTrickle coolersVapor–liquid separatorEngineering

The invention relates to a distributor for a falling-film evaporator of a low-pressure refrigerating system. The distributor comprises a gas-liquid separator, a channel assembly and a dripping plate; the gas-liquid separator comprises a gas-liquid separation cavity formed by matching of a first bottom plate and a first top plate, the first top plate comprises a liquid inlet plate and a gas storage plate which are connected, a liquid inlet is formed in the liquid inlet plate, a gas outlet is formed in the gas storage plate, the gas outlet is communicated with a gas guide cover, and a liquid outlet is formed in the first bottom plate; the channel assembly comprises a second top plate and a second bottom plate which are matched to form a sealed cavity, the second top plate is provided with a liquid inlet pipe and a plurality of liquid drainage holes, the liquid inlet pipe corresponds to the liquid outlet, and the plurality of liquid drainage holes are formed in the length direction of the second top plate; and the dripping plate comprises a rectangular shell, a plurality of dripping holes are formed in a third bottom plate of the dripping plate, the channel assembly is arranged in the dripping plate, and the gas-liquid separator is arranged on an end plate of the dripping plate. The speed of a liquid refrigerant flowing to the dripping plate is reduced through the liquid drainage holes, the splashing problem is solved, the refrigerant in the dripping plate is evenly distributed, and the heat exchange effect of a heat exchange pipe is guaranteed.

Owner:顿汉布什(中国)工业有限公司

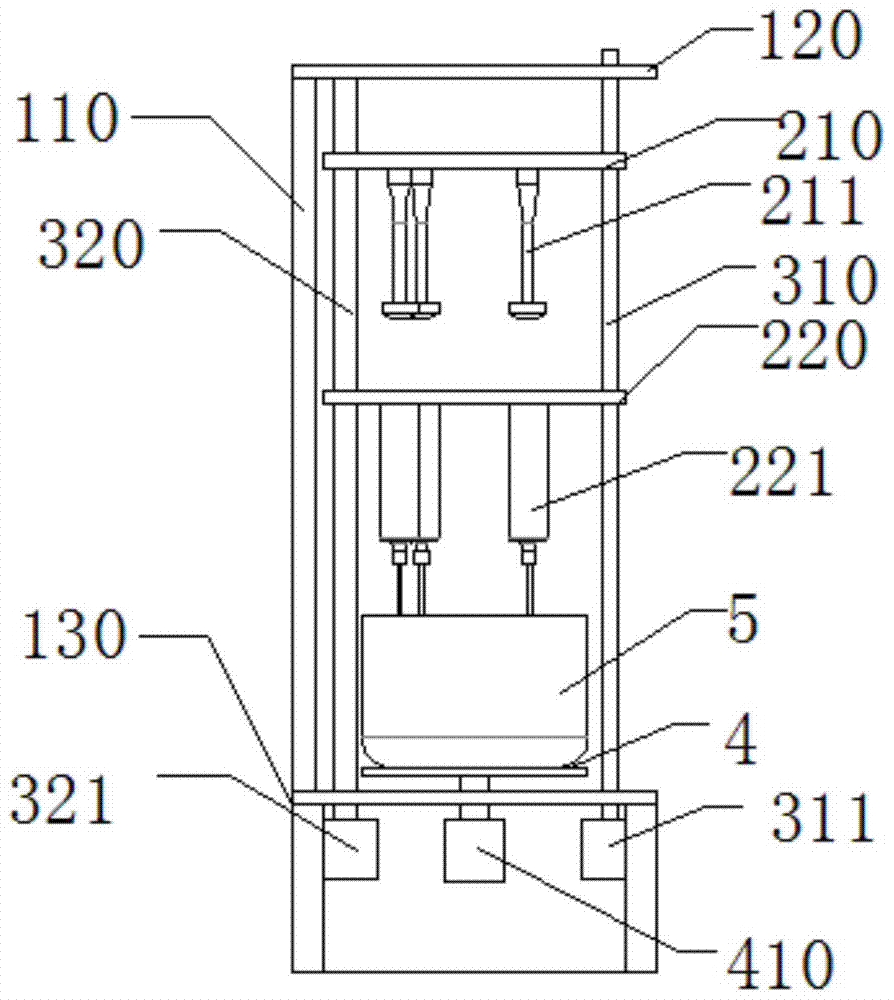

liquid drip device

The invention discloses a liquid dripping device. The liquid dripping device comprises a frame body, a first movable plate, a second movable plate, at least one first slide rod, at least one second slide rod and at least one third slide rod, wherein the first movable plate and the second movable plate are parallel to each other and are arranged between a first fixed plate and a second fixed plate, the first movable plate is positioned above the second movable plate, a plurality of syringe pistons with the injection direction facing downwards are clamped on the first movable plate, and a plurality of syringe sleeves with needles facing downwards matched with the syringe pistons are clamped on the second movable plate; the first movable plate and the second movable plate are driven to move up and down by controlling the slide rods to move up and down so as to control the dripping of liquid and the distance, liquid can be uniformly dropped on an object in a container by controlling the rotation of a rotating plate, and the dripping uniformity and dripping amount can be increased by arranging the slide rods and the rotating plate, so that the dripping operation can be easily carried out manually, and the dripping efficiency can be improved.

Owner:GUANGXI POLYTECHNIC

A soil sediment dgt sampling device and method

ActiveCN113447297BRealize field samplingEasy to replaceWithdrawing sample devicesSoil scienceSoil sediment

The invention relates to a soil sediment DGT sampling device and method, belongs to the technical field of soil sampling, and solves the problem that the existing DGT sampler cannot realize field sampling. The soil sediment DGT sampling device includes a DGT sampler and a dripping mechanism. The dripping mechanism includes a dripping pipeline and a container. The container is connected to the dripping pipeline. The pure water in the container drips continuously to the soil surface of the sampling point through the dripping pipeline, so that the soil surface layer Keep the wet state; DGT sampler is placed on the wet soil surface for adsorption sampling from the wet soil. The invention has the advantages of simple structure and convenient operation. By setting the dripping mechanism to continuously drip water, the soil of the sampling point is kept in a moist state, and field sampling is realized, and the application prospect is wide.

Owner:NAT RESERACH CENT OF GEOANALYSIS

Sprayer

The invention relates to the field of environmental protection equipment, and particularly provides a sprayer which comprises a tower body, a water distribution plate and a spraying assembly; the water distribution plate and the spraying assembly are located in the tower body, the water distribution plate is transversely arranged in the tower body and divides the tower body into an upper cavity and a lower cavity, and a plurality of water holes are formed in the water distribution plate; a spray head of the spraying assembly is used for spraying chemicals to the water distribution plate. An air inlet hole is formed in the bottom of the tower body, a spacer ring extending upwards is arranged on the air inlet hole, a water collecting tank is formed in a space between the spacer ring and theside wall of the tower body, and the water collecting tank is used for collecting chemicals falling from the water holes. According to the sprayer, due to the arrangement of the water distribution plate, the residence time of waste gas in the tower body can be prolonged; meanwhile, the waste gas flow speed can be controlled, and the waste gas uniformly flows everywhere in the tower body; furthermore, the water distribution plate can also control the spraying direction of the chemicals, so that the chemicals uniformly drip at each part of the lower cavity. Waste gas is subjected to spraying treatment through the sprayer, and the cooling and dust removing effects are obviously superior to those of a spraying tower in the prior art.

Owner:山东圣大环保工程有限公司

Jet flow pulse drip irrigation emitter and drip irrigation method

InactiveCN102577911BImprove transportation capacityImprove anti-clogging performanceClimate change adaptationWatering devicesElastomerWater flow

The invention belongs to the technical field of agricultural water-saving irrigation, relating to a drip irrigation emitter and especially to a jet flow pulse drip irrigation emitter and a drip irrigation method. The jet flow pulse drip irrigation emitter is composed of a water inlet groove, a jet flow pulse generator, a flow channel and a water outlet groove, the water inlet groove is provided with a filtering window and is communicated with the jet flow pulse generator, the jet flow pulse generator is communicated with the flow channel, and the water outlet groove is situated on the tail end of the flow channel. Jet flow control technology is used for driving water stream to intermittently flow in two flow channels so as to realize a continuous pulse process, form strong turbulent motion and impact water stream in the flow channels and reinforce the anti-clogging capability and irrigation uniformity of the drip irrigation emitter. The jet flow pulse drip irrigation emitter omits such elastomer structures of the current drip irrigation pulse generator, such as rubber, plastic film and spring, and the like, and the jet flow pulse drip irrigation emitter has simple structure, good reliability and strong durability, so that the jet flow pulse drip irrigation emitter can be extensively suitable for the irrigation demands of filed crops, vegetables and forest and fruit industry.

Owner:JIANGSU UNIV

A distributor for falling film evaporator of low pressure refrigeration system

ActiveCN113970198BTackle splashEvenly distributedEvaporators/condensersTrickle coolersVapor–liquid separatorEngineering

The invention relates to a distributor for a falling film evaporator of a low-pressure refrigeration system, which includes a gas-liquid separator, a channel assembly and a drip tray; the gas-liquid separator includes a gas-liquid separation chamber formed by cooperation of a bottom plate and the top plate , the top plate includes a connected liquid inlet plate and a gas storage plate, the liquid inlet plate is provided with a liquid inlet, the gas storage plate is provided with an air outlet, the air outlet is connected to the air guide cover, and the bottom plate is provided with a liquid outlet; The channel assembly includes the top plate 2 and the bottom plate 2 that cooperate to form a sealed cavity. The top plate 2 is provided with a liquid inlet pipe and a plurality of liquid discharge holes. The liquid inlet pipe corresponds to the liquid outlet. The length direction is set; the drip tray includes a rectangular shell, the bottom plate 3 of the drip tray is provided with a plurality of drip holes, the channel assembly is arranged in the drip tray, and the gas-liquid separator is on the end plate of the drip tray. The liquid discharge hole reduces the speed of the liquid refrigerant flowing to the drip tray, solves the problem of splashing, makes the refrigerant in the drip tray evenly distributed, and ensures the heat exchange effect of the heat exchange tube.

Owner:顿汉布什(中国)工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com