Jet flow pulse drip irrigation emitter and drip irrigation method

A technology of irrigators and pulse generators, which is applied to botany equipment and methods, watering devices, climate change adaptation, etc., and can solve the problems affecting the long-term operation and use of pulse drip irrigation systems, sensitivity, reliability decline, and pulse generators. Complicated structure and other problems, to achieve the effect of increasing anti-clogging ability, improving transportation capacity, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

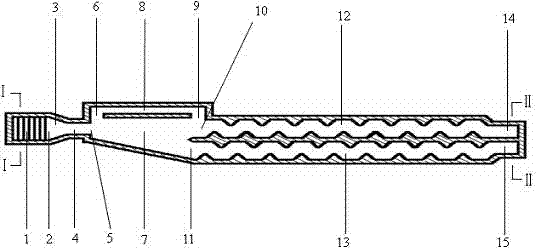

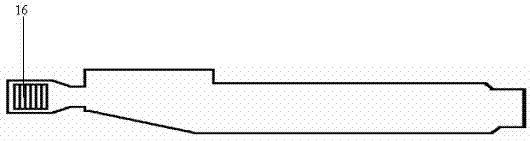

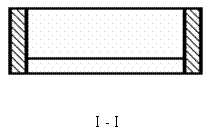

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 , the bottom of the water inlet tank 1 is provided with a filter window 16, and the end of the water inlet tank 1 is connected to the inlet 2 of the jet pulse generator; the jet pulse generator is composed of the inlet 2 of the jet pulse generator, the contraction section 3, the diversion section 4, the jet nozzle 5, and the control port 6. Jet space 7, control channel 8, signal port 9, straight jet outlet 10 and oblique jet outlet 11, the front end of the jet pulse generator is the jet pulse generator inlet 2, and the front of the jet pulse generator inlet 2 is connected to the water inlet tank 1 , the back of the jet pulse generator inlet 2 is connected to an inverted trumpet-shaped constriction section 3 with a large front and a small rear. The constriction section 3 is connected to a rectangular diversion section 4. The rectangular diversion section 4 is connected to a jet nozzle 5. A control port 6 is set on t...

Embodiment 2

[0026] refer to Figure 5 , figure 2 , Figure 6 , Figure 7 , the basic structural features are similar to Embodiment 1, and the difference from Embodiment 1 is that the water outlet groove is connected to form a jet pulse drip irrigation emitter with only one water outlet, and the water outlet groove 17 is located in the straight jet flow channel 12 and the oblique jet flow channel 13 Connect the ends of the two flow channels so that the two flow channels share one outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com