Automatic loading and unloading logistics vehicle

A technology for automatic loading and unloading, logistics vehicles, applied in motor vehicles, vehicles with inclined bearing motion, transportation and packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

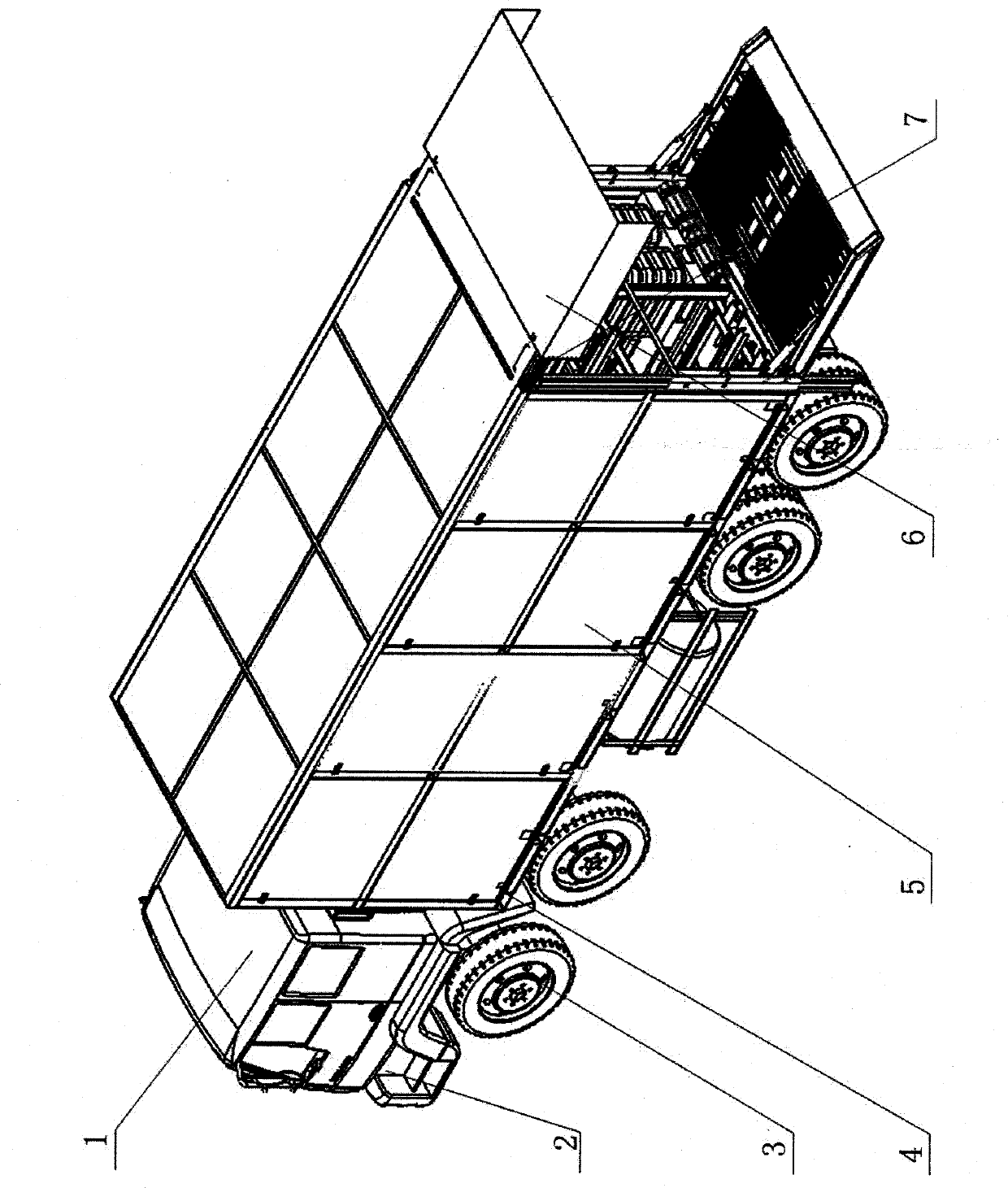

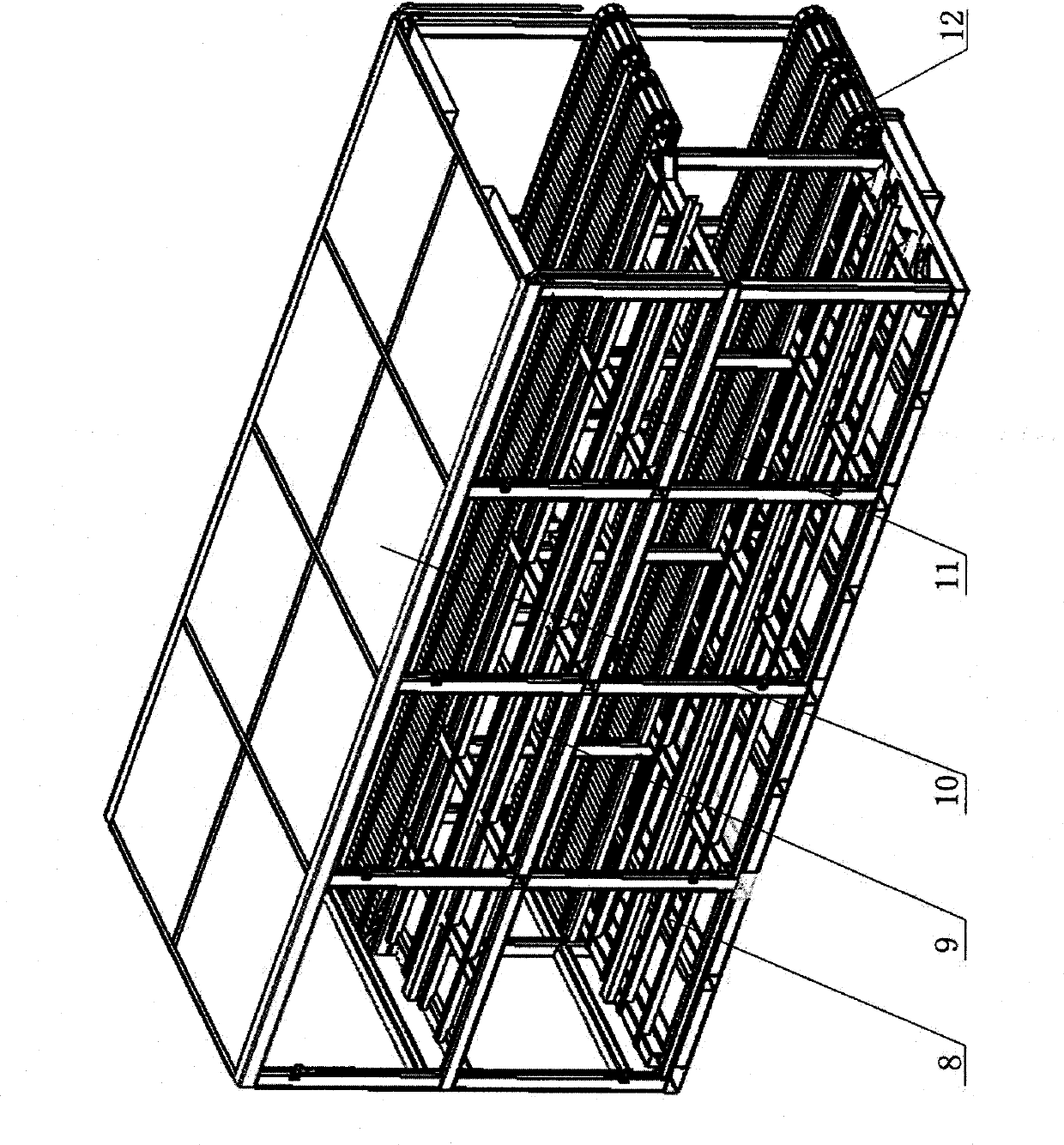

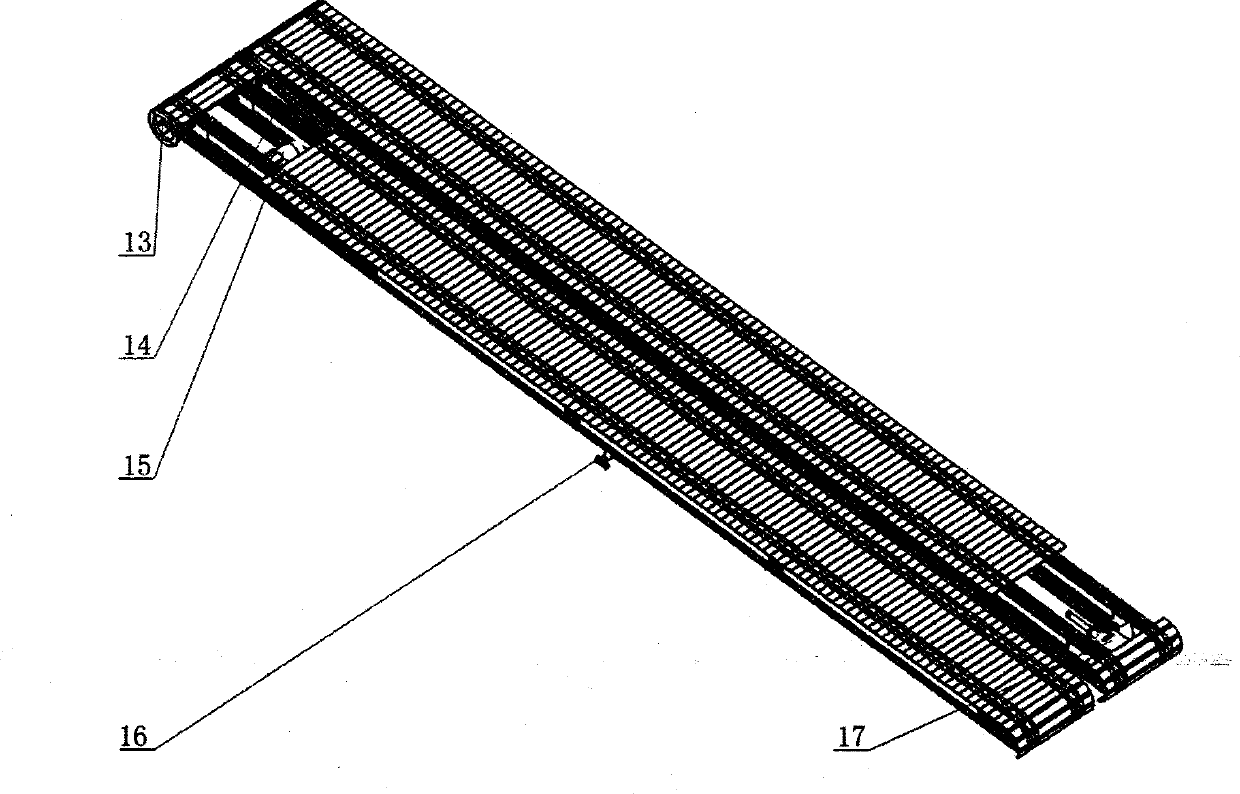

[0017] A kind of automatic loading and unloading logistics vehicle involved in embodiment 1, its structure is as follows Figure 1-Figure 6 Shown: The automatic loading and unloading logistics vehicle is mainly composed of a frame, a compartment, a tailgate system, a conveying system, a strapping system and a hydraulic control system. Among them, the frame is mainly composed of cab 1, chassis 2, wheels 3 and transmission 4; The system is mainly composed of track 11, chain plate 12, idler roller 16, chain plate tensioning device 17, chain plate drive shaft 13, reducer 14 and hydraulic motor 15; the tail lift system is mainly composed of frame 18, tail lift conveying system 19, The tail plate turning cylinder 20, the tail plate guide 21, the lifting cylinder 23 and the lifting chain 22 are composed; the binding system is mainly composed of cargo binding ropes 24, tensioning ropes 25, tensioning sliding rings 26, springs 27, spring guides 29 and tightening devices 28; the hydrau...

Embodiment 2

[0020] A kind of automatic loading and unloading logistics vehicle involved in embodiment 2 can change the compartment in embodiment 1 into one floor, as Figure 7 Shown, its work process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com