Deamination tower wastewater treatment device and use method thereof

A technology for wastewater treatment and deamination tower, which is used in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. It can solve the problem of inability to complete automatic cleaning operations, increase operator labor, and add chemicals. Insufficient uniformity and other problems, to achieve the effect of compact structure, reduced labor, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

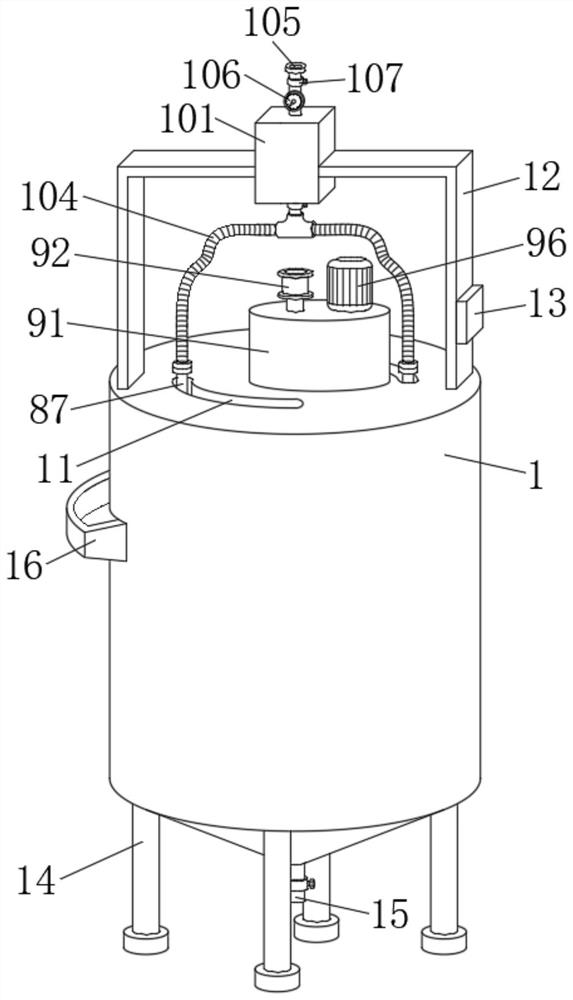

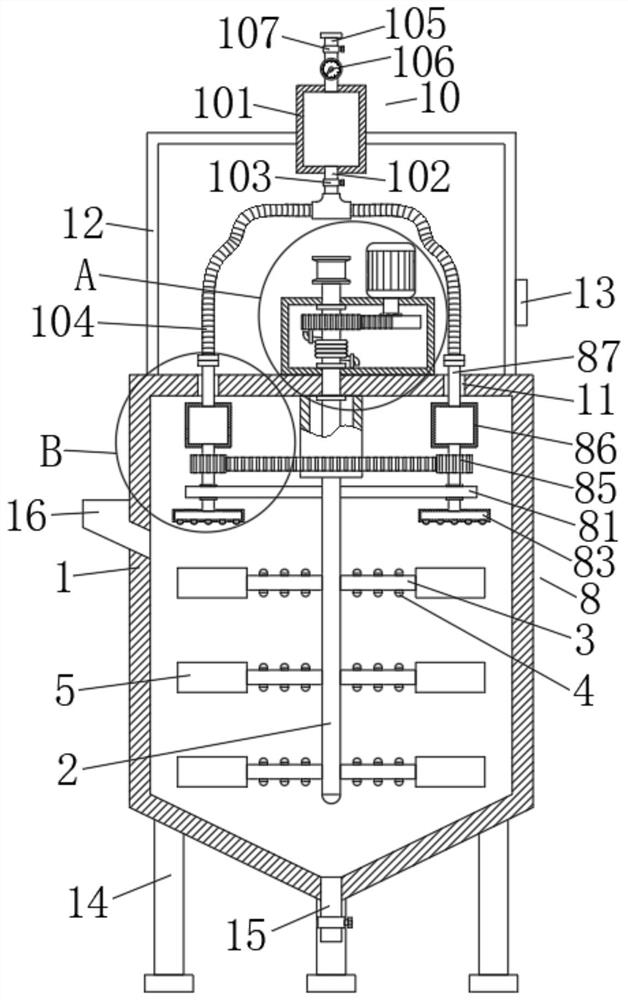

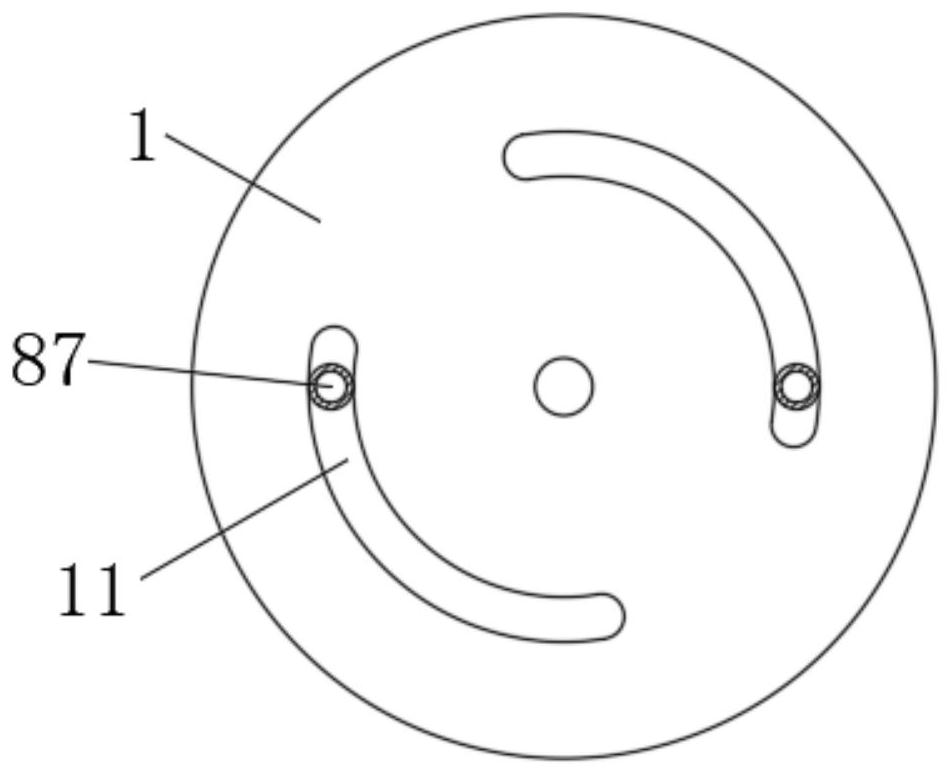

[0028] A deamination tower wastewater treatment device, comprising a treatment tank 1, the top of the inner wall of the treatment tank 1 is rotatably connected with a first rotating tube 2, and the outside of the first rotating tube 2 is equidistantly fixedly connected with a stirring tube 3, so The inside of the stirring tube 3 is connected with the inside of the first rotating tube 2, so that the cleaning liquid inside the first rotating tube 2 can be better transported to the inside of the stirring tube 3; There is a nozzle 4, through which the cleaning liquid can be better sprayed, thereby cleaning the inner wall of the treatment tank 1; the inside of the nozzle 4 is provided with a one-way valve, and by setting the one-way valve, it is convenient to better prevent waste water It flows into the inside of the stirring tube 3; the end of the stirring tube 3 away from the first rotating tube 2 is fixedly connected with a stirring blade 5, which facilitates better stirring of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com