Novel micro-irrigation belt and preparation method and application thereof

A technology of micro-irrigating tape and belt, which is applied in the field of new micro-irrigating tape and its preparation, to achieve the effect of uniform micropore distribution, easy installation and good anti-blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The raw material components and weight percentages of the micro-irrigation tape are:

[0044] Polyethylene particles 55% (w / w); antioxidant 9% (w / w); EVA particles 17% (w / w); toner 3% (w / w), defoamer 7% (w / w); toughening agent 9% (w / w); put the above ingredients into the container according to the proportion, stir evenly, enter the mold cavity to melt and plasticize at 130-150°C, extrude through the mold, and cool. Pulled by the tractor, the product is rolled into the winder to form the product. The diameter of the drip irrigation belt is 30mm, the wall thickness is 0.15mm, and the aperture is 0.6mm.

Embodiment 2

[0046] The raw material components and weight percentages of the micro-irrigation tape are:

[0047] Polyethylene particles 65% (w / w); antioxidant 8% (w / w); EVA particles 12% (w / w); toner 2% (w / w), defoamer 6% (w / w); toughening agent 7% (w / w); put the above ingredients into the container according to the proportion, stir evenly, enter the mold cavity to melt and plasticize at 130-150°C, extrude through the mold, and cool. Pulled by the tractor, the product is rolled into the winder to form the product. The diameter of the drip irrigation belt is 45mm, the wall thickness is 0.3mm, and the hole diameter is 0.8mm.

Embodiment 3

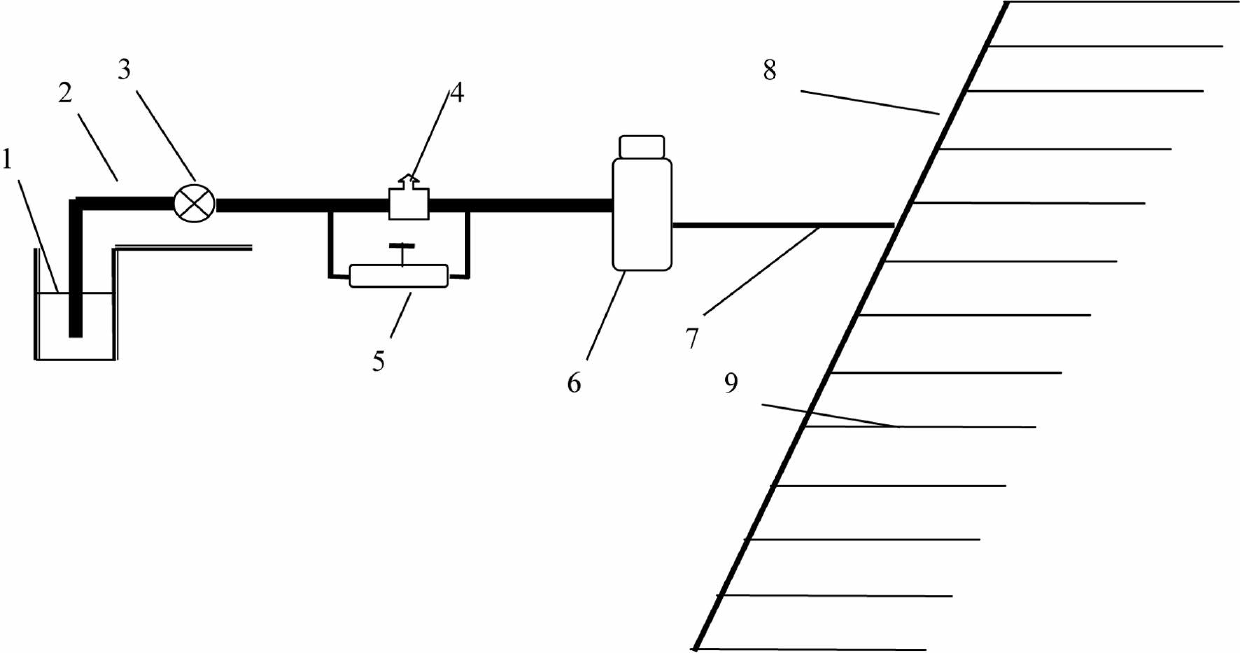

[0049] Such as figure 1 As shown, in a certain greenhouse (60 meters × 7 meters), a micro-irrigation belt 9 is laid every 0.6 meters, and the water is directly supplied by the water pump 3. 32mm, the water enters the filter 6 through the water delivery pipe 2, enters the main pipe 7, and has a diameter of 6mm; then enters the branch pipe 8, and finally transports the water to the micro-irrigation belt 9 to irrigate the crops. The above specific implementation methods are also applicable to farmland irrigation.

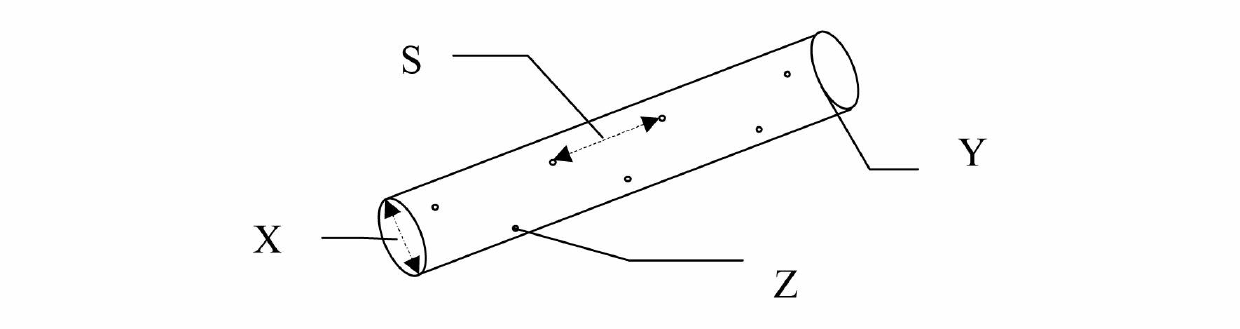

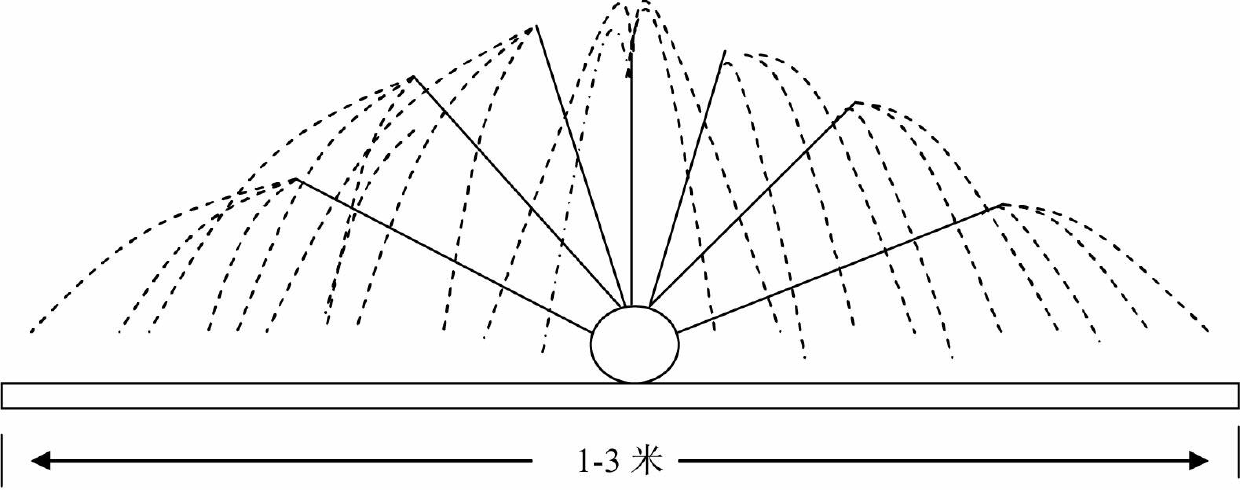

[0050] The technical parameters of the micro-irrigation tape: folding diameter X: 30-70mm; wall thickness Y: 0.1-0.3 mm; micropore diameter Z distribution range: 0.5-0.8mm; drip hole spacing S: 20-40 cm; working pressure: ≤0.02 MPa; burst pressure: ≥0.7 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com