Rubber extruding and spraying device

A spray device and rubber technology, applied in the field of rubber molding equipment, can solve the problems of the rubber strip hitting a shallow pit, the water flow is difficult to cover the entire width of the rubber strip, etc., to achieve the effect of large coverage and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

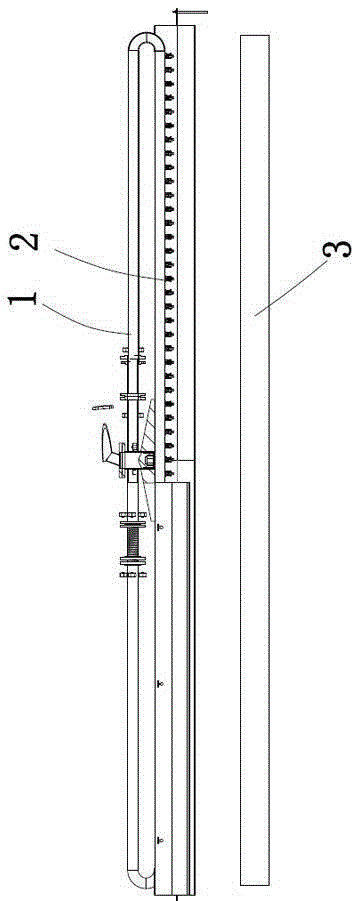

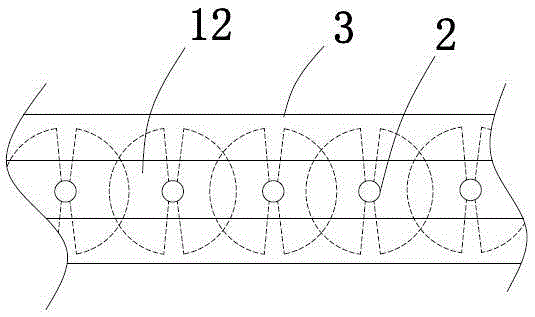

[0018] Embodiment: a kind of rubber extrusion spraying device, as figure 1 shown. The device includes a conveying tank 3 for conveying rubber strips 12, a water supply pipe 1 is arranged above the conveying groove 3, and a plurality of nozzles 2 are uniformly arranged on the water supply pipe along the conveying direction of the rubber strips.

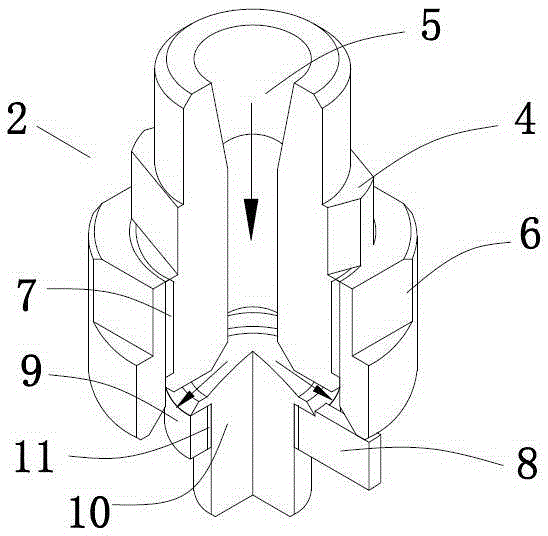

[0019] Nozzle structure such as figure 2 As shown, the axial position of the nozzle body 4 is provided with a vertical waterway 5, the upper port and the lower port of the waterway 5 are flared bell mouths, and the radius change rate of the upper port is smaller than that of the lower port. The upper end of the nozzle body 4 is fixed to the water supply pipe 1, and the upper port of the water channel is communicated with the water supply pipe. The outer wall of the lower end of the nozzle body is adjustablely connected with an adjustment seat 6 through a coarse adjustment thread 7 . The adjustment seat 6 is in the shape of a ring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com