Sprayer

A sprinkler and sprinkler component technology, applied in the field of sprinklers, can solve the problems of low waste gas treatment efficiency, uneven waste gas flow rate, and fast moving speed of waste gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

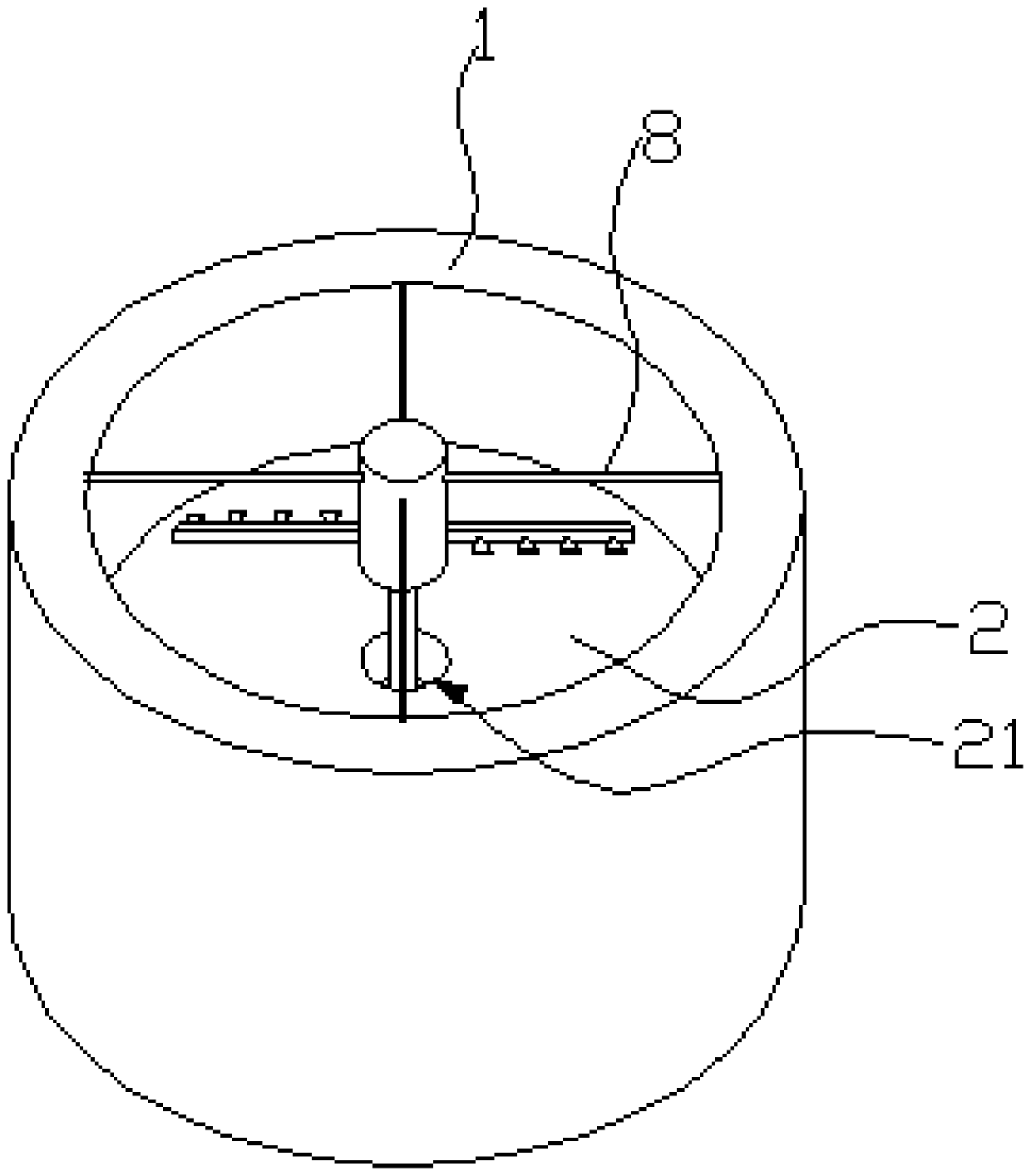

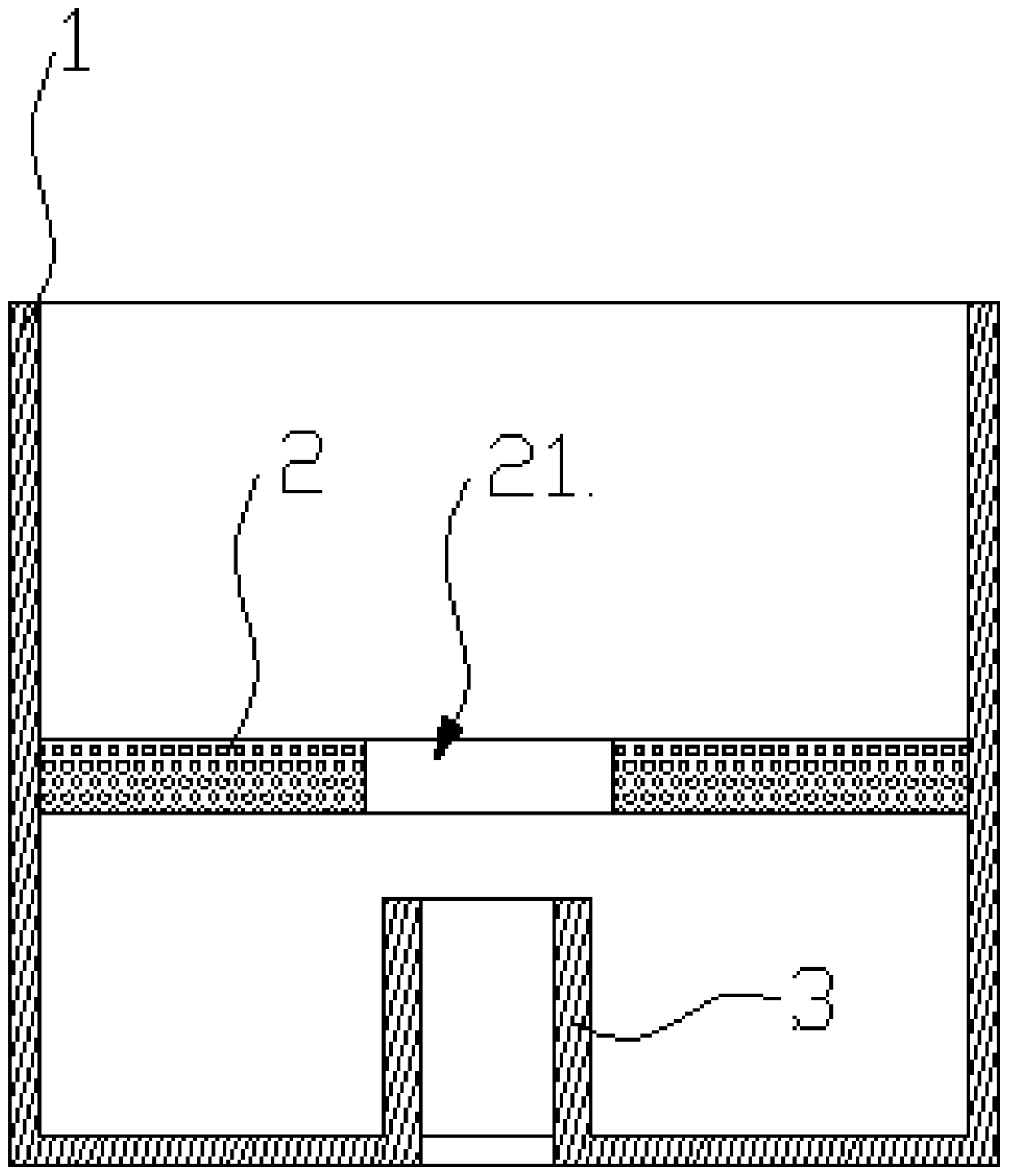

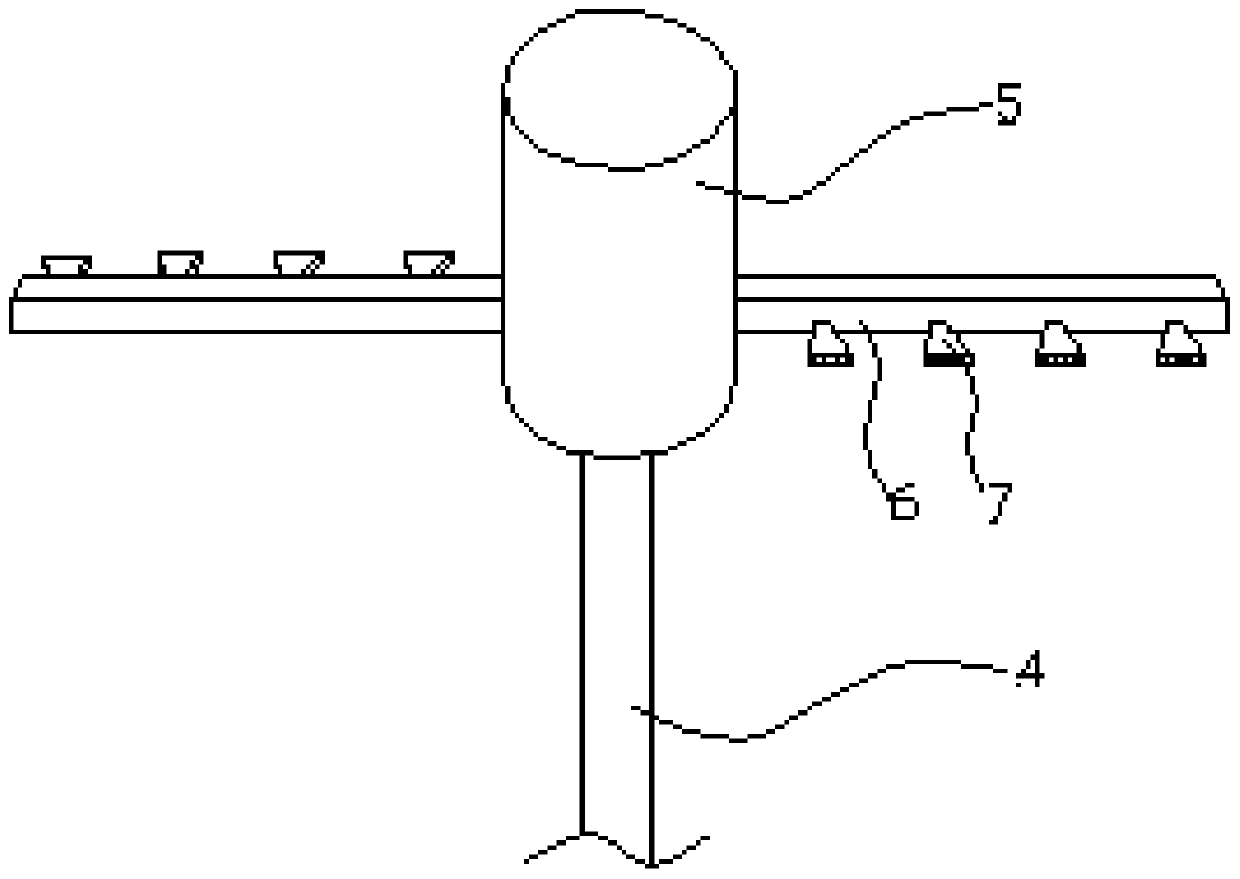

[0029] Such as figure 1 As shown, this embodiment provides a sprinkler, which includes a tower body 1, a water distribution plate 2 and a spray assembly located in the tower body 1, and the water distribution plate 2 is arranged laterally on the tower body 1, the water distribution plate 2 divides the cavity in the tower body 1 into an upper cavity and a lower cavity, and the water distribution plate 2 is provided with a There are multiple water holes in the cavity. In this embodiment, in order to prevent the medicine from clogging the water holes, the water holes can be square or other irregular shapes. The spray head 7 of the spray assembly is located on the upper part of the water distribution plate 2 , and the spray head 7 is used for spraying chemicals to the water distribution plate 2 . The bottom of the tower body 1 is provided with an air inlet, and an upwardly extending spacer ring 3 is arranged on the air inlet hole, and the space between the spacer ring 3 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com