Jet oscillation drop irrigation emitter

A sprinkler and jet technology, applied in spraying devices, spraying devices, watering devices, etc., can solve the problems of difficult design and application, high oscillation pulse frequency of positive feedback oscillation pulse generator, etc., to increase anti-blocking ability, Efficient energy dissipation effect, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

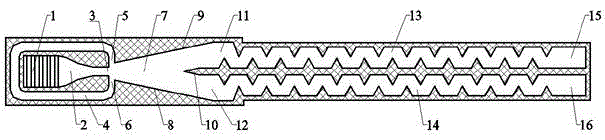

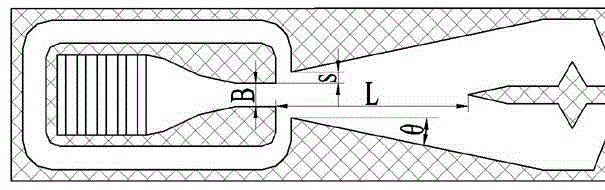

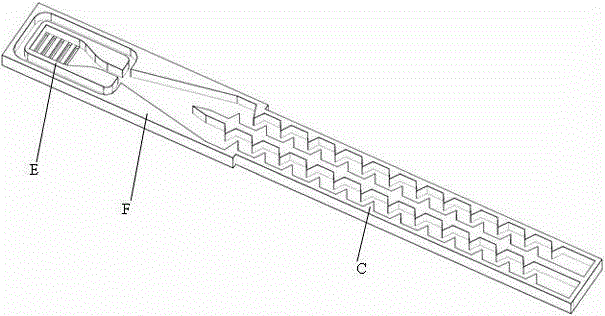

[0022] refer to figure 1 and image 3 The jet oscillating drip irrigation emitter shown in this embodiment is composed of a water inlet tank E, a jet element F and a flow channel body C. The water inlet tank E is provided with a filter window 1 and communicates with the inlet of the jet element F, and the outlet of the jet element F is connected to the inlet of the jet element F. The inlet of the flow channel body C is connected; the jet element F is composed of nozzle 3, control channel 4, control port I5, control port II6, jet space 7, side wall II8, side wall I9, splitter splitter 10, output port I11, output The front end of the jet element F is the nozzle 3, and the side walls on both sides of the outlet of the nozzle 3 are respectively provided with the control port Ⅰ5 and the control port Ⅱ6, and the control port Ⅰ5 and the control port Ⅱ6 are connected by the control channel 4. A jet space 7 with a small front and a large rear shape. The two sides of the jet space 7 ar...

Embodiment 2

[0027] refer to Figure 4 , Figure 6 , the basic structural features are similar to those of Example 1, and the difference from Example 1 is that the top of splitter splitter 10 is in a concave arc shape, and the flow channel I13 and flow channel II14 are respectively arranged in a U shape, with some differences in size. . refer to Figure 5 , the nozzle width B is 0.6mm, the ratio of the position difference S to the nozzle width B is 1:0.6, the ratio of the split distance L to the nozzle width B is 1:10, the opening angle θ is 16.3°, the nozzle depth and the nozzle width B The ratio is 1:1.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com