Distributor in falling film evaporator

A technology of falling film evaporator and distributor, which is applied in the direction of evaporator/condenser, fluid circulation arrangement, refrigeration components, etc., can solve the problem of stable operation of chillers that affect the heat transfer efficiency of falling film evaporators, and cannot be completely soaked and exchanged Problems such as heat pipes and unfavorable film boiling heat transfer can be achieved to reduce adverse effects, avoid suction back to liquid, and stabilize air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

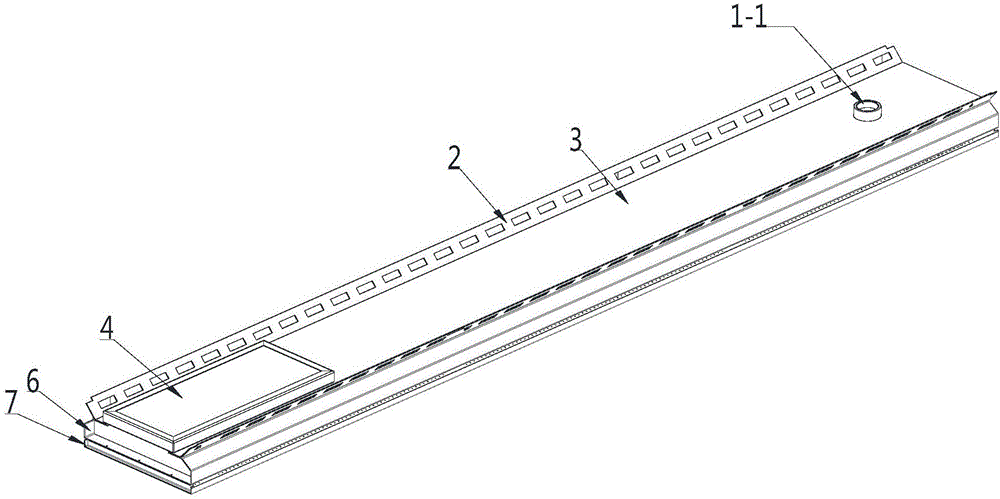

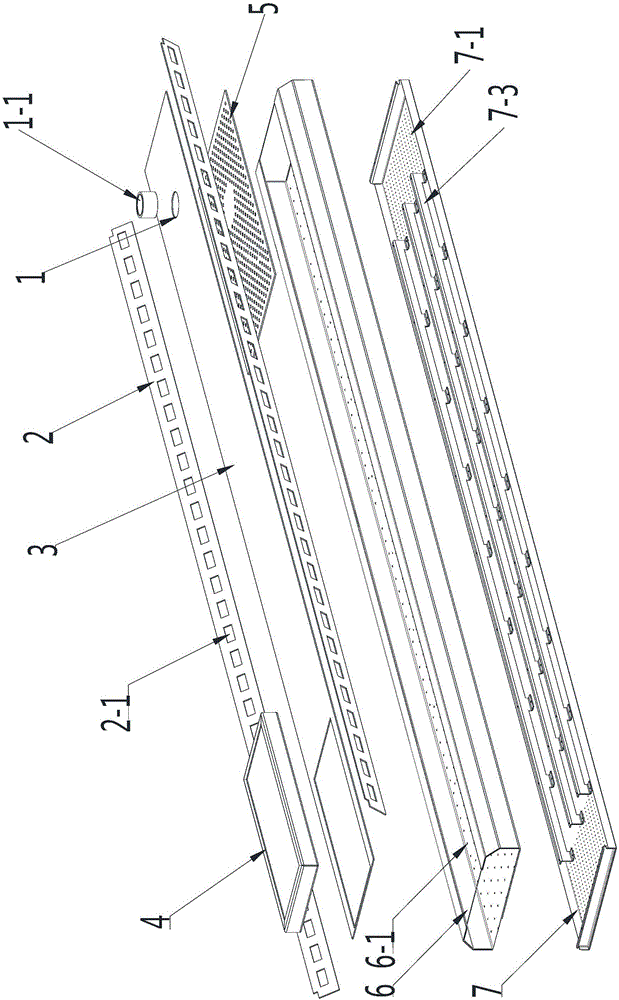

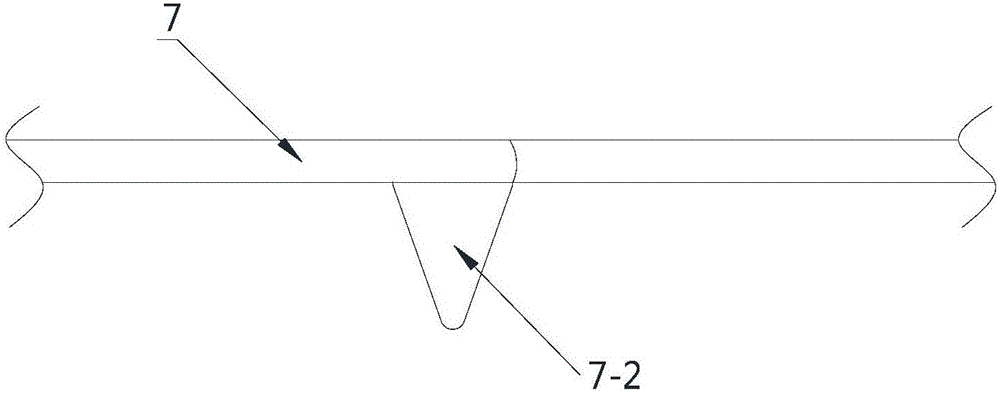

[0027] Such as Figure 1~2 As shown, it includes a cover plate 3, a gas-liquid separation tray 6 and a gravity drip tray 7, and the bottom 7 of the gravity drip tray is uniformly covered with water holes 7-1 and is provided with a plurality of partitions 7-3. The top of the gravity drip tray 7 is connected with the gas-liquid separation tray 6, the bottom plate of the gas-liquid separation tray 6 is evenly distributed with pressure holes 6-1, and the gas-liquid separation tray 6 is fixedly connected with a cover plate 3, The gas-liquid separation disc 6 and the cover plate 3 form a closed gas-liquid separation chamber, and the cover plate 3 is provided with a liquid inlet 1 and a demister 4, because the gas-liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com