Passive residual heat removal system with heat exchanger located at exterior of water tank for secondary side of marine pressurized water reactor

A waste heat removal system and heat exchanger technology, applied in reactors, nuclear power generation, reduction of greenhouse gases, etc., can solve problems such as isolation of heat removal systems in the ocean environment, decrease in flow rate of coolant in pressure vessels, and increase in temperature of pressurized water reactors , to achieve the effect of reducing the risk of leakage, small internal and external resistance, and alleviating space tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

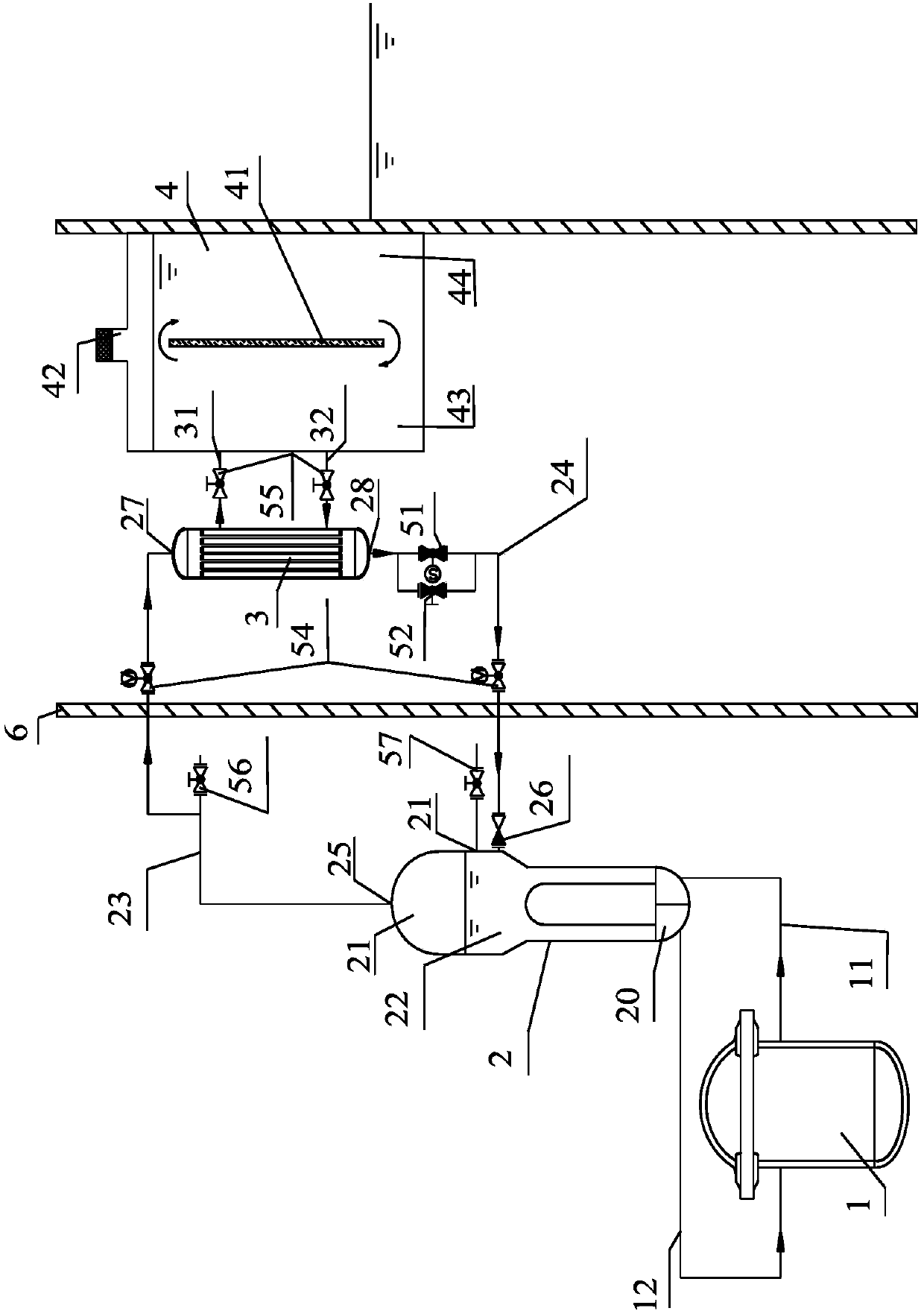

[0033] see figure 1 As shown, the embodiment of the present invention provides a passive waste heat removal system with a heat exchanger located outside the water tank on the secondary side of a marine PWR, which includes a reactor pressure vessel 1 and at least one heat removal subsystem. The heat removal subsystem includes a steam generator 2 arranged inside the containment vessel 6 and a condenser 3 and a water tank 4 arranged outside the containment vessel 6 inside the ship.

[0034] The steam generator 2 includes a heat exchange part 20 and a steam generating part 21, and the heat exchange part 20 and the above-mentioned reactor pressure vessel 1 form a heat exchange cycle through the main coolant pipeline, and the heat exchange part 20 is located above the reactor pressure vessel 1: The heat exchange part 20 contains a first part and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com