A distributor for falling film evaporator of low pressure refrigeration system

A falling-film evaporator, refrigeration system technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of abnormal formation of liquid film, poor heat exchange effect of evaporative heat exchange tube, uneven distribution of refrigerant, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

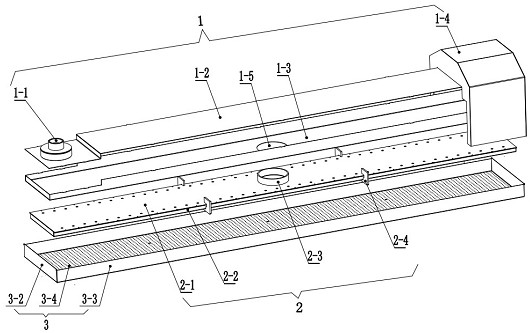

[0038] Please refer to figure 1 with figure 2 As shown, the invention discloses a distributor for a falling film evaporator of a low-pressure refrigeration system, which includes a gas-liquid separator 1, a channel assembly 2 and a drip tray 3;

[0039] Described gas-liquid separator 1 comprises bottom plate one 1-3 and the top plate one 1-2 that is installed on described bottom plate one 1-3, and described bottom plate one 1-3 and described top plate one 1-2 cooperate to form gas-liquid In the separation chamber, the top plate 1-2 includes a connected liquid inlet plate and a gas storage plate, the liquid inlet plate is provided with a liquid inlet 1-1, and the gas storage plate is provided with an air outlet, and the outlet The air port communicates with the air guide cover 1-4, and the bottom plate 1-3 is provided with a liquid outlet 1-5.

[0040] In this embodiment, the air guiding cover 1-4 is arranged at the end of the gas storage plate and away from the liquid inlet...

Embodiment 2

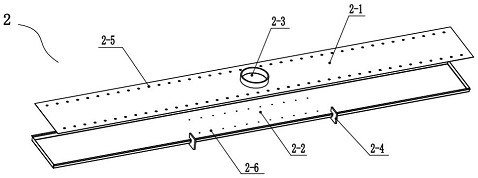

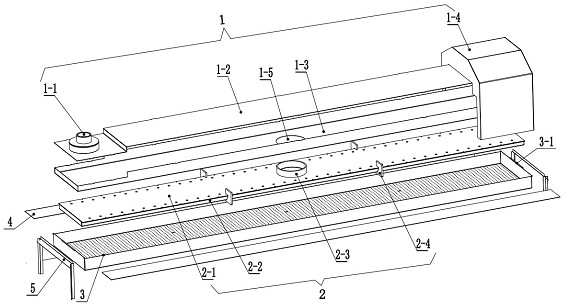

[0055] Different from Embodiment 1, Embodiment 2 provides a distributor for a falling film evaporator in a low-pressure refrigeration system that further includes a baffle 4 .

[0056] Please refer to image 3 As shown, a distributor for a falling film evaporator of a low-pressure refrigeration system includes a gas-liquid separator 1, a channel assembly 2 and a drip tray 3, and the channel assembly 2 is arranged in the drip tray 3, The gas-liquid separator 1 is installed on the end plate 3-2, the channel assembly 2 includes a top plate 2-1 and a bottom plate 2-2 that cooperate to form a sealed cavity, and the top plate 2-1 is There is a liquid inlet pipe 2-3 and a plurality of liquid discharge holes 2-5, the liquid inlet pipe 2-3 corresponds to the liquid outlet 1-5, and the plurality of liquid discharge holes 2-5 are along the The length direction of the top plate 2-1 is uniformly arranged. Baffles 4 are provided on both sides of the channel assembly 2, and the baffles 4 a...

Embodiment 3

[0060] Different from Embodiment 1, the distributor provided in Embodiment 3 for a falling film evaporator of a low-pressure refrigeration system further includes a baffle 4, and the baffle 4 is L-shaped.

[0061] Please refer to Figure 4 to Figure 7 As shown, a distributor for a falling film evaporator in a low-pressure refrigeration system includes a gas-liquid separator 1, a channel assembly 2 and a drip tray 3, and the channel assembly 2 is placed on a drip tray through a support plate 2-4. In the tray 3, the baffle 4 is L-shaped. The baffle 4 includes a short side 4-1 and a long side 4-2. The baffle 4 is placed on the drip tray 3 through the short side 4-1. and the short side 4-1 is located above the drain hole 2-5, and the distance between the two long sides 4-2 is greater than the width of the drip tray 3.

[0062] The height of the support plate 2-4 is equal to the height of the end plate 3-2 of the drip tray 3, and the short side 4-1 of the baffle plate 4 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com