Shell-tube type dripping heat exchanger

A heat exchanger, shell-and-tube technology, applied in the field of heat exchangers, can solve the problems of increased manufacturing and material costs, increased possibility of errors, complex distributor structure, etc., and achieves the effect of simple structure and less man-hours for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0024] The invention relates to a heat exchanger in the refrigeration industry, in particular to a horizontally installed shell-and-tube drip heat exchanger.

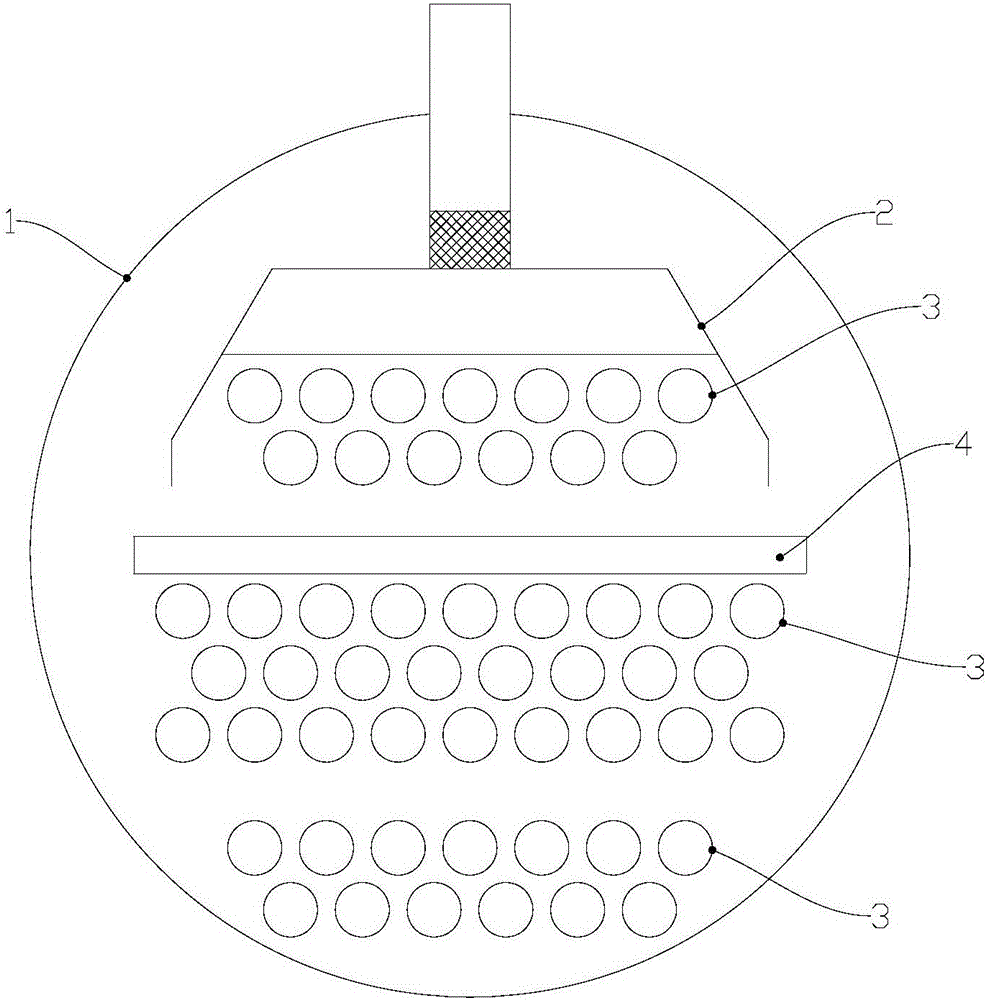

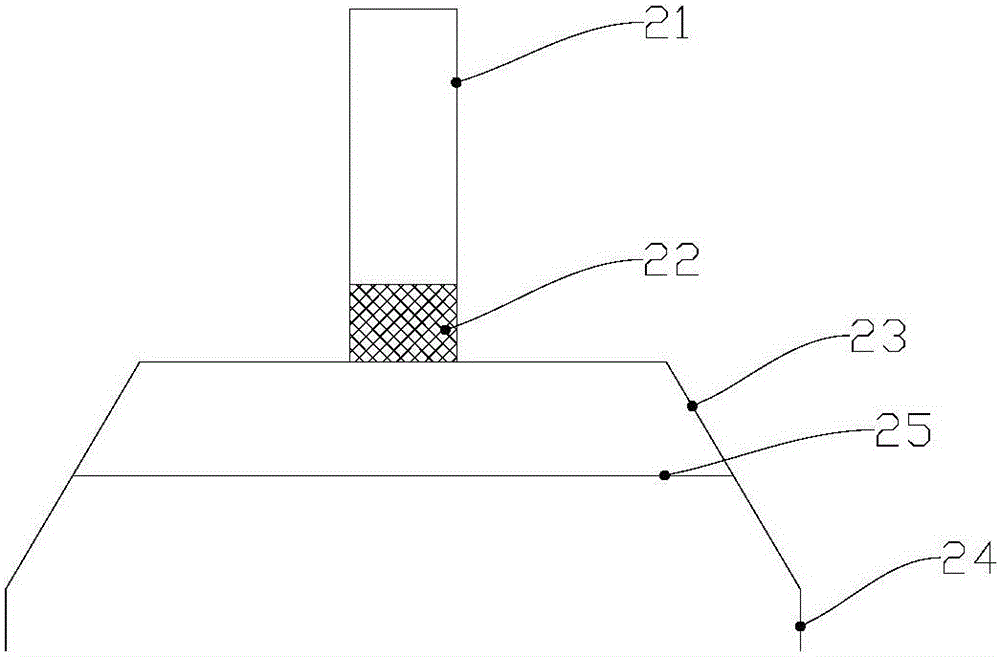

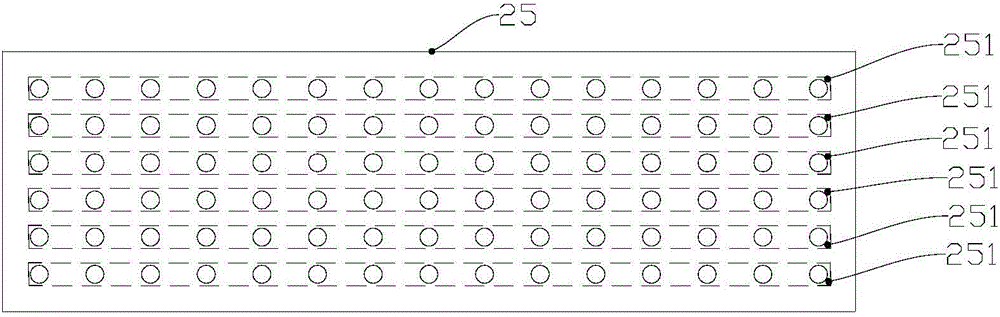

[0025] see figure 1 , The first preferred embodiment of the present invention provides a shell-and-tube drip heat exchanger, including a heat exchanger cylinder 1 , a distributor 2 , a heat exchange tube 3 and a liquid collector 4 . Distributor 2 , heat exchange tube 3 and liquid collector 4 are arranged in cylinder body 1 . After being distributed by the distributor 2 , the refrigerant enters the cylinder 1 and undergoes a heat exchange reaction with the brine in the heat exchange tube 3 . The liquid collector 4 is arranged between the tube groups of the heat exchange tubes 3, and collects the refrigerant before distributing it. The liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com