Refrigerant distributor of falling film evaporator for water chilling unit

A technology for falling film evaporators and refrigerant distributors, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., and can solve complex structures, high processing precision requirements for distributors, and increased manufacturing and processing difficulty and cost. and other issues to achieve high-purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

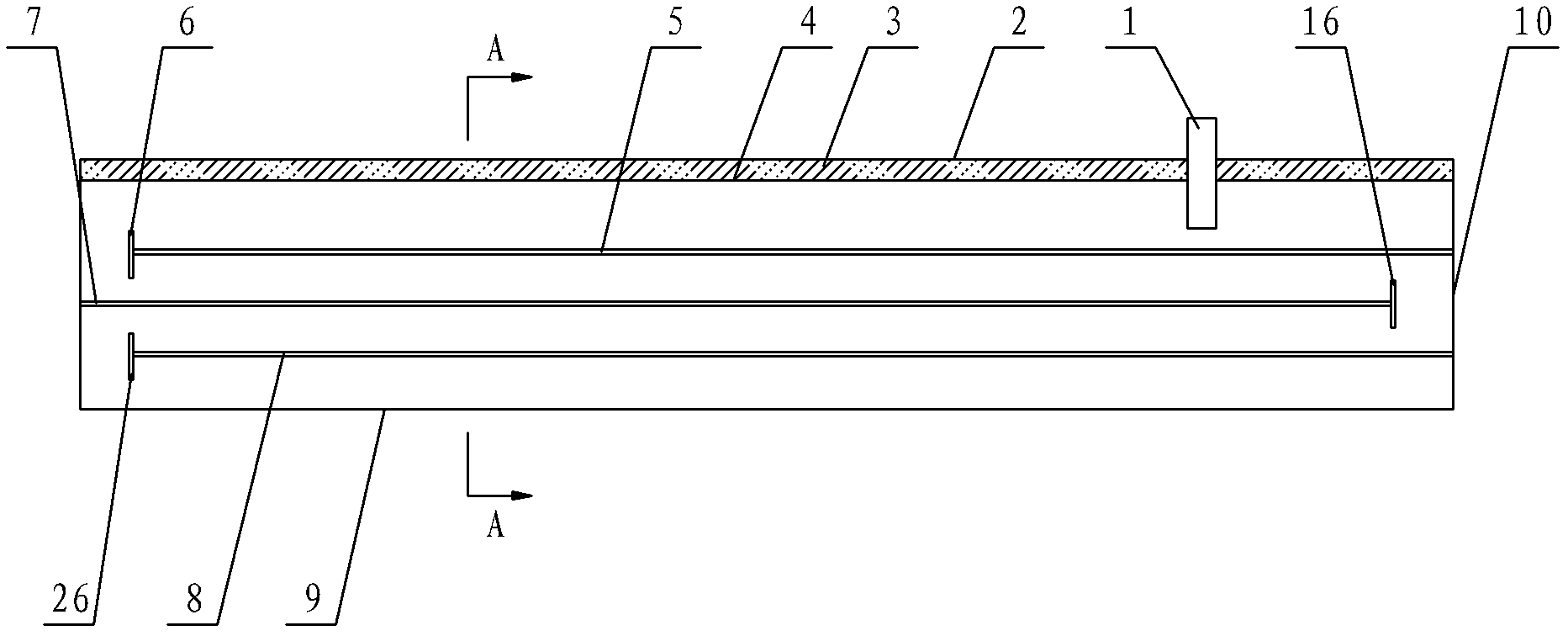

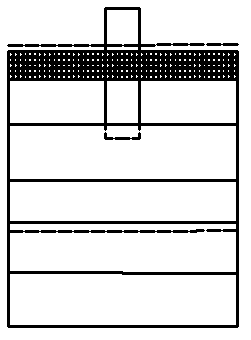

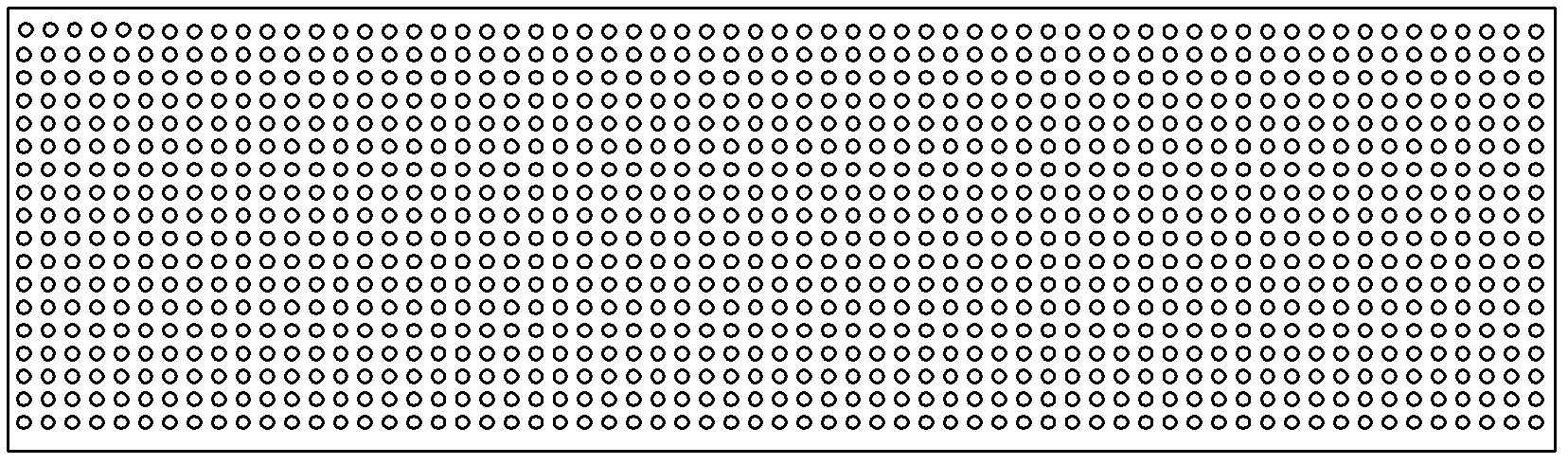

[0030] see Figure 1-Figure 3 , the refrigerant distributor of the falling film evaporator used in this water chiller includes a refrigerant inlet 1, an upper porous top plate 2, a filter screen 3, a lower porous top plate 4, a porous bottom plate 9 and a side plate 10, and the filter screen 3 is sandwiched between Between the upper porous top plate 2 and the lower porous top plate 4, the porous bottom plate 9 is located below the lower porous top plate 4, and the upper porous top plate 2, the filter screen 3, the lower porous top plate 4, the porous bottom plate 9 and the side plates 10 jointly form a chamber. The chamber is provided with more than one distribution orifice plate, and one end of the refrigerant inlet 1 passes through the upper porous top plate 2, the filter screen 3 and the lower porous top plate 4 in sequence, and then opens above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com