Preparation method of high-strength composite color steel plate

A color steel plate, high-strength technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as reduced production efficiency, increased labor intensity, and inability to perform processing operations at the same time, to improve work efficiency, use Safe and convenient, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

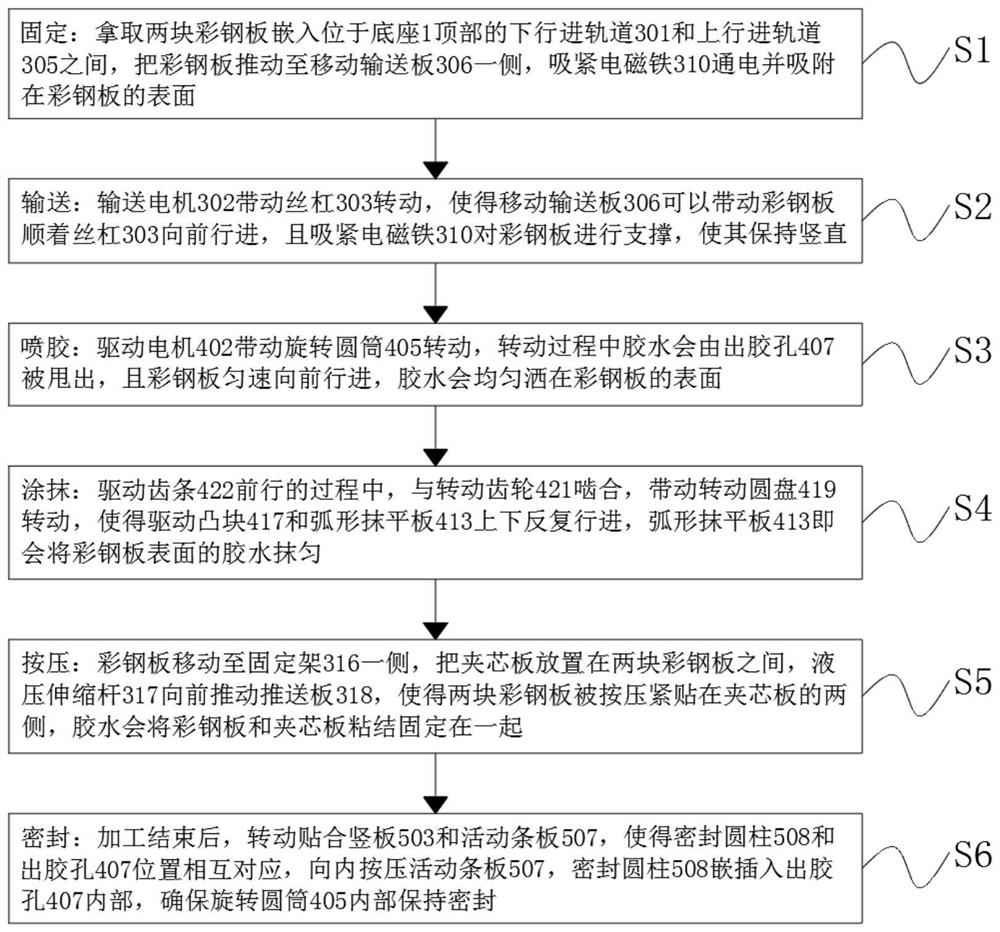

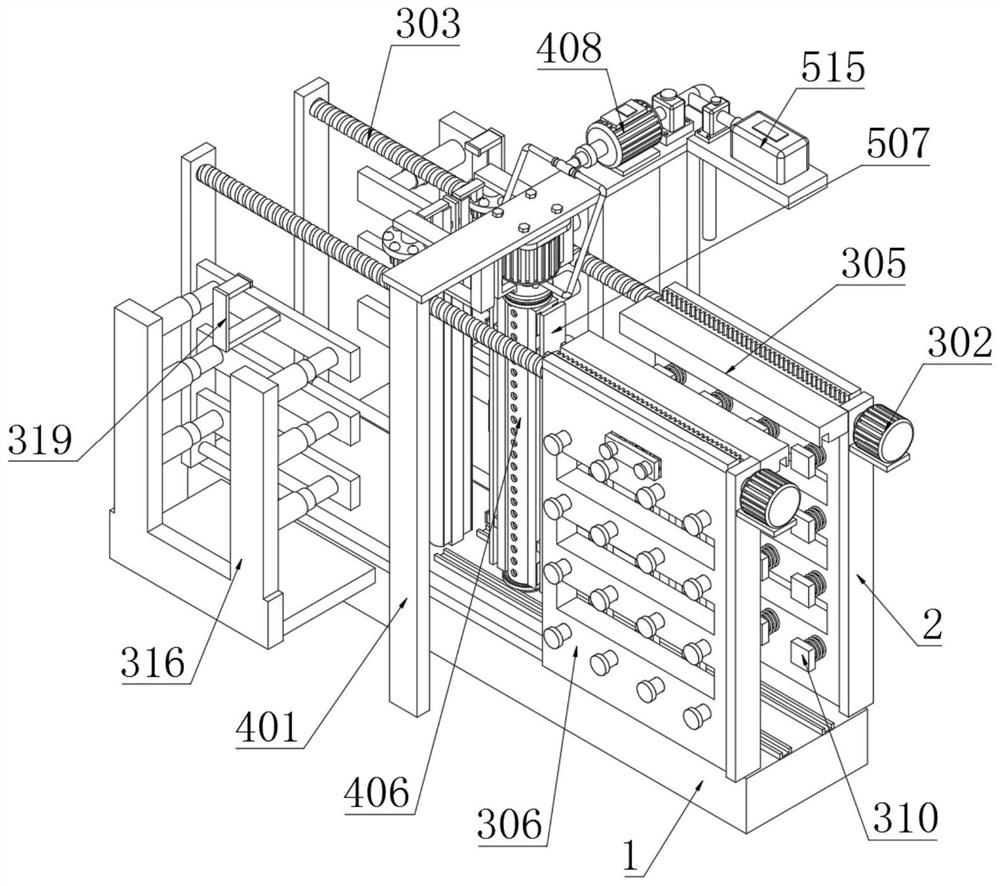

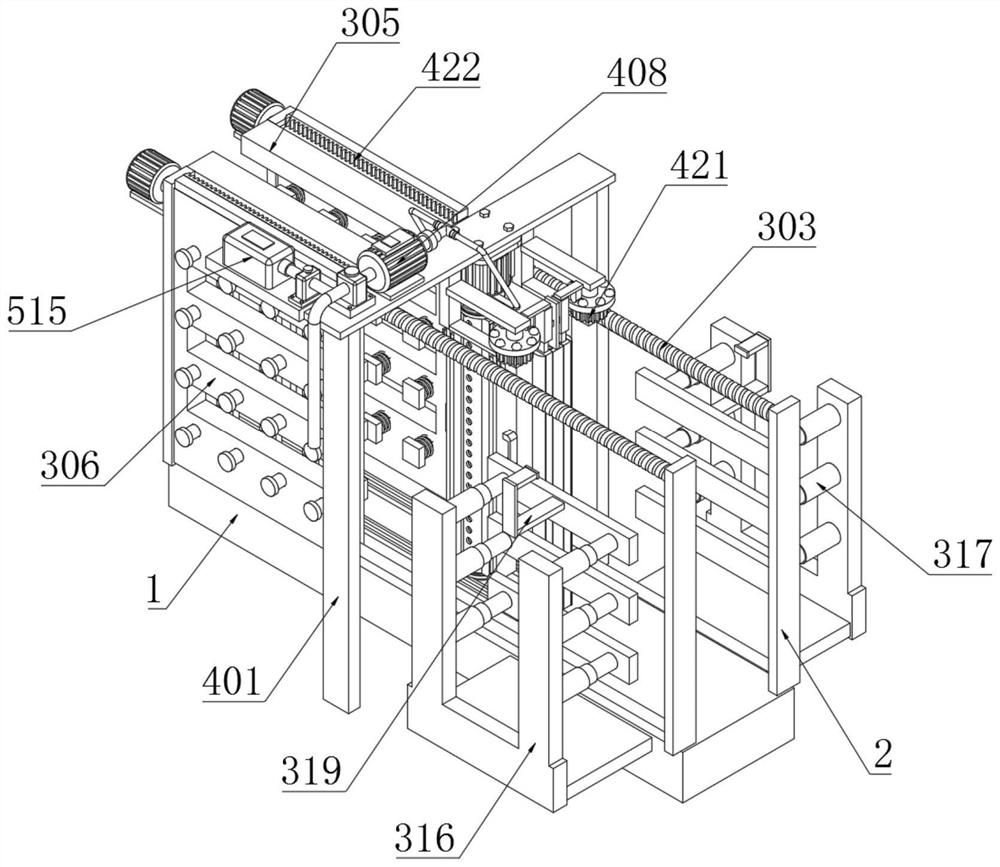

[0040] Example: such as figure 1 As shown, the present invention provides a technical solution, a method for preparing a high-strength composite color steel plate, comprising the following steps:

[0041] S1. Fixing: Take two color steel plates and embed them between the lower running track 301 and the upper running track 305 at the top of the base 1, push the color steel plates to the side of the moving conveying plate 306, power on the suction electromagnet 310 and absorb it on the color plate the surface of the steel plate;

[0042] S2, conveying: the conveying motor 302 drives the lead screw 303 to rotate, so that the moving conveying plate 306 can drive the color steel plate to advance along the lead screw 303, and the suction electromagnet 310 supports the color steel plate to keep it vertical;

[0043] S3. Glue spraying: the driving motor 402 drives the rotating cylinder 405 to rotate. During the rotation, the glue will be thrown out from the glue outlet 407, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com