Vacuum belt dryer

A technology of vacuum belt drying and conveyor belt, which is applied in the direction of evaporator accessories, spray evaporation, etc., which can solve the problems of waste, small spraying height, and unsmooth discharge, achieve good solubility and preservation, improve drying efficiency, and reduce The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

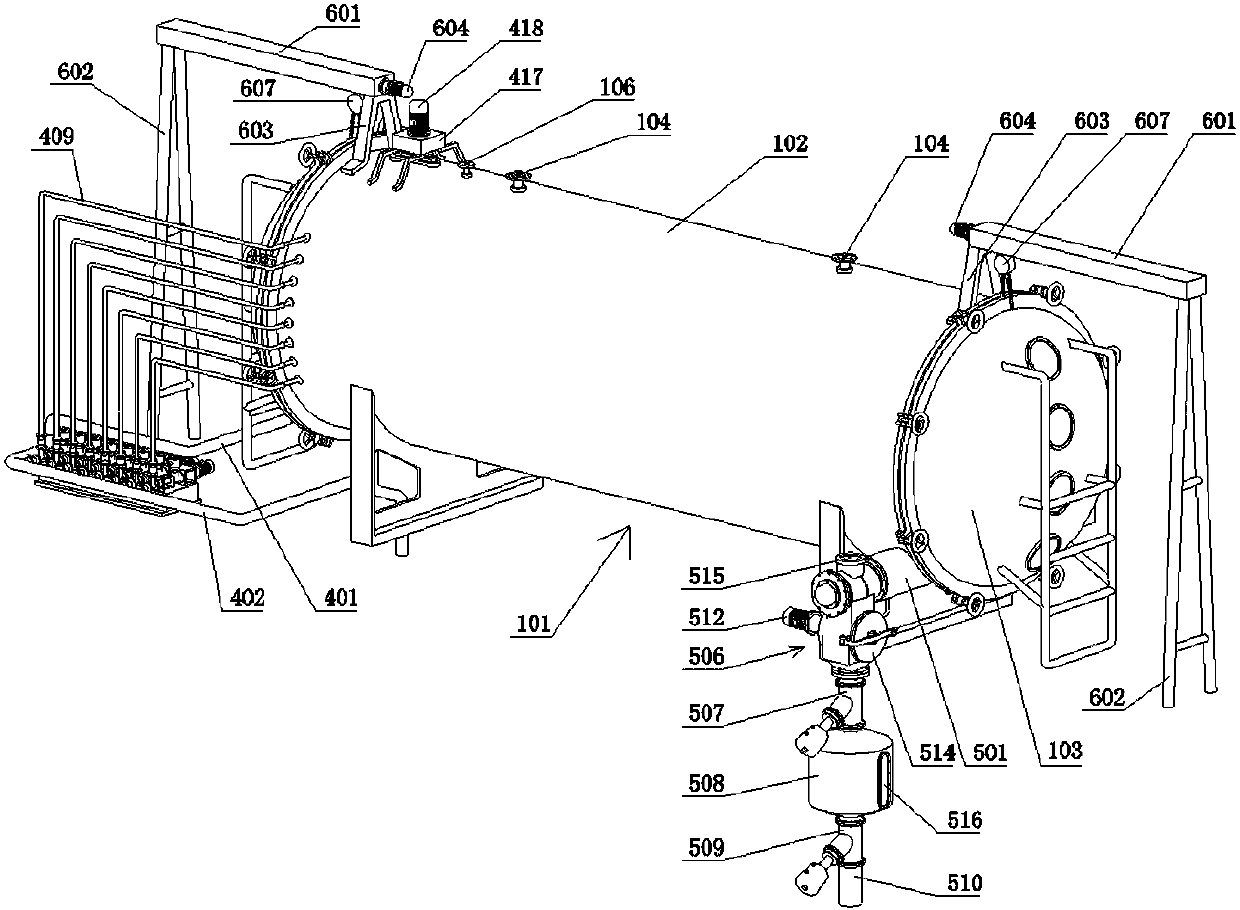

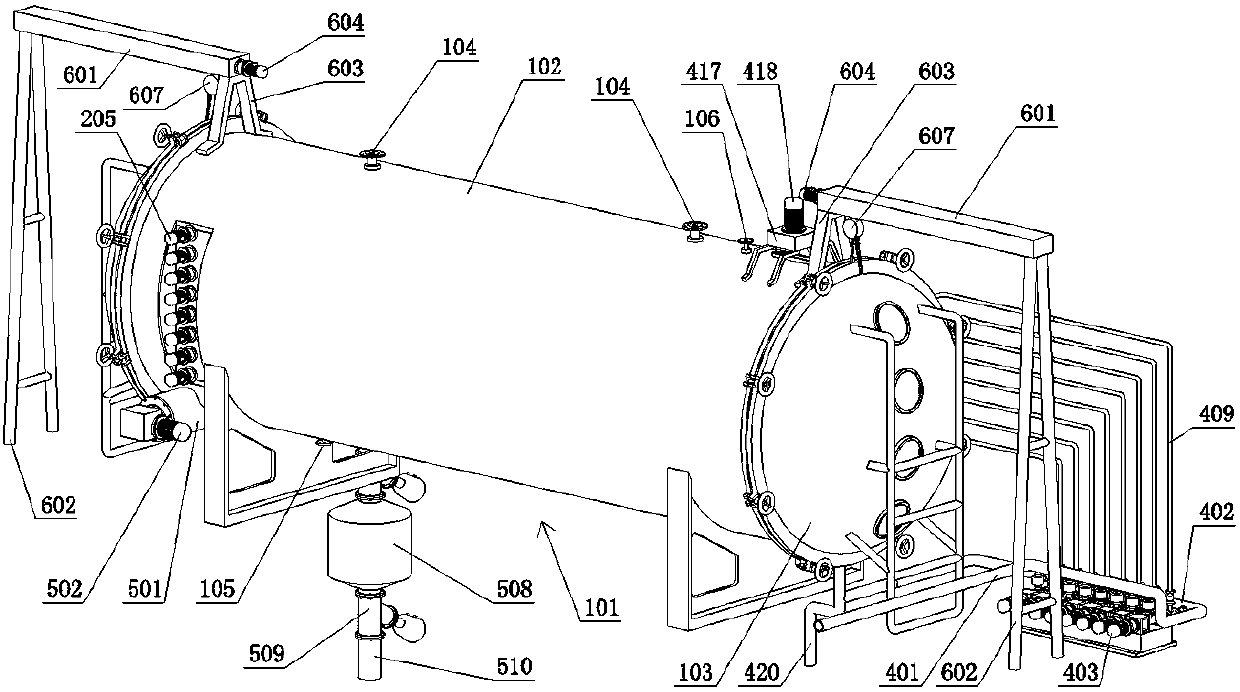

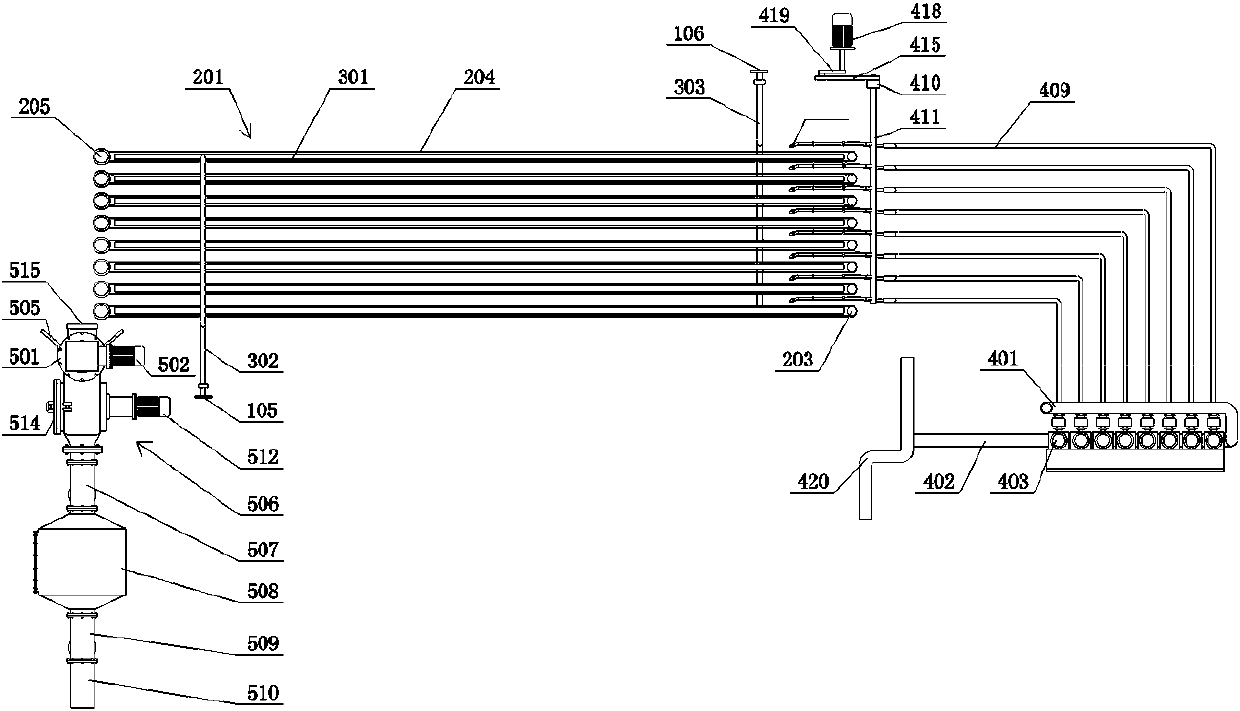

[0040] Such as Figure 1 to Figure 4 As shown, a vacuum belt dryer includes a cylinder 101 composed of a cylinder 102 and cylinder covers 103 at both ends, an 8-layer conveyor belt 201 arranged inside the cylinder 101, a feeding system and a discharging system; the cylinder 102 There is a vacuum port 104, a heat source inlet 105 and a heat source outlet 106; the conveyor belt 201 is composed of a driving roller 202, a driven roller 203 and a belt 204; a lifting upper belt 204 is provided between the driving roller 202 and the driven roller 203 One end of the heating plate 301 is connected to the heat source inlet 105 through the heating pipe 302, and the other end of the heating plate 302 is connected to the heat source outlet 106 through the heat return pipe 303; The co-rotating conveying motor 205 is driven to rotate to synchronously convey the material from the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com