Grinding wheel grinding roller

A technology for dressing grinding wheels and rollers, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc. It can solve the problems of poor grinding accuracy, difficulty in fully automated production, and low efficiency, and achieve the goal of overcoming the width of workpieces. error, realize full automation, and improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

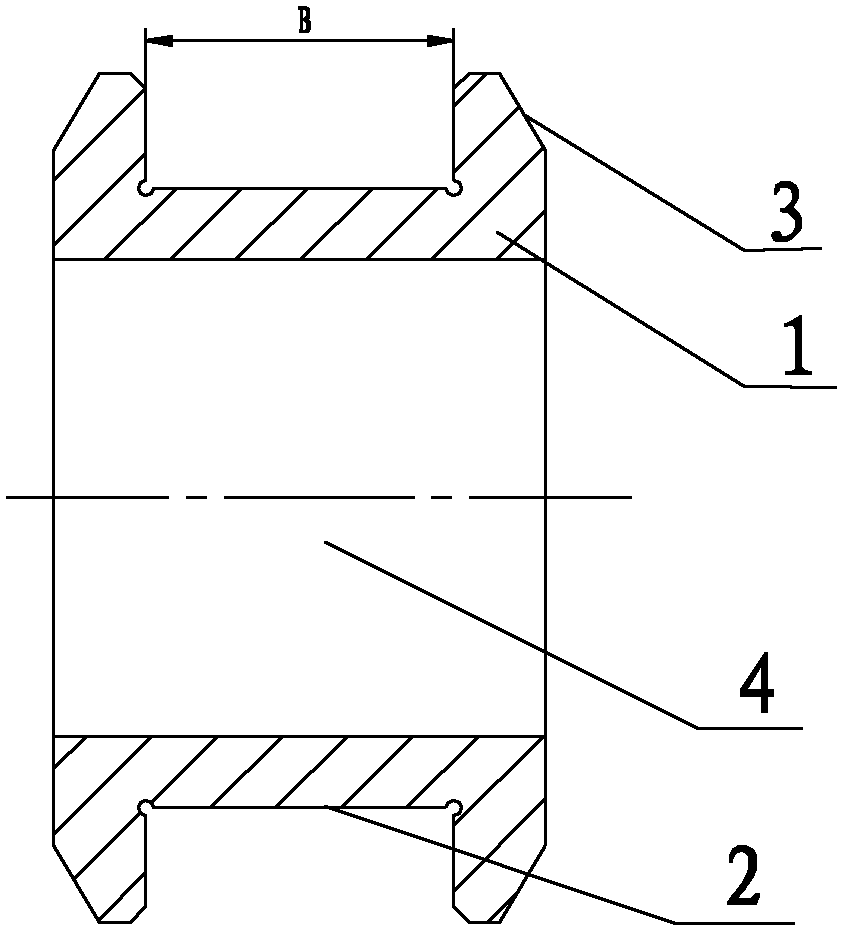

[0018] combine figure 1 and figure 2 , the dressing roller 1 of this embodiment is a revolving body, the front projection is H-shaped, the center of rotation is provided with a central hole 4, the middle part of the outer ring is provided with an annular groove 2, and the grinding wheel dressing position 6 of the outer diameter of the grinding wheel is disposed in the groove 2 Inside; chamfering 3 is provided on the outer ring of both ends of the trimming roller. Among them, the width B of the groove with a suitable width is designed so that the width dimension B of the grinding wheel after dressing is equal to the raceway width B after the grinding wheel grinds the rib.

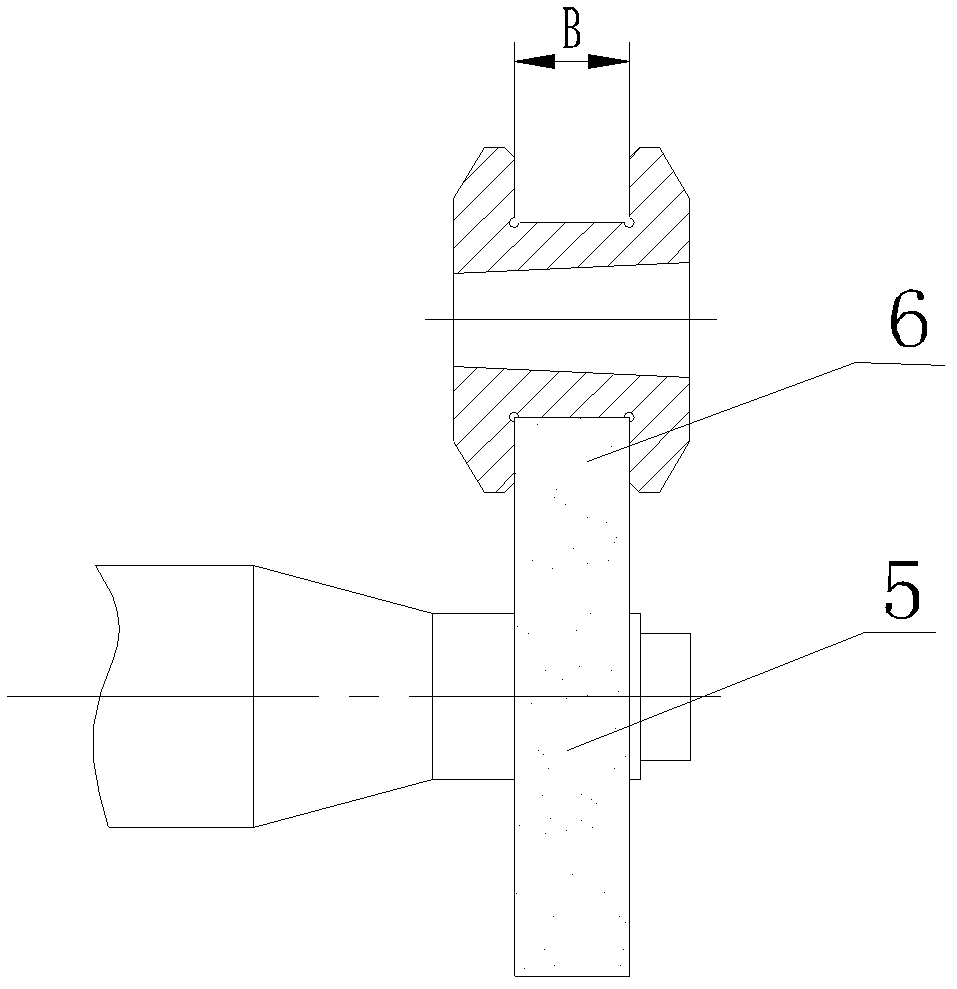

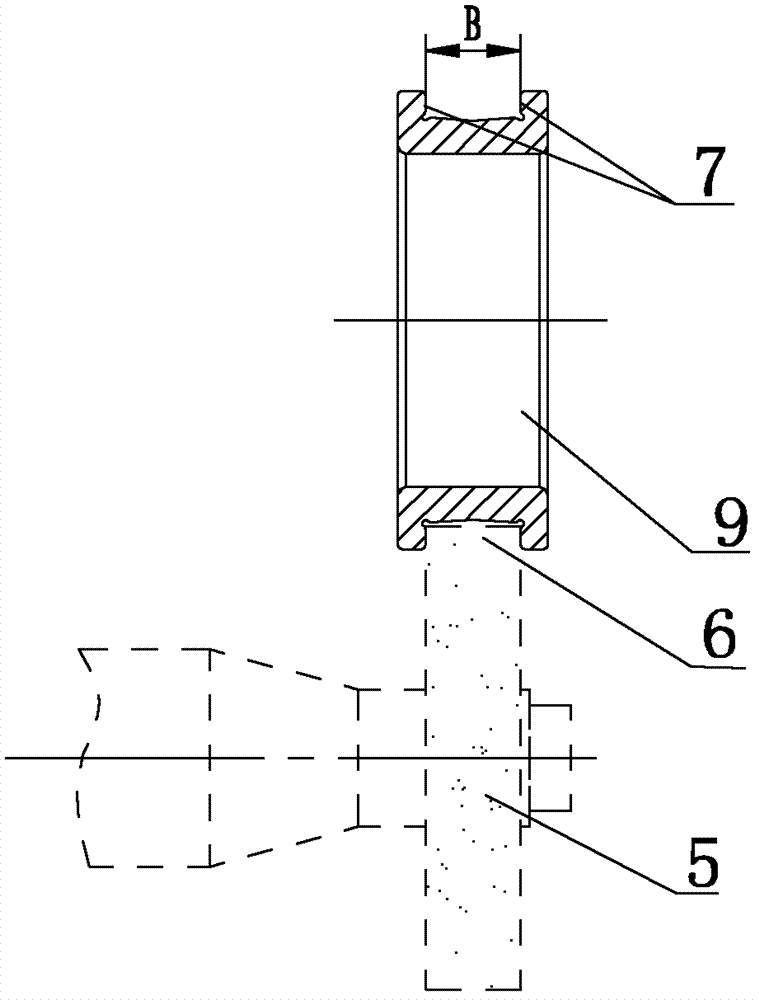

[0019] combine image 3 and Figure 4 , On the 3MZK1310 or 3MZK1410 machine tool, the dressing roller cooperates with the grinding wheel dresser to dress the grinding wheel to control the width of the grinding wheel. The width dimension B of the dressing roller can be designed according to the different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com