Polishing device and method for communication shell machining

A technology for polishing devices and shells, which is applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of low grinding efficiency, many surface burrs, easy to damage gloves, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

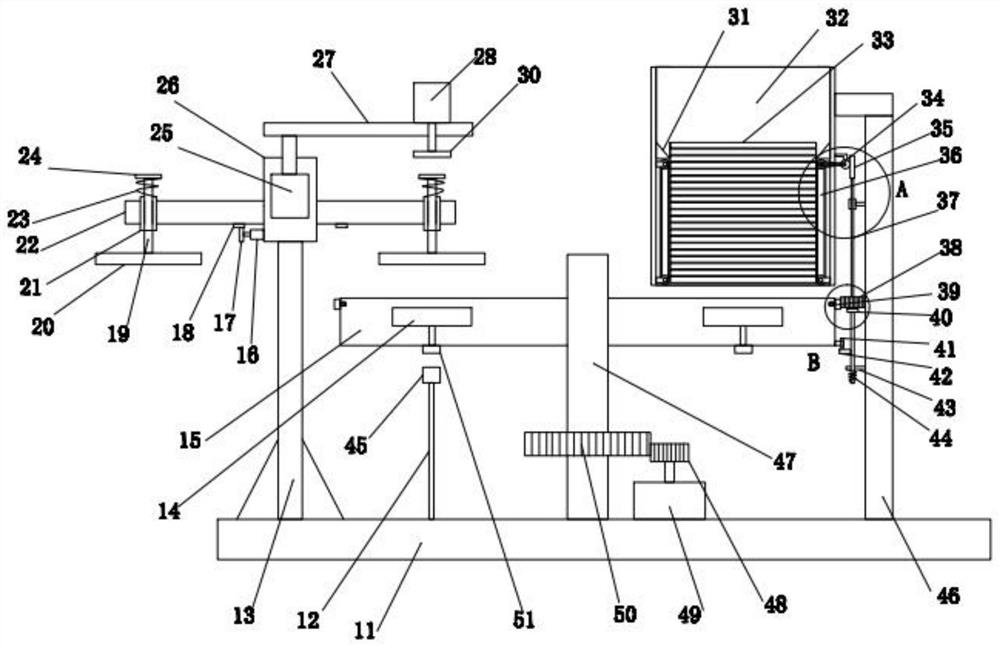

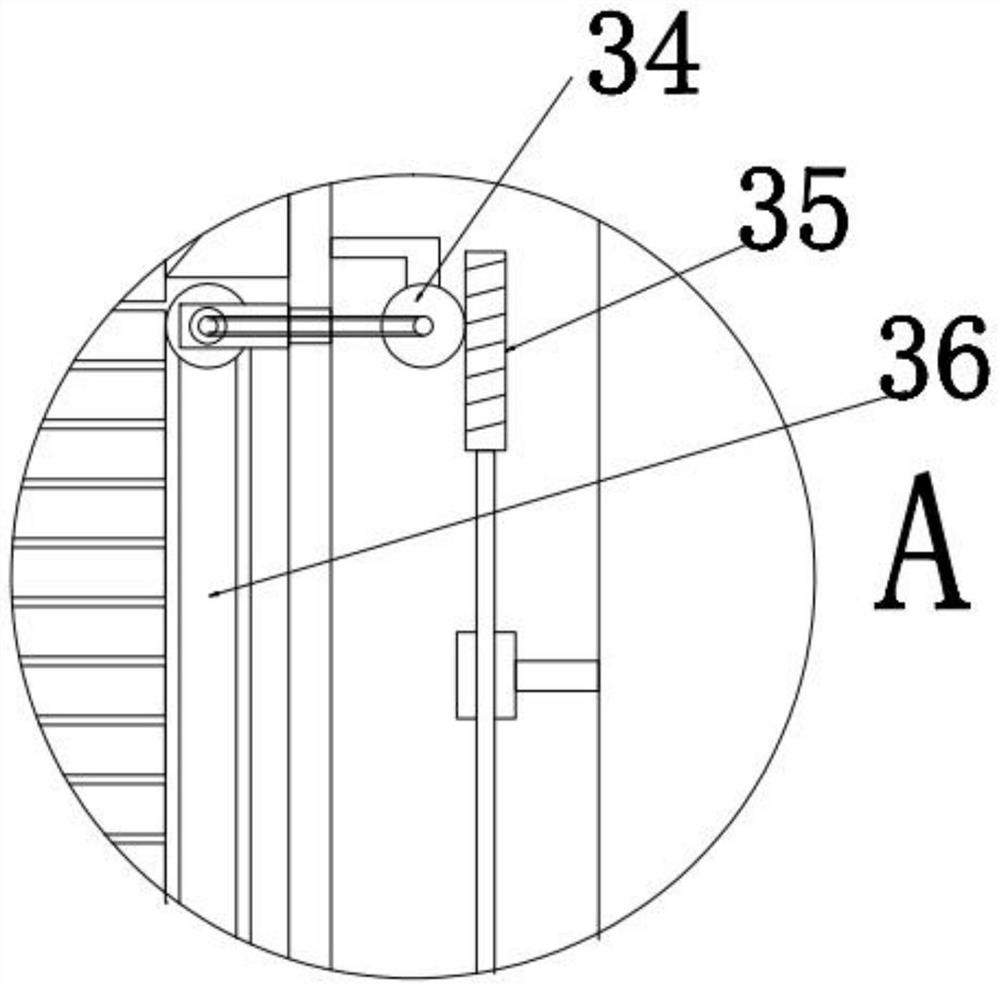

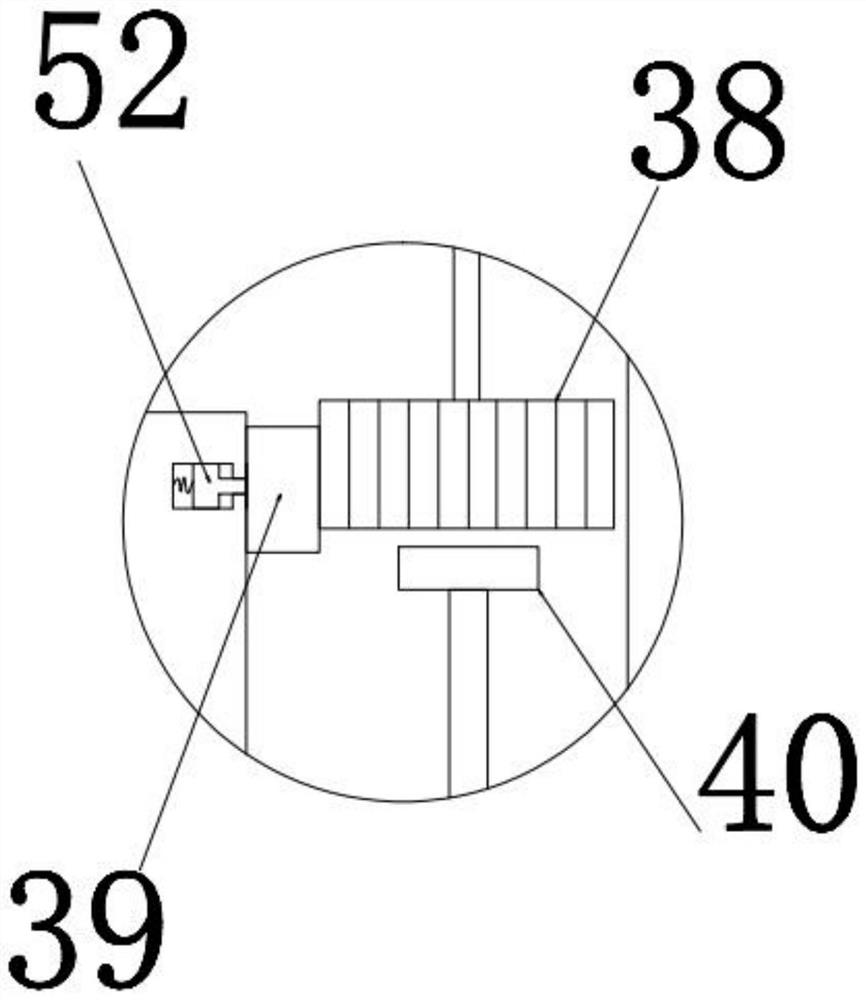

[0024] see Figure 1-Figure 5 , in an embodiment of the present invention, a polishing device for communication shell processing includes a base 11 and a rotating column 47 that is rotated at the middle position of its upper end, and the lower end of the rotating column 47 is connected to drive it to rotate to realize station switching The rotating drive member, the upper end of the rotating column 47 is coaxially provided with a rotating disk 15 for placing workpieces, and the inner array of the rotating disk 15 is distributed with several magnetic adsorbers 14 for auxiliary positioning of the workpieces. The bottom of the magnetic absorber 14 is provided with a signal receiver 51 for starting it, the upper end of the base 11 is provided with a fixed rod 12, and the end of the fixed rod 12 is provided with a signal transmitter for sending an opening signal to the signal receiver 51 45, only when the rotating disk 15 drives the magnetic force absorber 14 to rotate to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com