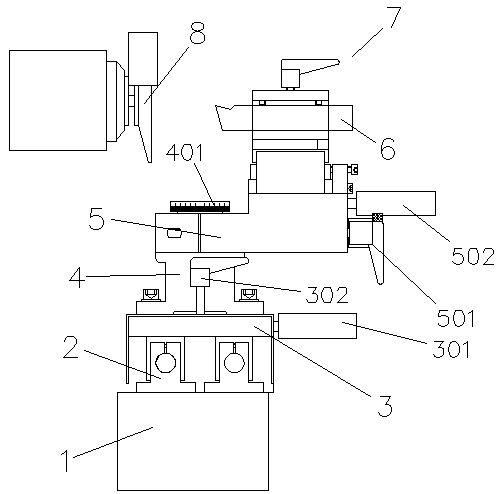

Turning tool feeding device for grinding turning tool

A technology of feeding device and turning tool, which is applied in the direction of grinding drive device, tool for lathe, grinding/polishing safety device, etc. Convenient and quick grinding and reprocessing, improve the quality of grinding, and facilitate the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

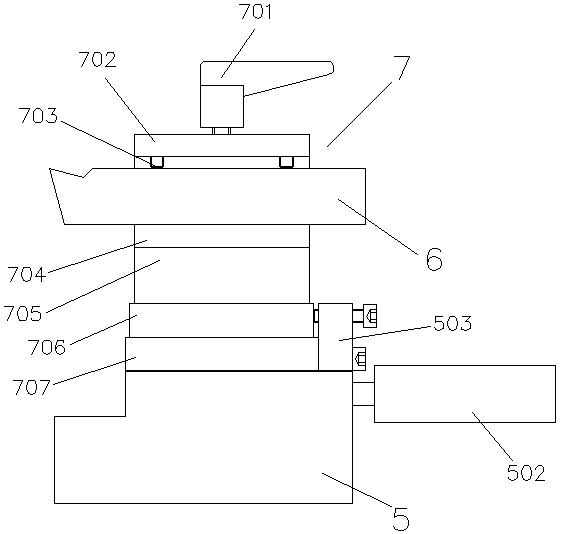

[0028] As another preferred embodiment of the present invention, the two ends of the bottom of the upper clamping plate 702 are provided with protrusions 703 for tightening the turning tool 6;

[0029] As another preferred embodiment of the present invention, the height of the working platform 1 can be raised and lowered, thereby adjusting the height of the turning tool clamping mechanism 7;

[0030] As a further optimization of the last preferred embodiment of the present invention, the working platform 1 is rectangular, and its four sides are respectively equipped with synchronously moving lifting screws through threaded holes, and the four lifting screws are output by the same motor. The power drives the four to move synchronously, so that the working platform 1 can be controlled to stop at any height;

[0031] As another preferred embodiment of the present invention, the upper half of the grinding wheel 8 is covered with a grinding wheel cover, and the grinding wheel 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com