Assembly line type hardware product polishing equipment

An assembly-line, hardware technology, used in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of affecting processing rate, uneven grinding effect, low efficiency, etc., to achieve simple and convenient use and operation, human-friendly Design, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

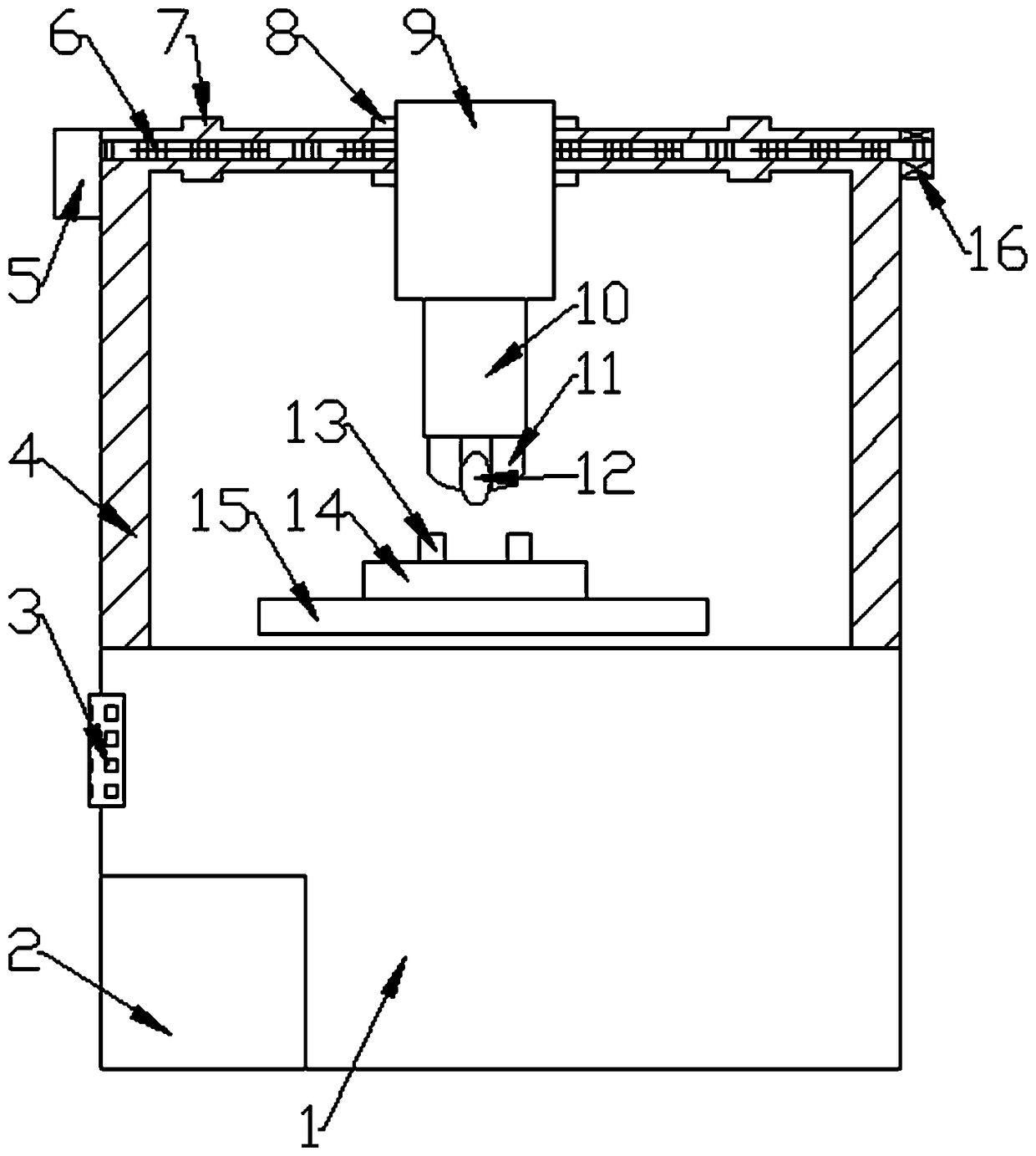

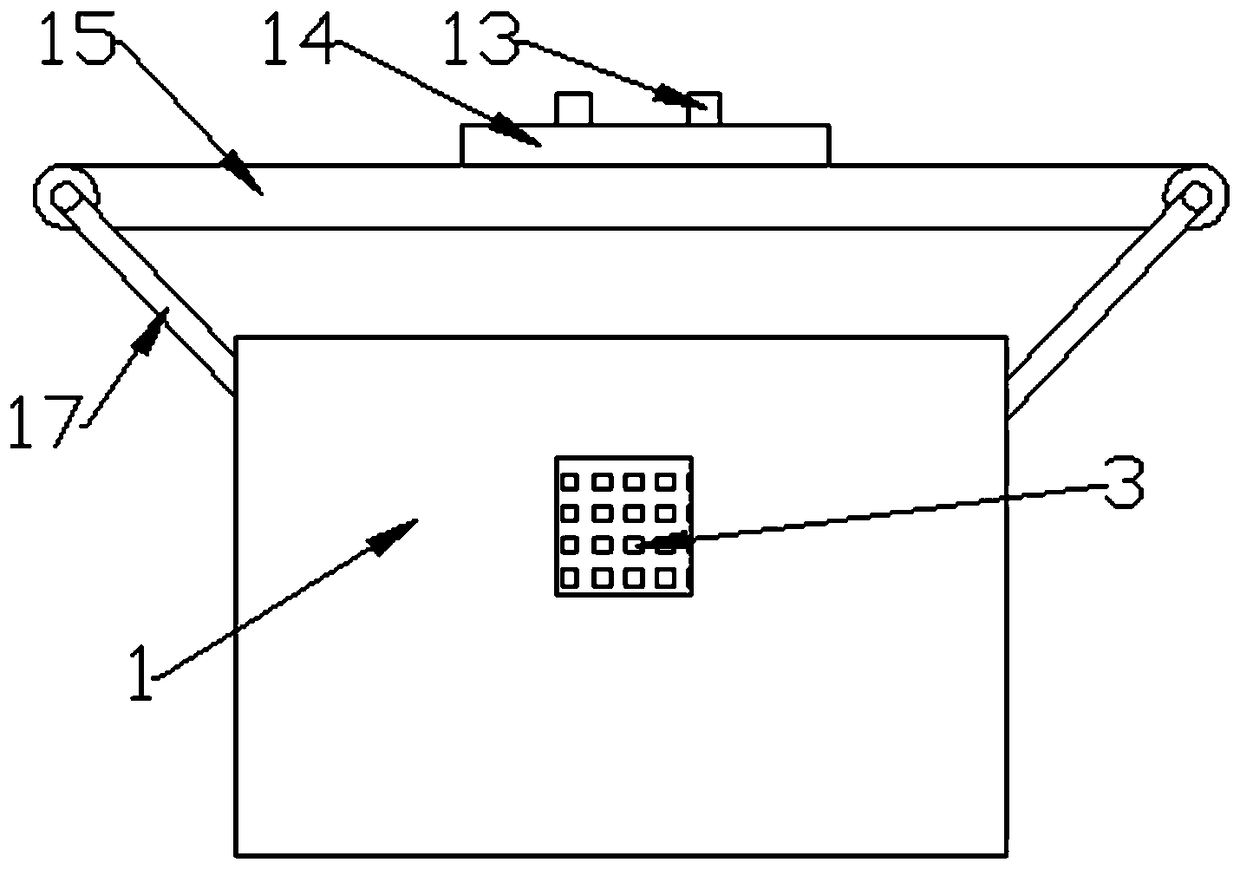

[0015] see Figure 1-3 , an assembly line type hardware product grinding equipment, including a workbench 1, a protective box 4, a transmission screw 6, a buffer block 7, a hydraulic telescopic rod 10, an oval grinding head 12, a special-shaped clamp 14 and a support rod 17; The workbench 1 is placed at the lower part of the entire equipment, providing installation space for the components installed on it and carrying the grinding work of hardware products; the protective box 4 is fixedly installed above the workbench 1, which plays a protective role to prevent grinding during the grinding process. Danger occurs in the middle; the transmission screw 6 is installed in the upper inner wall of the protective box 4, and the moving power is transmitted through the rotation of the thread; the hydraulic cylinder 9 passes through the protective box 4 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com