Colloid mill for producing capsule tablets

A colloid mill and tablet technology, applied in grain processing, etc., can solve the problems of resource waste, insufficient grinding efficiency, and inability to conveniently adjust the gap between the static grinding disc and the dynamic grinding disc, so as to improve efficiency and meet the needs of grinding. The effect of demand, speeding up the efficiency of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

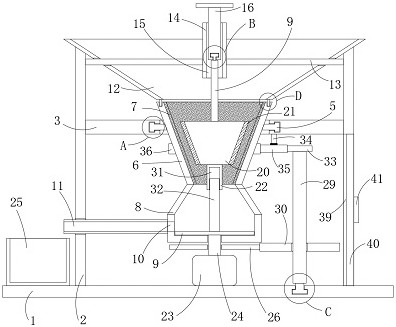

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

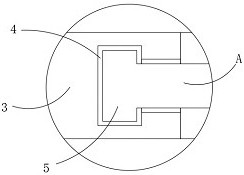

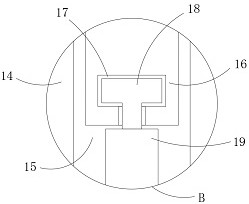

[0021] refer to Figure 1-6 , a colloid mill for producing capsule tablets, comprising a base 1, the upper end face of the base 1 is fixedly connected with a support tube 2, a side wall of the support tube 2 is provided with an opening 39, and a door panel 40 is provided in the opening 39, the door panel 40 One side wall away from the working bucket 6 is fixedly connected with a hinge 41, the hinge 41 is arranged on one side of the door panel 40, the end of the hinge 41 away from the door panel 40 is fixedly connected to the support tube 2, and the door panel 40 is away from the one end side of the hinge 41. A buckle 42 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com