Shaft outer ring polishing device

A technology for outer rings and moving devices, applied in the direction of grinding drive devices, devices for fixing grinding wheels, grinding machines, etc., can solve problems such as difficulties in grinding work, meet the needs of grinding, realize mechanized grinding operations, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

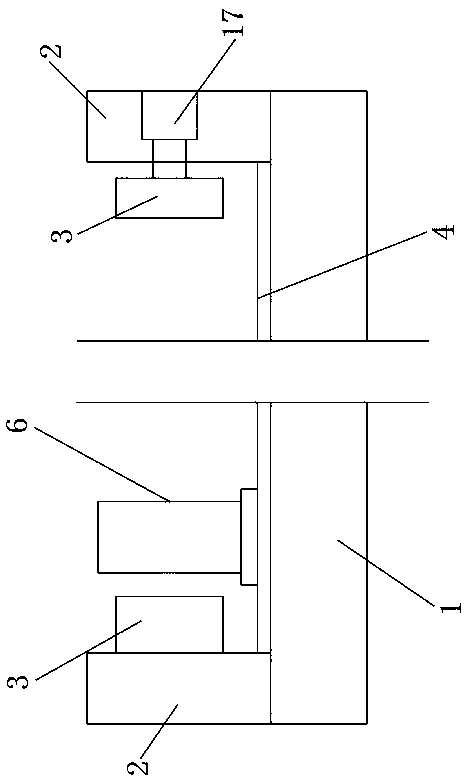

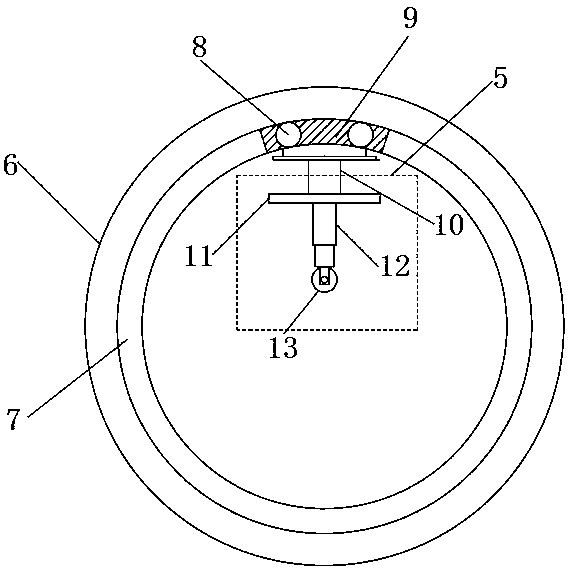

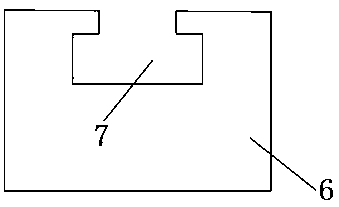

[0018] Such as Figure 1-5 It is a schematic diagram of the structure of the present invention, a shaft outer ring grinding device, including a base 1, side plates 2 of equal height on both sides of the base 1, and a concentric three-jaw chuck 3 installed on the inner side of the side plate 2, the base 1 The upper floor is provided with a reciprocating cylinder 4, a support ring 6 is installed on the slider of the reciprocating cylinder 4, and a grinding device 5 is installed inside the support ring 6.

[0019] When this kind of shaft outer ring grinding device is used, the shaft is hoisted by the hoisting equipment in the workshop, and the shaft is transferred to the top of the device. The support ring 6 installed on the slider of the reciprocating cylinder 4 is connected to the reciprocating cylinder. 4 is driven by the air pump to move to the end of the reciprocating cylinder 4, loosen the three-jaw chuck 3 with a wrench, place the shaft in the three-jaw chuck 3, and then l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com