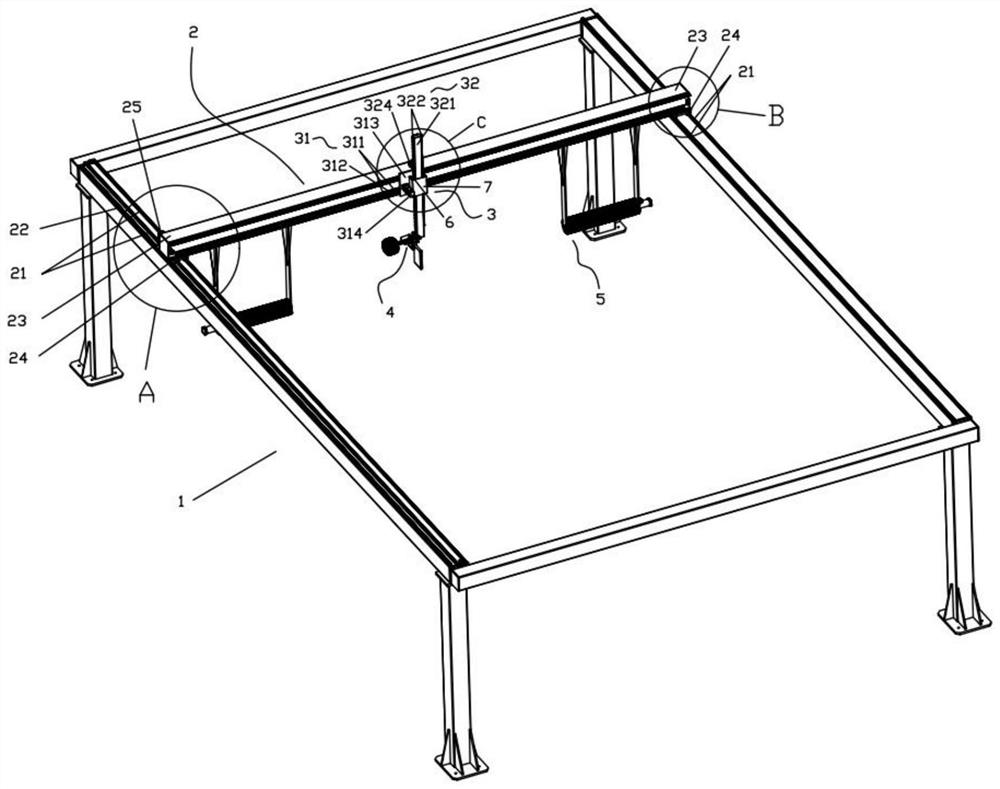

Lower die polishing device and polishing method

A technology of lower mold and grinding head, which is applied in the direction of grinding drive device, grinding machine, grinding slide, etc. It can solve the problems of not being able to meet the factory operation, the influence of the production efficiency of the cover beam, and the limitation of grinding efficiency, so as to improve the construction safety , Improve grinding efficiency and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0116] The present application also provides a grinding method for the lower mold grinding die device, comprising the following steps:

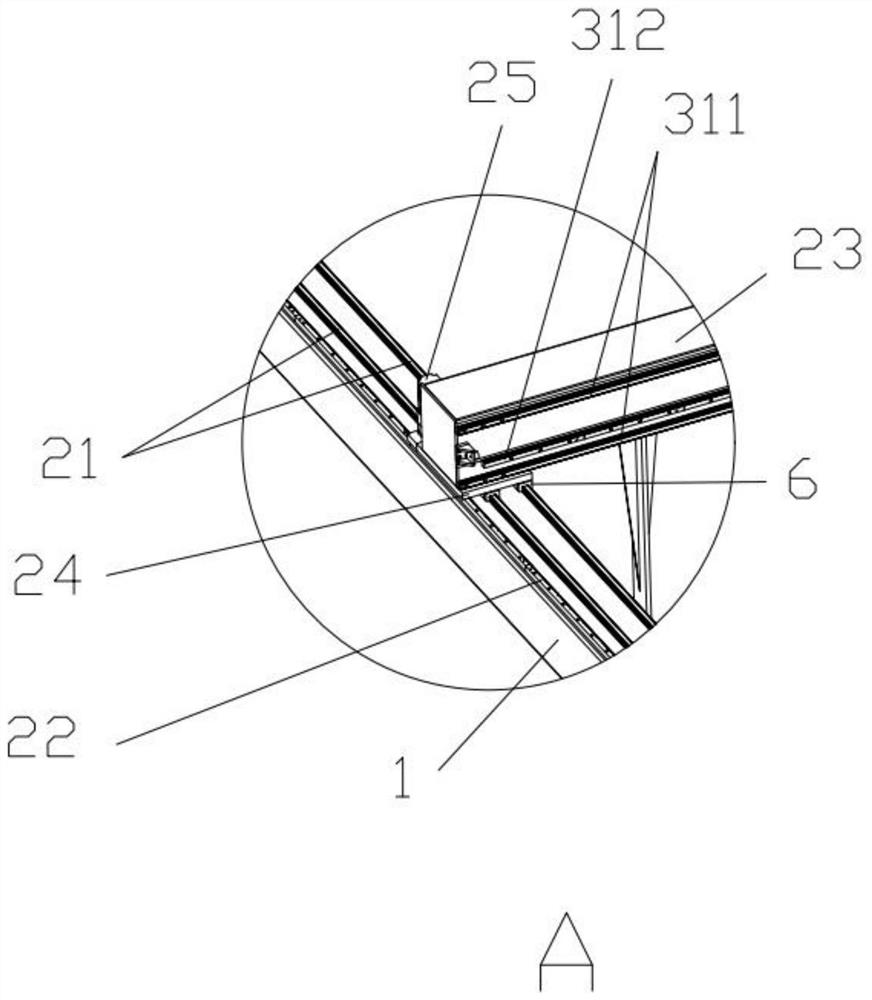

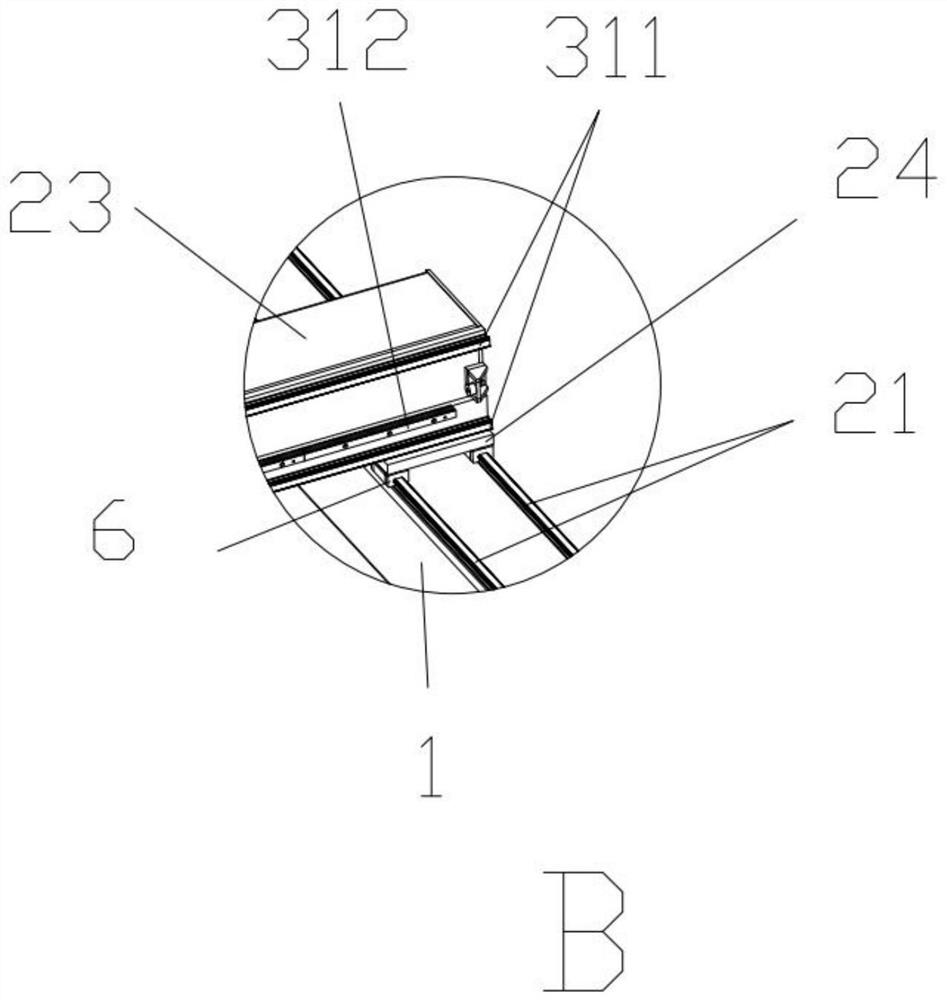

[0117] Step 100: Transport the lower mold 11 to the bottom of the truss 1 by the transport vehicle 12;

[0118] Step 200: Determine the required grinding position of the lower mold 11, adjust the positions of the main grinding head mechanism 4 and the auxiliary grinding head mechanism 5 in the first direction of the truss 1 through the longitudinal beam moving mechanism 2, and adjust the main grinding through the bidirectional moving mechanism 3 The position of the head mechanism 4 in the second direction of the truss 1 and the position of the main grinding head mechanism 4 in the third direction of the truss 1;

[0119] Step 300 : After the main grinding head mechanism 4 and the auxiliary grinding head mechanism 5 are adjusted to the desired grinding position of the lower mold 11 , the main grinding head mechanism 4 and the auxiliary grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com