Patents

Literature

108results about How to "Meet grinding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

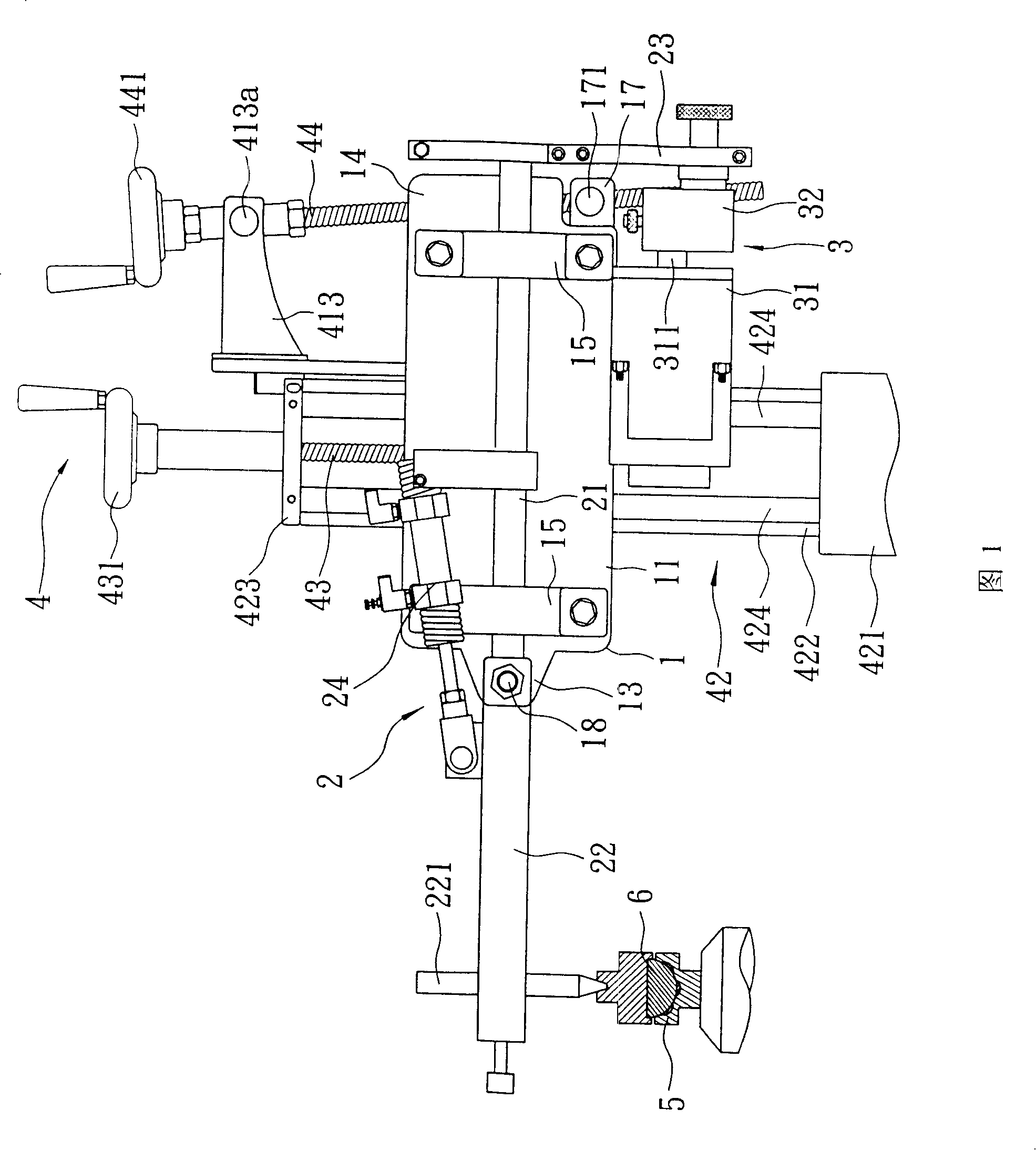

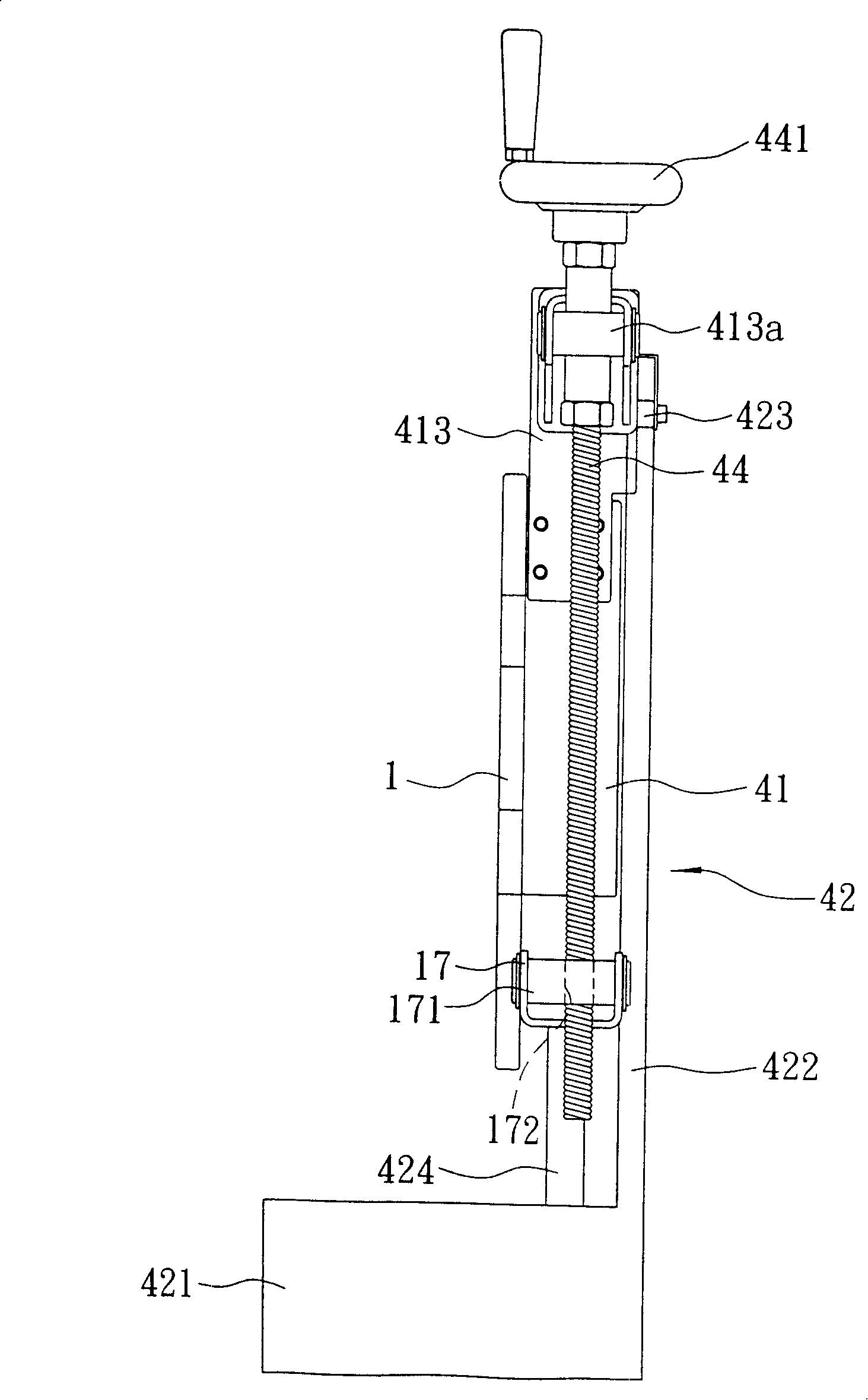

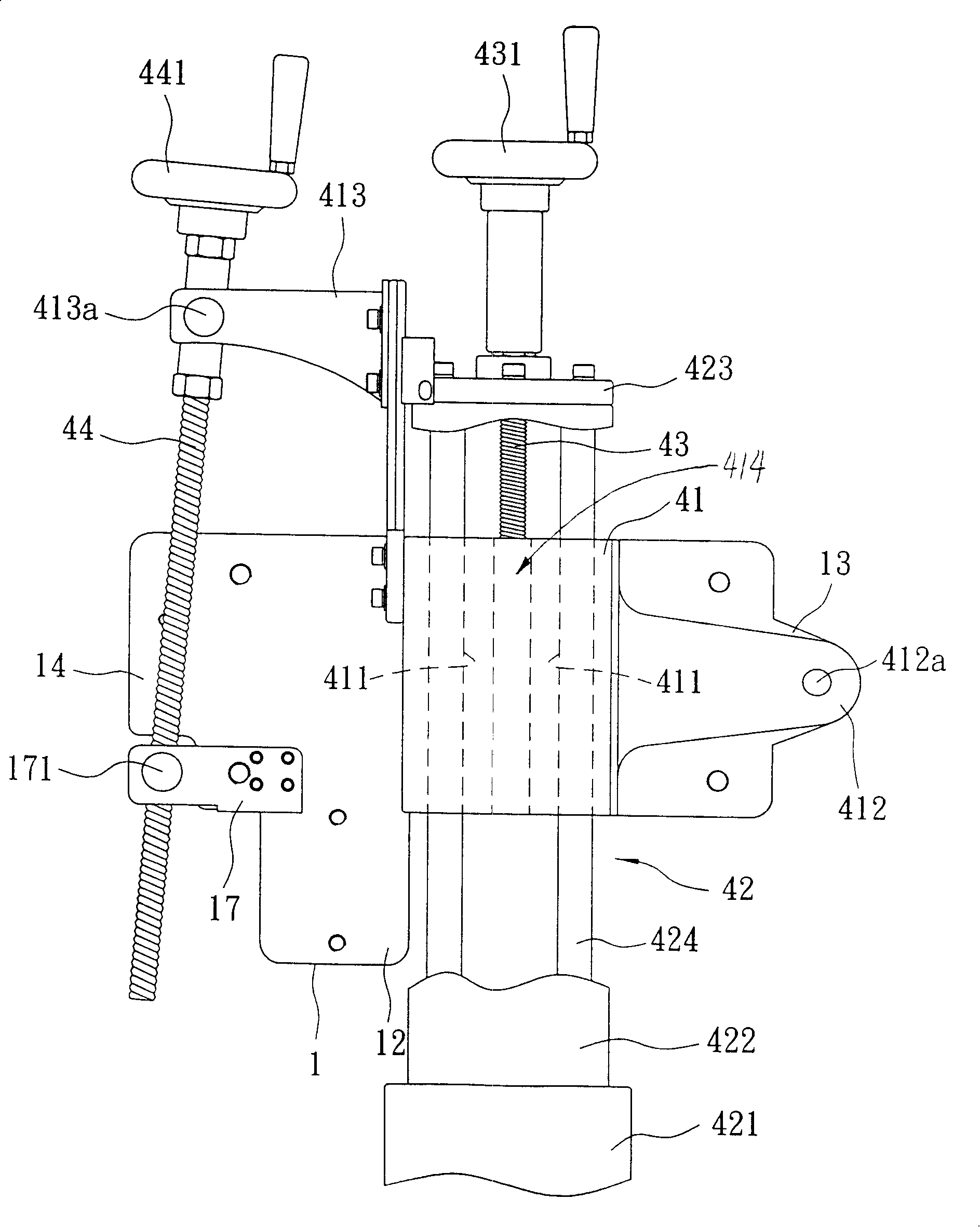

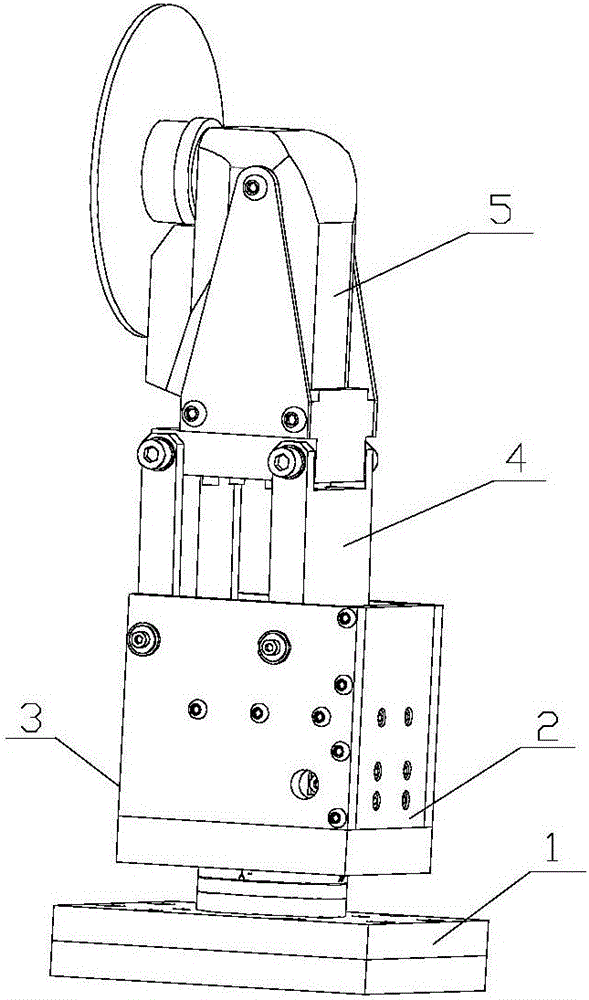

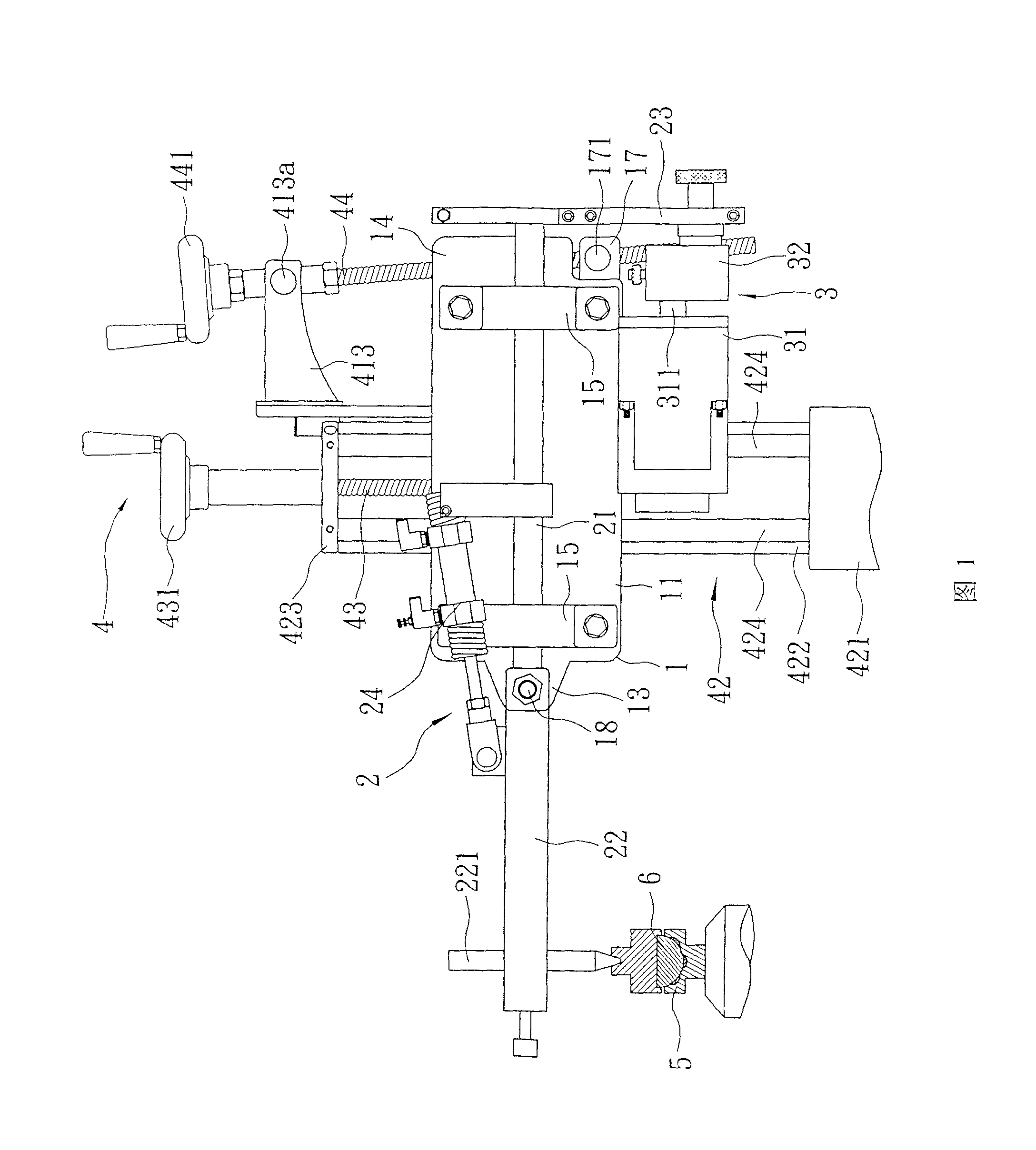

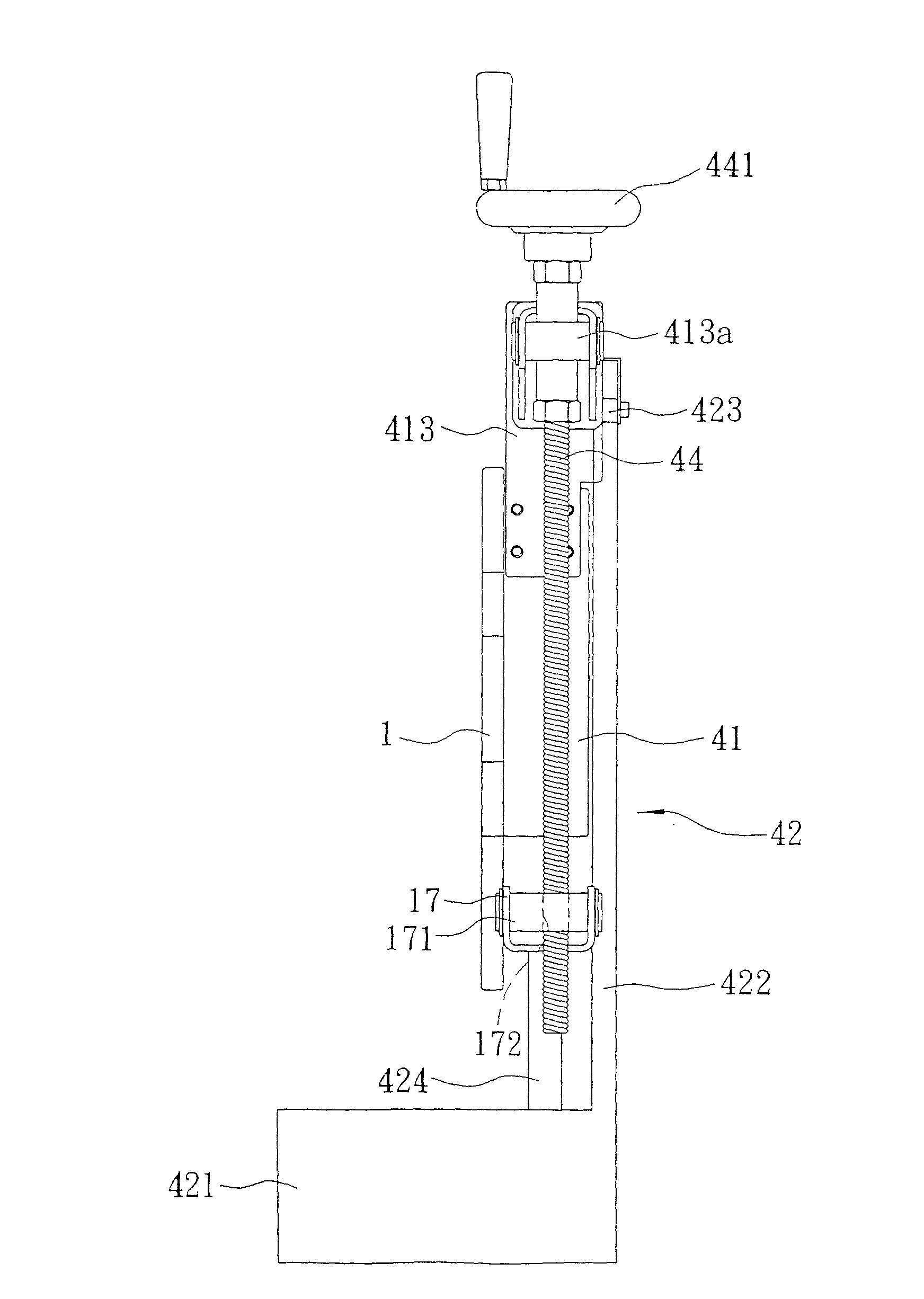

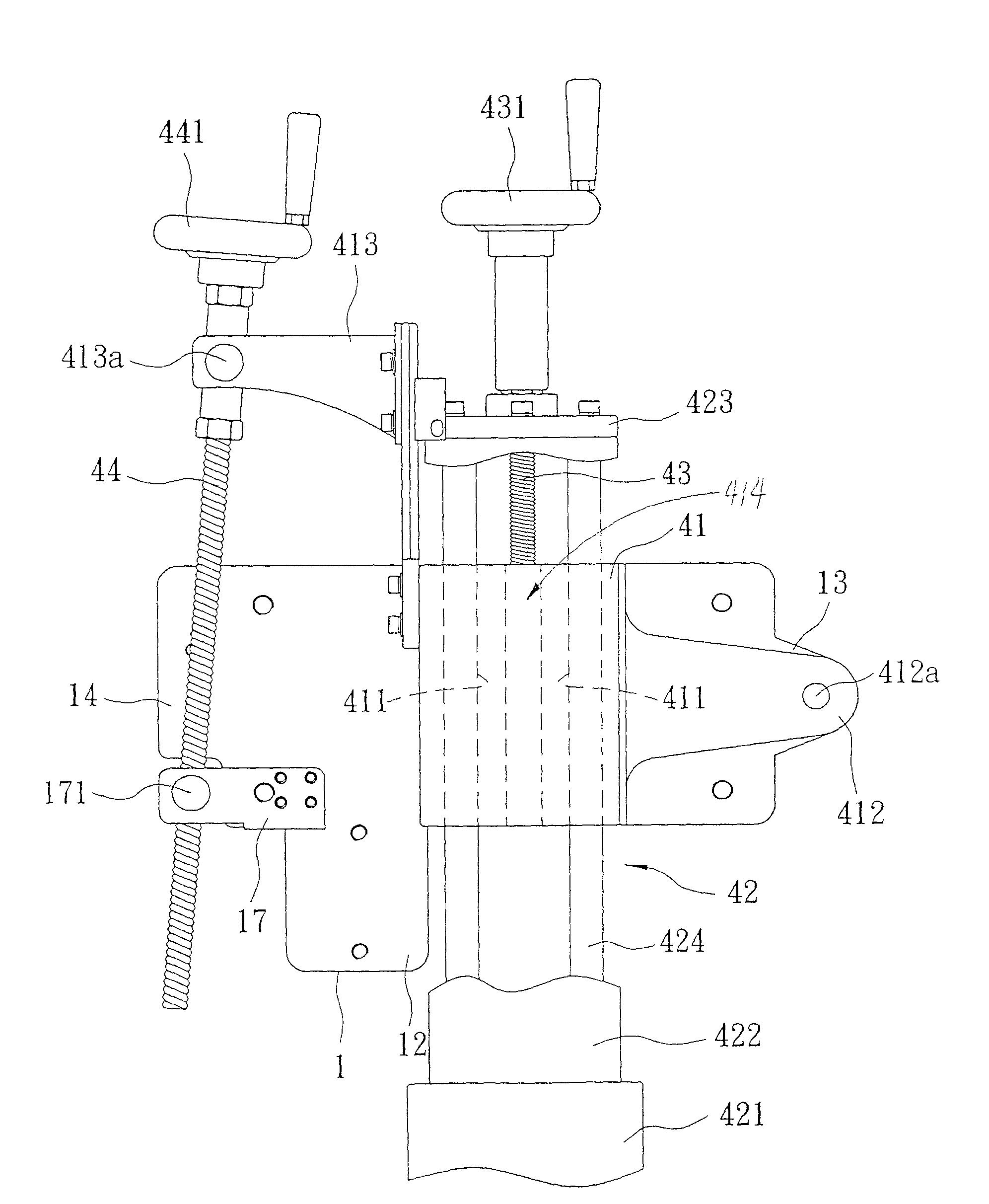

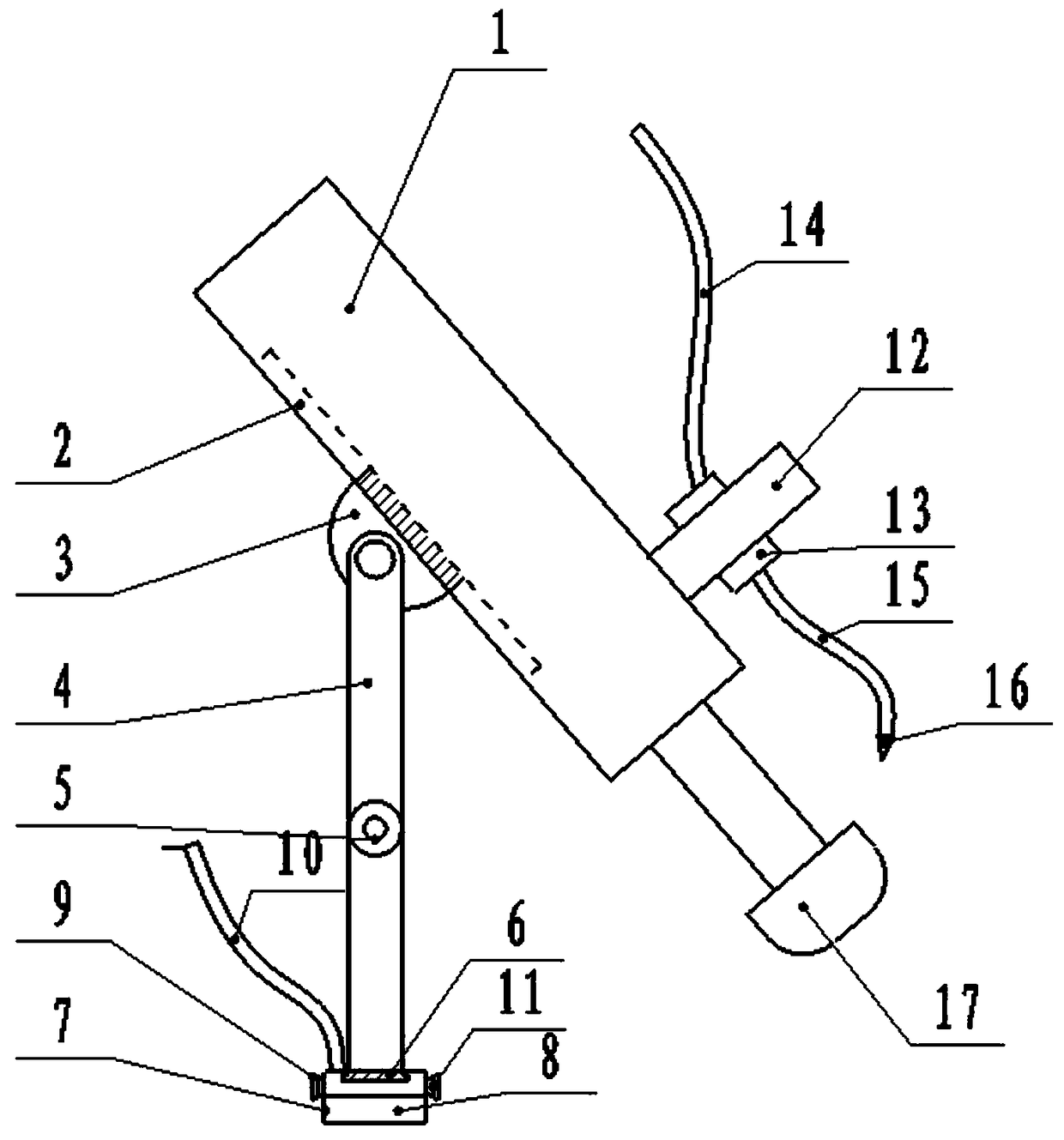

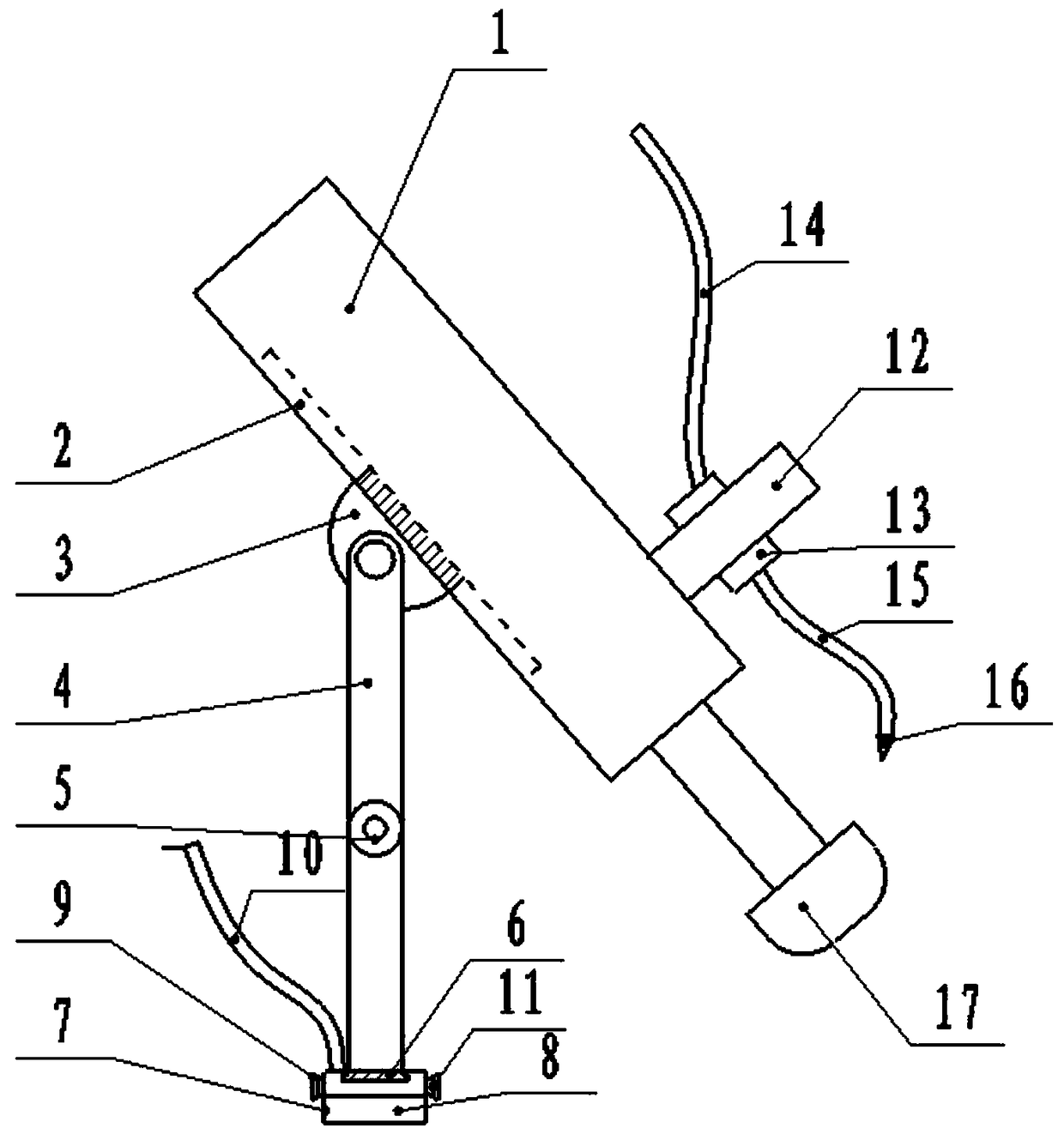

Adjustable lens grinding device according to lens centre and arc radius

ActiveCN101224554AMeet grinding needsOptical surface grinding machinesGrinding drivesEngineeringLens plate

The invention provides an eyeglass grinding device which can be adjusted according to the spherical center and the diameter of the arc of the eyeglass. The invention is provided with a vertical basic plate which is connected with a grinding mechanism which can be adjusted in an inclined angle by the vertical basic plate and can be driven to swing by a driving mechanism, and a displacement mechanism which is provided with a sliding block which can longitudinally move and can be used for supporting the vertical basic plate; by adopting the structure, the grinding device can correct the amplitude of swing and the central point of the swing amplitude according to the spherical center and the diameter of the arc of the processed eyeglass correspondingly before the grinding operation is carried out, so as to position the best grinding position.

Owner:MAI JIUN MASCH CO LTD

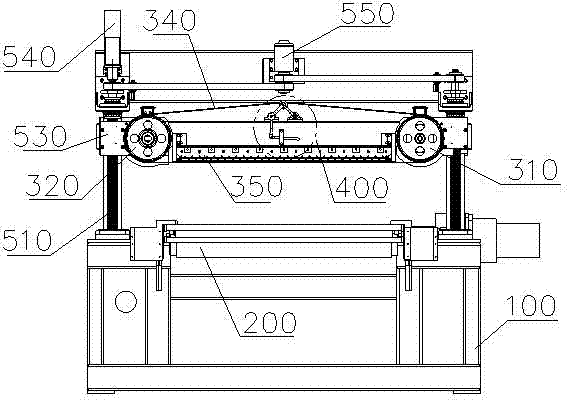

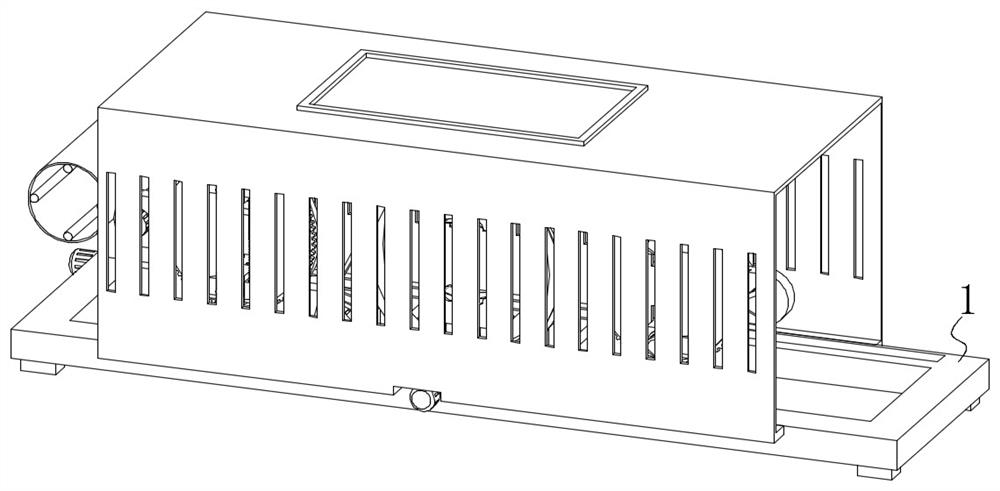

Automatic grinding device

The invention discloses an automatic grinding device. The automatic grinding device comprises a working table, a conveyor belt and at least one grinding mechanism, wherein the conveyor belt is arranged on the working table, and the grinding mechanism is arranged above the conveyor belt. The grinding mechanism comprises a driving wheel, a driven wheel, a grinding motor and an abrasive belt, wherein the driving wheel and the driven wheel are arranged on the two sides of the conveyor belt respectively, the grinding motor is connected with the driving wheel and supplies power to the driving wheel, and the abrasive belt winds the surface of the driving wheel and the surface of the driven wheel. The abrasive belt winds the driving wheel and the driven wheel and makes contact with grinded materials to form a grinding plane. The automatic grinding device is high in grinding efficiency, good in grinding effect, high in accuracy, and especially suitable for grinding different materials.

Owner:徐成炳

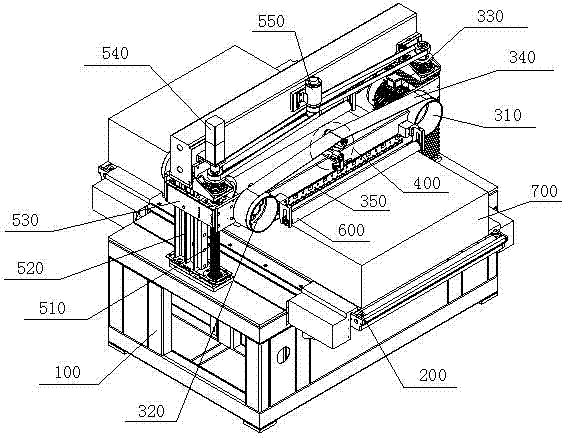

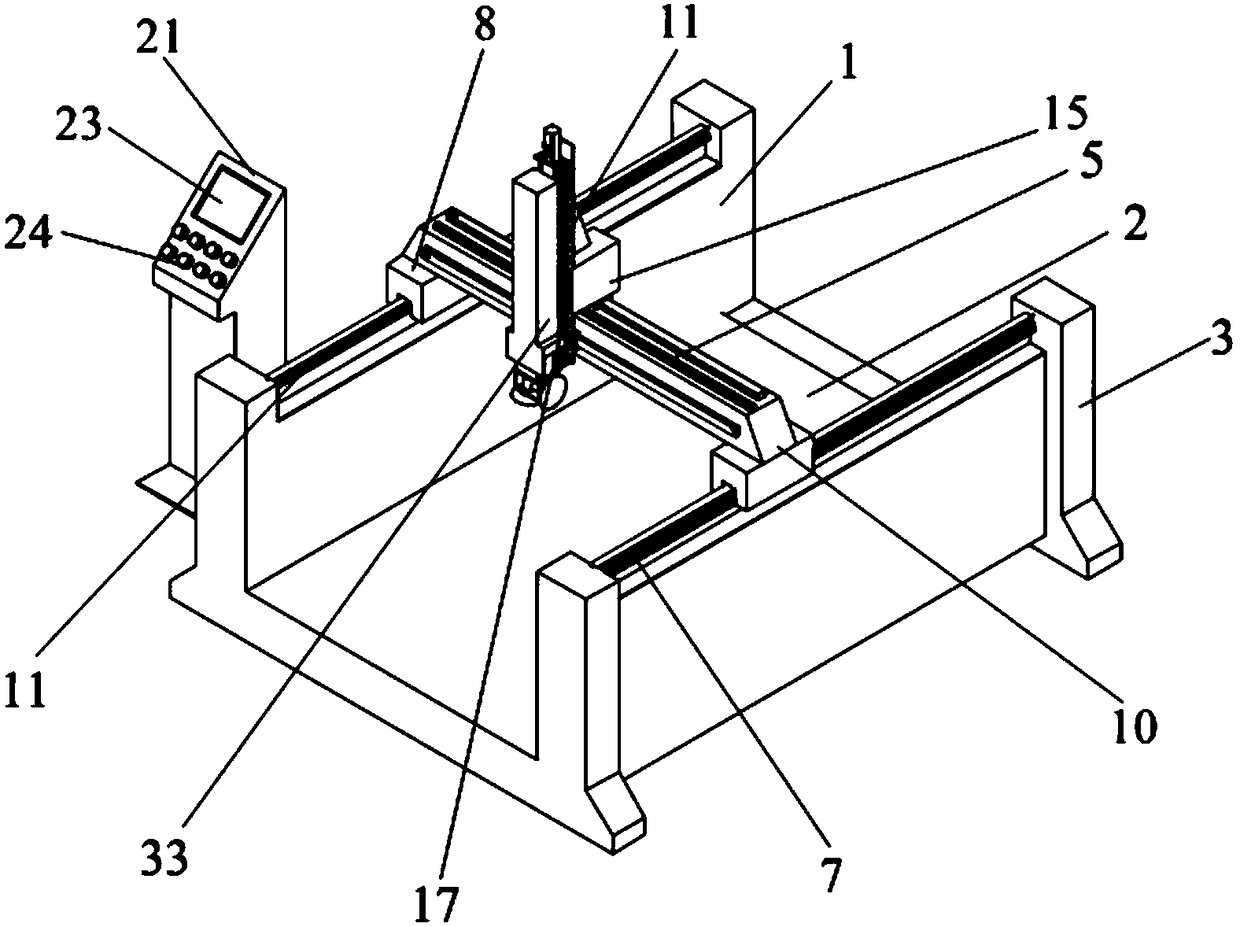

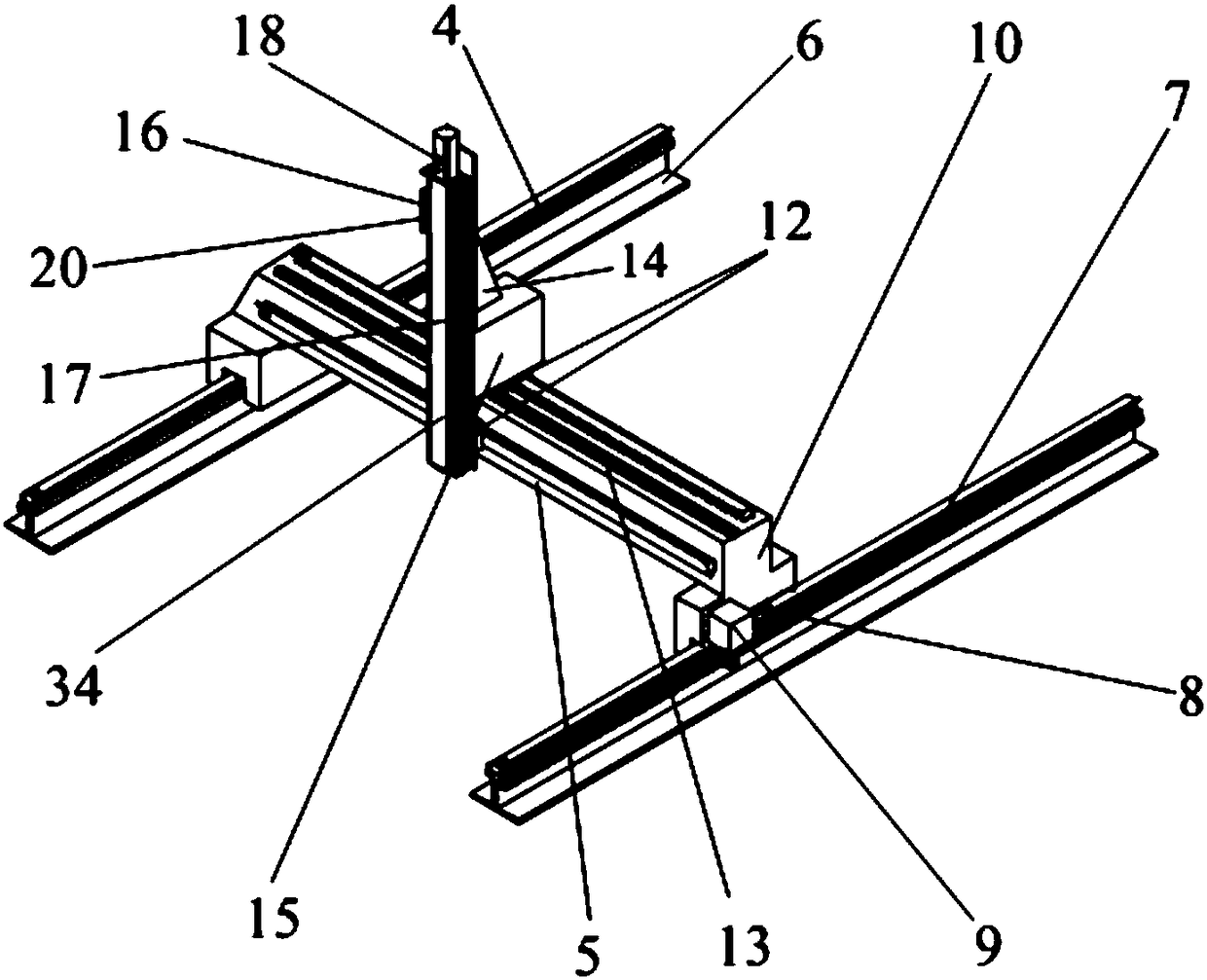

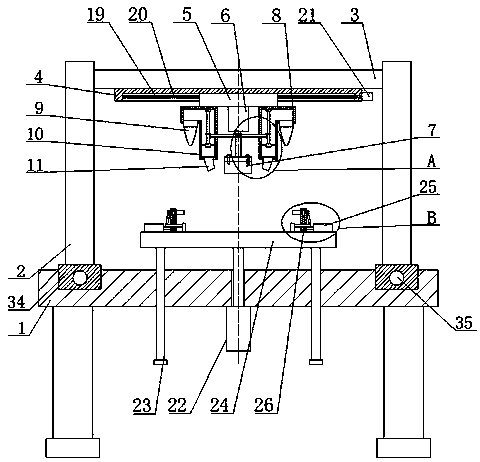

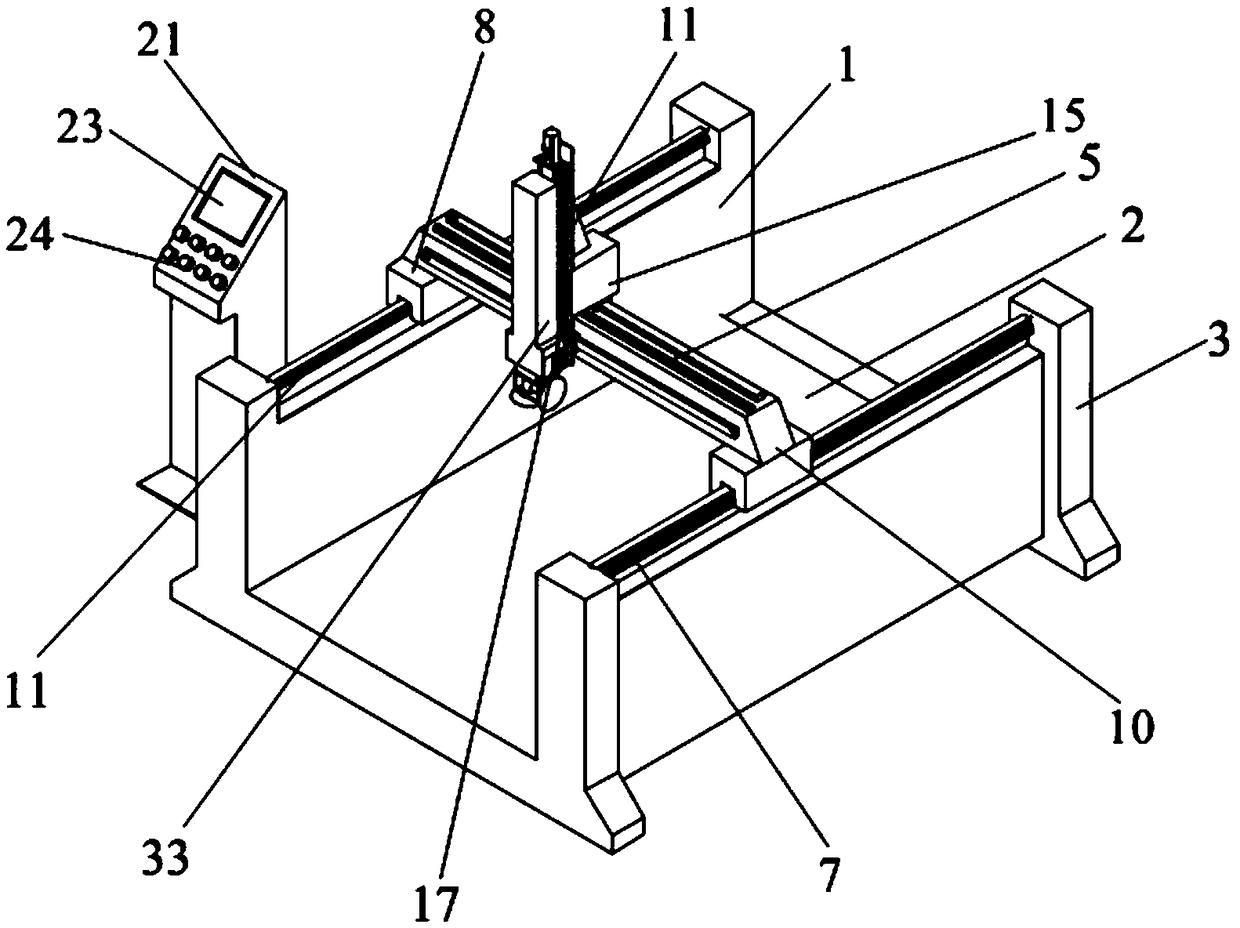

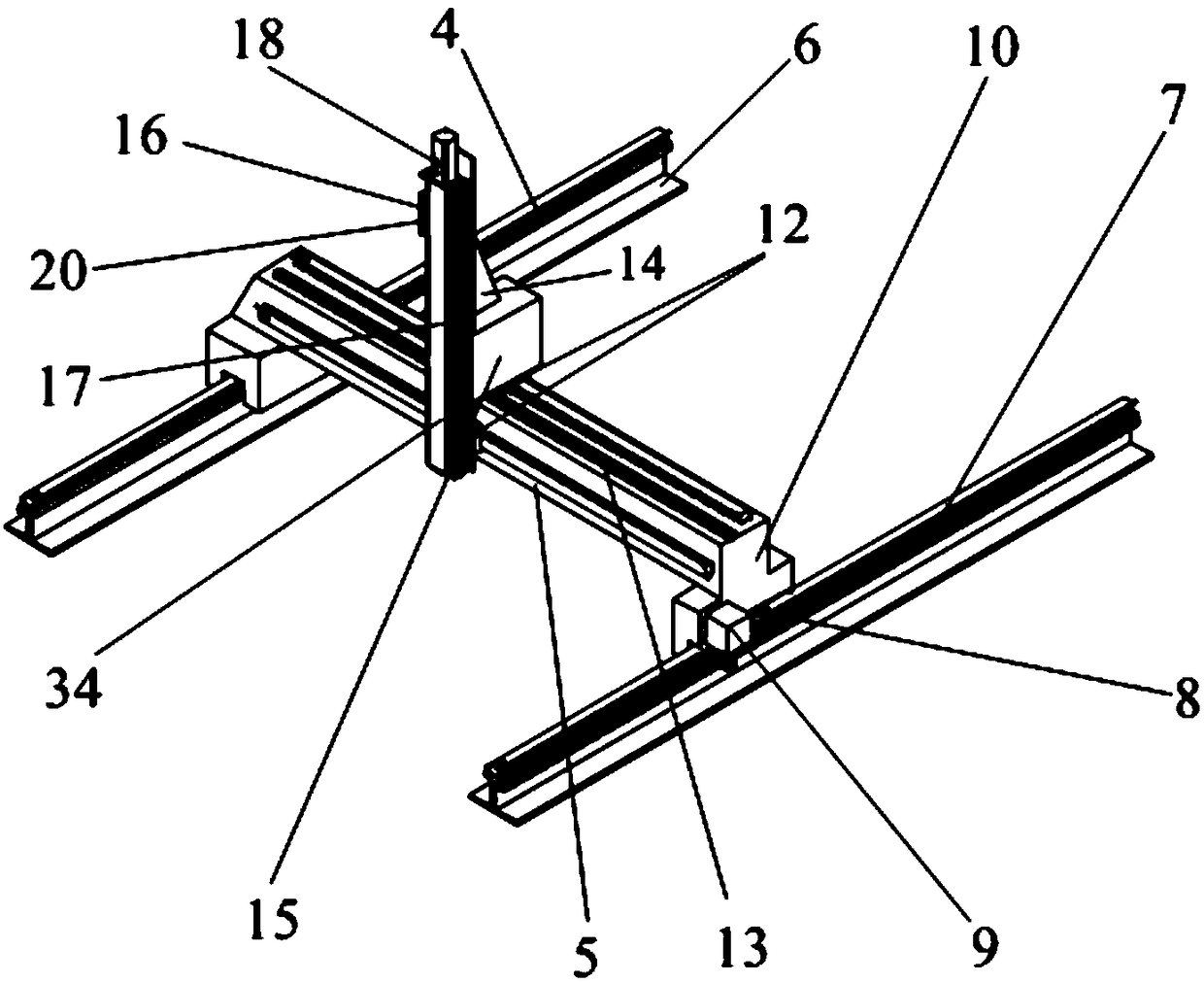

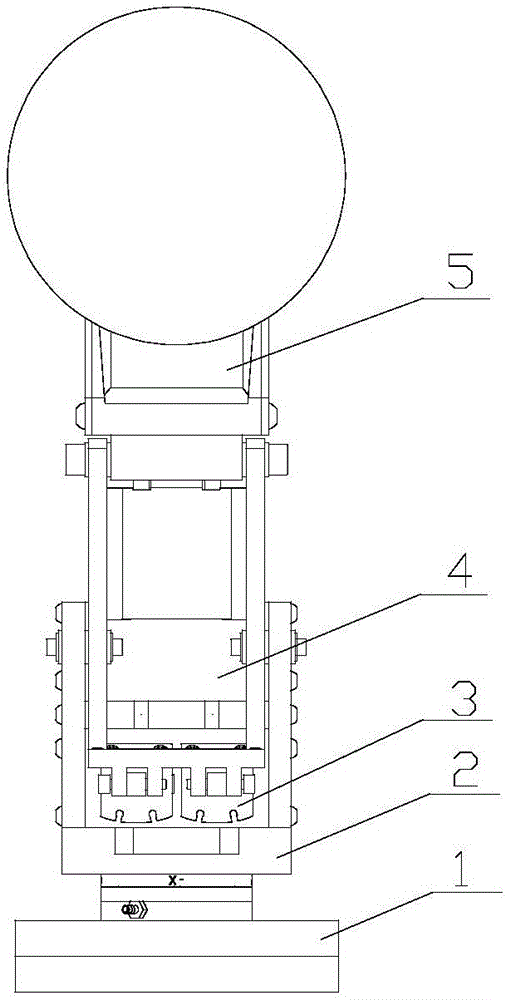

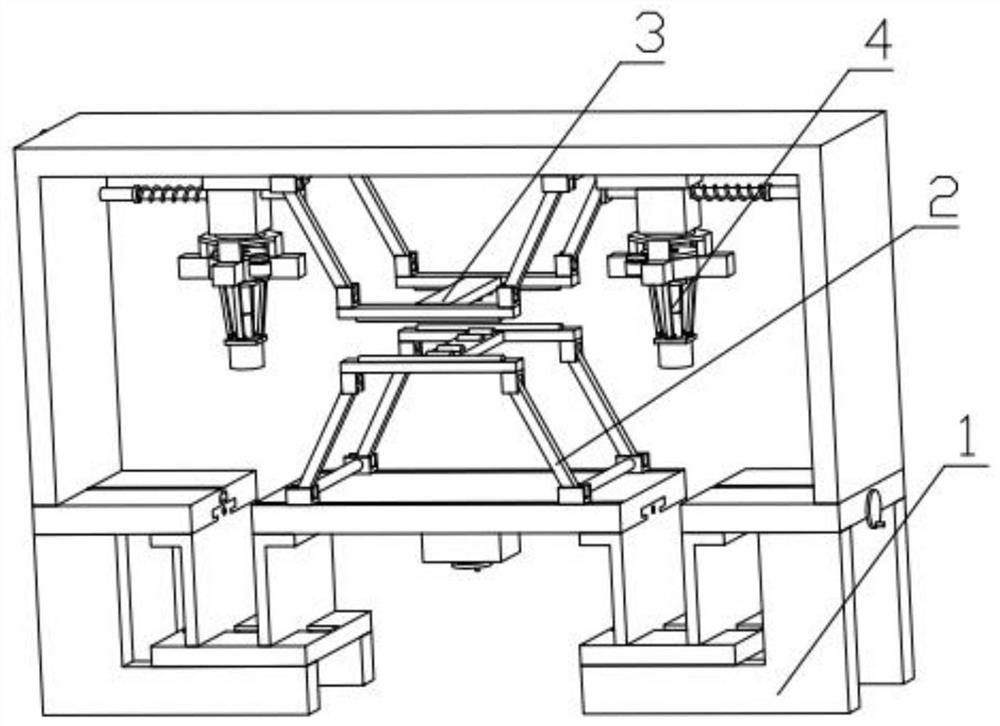

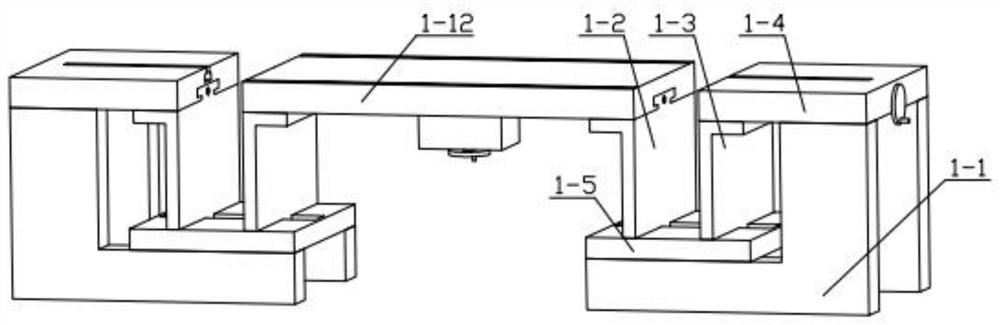

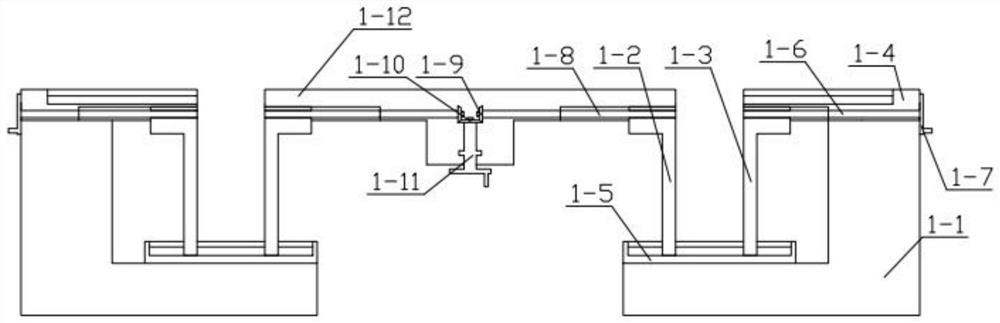

Multi-degree-of-freedom robot for grinding

InactiveCN108500841APrevention of voluntary fallsHigh control precisionGrinding drivesGrinding machinesMulti degree of freedomEngineering

The invention discloses a multi-degree-of-freedom robot for grinding. The multi-degree-of-freedom robot comprises a working platform, a grinding device and a control device, wherein the two longitudinal guide rails are arranged at the top end of the working platform in parallel, a transverse guide rail capable of moving back and forth along the longitudinal guide rails is arranged on the longitudinal guide rails, and the transverse guide rail is provided with a vertical guide rail capable of moving left and right along the transverse guide rail; the grinding device can move up and down in thevertical direction of the vertical guide rail; and the transverse guide rail, the longitudinal guide rails and the grinding device are correspondingly connected with driving mechanisms for driving thetransverse guide rail, the longitudinal guide rails and the grinding device to move. The multi-degree-of-freedom robot for grinding has the advantages of being simple and compact in structure, low inmanufacturing cost and convenient and fast to use.

Owner:南京航扬机电科技有限公司

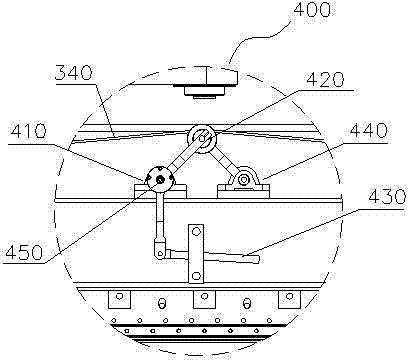

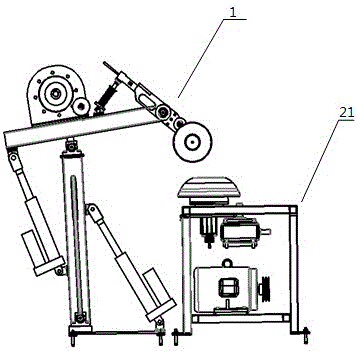

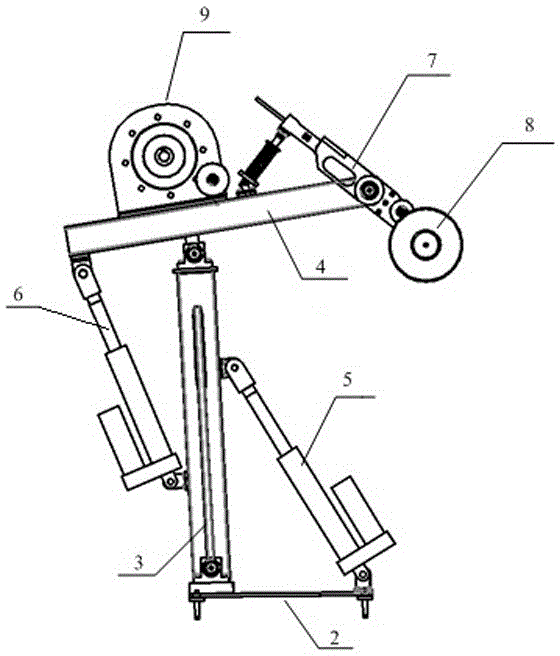

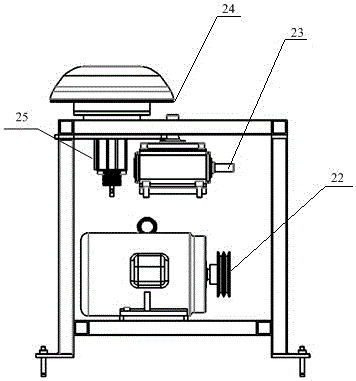

Grinding equipment and grinding method

ActiveCN105666280AAchieve grindingImplement servo controlSpherical surface grinding machinesGrinding feed controlControl systemEngineering

The invention discloses grinding equipment and a grinding method. The grinding equipment and the grinding method aim at solving the problems that at present, manpower is mainly adopted to grind a pot billet, consequently, operation efficiency is low, the requirement of an existing grinding device for the position of the pot billet is low, and certain limitation exists. The grinding equipment comprises a grinding mechanism and a control system; and the grinding mechanism comprises a grinding support, a first supporting rod, a second supporting rod, a first telescopic arm, a second telescopic arm, a third supporting rod, a grinding wheel and a grinding wheel driving device. One end of the first supporting rod is movably connected with the grinding support, and the first supporting rod can rotate relative to the grinding support; and the other end of the first supporting rod is movably connected with the second supporting rod. According to the grinding equipment, the automatic grinding requirement for workpieces with different sizes can be met, the extremely-high adaption is achieved, the grinding quality is good, efficiency is high, the production period is short, the cost is low, the good application prospect is achieved, and the equipment is worth applying and popularizing in a large-scale manner.

Owner:SICHUAN FUDE ROBOT

Polishing device for mold production

The invention discloses a polishing device for mold production and relates to the technical field of mold manufacturing. The polishing device comprises a base, a shell is fixedly connected to one side of the top of the base, a first motor is fixedly connected to the bottom of the inner wall of the shell, a first belt wheel is fixedly connected to an output shaft of the first motor, a second belt wheel is connected to the surface of the first belt wheel through a belt in a transmission mode, and a first gear is fixedly connected to one side of the second belt wheel and meshed with a second gear fixedly installed at the top of the inner wall of the shell. According to the polishing device for mold production, a lead screw is driven to move through the first motor and drives an ejector rod to ascend and descend to drive a top plate to ascend and descend, the height of a polishing wheel is adjusted, a rotating handle is rotated to drive the lead screw to rotate to drive a movable rod to move, a mold is clamped and fixed, a moving plate is driven to move by pushing a handle to polish the mold in all directions, and therefore the using effect is good.

Owner:LIXING PLASTICS SHENZHEN

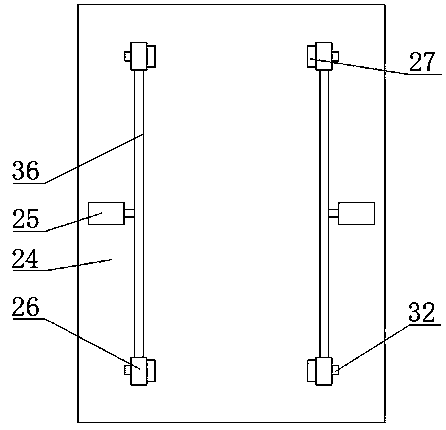

Convenient-to-adjust polishing device for sofa processing

InactiveCN111283519AImprove stabilityEasy to fixGrinding drivesGrinding machinesPolishingElectric machinery

The invention belongs to the technical field of sofa plate polishing, and particularly relates to a convenient-to-adjust polishing device for sofa processing. In order to solve the problems that the position of an existing polishing mode is inconvenient to adjust, dust generated by polishing cannot be cleaned, the fixing mode is single, and the fixing effect is poor, the following scheme is provided. The convenient-to-adjust polishing device for sofa processing comprises a machining plate, two vertical rods are slidably mounted at the top of the machining plate, one same connecting rod is fixedly mounted between the two vertical rods, a transverse mechanism is arranged at the bottom of the connecting rod, a guide block is connected to the transverse mechanism, a grinding motor is fixedly connected to the bottom of the guide block, a worm is fixedly connected to an output shaft of the grinding motor, a grinding head is connected to the bottom end of the worm, and two dust collection structures are symmetrically installed at the bottom of the guide block and matched with the worm. According to the convenient-to-adjust polishing device, the grinding position can be conveniently adjusted, comprehensive grinding can be achieved, the dust generated by grinding can be cleared away, and the fixing efficiency is improved.

Owner:杨明清

Multi-freedom-degree robot used for polishing

ActiveCN109227322APrevention of voluntary fallsHigh control precisionGrinding drivesAutomatic grinding controlMulti degree of freedomEngineering

Owner:南京航扬机电科技有限公司

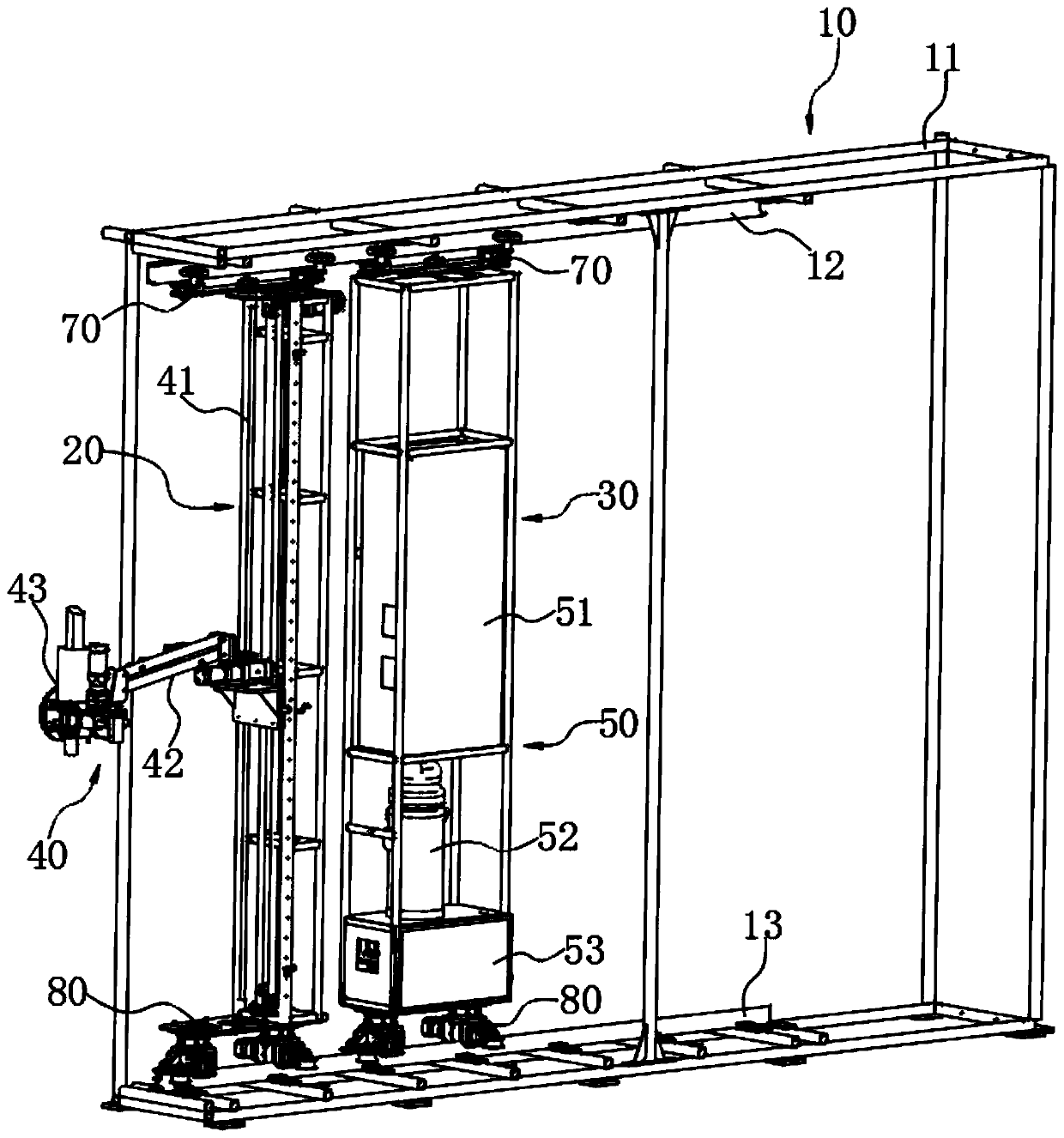

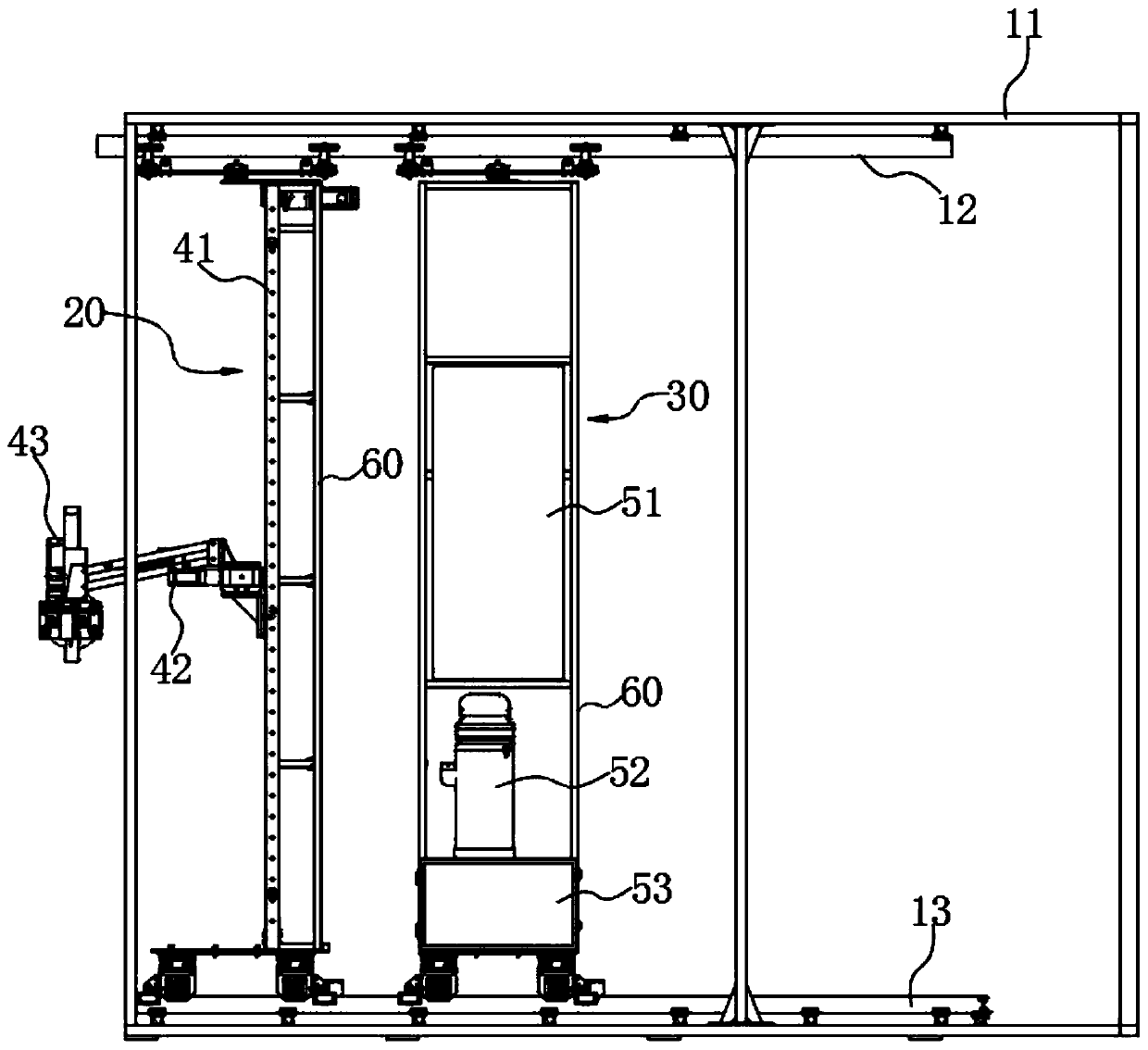

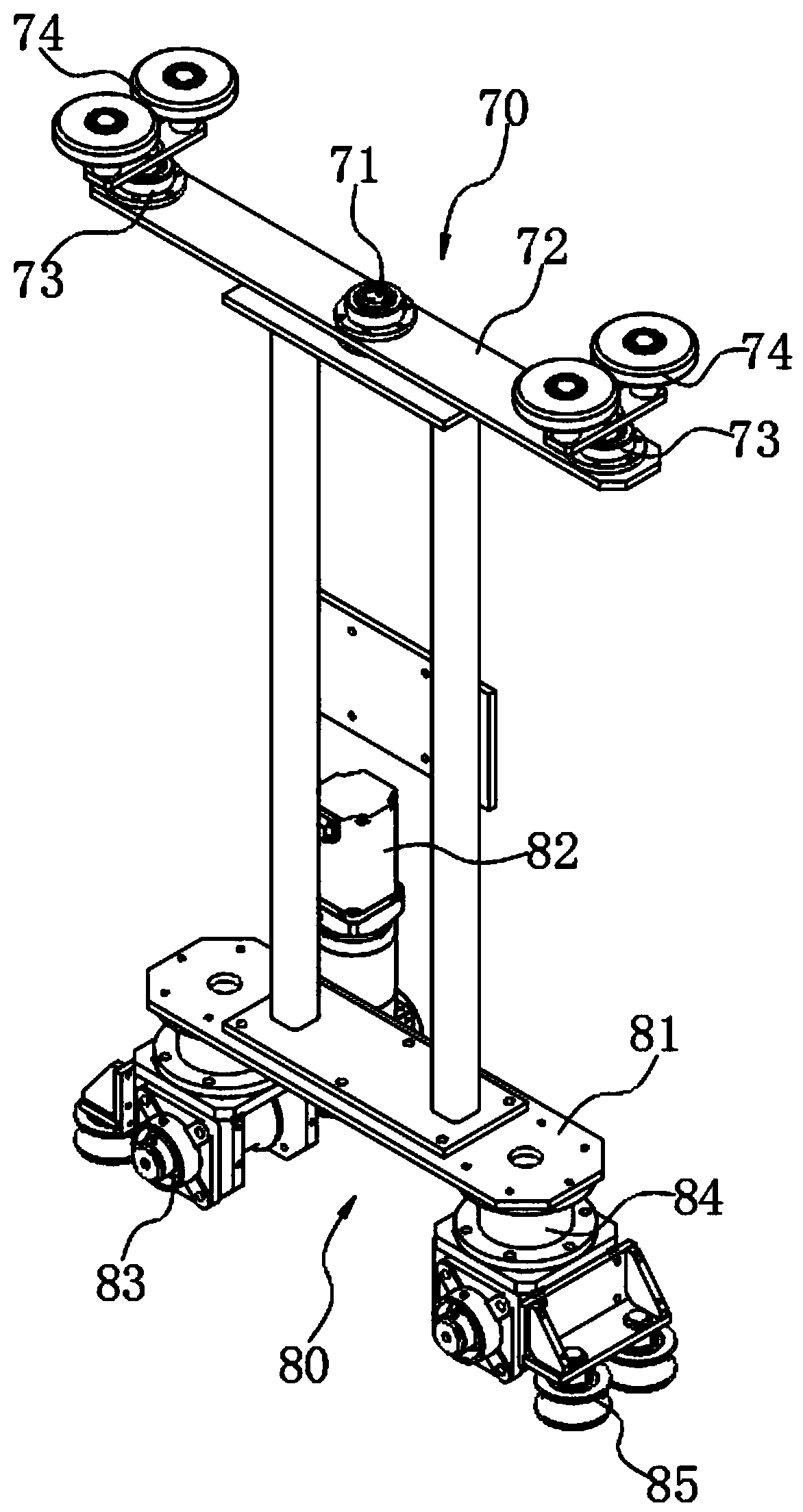

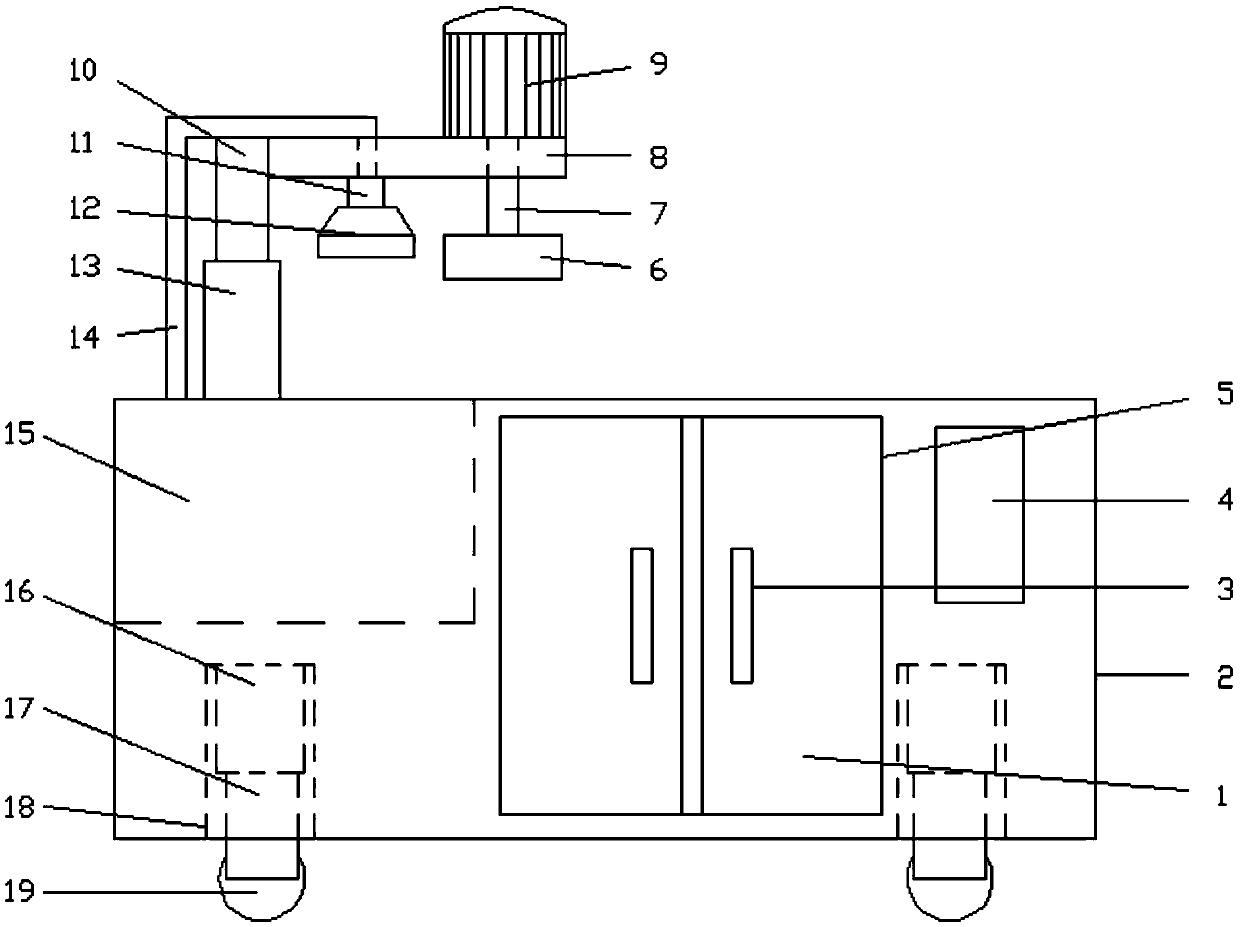

Polishing robot

ActiveCN111037392AImprove safety and reliabilityReduce loadGrinding drivesGrinding feed controlPolishingEngineering

The invention relates to a polishing robot comprising a rail frame; a main walking device which is movably arranged on the rail frame and provided with a polishing execution device; and an auxiliary walking device which is movably arranged on the rail frame and used for being cooperatively matched with the main walking device and is provided with a polishing auxiliary device, wherein the polishingauxiliary device is used for assisting the polishing execution device in conducting polishing operation. The composition structures of the main walking device and the auxiliary walking device are greatly simplified, the weight is also greatly reduced, the rail frame can be effectively prevented from deforming and breaking due to overload, and the operation safety and reliability of the polishingrobot are improved; when the robot passes through a rail section with a small turning radius, the main walking device and the auxiliary walking device can be located at different turning angle positions so that the excellent curve passing capacity is achieved, the internal and external corner polishing requirement can be met and the polishing work performance can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

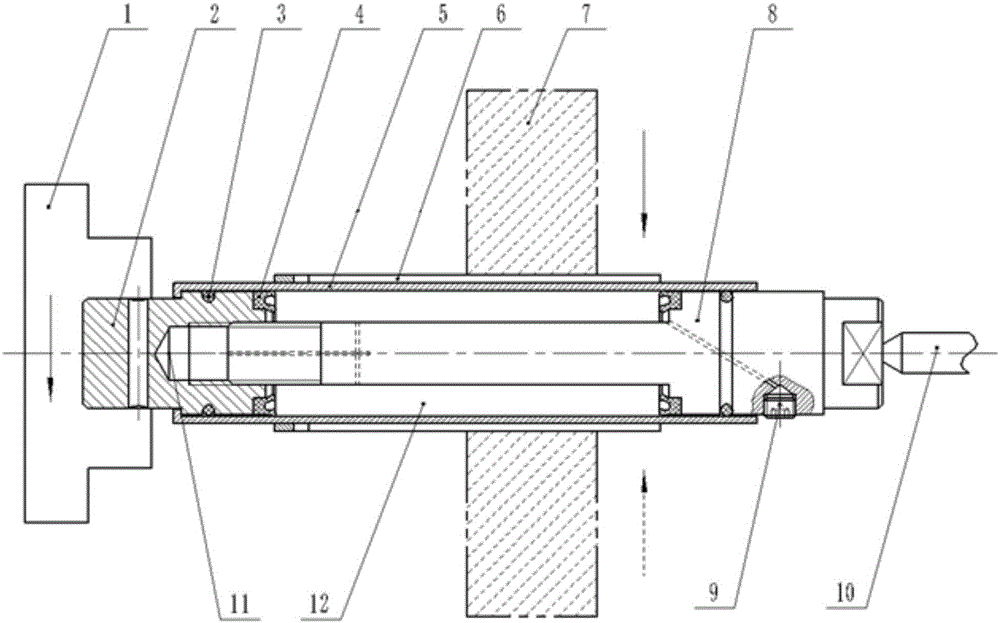

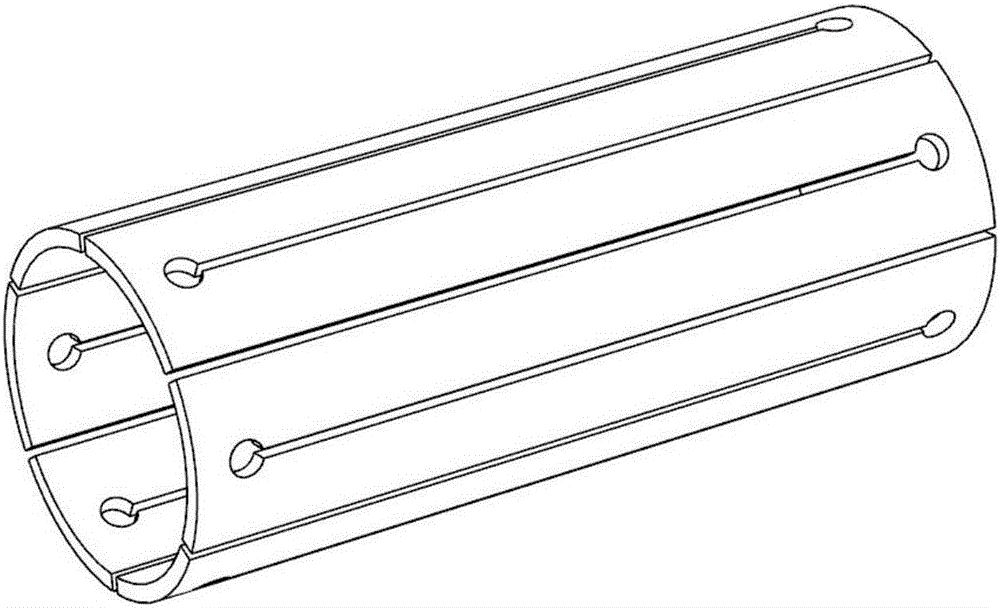

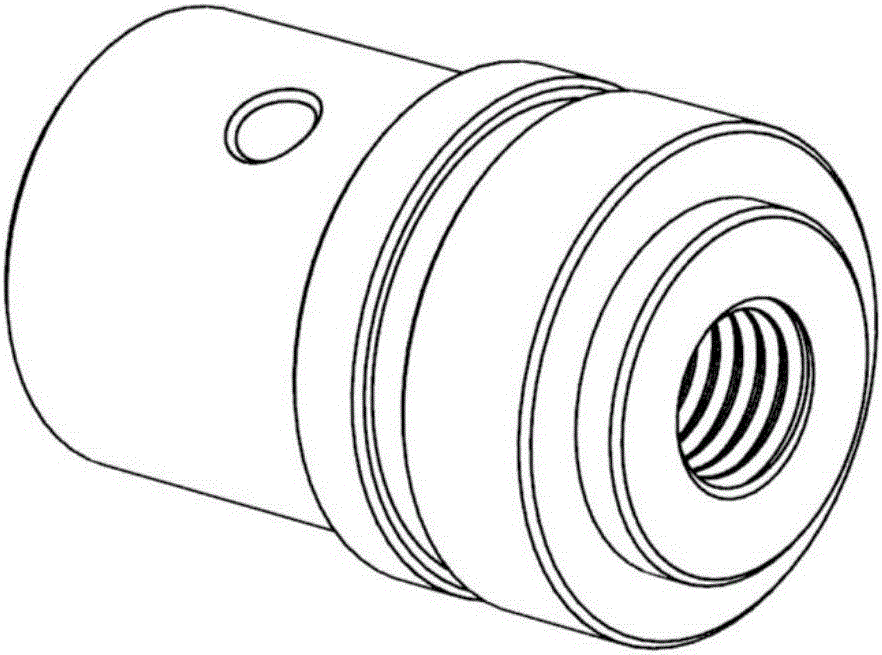

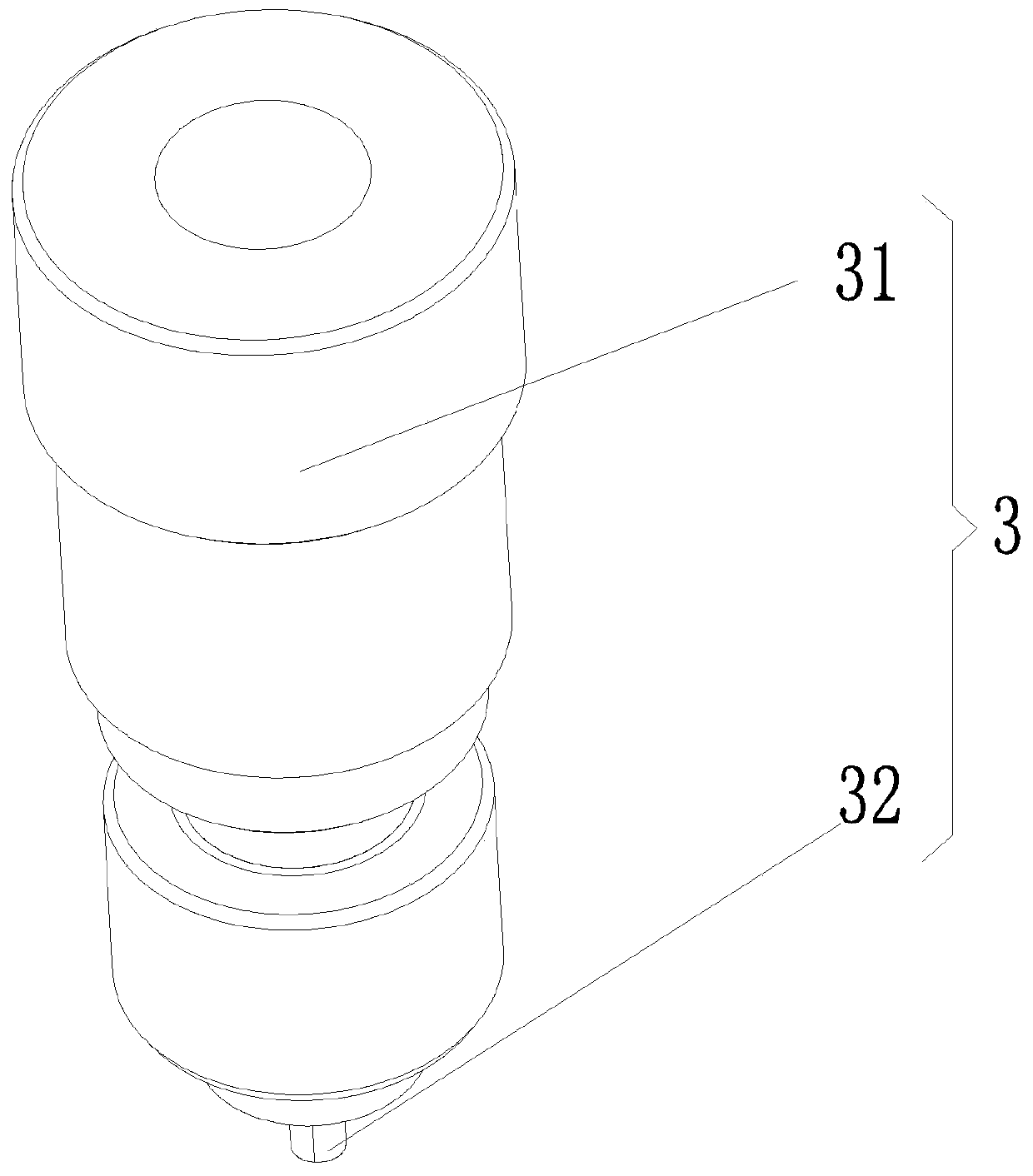

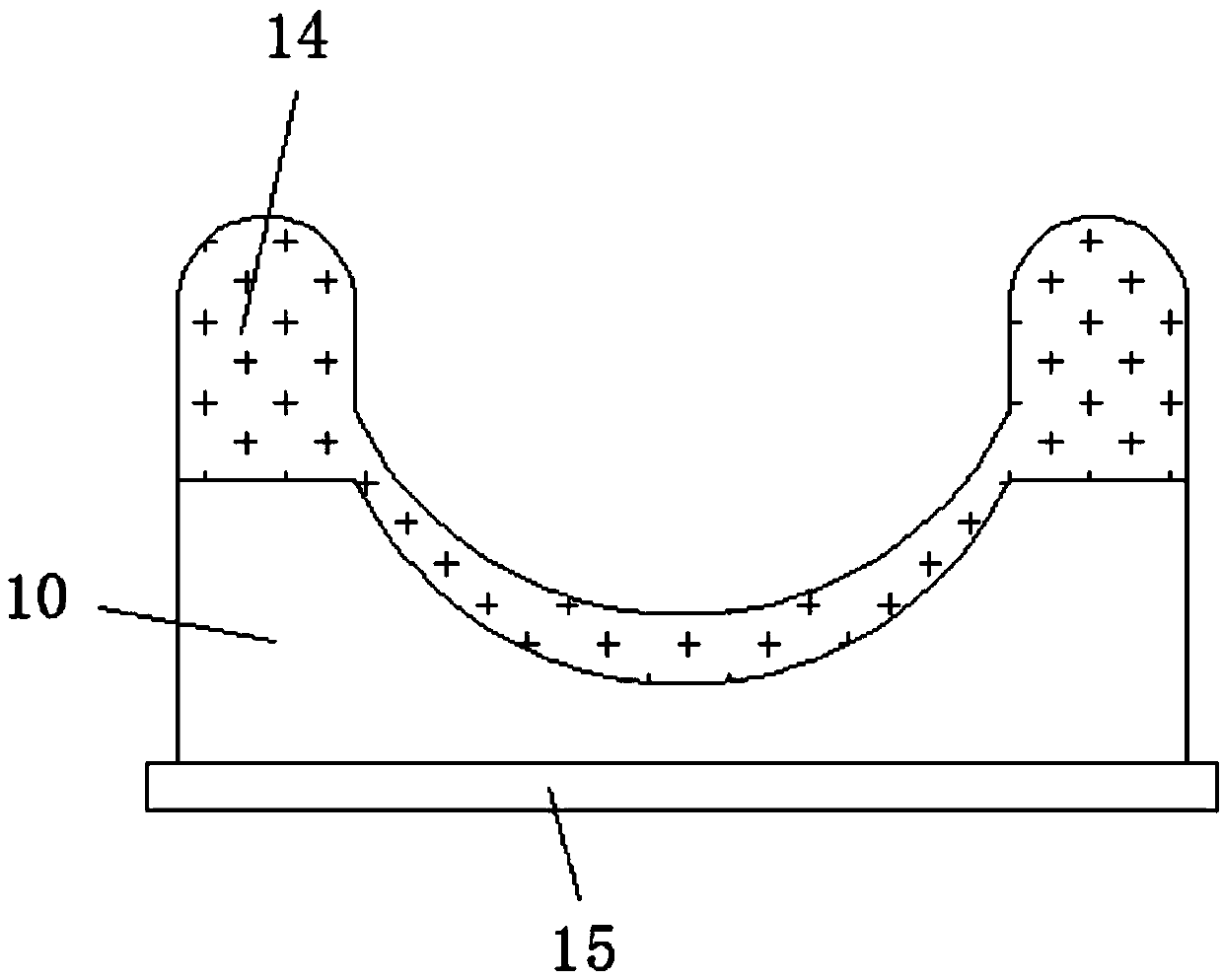

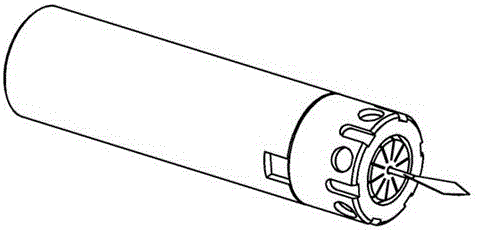

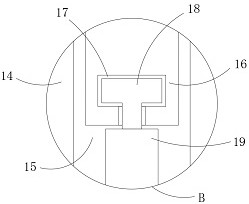

Liquid expansion type precision grinding tool for inner hole

ActiveCN106425832ASimple structureEasy to operateLapping machinesWork carriersDriven elementThin walled

The invention belongs to the technical field of precision machining and provides a liquid expansion type precision grinding tool for an inner hole. The liquid expansion type precision grinding tool comprises a plunger nut, two sets of O-shaped seal rings, two sets of Y-shaped seal rings, an expansion sleeve, a grinding shaft sleeve, a plunger screw and an oil plug. According to the grinding tool, a thin-walled hydraulic expansion mandrel is used as a driving element for the radial deformation of the cylindrical thin-walled grinding shaft sleeve, a distance between the plunger screw and the plunger nut is reduced by tightening the plunger screw, the pressure intensity of hydraulic oil in a cavity of the expansion mandrel increases, the radial deformation of the thin-walled elastic expansion sleeve is caused, and the radial expansion of the cylindrical elastic grinding shaft sleeve is accordingly driven, so that the precision grinding of the inner hole with a bulging tendency is realized. The grinding tool can be operated on a lathe, has the advantages that the structure is simple, the grinding shaft sleeve is changeable, the operation is convenient, the inner hole grinding precision is high, saddle-shaped error cannot be produced, and the like, can meet the superhigh precision grinding requirement of the inner hole, and has great market application prospects and popularization value.

Owner:金齿传动科技(大连)有限公司

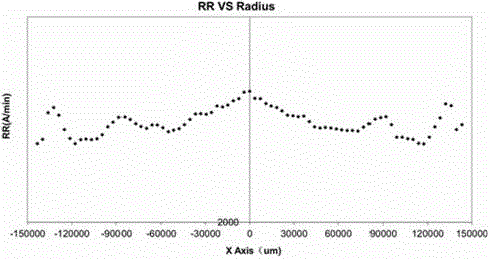

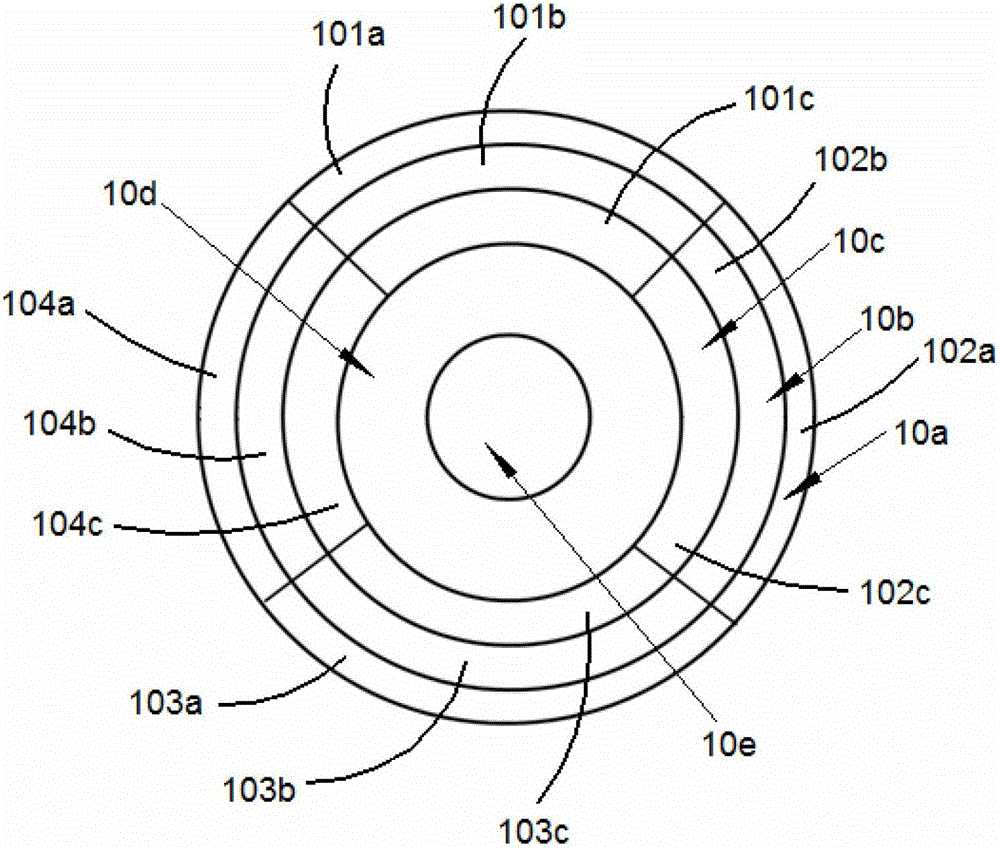

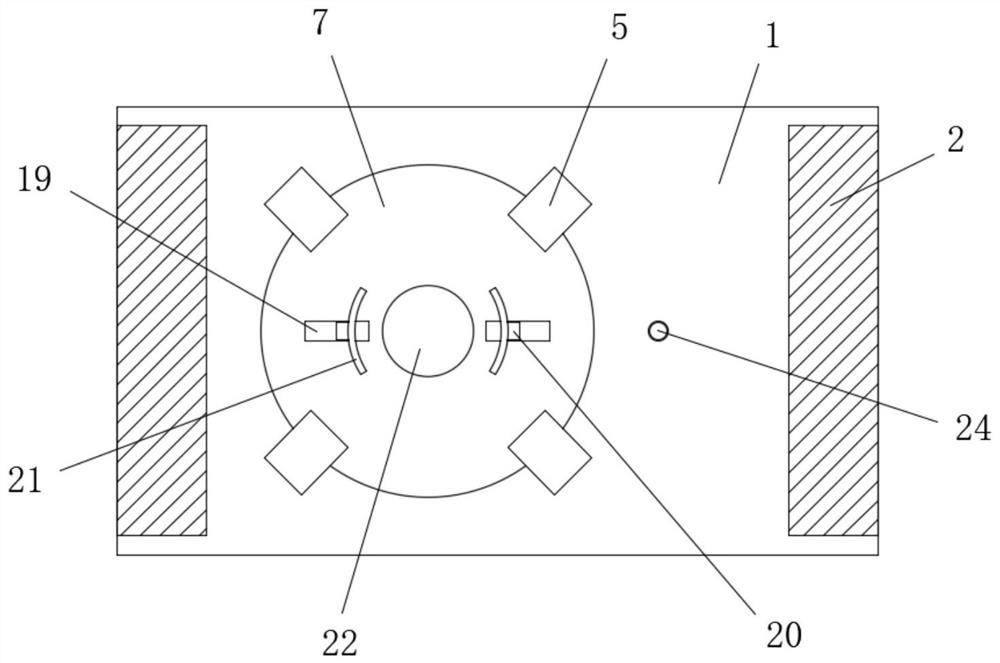

Polishing head for chemical polishing device and chemical polishing device with polishing head

InactiveCN102909651AEasy to operateEasy to useLapping machinesLapping toolsAsymmetric distributionEngineering

A polishing head for a chemical polishing device comprises concentric annular polishing areas with independent polishing subareas, and a force application device, wherein the concentric annular polishing areas are symmetrically distributed by taking the center of the polishing head as the center; the independent polishing subareas are arranged in the concentric annular polishing areas respectively; and the force application device acts on the polishing head and independently controls stresses of the polishing subareas respectively. The invention further relates to the chemical polishing device with the polishing head. The chemical polishing device further comprises a rotating shaft, a polishing table and a polishing pad. Asymmetric polishing in a wafer can be achieved by adopting the polishing head, applying larger pressure in an area with a thicker film and applying smaller pressure in an area with a thinner film, so as to improve the polishing uniformity of asymmetric distribution of film thickness in the wafer. The polishing head is simple to operate, convenient to use and popularize and high in practicability, and can satisfy polishing requirements of different products.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

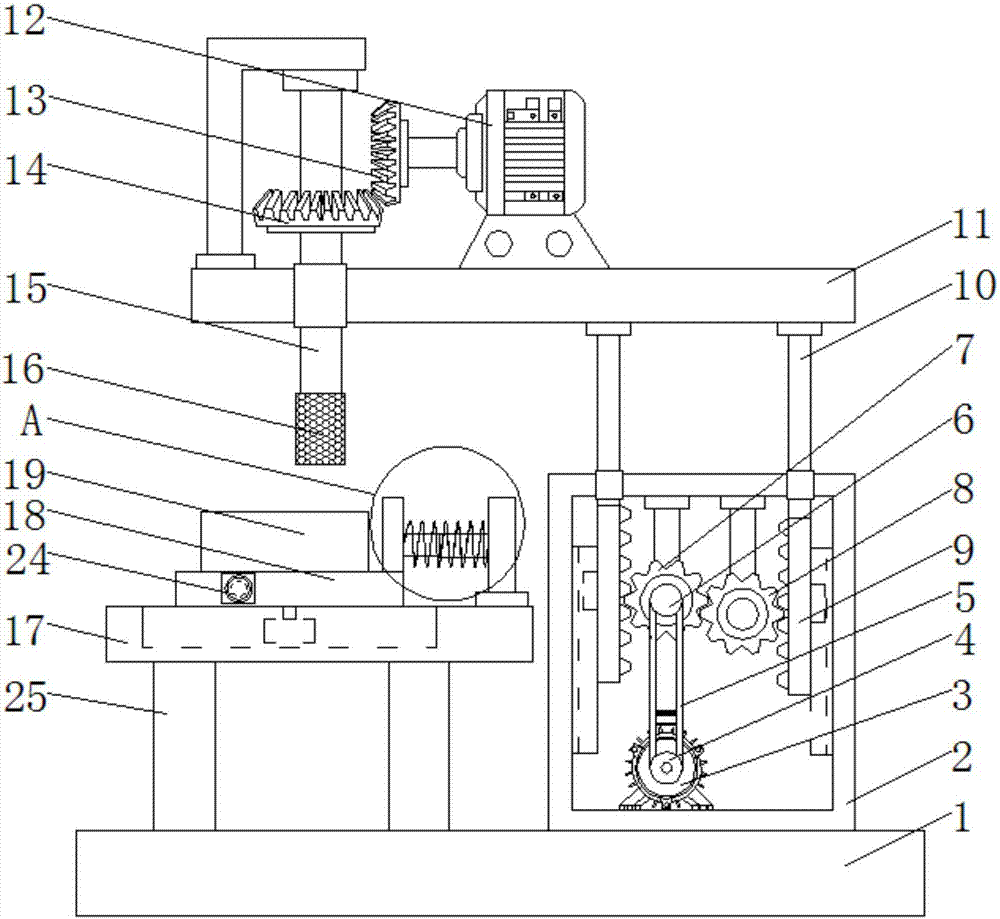

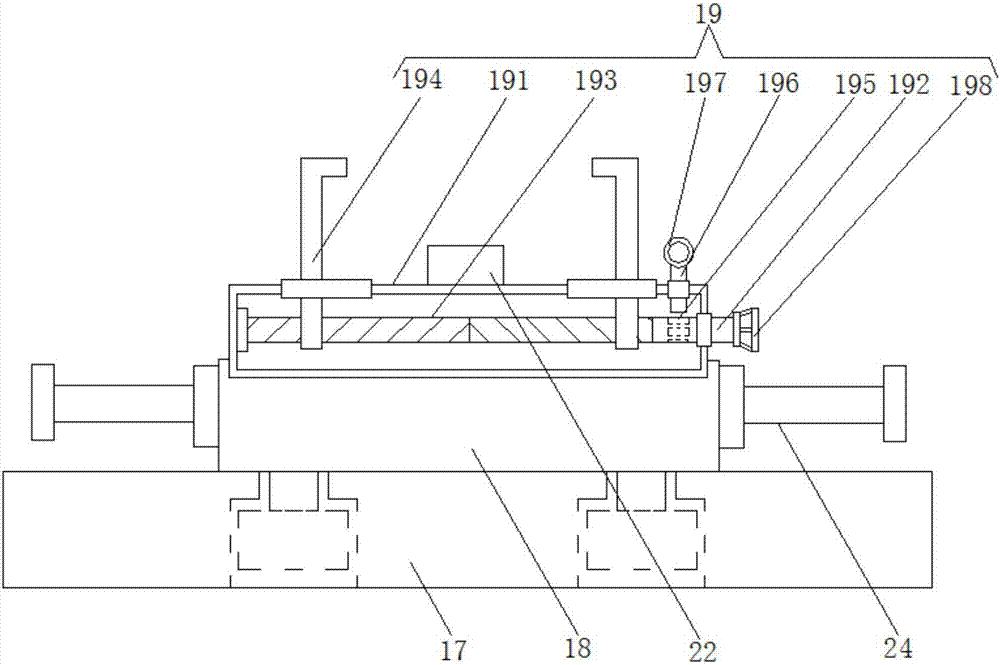

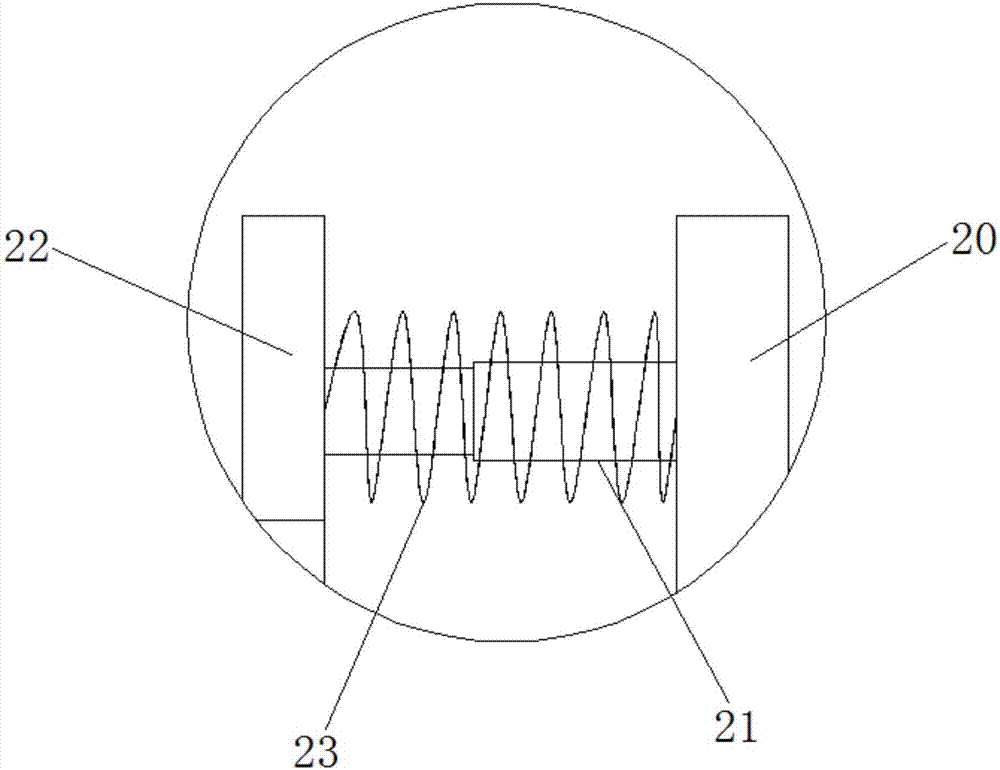

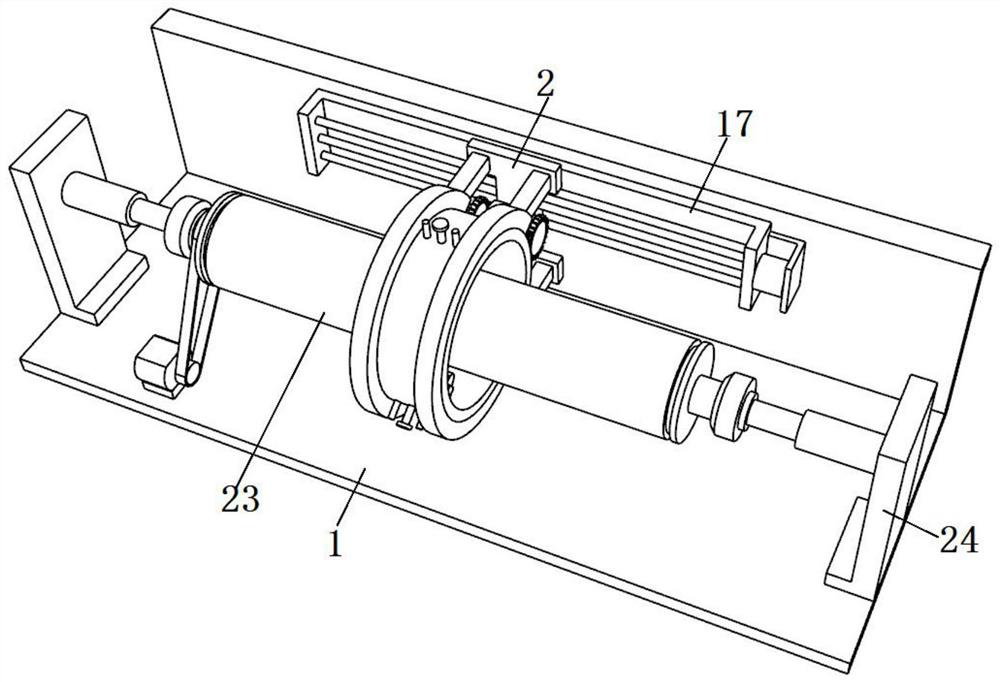

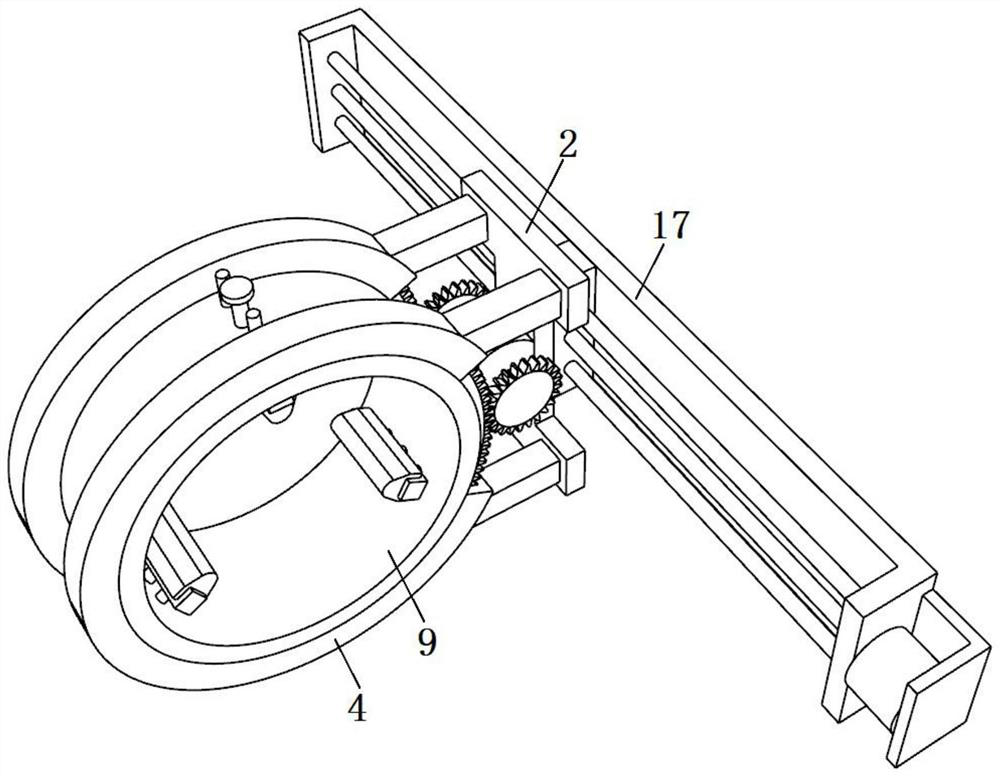

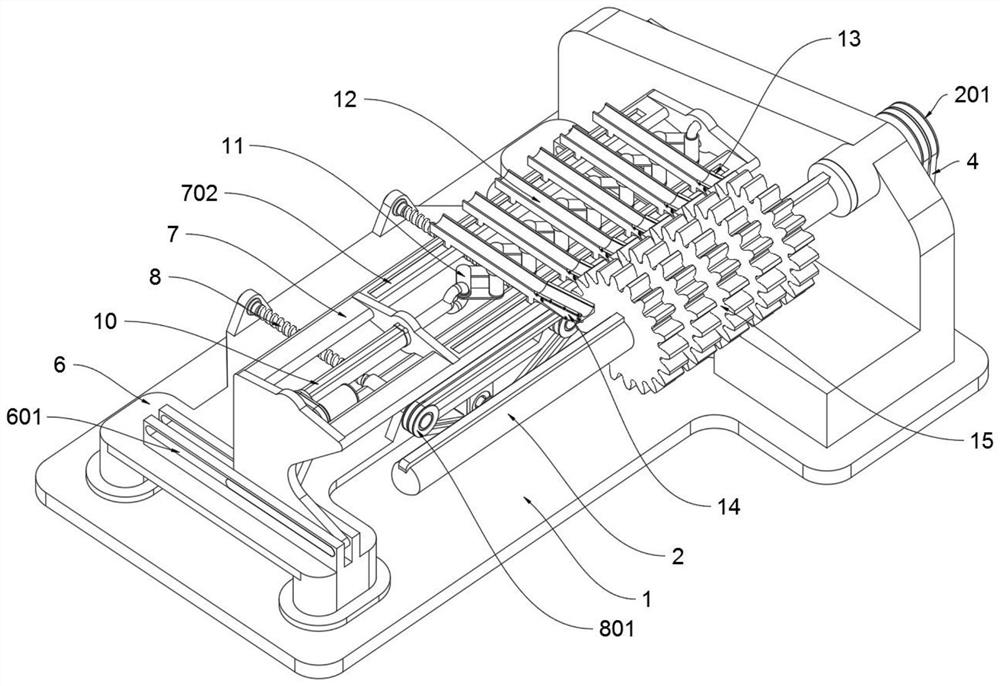

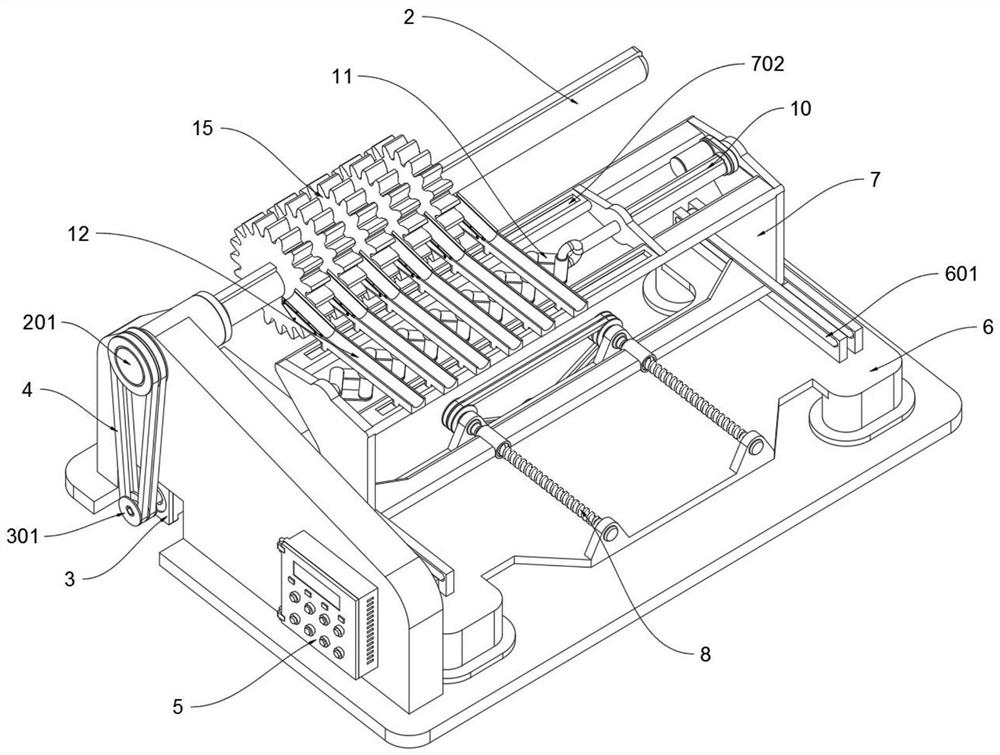

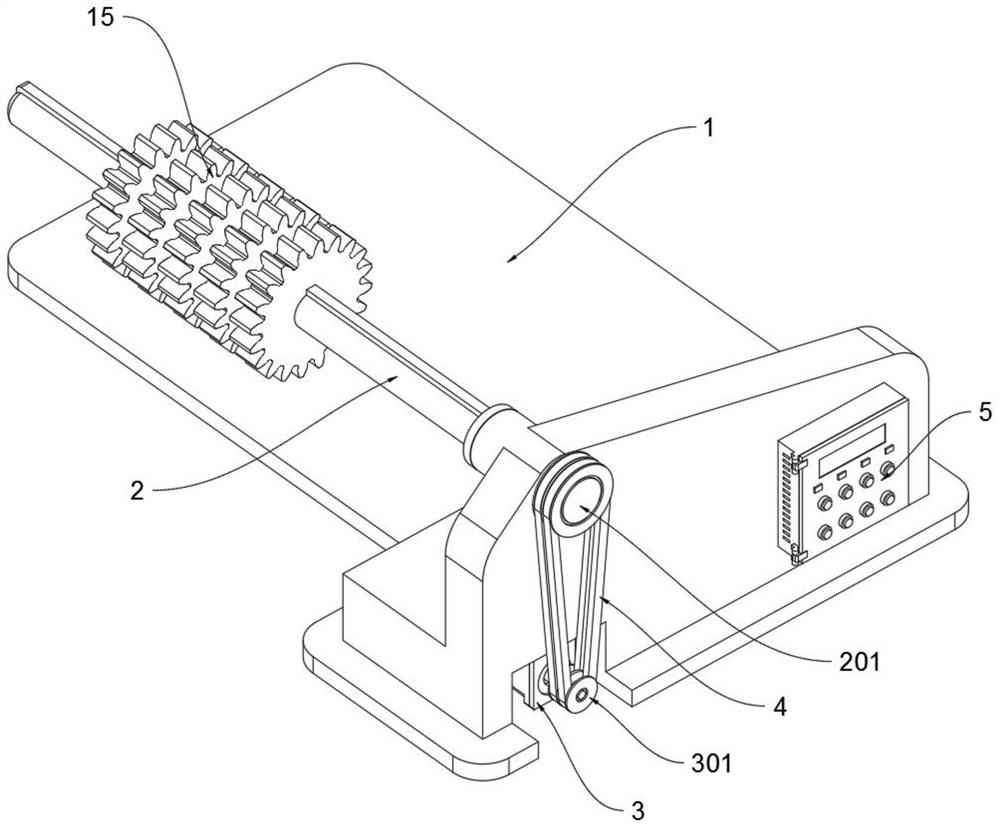

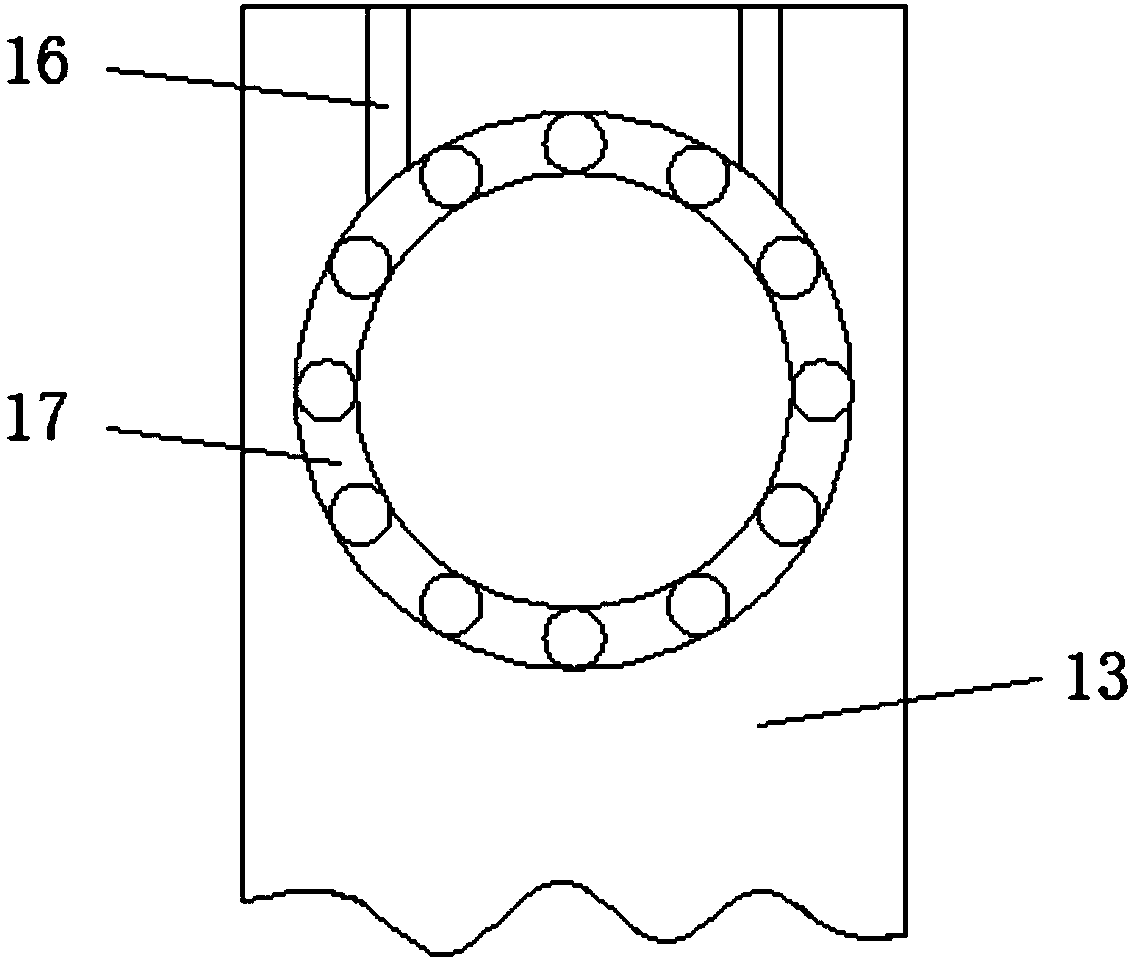

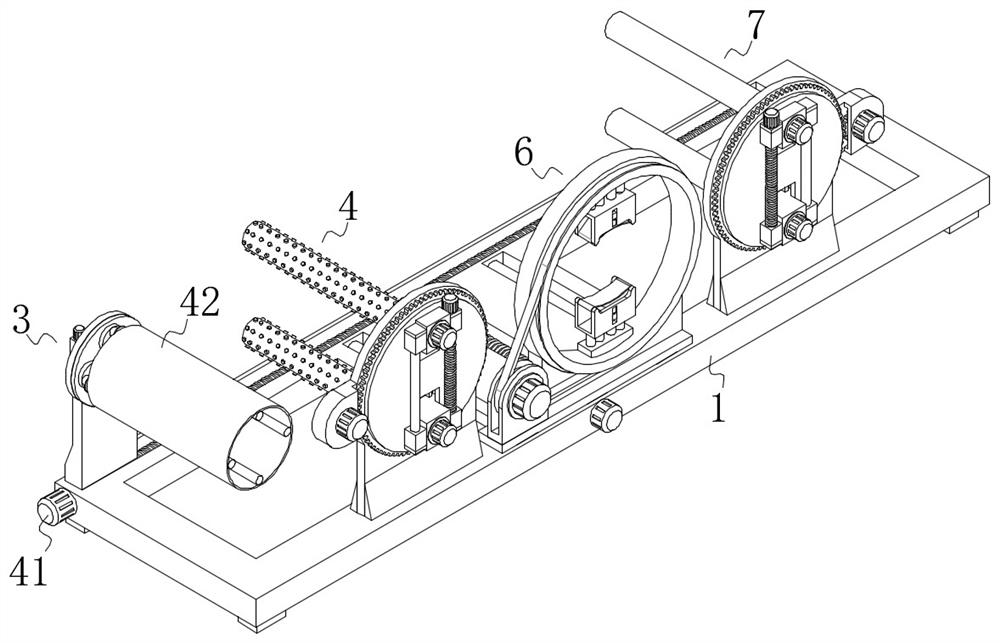

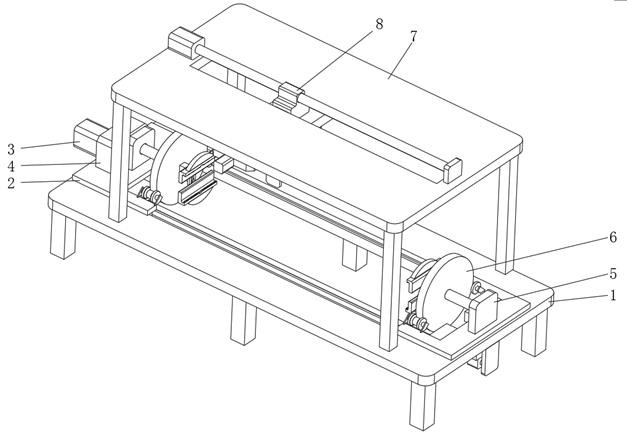

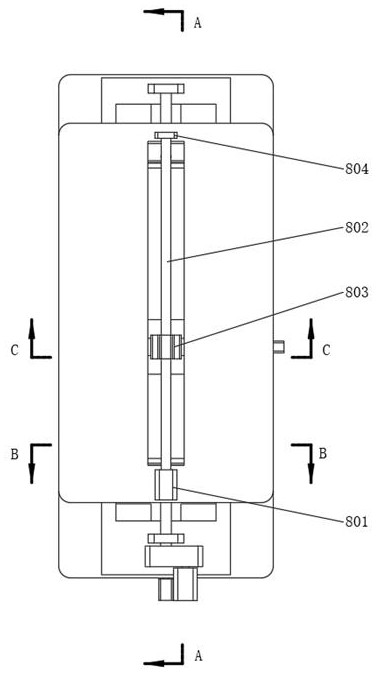

Grinding device for mechanical parts

InactiveCN112846963AEffective sandingConvenient grinding operationRevolution surface grinding machinesGrinding drivesMechanical componentsGear drive

The invention discloses a grinding device for mechanical parts, and relates to the technical field of mechanical part machining. The grinding device for the mechanical parts comprises a supporting seat, wherein a group of clamping mechanisms is fixed on the supporting seat, a mechanical pipe fitting is fixed between the two clamping mechanisms, the two clamping mechanisms are symmetrically distributed about the mechanical pipe fitting, a grinding mechanism is fixed to one surface of the supporting seat, and connected outside the mechanical pipe fitting in a sleeved mode, and the grinding mechanism comprises a transmission assembly and a sleeve. According to the invention, a first single-shaft motor in the transmission assembly is controlled to run, so that the first single-shaft motor drives a threaded lead screw to rotate, a plurality of grinding blocks are driven to move along the mechanical pipe fitting to be ground in the mode of lead screw transmission, the plurality of grinding blocks can be driven by a double-shaft motor to rotate in the mode of gear transmission, then effective grinding treatment is carried out on the mechanical pipe fitting, and the grinding operation for the mechanical pipe fitting is simpler and more convenient, so that the grinding efficiency for the mechanical pipe fitting is increased, and manpower consumption in the grinding process for the mechanical pipe fitting is reduced.

Owner:广州市魅雅特贸易有限公司

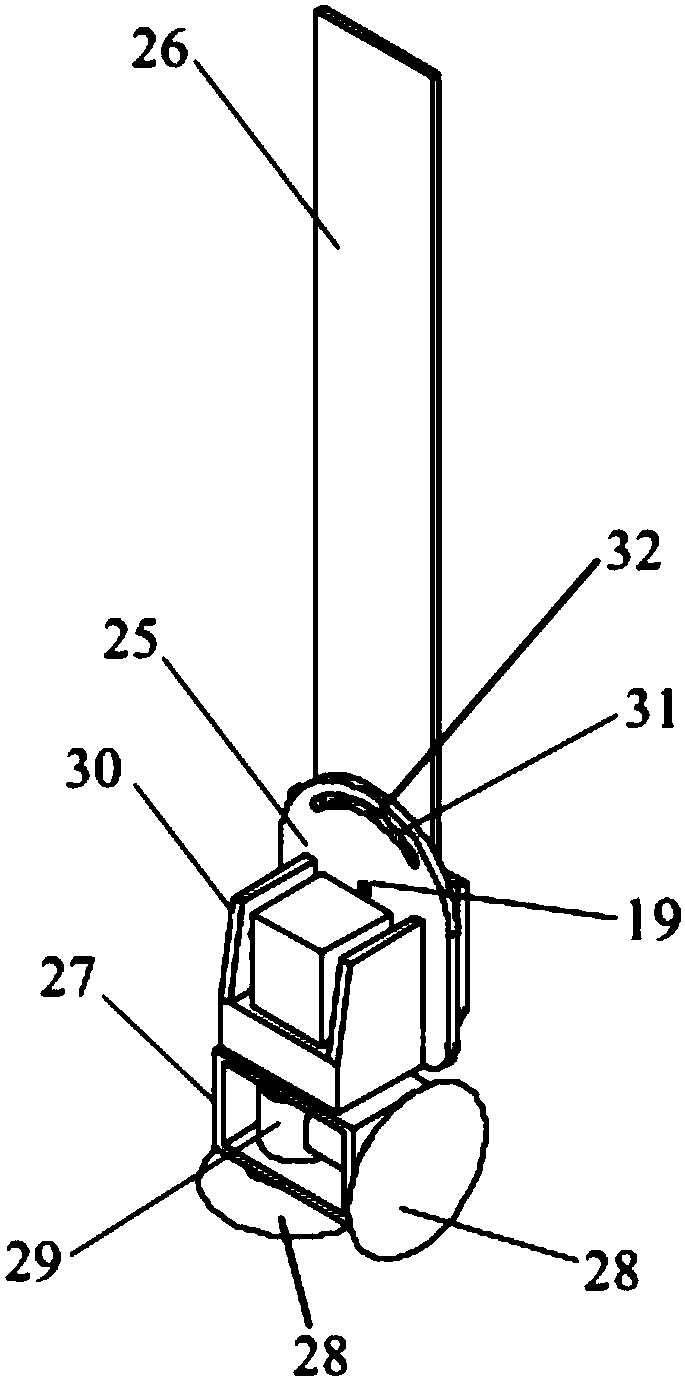

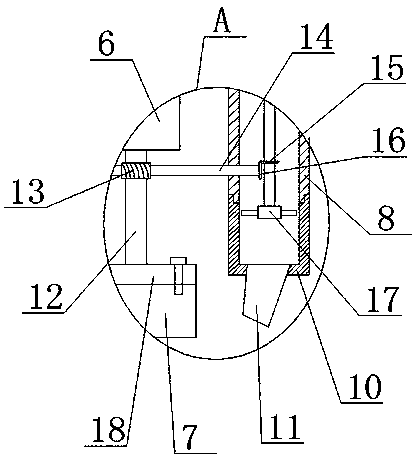

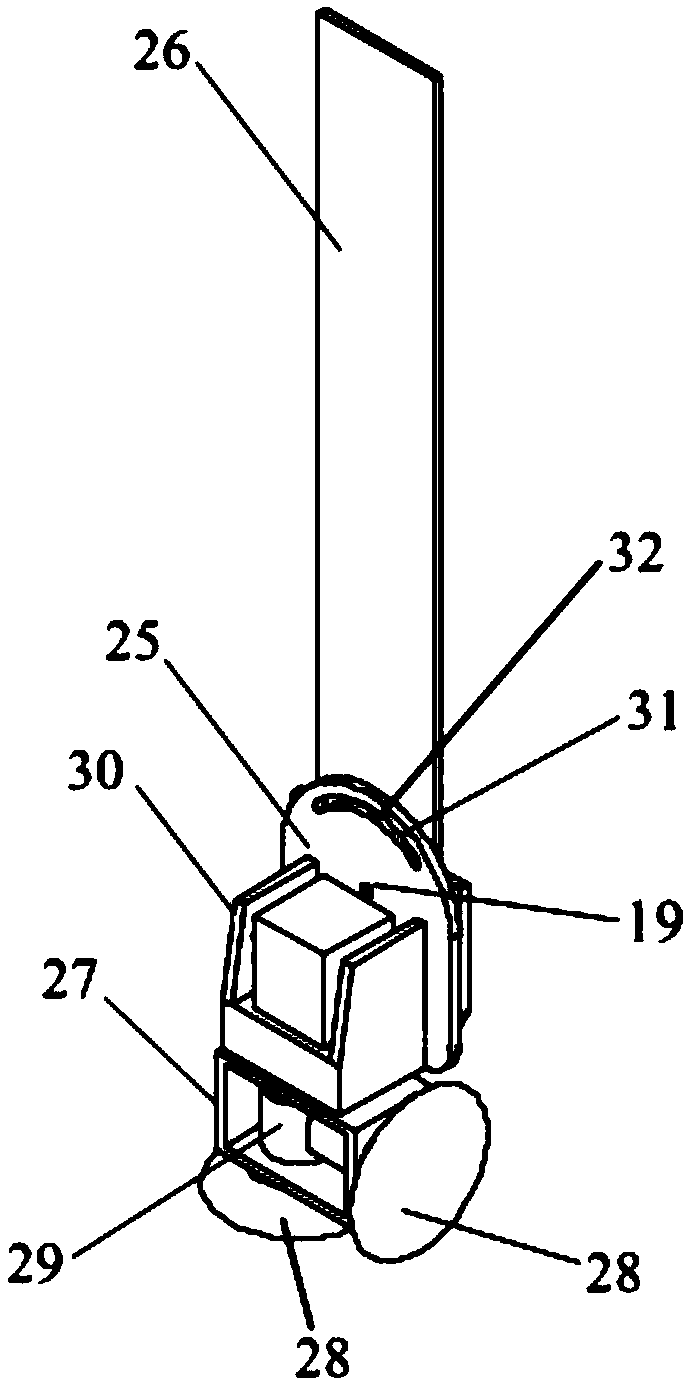

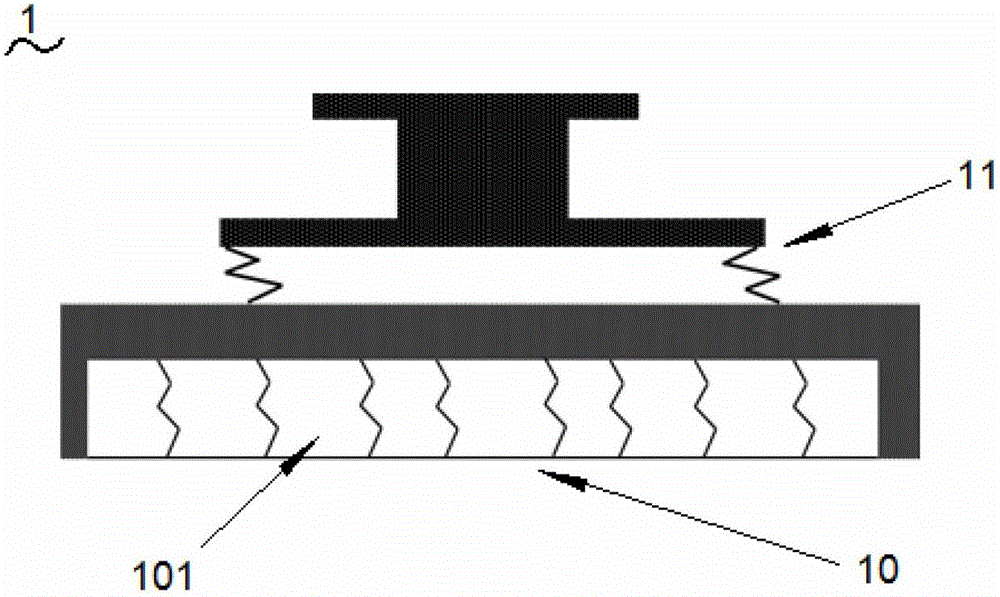

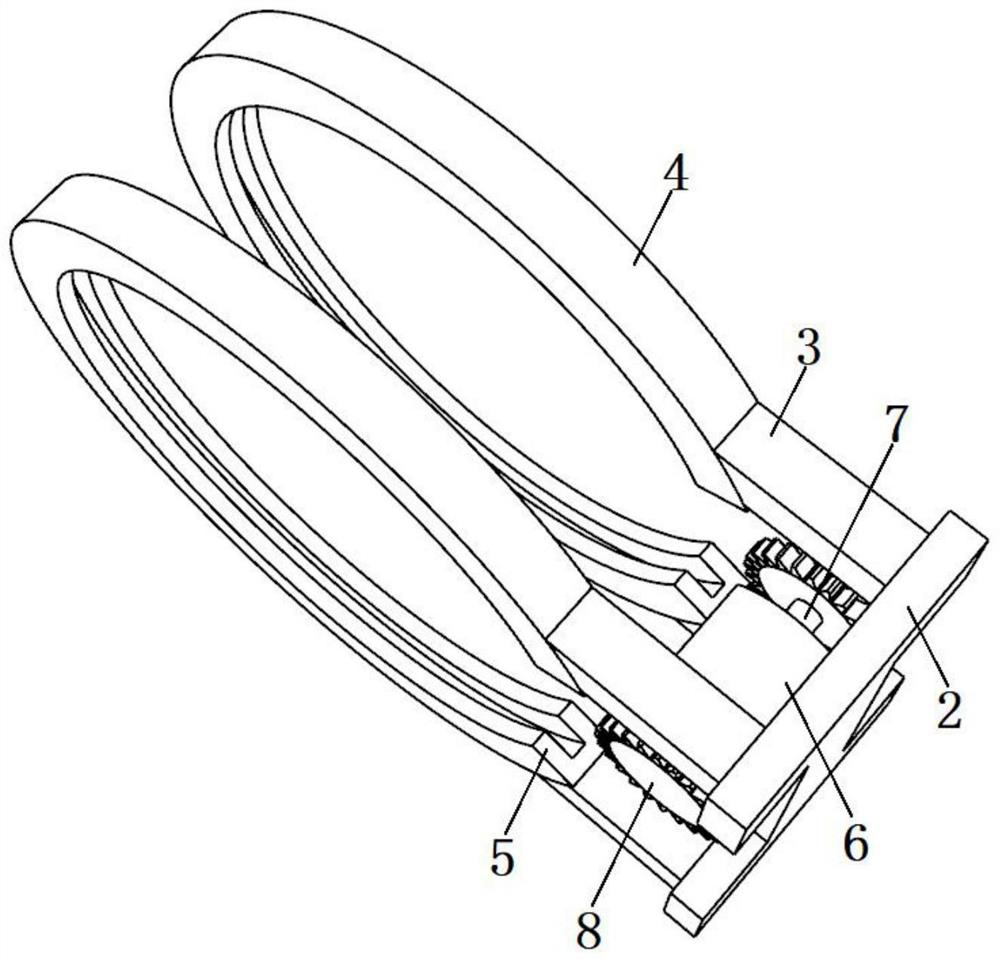

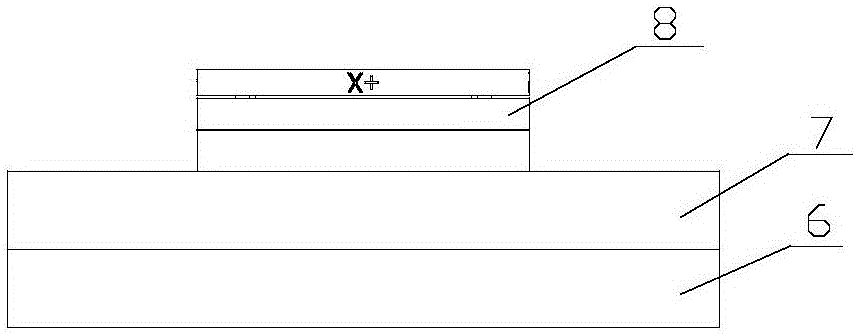

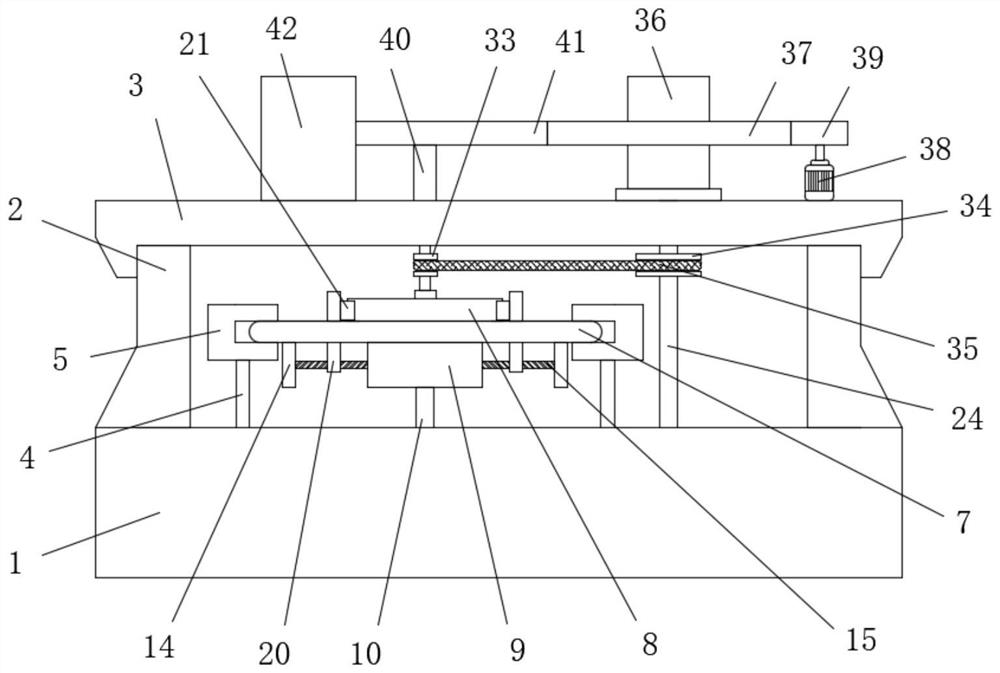

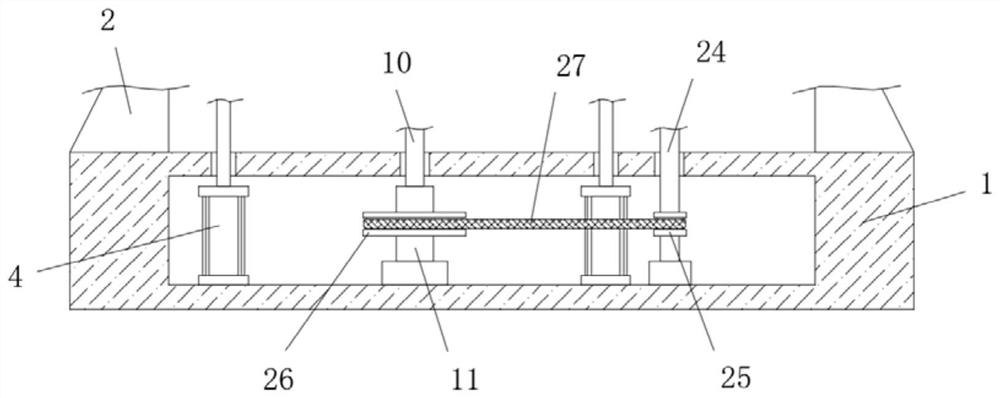

Flexible polishing device based on pneumatic flotation

InactiveCN106392889AAutomate operationsMeet the needs of grindingGrinding feed controlGrinding/polishing safety devicesEngineeringConstant force

The invention relates to equipment for workpiece polishing, in particular to a flexible polishing device based on pneumatic flotation. The flexible polishing device comprises a connecting and measuring device, a base plate mounting device, a pneumatic device, an actuating device and a polishing head device. The base plate mounting device is installed on the connecting and measuring device. The pneumatic device is installed in the base plate mounting device. The actuating device is installed on the base plate mounting device and connected with the pneumatic device. The polishing head device is installed on the actuating device. The pneumatic device conducts pressure setting, constant-force floating polishing of a polishing head is achieved through the actuating device, the connecting and measuring device measures data of polishing force in real time, data collection is achieved, and then pressure setting of the pneumatic device is controlled. According to the flexible polishing device, the capacity of automatically polishing a workpiece with constant force in a floating mode is achieved, the polishing quality of the surface of the workpiece can be further guaranteed, and requirements for workpiece polishing are met.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

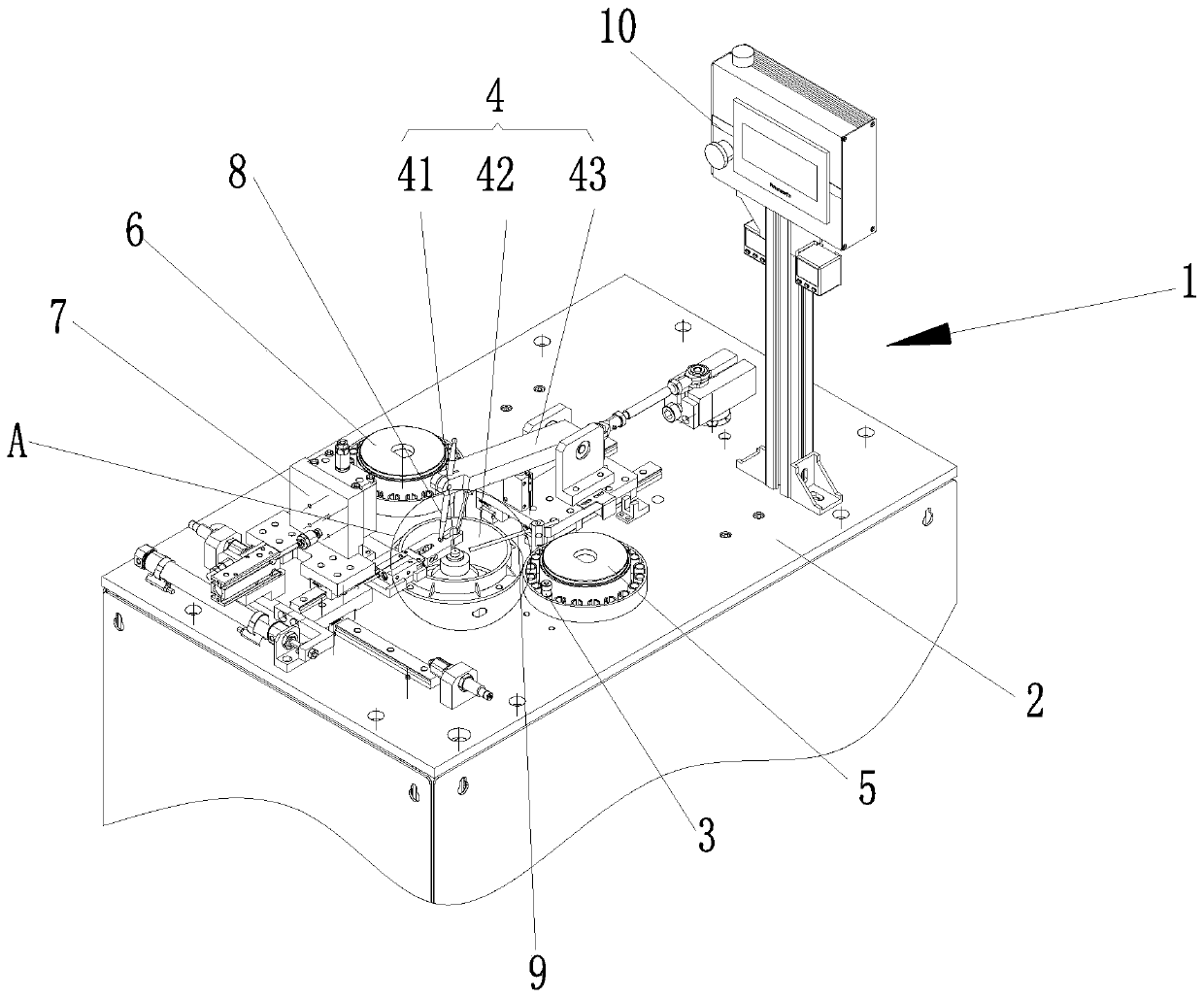

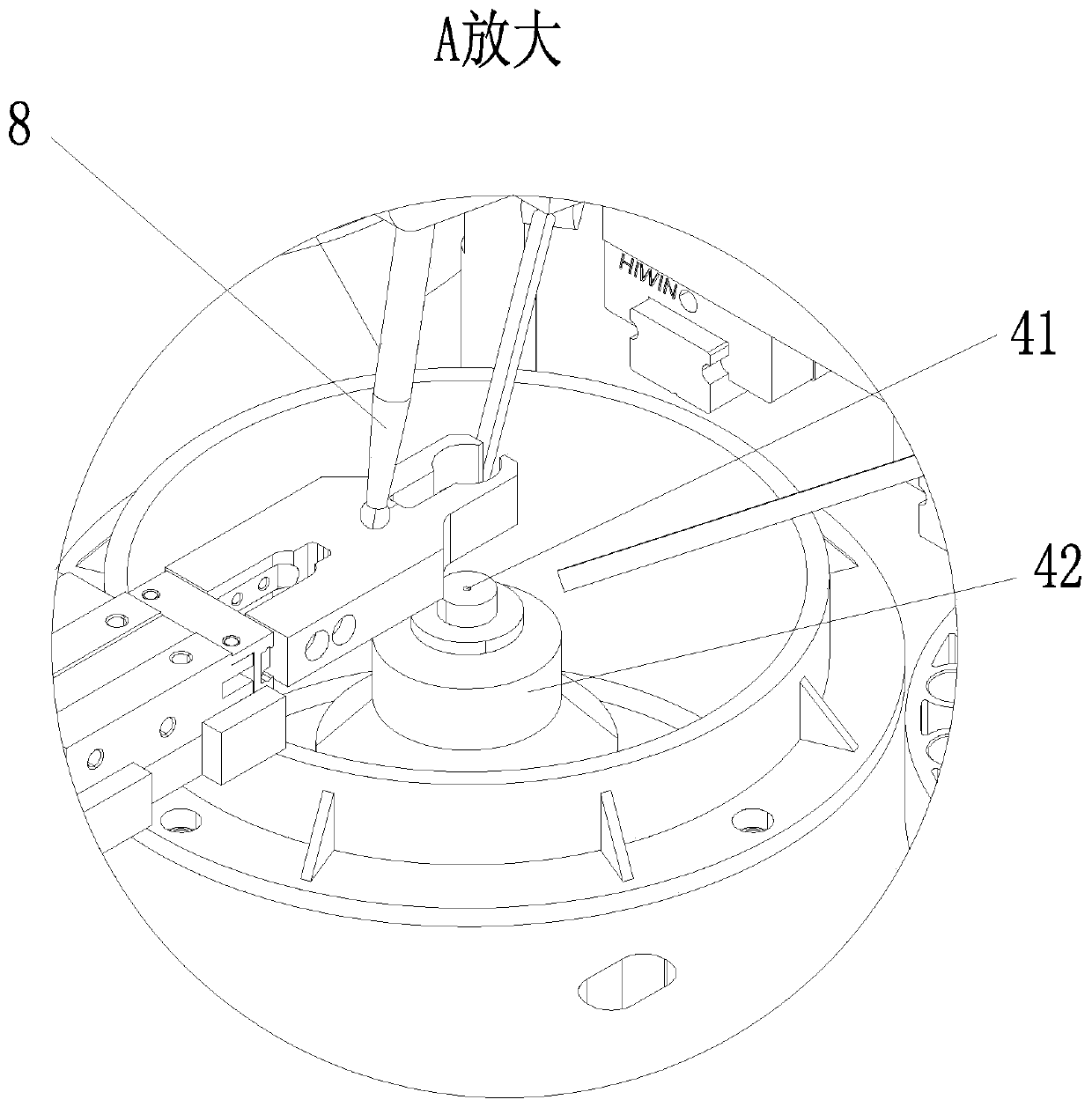

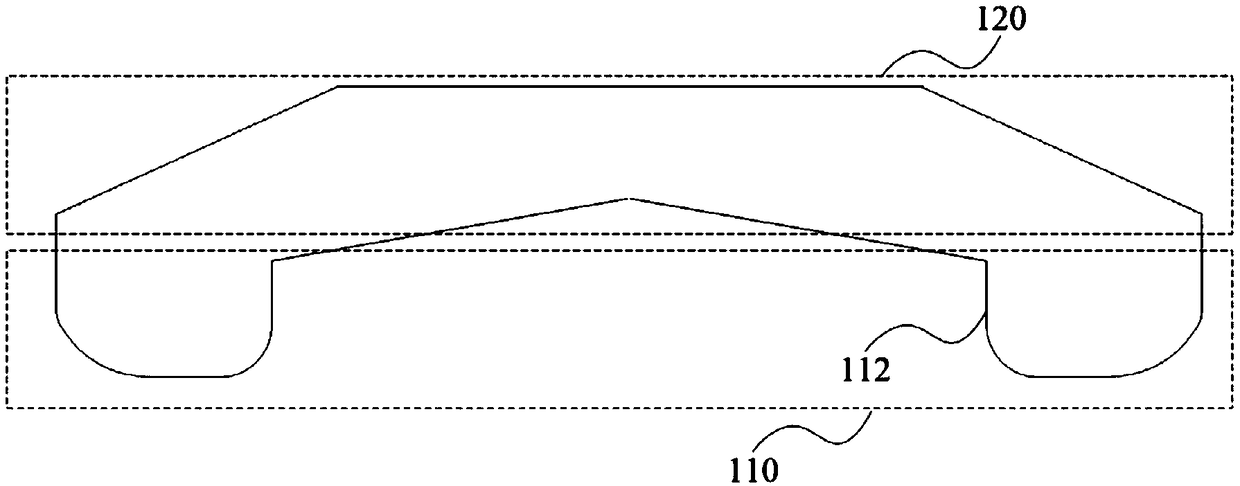

Upper swinging type lens grinding machine

PendingCN110153838AImprove grinding efficiencyImprove grinding uniformityOptical surface grinding machinesGrinding drivesMaterial transferEngineering

The invention relates to an upper swinging type lens grinding machine. One or more grinding complete machines are included. Each grinding complete machine comprises a rack, wherein the rack is provided with a grinding mechanism for grinding to-be-machined materials, a material storage mechanism arranged on one transverse side of the grinding mechanism, and a finished product storage mechanism arranged on the other transverse side of the grinding mechanism, and the rack is further provided with a material transferring mechanism. The materials include a material clamp and a material body arranged on the material clamp, wherein the material to-be-machined face at the bottom of the material body is exposed out of the bottom of the material clamp. Each grinding mechanism comprises a grinding groove, a grinding rotation driving mechanism, a material pressing bar arranged above the grinding groove, and a swing arm mechanism which is used for clamping the material pressing bar and driving thematerial pressing bar to swing around the contact point where the material pressing bar and the materials are in contact in the longitudinal direction of the grinding groove in a reciprocating manner.The upper swinging type lens grinding machine can replace manual grinding, the grinding efficiency of the grinding machine is high, operation is simple, and the quality of ground finished products isgood.

Owner:福州研达自动化有限公司

Adjustable lens grinding device according to lens centre and arc radius

ActiveCN100528481CMeet grinding needsOptical surface grinding machinesGrinding drivesEngineeringLens plate

Owner:MAI JIUN MASCH CO LTD

Rotatable gear machining and polishing device

ActiveCN111890144APlay a fixed effectExactly atGrinding carriagesRevolution surface grinding machinesGear wheelPolishing

The invention belongs to the technical field of gear machining, particularly discloses a rotatable gear machining and polishing device, and puts forward the following scheme so as to solve the problemof gear machining and polishing devices are very inconvenient to use due to the fact that the gear machining and polishing devices are poor in adjustment flexibility, are troublesome to operate and cannot meet polishing requirements of gears in different hole diameters in the prior art. The rotatable gear machining and polishing device comprises a base; the base is of a hollow structure; two vertical plates are symmetrically and fixedly connected on the two sides of the outer wall of the top of the base; and the tops of the two vertical plates are fixedly connected with a same top plate. According to the rotatable gear machining and polishing device, the height of a round plate can be adjusted by the aid of lifting air cylinders, the clamping effect on machining gears can be achieved through starting of a first servo motor, the machining gears and a polishing roller can be driven simultaneously to perform synchronous operation through starting of a driving motor, the requirement for polishing the machining gears in different hole diameters can be realized under the condition that normal work of the polishing roller is not affected through starting of a second servo motor, and thusthe machining and polishing efficiency is improved.

Owner:WENZHOU UNIVERSITY

High-efficiency adjustable gear burr grinding device for machining

The invention provides a high-efficiency adjustable gear burr grinding device for machining, and relates to the technical field of machining. The device solves the problems that when an existing gearburr grinding device is used, the grinding effect on burrs contained in tooth profile parts on the two sides of a gear is poor, secondary grinding operation generally needs to be conducted on the tooth profile parts on the two sides of the gear manually, the grinding efficiency is low, and the requirement for large-batch gear machining cannot be met. The high-efficiency adjustable gear burr grinding device for machining comprises a cutter supporting seat and a cutter supporting frame, a driving motor is electrically connected with a control electric box through a power line, the control electric box is installed on the outer wall of the right side of a base, the control electric box is connected with an external power supply circuit, and the cutter supporting seat is located at the top ofthe base. According to the high-efficiency adjustable gear burr grinding device for machining, a cutting blade at the front end of a U-shaped cutter is used for cutting and removing burrs left on thetooth profile part of the outer side of the gear, and after the burrs are cut and removed, the tooth profile part of the outer side of the gear is ground through grinding blocks, so that the smoothness of the tooth profile parts of the two sides of the gear is guaranteed.

Owner:闫政凤

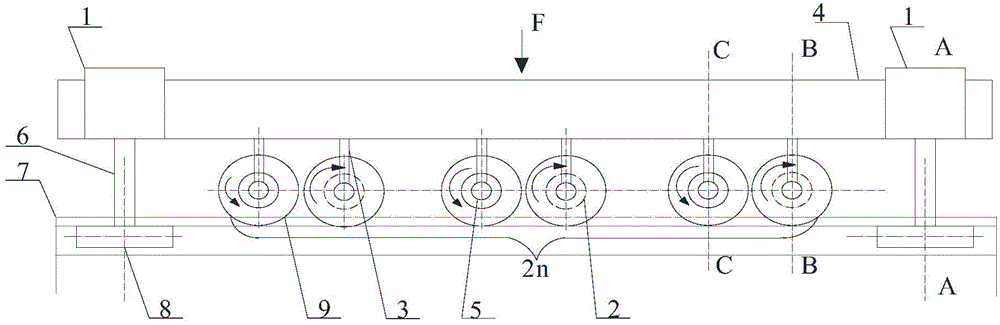

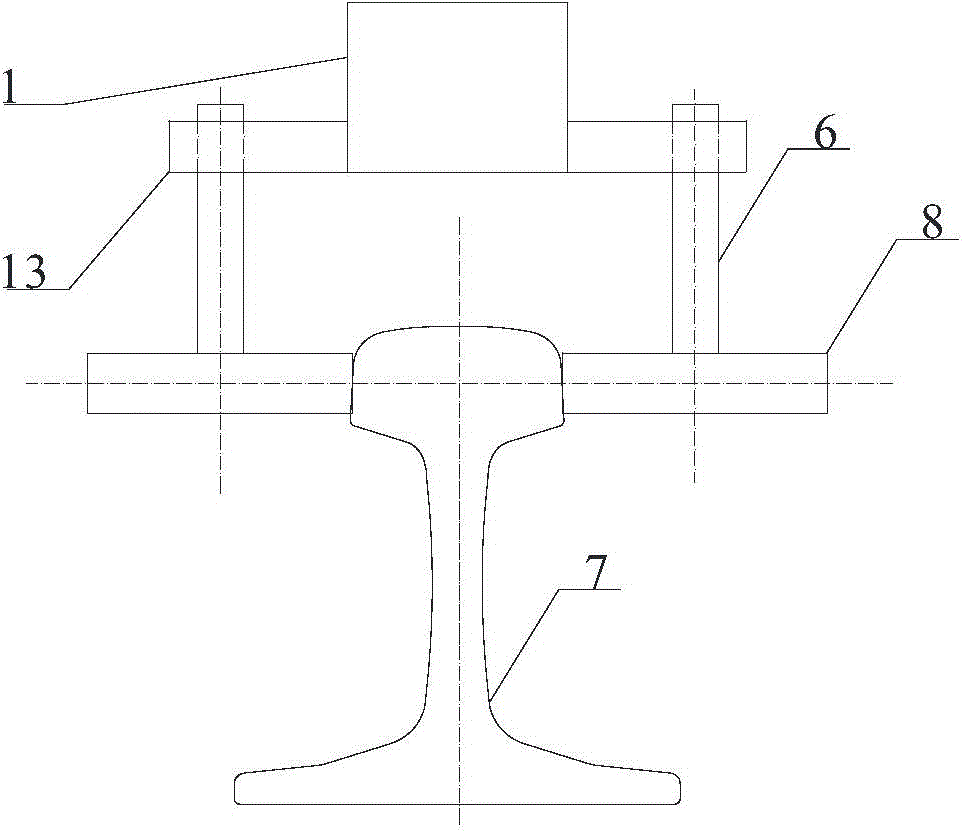

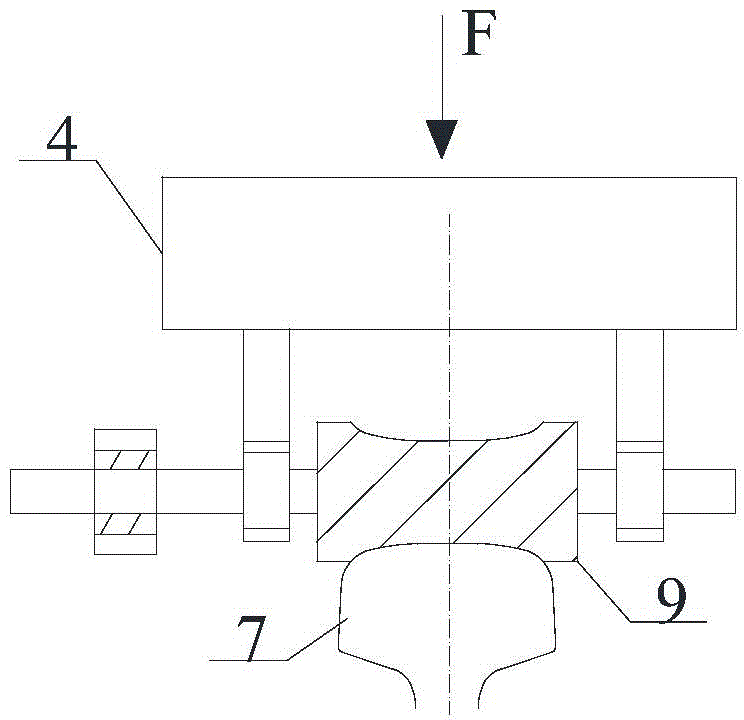

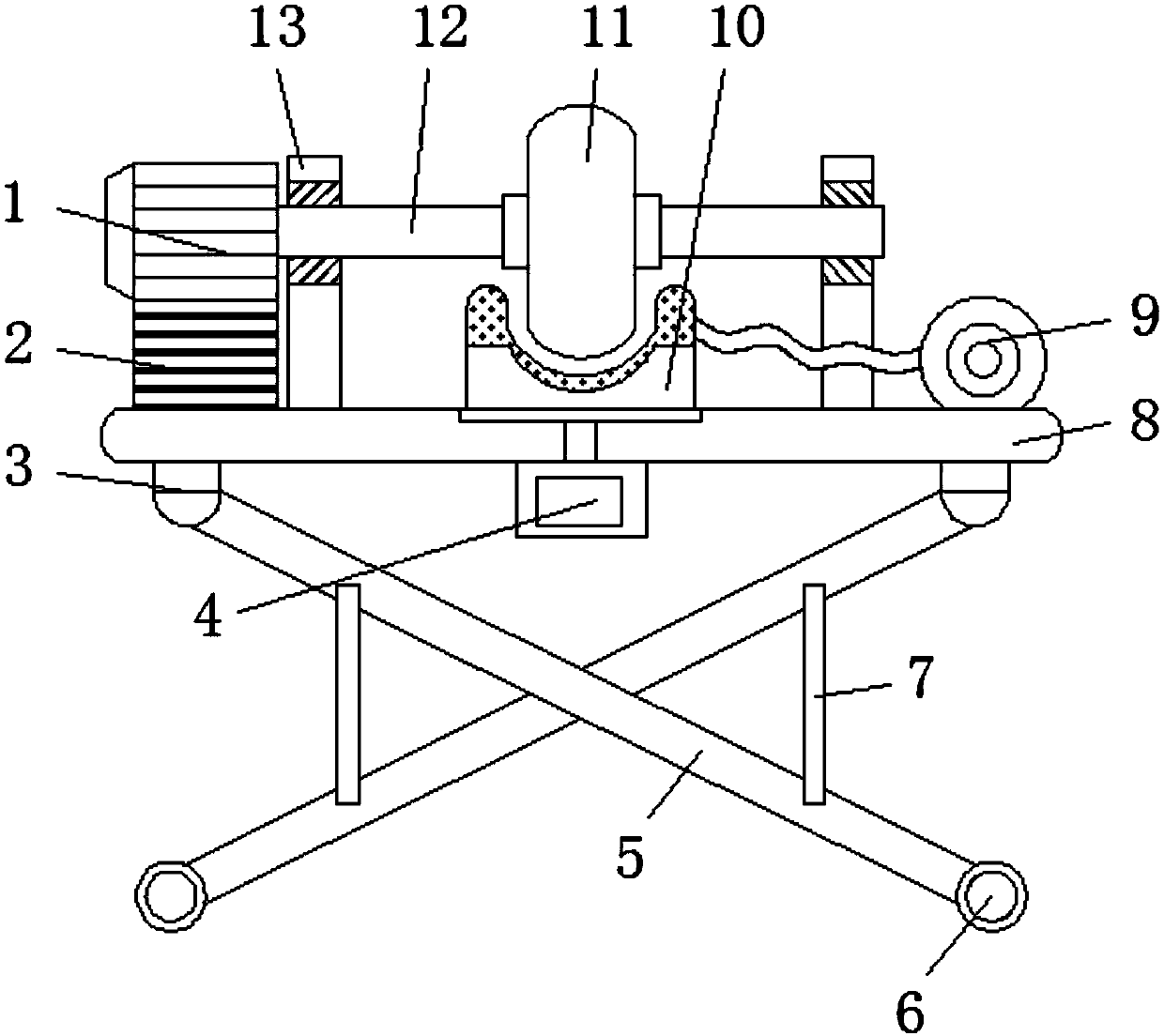

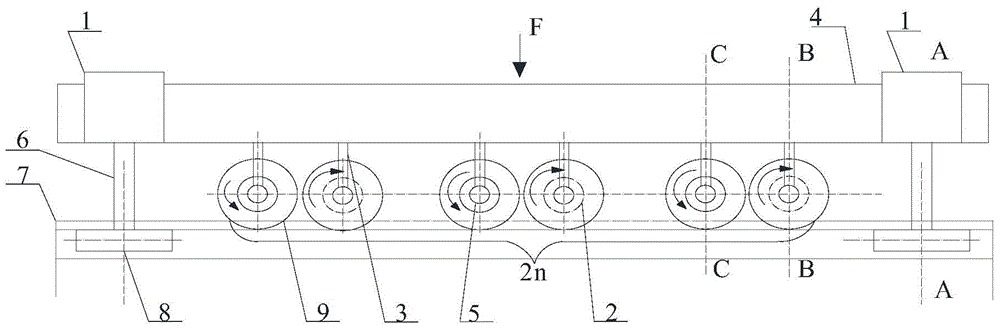

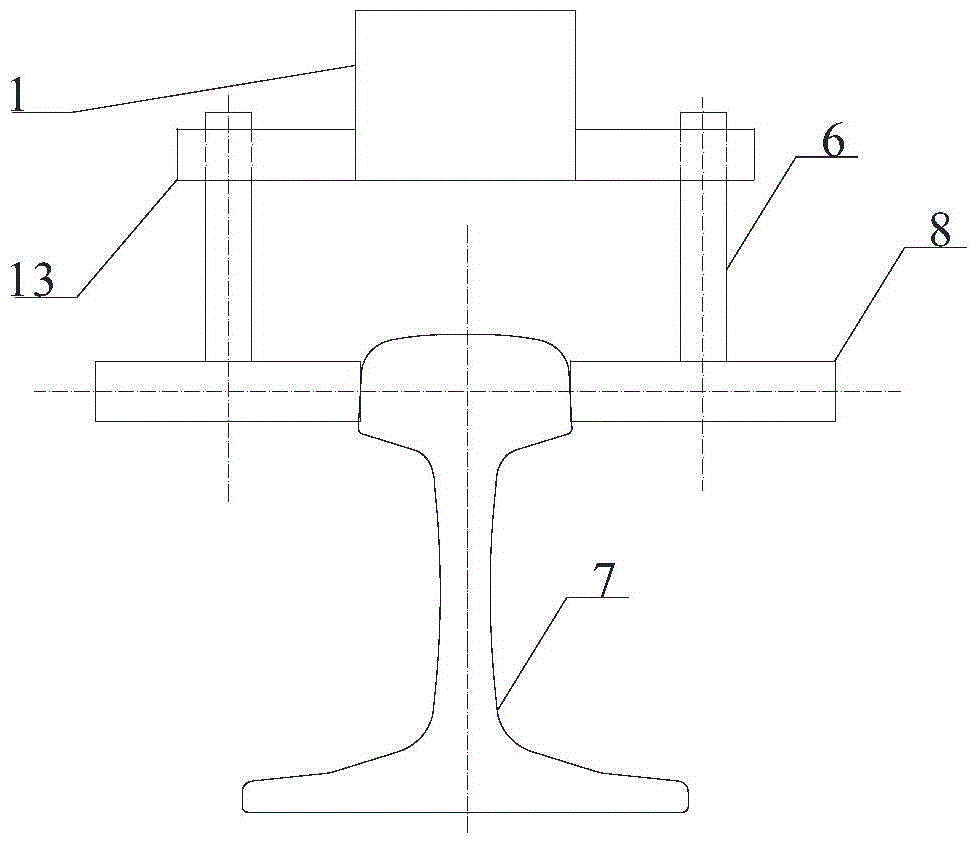

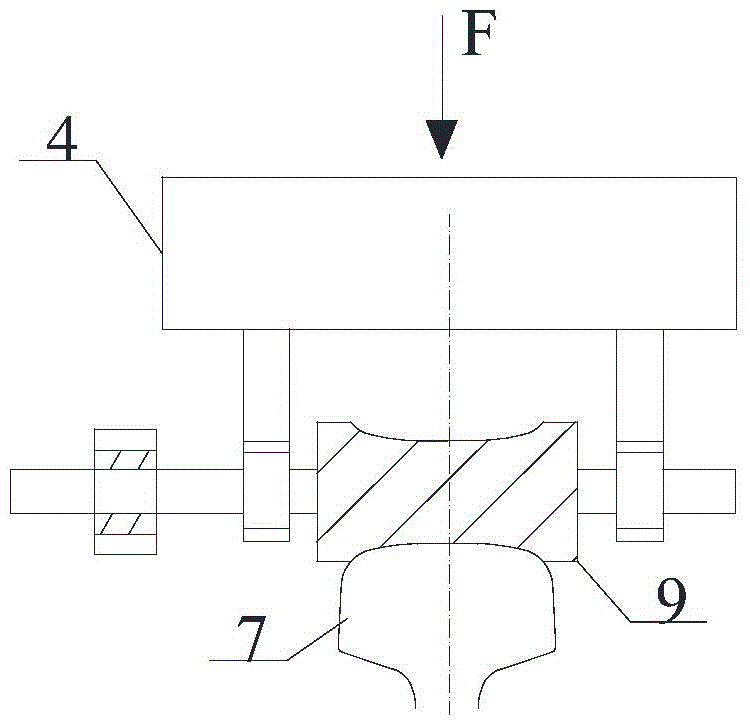

Light-weight and convenient type steel rail corrugation grinding machine

InactiveCN104674617AImprove grinding accuracyImprove efficiencyTrack superstructureRailway track constructionEngineeringMechanical engineering

The invention relates to a light-weight and convenient type steel rail corrugation grinding machine, which is used for performing corrugation grinding on a steel rail. The light-weight and convenient type steel rail corrugation grinding machine comprises a support transverse beam, wherein a support device is arranged at one end of the support transverse beam, a grinding device is arranged at the other end of the support transverse beam, the grinding device comprises a grinding mechanism frame, two clamping and guiding assemblies and a plurality of grinding assemblies, the clamping and guiding assemblies are used for clamping and guiding the steel rail, each grinding assembly is moved relative to the steel rail and is used for grinding the steel rail, the clamping and guiding assemblies are respectively arranged at the two ends of the grinding mechanism frame, and the grinding assemblies are connected with the bottom part of the grinding mechanism frame, and are sequentially arranged between the two clamping and guiding assemblies. Compared with the prior art, the light-weight and convenient type steel rail corrugation grinding machine has the advantages that the cost is low, the grinding efficiency is high, the control is simple and reliable, the structure is compact, the stability is good, the firmness and durability are realized, and the like.

Owner:TONGJI UNIV

Polisher

InactiveCN105364669AImprove grinding efficiencyEasy to adjustGrinding machinesGrinding/polishing safety devicesArchitectural engineeringDust collector

The invention relates to a polisher which comprises a support seat and a polishing wheel, wherein a groove is formed at the bottom of the inner chamber of the support seat, a second driving hydraulic rod is arranged at the top of the inner chamber of the groove, a second driven hydraulic rod is arranged at the bottom of the outer surface of the second driving hydraulic rod, the second driven hydraulic rod is sheathed in the inner chamber of the second driving hydraulic rod, a roller is arranged at the bottom of the outer surface of the second driven hydraulic rod, a dust collecting box is arranged at the left end of the top of the inner chamber of the support seat, the dust collecting box is connected with a dust collector by a pipeline, the dust collector is arranged at the bottom of the outer surface of a support rod, the support rod is arranged at the left end of the lower surface of a cross rod, a motor is arranged at the right end of the upper surface of the cross rod, the motor is connected with the polishing wheel by a rotating shaft, and the cross rod is arranged at the right end of the top of the outer surface of the first driven hydraulic rod. The first driving hydraulic rod is arranged for the polisher, so that automatic adjustment for the height of the polishing wheel can be achieved, and requirements of people on polishing of woodware with different thickness can be met.

Owner:湖北省华建石材股份有限公司

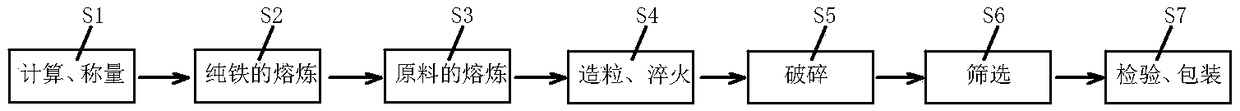

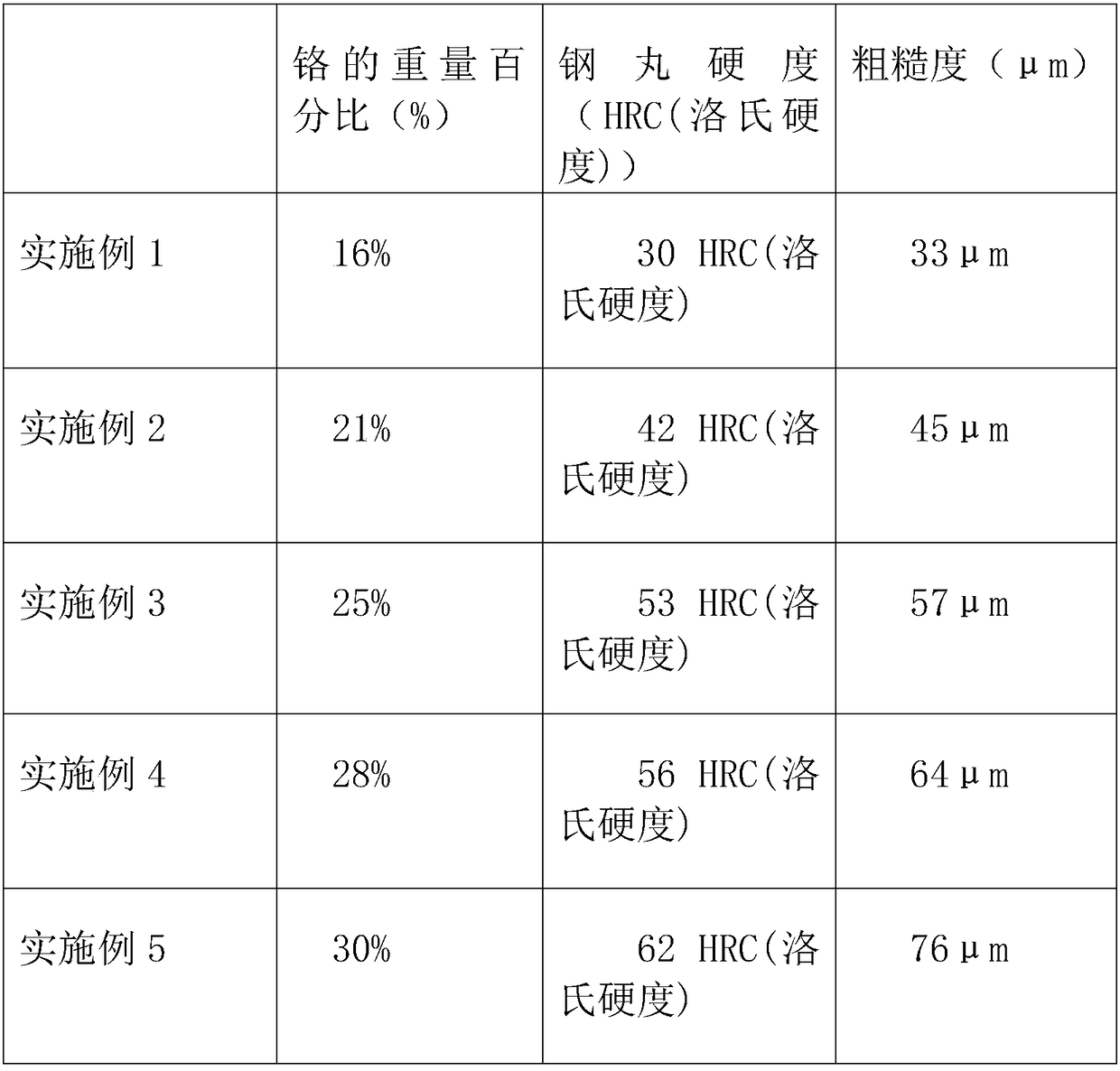

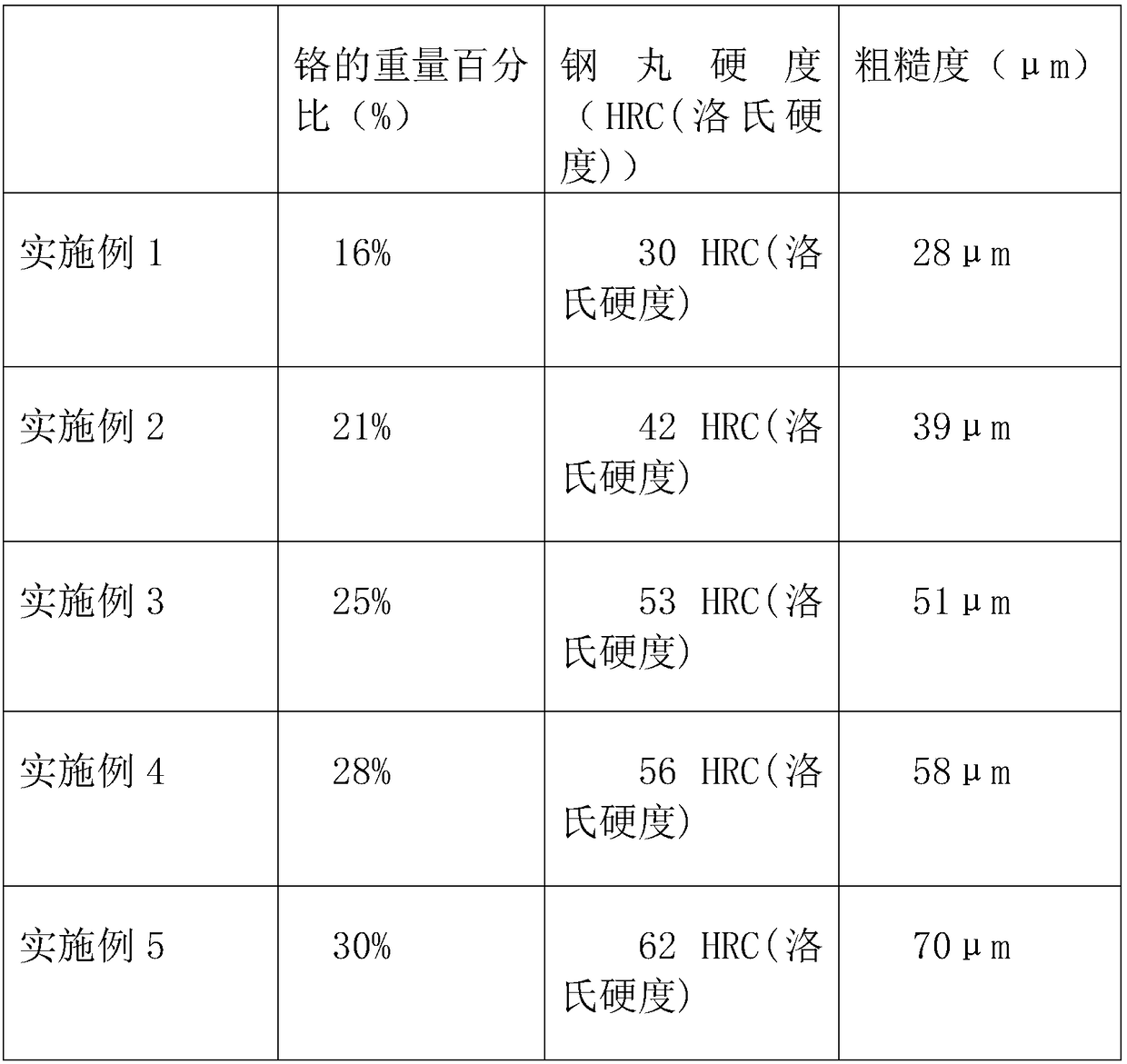

High-hardness alloy novel grinding material and manufacturing process thereof

The invention discloses a high-hardness alloy novel grinding material and a manufacturing process thereof. The alloy novel grinding material comprises, by weight percent, 16%-30% of chromium, 1.5%-2.5% of carbon, 1.5%-2.5% of silicon, 0.8%-1.2% of manganese and the balance iron. The high-hardness alloy novel grinding material has the advantages of being higher in hardness, more resistant to wear and better in grinding effect.

Owner:中山市恒翔不锈钢丸有限公司

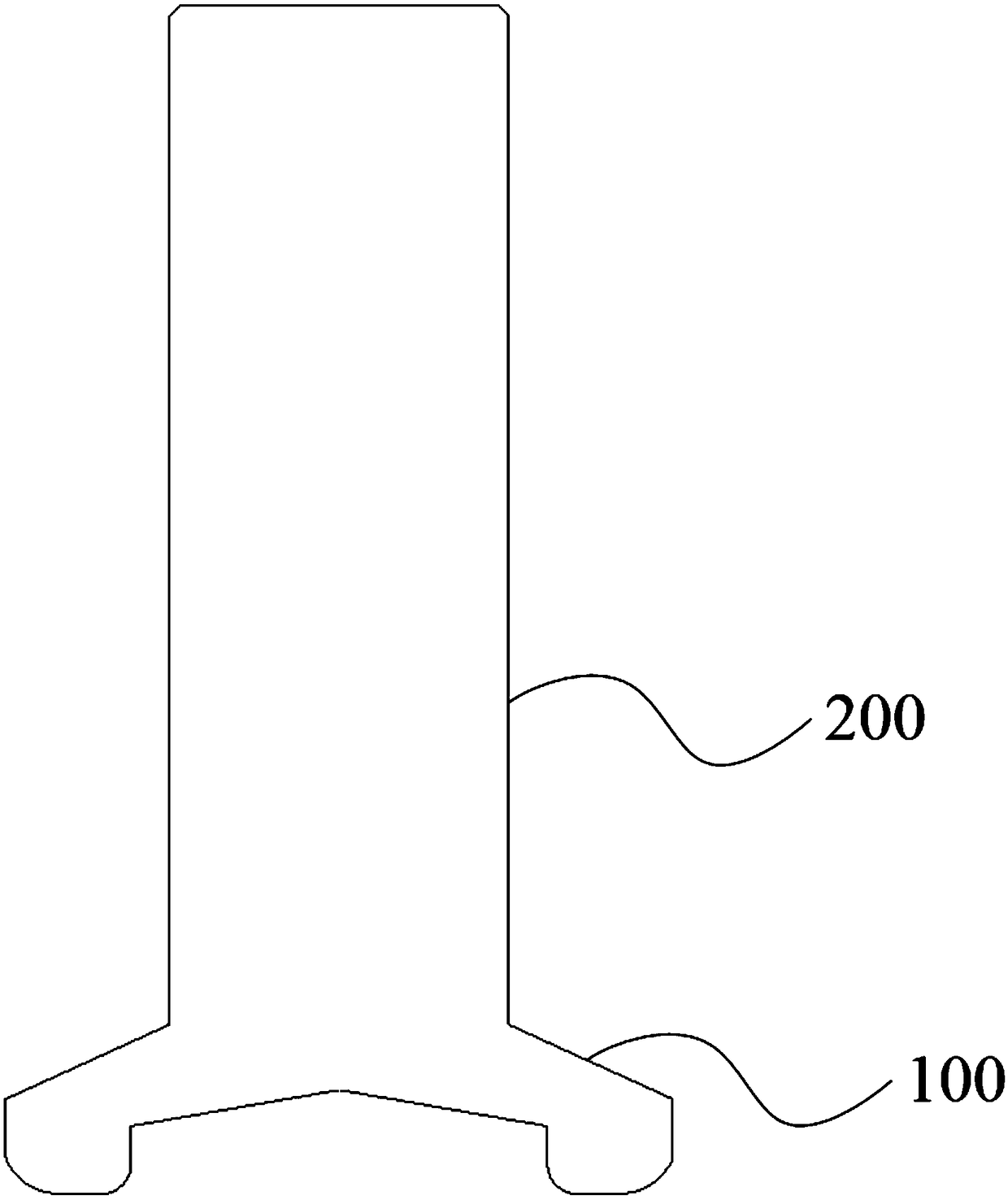

Fine finish polishing tool

PendingCN108890544AReduce usageRealize small area processingBonded abrasive wheelsCircular coneEngineering

The invention provides a fine finish polishing tool. The fine finish polishing tool comprises a grinding body and an installing connecting rod. The installing connecting rod is cylindrical, and the grinding body is disc-shaped. The installing connecting rod is coaxially connected with the grinding body, and a specific value of a diameter of the grinding body and a diameter of the installing connecting rod is 1.2-2.4. The grinding body comprises a connecting part and a polishing part. The connecting part is truncated cone-shaped, and has circular top face and bottom face, and a side face of which a shape is a circular conical surface. A diameter of the top face is less than a diameter of the bottom face. The top face is coaxially connected with the installing connecting rod. The polishing part is formed on the bottom face. The polishing part is annular and protruded and installed at the peripheral part of the bottom face of the connecting part, and the polishing part is provided with multiple discharging channels for discharging wastes generated in a polishing process. It can be clearly shown that the described fine finish polishing tool is capable of meeting multiple polishing requirements through a high-precision small-scale design, improving processing efficiency, and improving a processing success rate.

Owner:CONPROFE TECH GRP CO LTD +1

Medical western medicine grinding table

The invention discloses a medical western medicine grinding table. The medical western medicine grinding table comprises a table plate. The two sides of the bottom of the table plate are provided withclamping plates in a welded manner, the bottoms of the clamping plates are rotationally connected with foldable supports. The bottoms of the foldable supports are provided with balance shafts in a welded manner. A telescopic cylinder is arranged at the center position of the bottom of the table plate, and the telescopic cylinder is connected with a transmission plate on the table plate through ahydraulic expansion link. One side of the top of the table plate is provided with a damping plate, a motor is arranged on the top of the damping plate, and the motor is in transmission connection witha grinding roller shaft in a manner that a rotating shaft penetrates clamping rods on the table plate. The grinding roller shaft is internally provided with a fixing bearing, and the top of the fixing bearing is provided with an oil guide pipe. A grinding disk is connected with a heater on the other side of the top of the table plate through a heat conduction pipe. The medical western medicine grinding table is simple and reasonable in overall structural design, meets grinding requirements of different processes and is convenient and fast to install, flexible in operation and relatively highin practicality.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

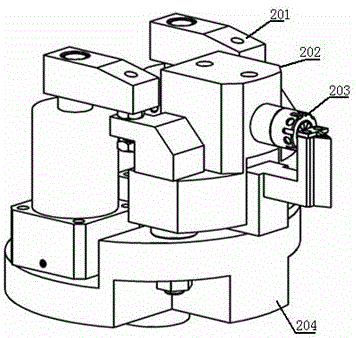

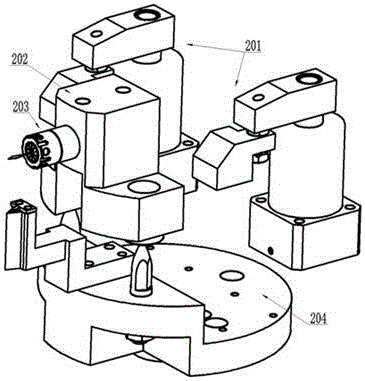

The combined clamp for grinding small circular handle special-shaped blade edge

ActiveCN106335002ARealize automatic grindingImprove grinding efficiencyGrinding work supportsEngineeringKnife handles

The invention discloses a combined clamp for grinding small circular handle special-shaped blade edge, which comprises a rotary cylinder, a clamp base body, a clamp knife handle, a clamp base, a screw and a screw hole. The clamp base is provided with a screw hole. The two rotary cylinders are fixed on the screw holes of the clamp base by screws. The clamp base body is fixed on the clamp base. The clamp base body is fixed to the clamp base by two rotary cylinders. The clamp base body is positioned between two rotary cylinders. The clamp base body is provided with a clamping knife handle. The invention is capable of grinding small circular handle special-shaped blade edge with high efficiency and good effect and meeting the grinding demand of the small circular handle special-shaped blade edge.

Owner:SUZHOU BOYINUO INTELLIGENT EQUIP

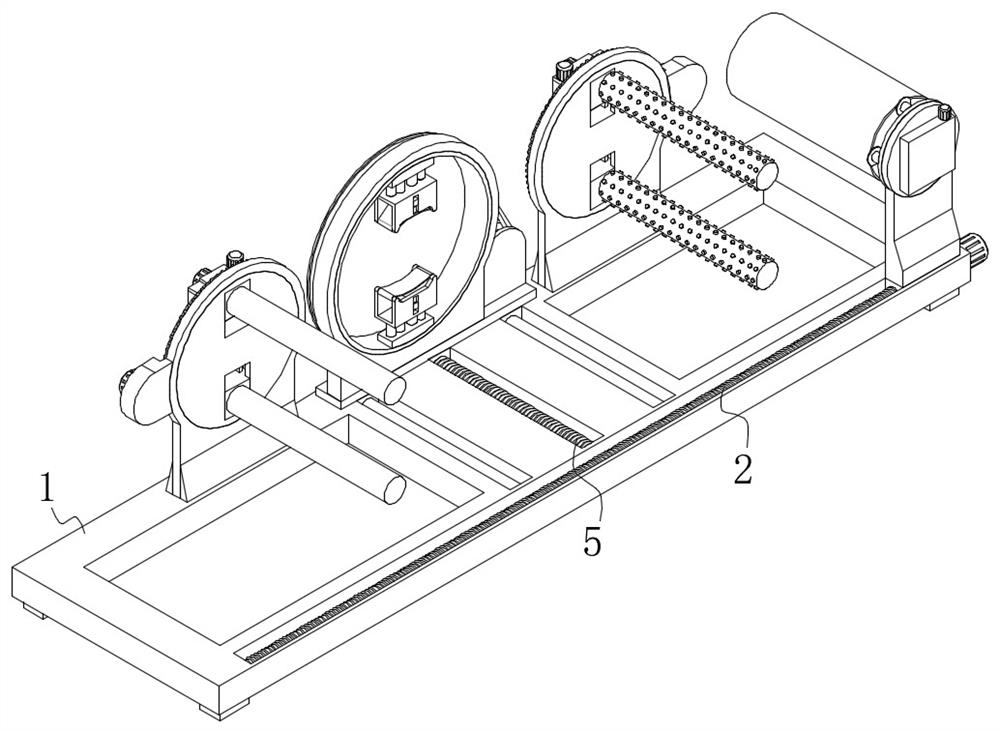

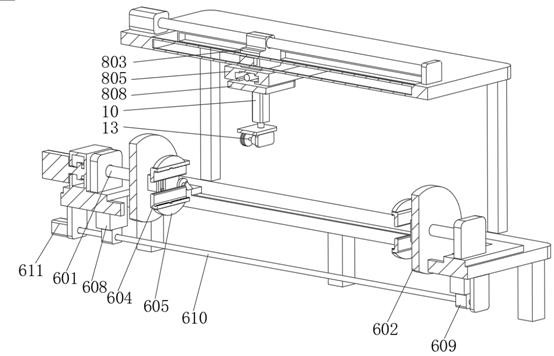

Multi-stage grinding and polishing device for metal pipe machining and grinding and polishing process

ActiveCN112518536AImprove sanding effectAffect the grinding effectRevolution surface grinding machinesGrinding drivesMetal machiningScrew thread

The invention discloses a multi-stage grinding and polishing device for metal pipe machining, and belongs to the technical field of metal machining. The multi-stage grinding and polishing device for metal pipe machining comprises a base, the inner wall of the base is rotationally connected with a threaded lead screw a, the peripheral side face of the threaded lead screw a is in threaded connectionwith a metal pipe fixing assembly, the upper surface of the base is fixedly connected with a pipe wall cleaning mechanism, the inner wall of the base is rotationally connected with a threaded lead screw b, a first-stage grinding mechanism is in threaded connection with the peripheral side face of the threaded lead screw b, the upper surface of the base is fixedly connected with a second-stage grinding mechanism, the metal pipe fixing assembly comprises a movable base, the inner wall of the movable base is in threaded connection with the threaded lead screw a, one surface of the movable base is fixedly connected with a support, and one surface of the support is fixedly connected with a fixed base. Through the design of the metal pipe fixing assembly, the pipe wall cleaning mechanism, the first-stage grinding mechanism and the second-stage grinding mechanism, the problem that an existing metal pipe grinding device is poor in practicability due to the fact that only one-time grinding isconducted on a metal pipe and the operation process is complex is solved.

Owner:无锡亚尔特金属制品有限公司

Mold grinding and automatic cleaning method

InactiveCN108481112AReduce the strength of the handReduce labor intensityEdge grinding machinesCombination devicesEngineeringElectromagnet

The invention discloses a mold grinding and automatic cleaning method. The method comprises the steps that (1) a sliding groove is formed in one side of a handheld grinding machine, a hinge seat is arranged in the sliding groove, a supporting rod is hinged to the hinge seat, and a folding hinge shaft is arranged in the middle of the supporting rod; (2) the bottom end of the supporting rod is connected with a base through a rotary block, an electromagnet is arranged at the bottom of the base, the upper portion of the base is provided with a plurality of dust suction ports, the dust suction ports communicate with a dust suction pipe, and iron wire filter screens are arranged in the dust suction ports; and (3) a support is arranged on the other side of the handheld grinding machine, an atomizer is arranged on the support, the upper side of the atomizer is connected with a water inlet pipe, the lower side of the atomizer is provided with an atomization dust collection pipe, and the pipe head of the atomization dust collection pipe is arranged corresponding to a grinding head of the handheld grinding machine (1).

Owner:合肥梦飞电器有限公司

Mold grinding automatic cleaning system

InactiveCN108340251AFix damageImprove working environmentGrinding machine componentsPortable grinding machinesWater pipeElectromagnet

The invention discloses a mold grinding automatic cleaning system. The mold grinding automatic cleaning system comprises a handheld grinder. A sliding groove is formed in one side of the handheld grinder. A hinge base is arranged in the sliding groove. A supporting rod is hinged to the hinge base. A folding hinge shaft is arranged in the middle of the supporting rod. A base is connected with the bottom end of the supporting rod through a rotary block. An electromagnet is arranged at the bottom of the base. A plurality of dust suction inlets are formed in the upper portion of the base in a surrounding mode and communicate with dust collection pipes correspondingly. Iron wire filter screens are arranged in the dust suction inlets. A support is arranged on the other side of the handheld grinder. An atomizer is arranged on the support. A water inlet pipe is connected with the upper side of the atomizer. An atomizing dedusting pipe is arranged on the lower side of the atomizer. A pipe headof the atomizing dedusting pipe corresponds to a grinding head of the handheld grinder.

Owner:合肥梦飞电器有限公司

A Portable Rail Wave Grinding Machine

InactiveCN104674617BImprove grinding accuracyImprove efficiencyTrack superstructureRailway track constructionMechanical engineeringTransverse beam

The invention relates to a light-weight and convenient type steel rail corrugation grinding machine, which is used for performing corrugation grinding on a steel rail. The light-weight and convenient type steel rail corrugation grinding machine comprises a support transverse beam, wherein a support device is arranged at one end of the support transverse beam, a grinding device is arranged at the other end of the support transverse beam, the grinding device comprises a grinding mechanism frame, two clamping and guiding assemblies and a plurality of grinding assemblies, the clamping and guiding assemblies are used for clamping and guiding the steel rail, each grinding assembly is moved relative to the steel rail and is used for grinding the steel rail, the clamping and guiding assemblies are respectively arranged at the two ends of the grinding mechanism frame, and the grinding assemblies are connected with the bottom part of the grinding mechanism frame, and are sequentially arranged between the two clamping and guiding assemblies. Compared with the prior art, the light-weight and convenient type steel rail corrugation grinding machine has the advantages that the cost is low, the grinding efficiency is high, the control is simple and reliable, the structure is compact, the stability is good, the firmness and durability are realized, and the like.

Owner:TONGJI UNIV

Extending-and-contracting drill bit grinding device

InactiveCN111975538AAchieve a fixed purposeEasy to moveEdge grinding machinesGrinding carriagesStructural engineeringGrinding wheel

The invention relates to building material machinery, in particular to an extending-and-contracting drill bit grinding device. The extending-and-contracting drill bit grinding device comprises a vertical plate adjustment mechanism, a bottom adjustment mechanism, a top pressing mechanism and an adjustment grinding mechanism. The bottom adjustment mechanism is fixedly mounted on the vertical plate adjustment mechanism. The top pressing mechanism is fixedly mounted on the vertical plate adjustment mechanism. The adjustment grinding mechanism is fixedly mounted on the top pressing mechanism. The device can be arranged to be in two states, and edges and notches of plates can be ground; and in the grinding process, on the premise that the grinding effect is guaranteed, the abrasion degree of grinding wheels can be lowered to the greatest extent; the service life of each grinding wheel is prolonged; and the machining cost is lowered.

Owner:哈尔滨市阿城区胜达建筑材料厂

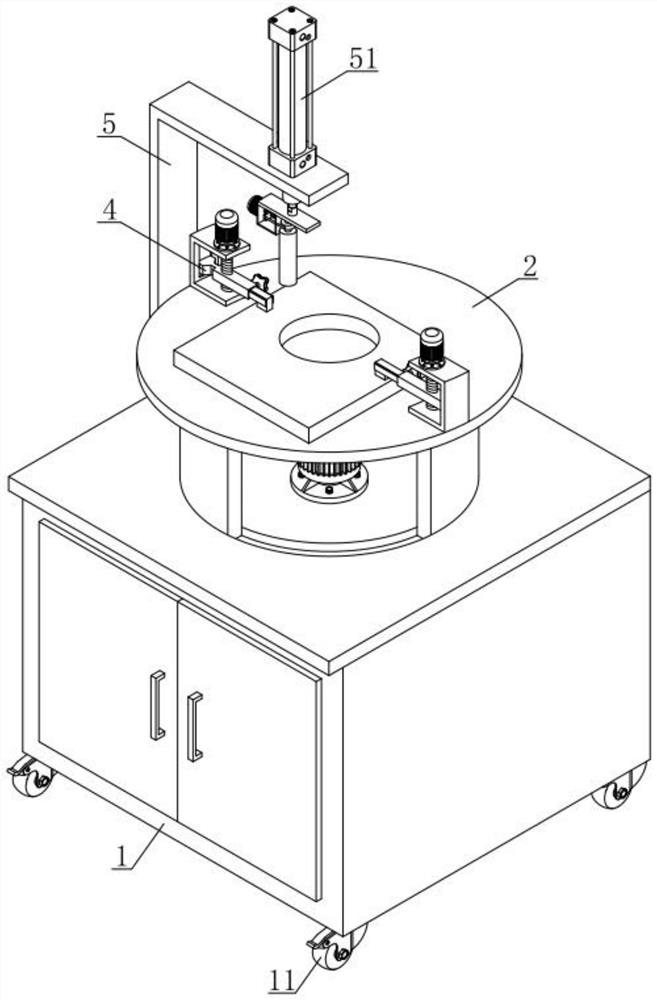

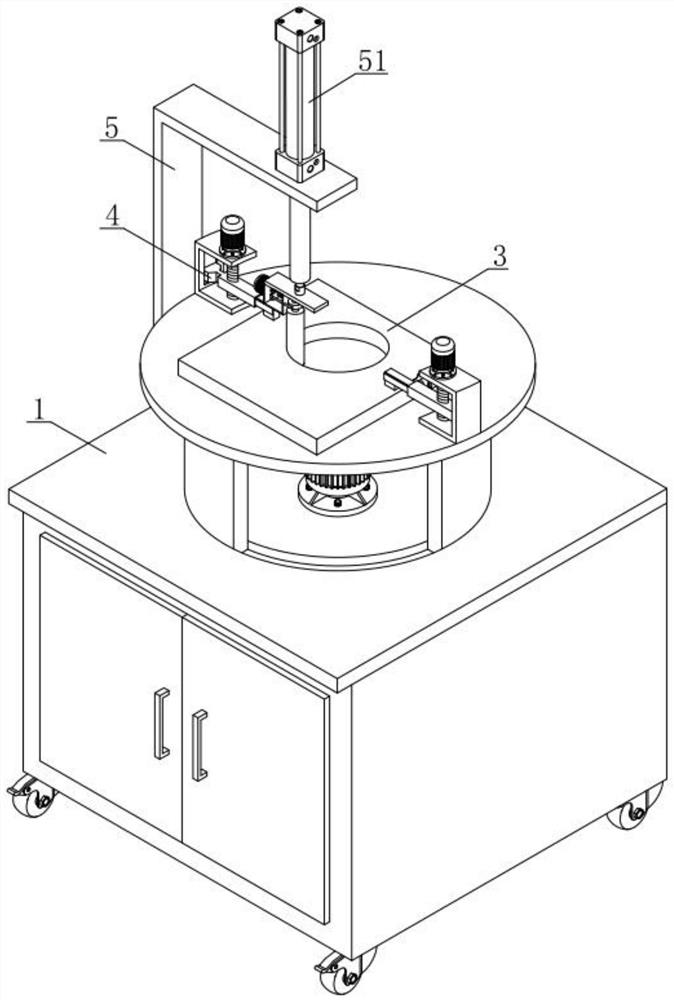

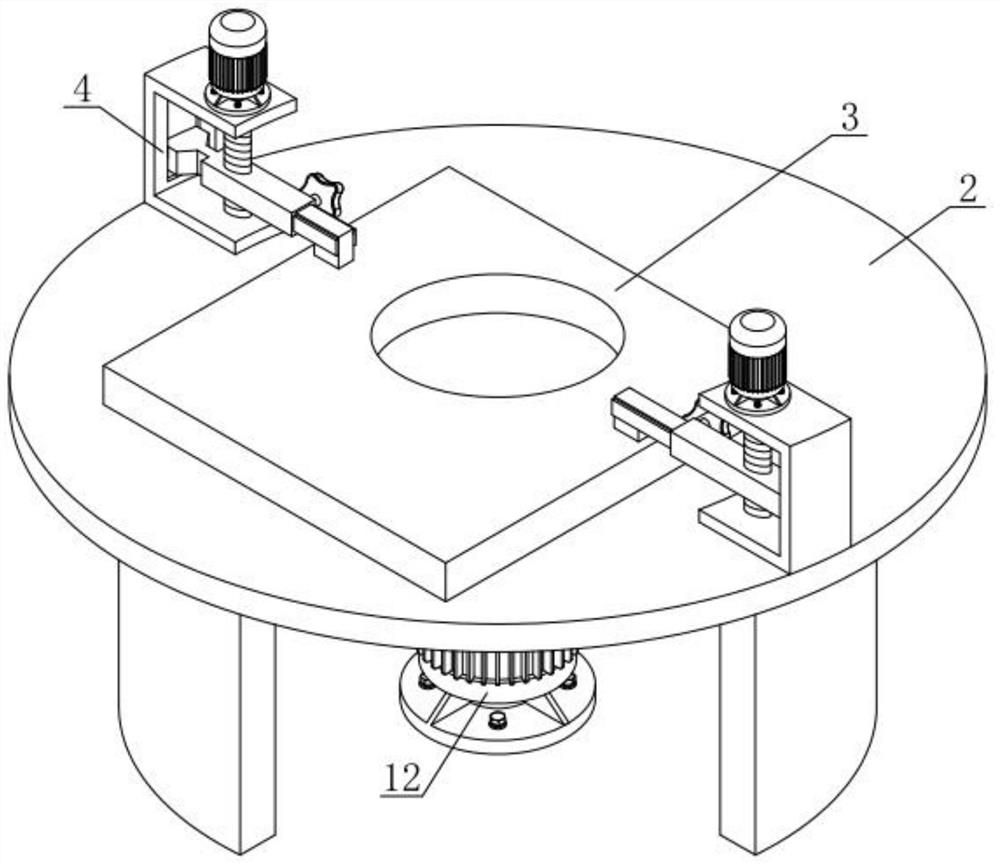

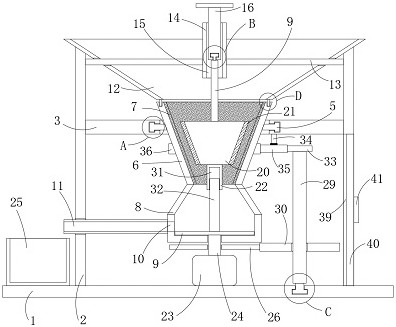

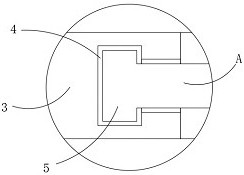

Aluminum alloy support inner hole high-precision grinding device and implementation method thereof

PendingCN113370011AImprove grinding accuracyImprove product qualityRevolution surface grinding machinesGrinding work supportsHydraulic cylinderElectric machinery

The invention discloses an aluminum alloy support inner hole high-precision grinding device and an implementation method thereof, and belongs to the technical field of aluminum alloy supports. The aluminum alloy support inner hole high-precision grinding device comprises a machining table, wherein a rotating motor is installed at the middle end of the machining table, an output shaft of the rotating motor is connected with a rotating disc, a to-be-machined aluminum alloy support is placed on the rotating disc, the to-be-machined aluminum alloy support is fixed to the rotating disc through a clamping mechanism, a supporting base is further installed on the machining table, a hydraulic cylinder is installed on the supporting base, a piston rod of the hydraulic cylinder is connected with a guide plate, and a grinding wheel is installed on the guide plate. According to the aluminum alloy support inner hole high-precision grinding device and the implementation method thereof, the grinding precision of the inner hole of the to-be-machined aluminum alloy support can be improved, the quality of a ground product is high, the grinding wheel can be adjusted to a proper grinding position, the grinding wheel can grind the inner holes of the to-be-machined aluminum alloy supports with different sizes, the application range is wide, and the polishing requirements of the inner hole of the to-be-machined aluminum alloy supports under different conditions can be met.

Owner:深圳市鑫雅豪智能科技股份有限公司

Colloid mill for producing capsule tablets

PendingCN114870937AMeet the needs of grindingImprove grinding efficiencyGrain treatmentsStructural engineeringColloid mill

The colloid mill for producing the capsule tablets comprises a base, a supporting pipe is fixedly connected to the upper end face of the base, a supporting ring is fixedly connected to the inner wall of the supporting pipe, an annular groove is formed in the inner wall of the supporting ring, and a plurality of supporting sliding blocks are slidably connected into the annular groove; the ends, away from the supporting ring, of the multiple supporting sliding blocks are jointly and fixedly connected with a working hopper, a first grinding layer is fixedly connected to the inner wall of the working hopper, a discharging hopper is fixedly connected to the side wall, close to the base, of the working hopper, the discharging hopper and the working hopper are symmetrically arranged, and a discharging disc is rotationally connected into the discharging hopper. The discharging disc is attached to the inner wall of the side, close to the base, of the discharging hopper, and a discharging opening is formed in one side wall of the discharging hopper. The grinding efficiency can be greatly improved through bidirectional rotation, the grinding gap can be conveniently adjusted, and use is greatly facilitated.

Owner:青岛浩大生物科技工程有限责任公司

Metal product weld join polishing device

ActiveCN113478329AAchieve clamping and fixingAchieve rotationEdge grinding machinesGrinding drivesPolishingEngineering

The invention relates to the technical field of weld joint polishing, in particular to a metal product weld joint polishing device. The metal product weld joint polishing device comprises a workbench, wherein movable mounting plates are slidably mounted at the two ends of the upper surface of the workbench, a servo motor is mounted on one side of one movable mounting plate, a gearbox is arranged at the output end of the servo motor, an adjusting mechanism is arranged at the other end of the gearbox, a mounting frame is arranged on the upper surface of the workbench, a direction changing mechanism is arranged on the mounting frame, an air cylinder is arranged at one end of the direction changing mechanism, and a third fixing plate is mounted at the output end of the air cylinder. According to the metal product weld joint polishing device, an adjusting lead screw is driven to rotate by rotating a rocker, a first ejector rod and a second ejector rod are pushed to move under the action of an adjusting lead screw sleeve, angle adjustment of grinding piece mounting plates on the two sides is achieved under the hinging action, then the grinding shape and the thickness of the two sides can be controlled, a weld joint is ground into a regular shape, and the using effect of the metal product is better.

Owner:海门市柳祥铸件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com